The lead acid battery charger circuits I have explained in this article can be used for charging all types of lead acid batteries at a specified rate.

This article explains a few lead acid battery charger circuits with automatic over charge, and low discharge cut off. All these designs are thoroughly tested and can be used to charge all automotive and SMF batteries up to 100 Ah, and even 500 Ah.

Introduction

Lead acid batteries are normally used for heavy duty operations involving many 100s of amps. To charge these batteries we specifically need chargers rated to handle high ampere charging levels for long periods of time.

Lead acid battery charger are specifically designed for charging heavy duty batteries through specialized control circuits.

The 5 useful and high power lead acid battery charger circuits presented below can be used for charging large high current lead acid batteries in the order of 100 to 500 Ah, the design is perfectly automatic and switches of the power to the battery and also itself, once the battery gets fully charged.

UPDATE: You may also want to build these simple Charger circuits for 12 V 7 Ah Batteries, check them out.

What does Ah Signify

The unit Ah or Ampere-hour in any battery signifies the ideal rate at which the battery would be fully discharged, or fully charged within a span of 1 hour.

For example, if a 100 Ah battery was charged at 100 ampere rate, it would take 1 hour for the battery to get fully charged. Likewise, if the battery was discharged at 100 ampere rate, the backup time would last not more an hour.

But wait, never try this, as charging/discharging at the full Ah rate can be disastrous for your lead acid battery.

The unit Ah is there only to provide us with a benchmark value which can be used for knowing the approximate charge/discharge time of the battery at a stipulated current rate.

For example when the above discussed battery is charged at 10 ampere rate, using the Ah value we can find the full charge time through the following formula:

Since charging rate is inversely proportional to the time, we have:

Time = Ah Value / Charging Rate

T = 100 / 10

where 100 is the Ah level of the battery, 10 is the charging current, T is the time at the 10 amp rate

T = 10 Hours.

The formula suggests it would ideally require around 10 hours for the battery to get optimally charged at 10 amp rate, but for a real battery this may be around 14 hours for the charging, and 7 hours for the discharging.

Because in real world even a new battery won't work with ideal conditions, and as it ages the situation may get even worse.

Important Parameters to be Considered

Lead acid batteries are expensive, and you will want to ensure that it lasts as long as possible. So please do not use cheap and untested charger concepts, which may look easy but may harm your battery slowly.

The big question is, is ideal method of charging a battery essential? The simple answer is NO. Because when we apply ideal charging method as discussed in "Wikipedia" or "Battery University" websites, we try to charge the battery at its maximum possible capacity.

For example, at the ideal 14.4 V level your battery may be fully charged, but it can be risky to do this using ordinary methods.

To achieve this without risks you may have to employ an advanced charger step charger circuit, which can be difficult to build, and might require too many calculations.

If you want to avoid this, you can still charge your battery optimally (@ around 65%) by ensuring that the battery is cut-off at a little lower level.

This will allow the battery to be always under less stressful condition. The same goes for the discharge level and rate.

Basically it must have the following parameters for a safe charging which does not require special step chargers:

- Fixed Current or Constant Current (1/10th of Battery Ah Rating)

- Fixed Voltage or Constant Voltage (17% higher than Battery Printed Voltage)

- Over Charge Protection (Cut-OFF when Battery gets charged to the above level)

- Float Charge (Optional, not compulsory at all)

If you do not have these minimum parameters in your system, then it may slowly degrade the performance and damage your battery, reducing its back up time drastically.

- For example, if your battery is rated at 12 V, 100 Ah, then the fixed input voltage should be 17% higher than the printed value, that's equal to around 14.1 V ( not 14.40 V, unless you are using a step charger).

- Current (ampere) ideally should be 1/10th of the Ah level printed on the battery, so in our case this can be 10 amperes. A slightly higher Amp input can be fine since our full charge level is already lower.

- Charging auto cut off is recommended at the above mentioned 14.1 V, but it's not compulsory since we already have the full charge level slightly lower.

- Float Charge is a process of reducing the current to negligible limits after the battery has reached full charge. This prevents the battery from self discharging and holds it at the full level continuously until it's removed by the user for usage. It is completely optional. It may be necessary only if you are not using your battery for long periods of time. In such cases too it's better to remove the battery from the charger and top it up occasionally once every 7 days.

The easiest way to get fixed voltage and current is by using voltage regulator ICs, as I will explain below.

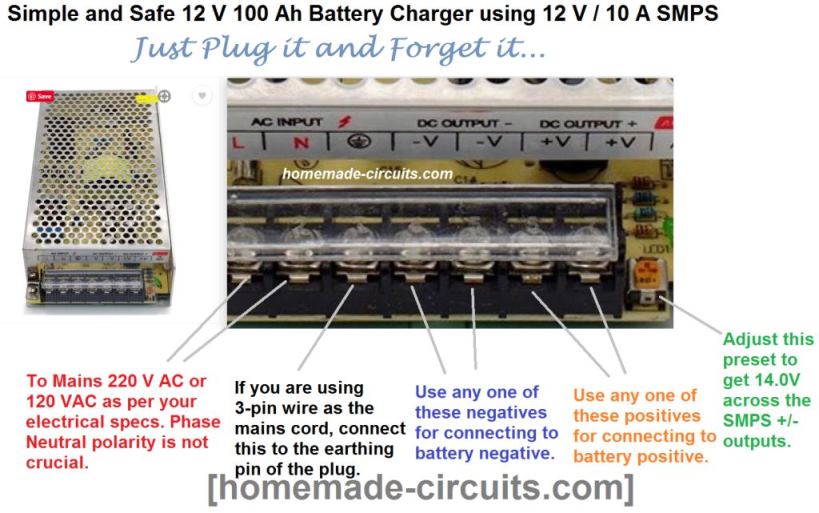

Another easy way is to use a ready made 12 V SMPS 10 Amp unit as the input source, with an adjustable preset. The SMPS will have a small preset at the corner which can be tweaked to 14.0 V.

Remember you will have to keep the battery connected for at least 10 to 14 hours, or until your battery terminal voltage reaches 14.2 V.

Although this level may look slightly undercharged than the standard 14.4 V full level, this ensures your battery can never get over charged and guarantees a long life for the battery.

All the details are presented in this infographic below:

However, if you are an electronic hobbyist and interested to build a full fledged circuit with all the ideal options, in that case you can go for the following comprehensive circuit designs.

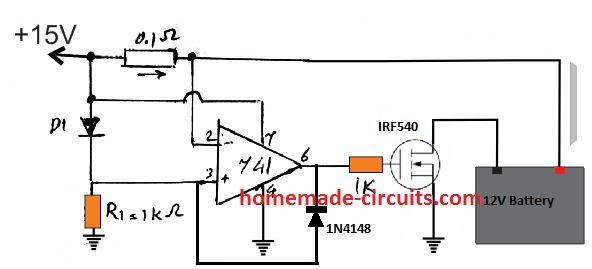

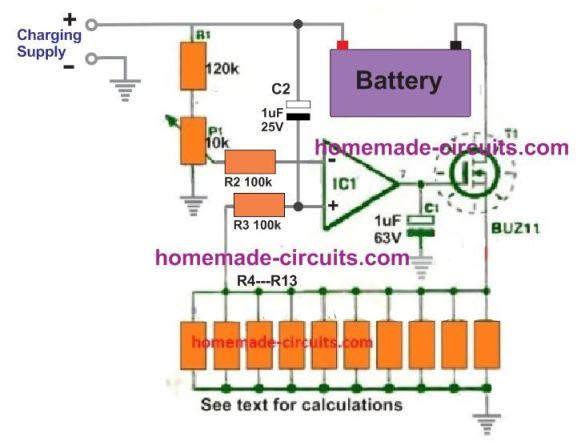

[New Update] Current Dependent Battery Auto Cut OFF

Normally, a voltage detected or voltage dependent automatic cut off is used in all conventional battery charger circuits.

However, a current detection feature can be also employed for initiating an auto cut off when the battery reaches its most optimal full charge level. The complete circuit diagram for the current detected auto cut off is shown below:

How it Works

The 0.1 Ohm resistor acts like a current sensor by developing an equivalent potential difference across itself .

The value of the resistor must be such that the minimum potential deference across it is at least 0.3V higher than the diode drop at pin 3 of the IC, until the battery has reached the desired full charge level.

When the full charge is reached this potential should come down below the diode drop level.

Initially , while the battery is charging, the current draw develops a negative potential difference of say -1V across the input pins of the IC.

Which means that the pin 2 voltage now becomes lower than the pin3 voltage by at least 0.3V. Due to this pin 6 of the IC goes high allowing the MOSFET to conduct and connect the battery with the supply source.

As the battery charges to its optimal level, the voltage across the current sensing resistor drops to a sufficiently lower level causing the potential difference across the resistor to become almost zero.

When this happens, pin 2 potential rises higher than pin3 potential, causing pin 6 of the IC to go low, and switching OFF the MOSFET.

The battery thus gets disconnected from the supply disabling the charging process. The diode connected across pin 3 and pin 6 locks or latches the circuit in this position until power is switched OFF and ON again for a fresh cycle.

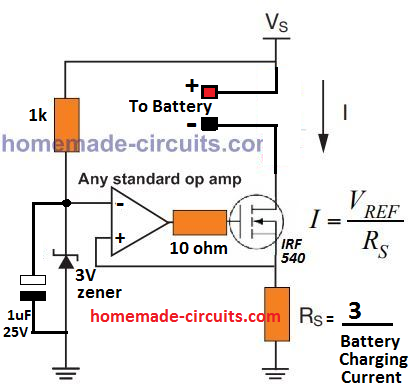

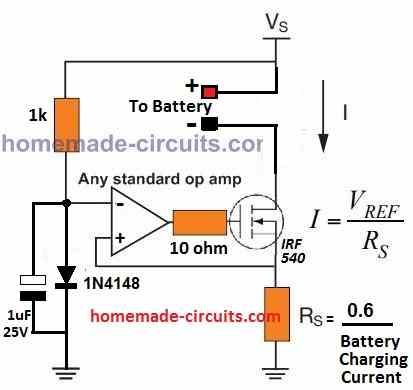

The above current dependent charging circuit can be also expressed as given below:

When power is switched ON, the 1 uF capacitor grounds the inverting pin of the op amp causing a momentary high at the op amp output, which switches ON the MOSFET. This initial action connects the battery with the supply via the MOSFET and the sense resistor RS.

The current drawn by the battery causes an appropriate potential to develop across RS which raises the non-invering input of the op amp above the reference inverting input (3V).

The op amp output now latches ON and charges the battery, until the battery is almost fully charged. This situation reduces the current through RS such that the potential across it drops below 3 V reference and the op amp output turns low, switching OFF the MOSFET and the charging process for the battery.

The above current dependent battery charging system design can be understood more elaborately in the below comprehensively drawn diagram, which can be used for charging very high capacity batteries in the order of 200 Ah to 500 Ah very safely:

Adjust the 10 k preset so that just around 0.3 V or 0.4 V is available at the (-) input of the op amp, and set the R4---R13 resistor bank such that their net resistance is:

R = 1 / Max charging current.

Suppose the battery is 100 Ah, then the max charging current will be 10 amps, therefore,

R = 1 / 10 = 0.1 Ohms

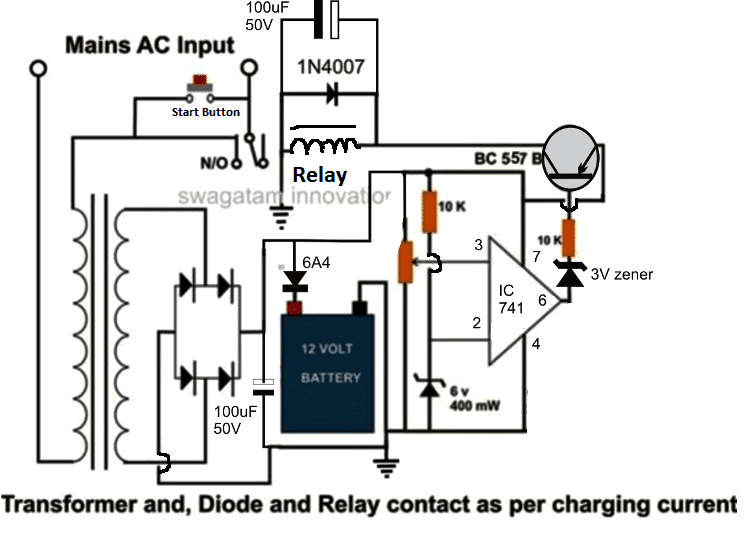

1) Using a Single Op amp

Looking at the first high current circuit for charging large batteries, we can understand the circuit idea through the following simple points:

There are basically three stages in the shown configuration viz: the power supply stage consisting of a transformer and a bridge rectifier network.

A filter capacitor after the bridge network has been ignored for the sake of simplicity, however for better DC output to the battery one can add a 1000uF/25V capacitor across the bridge positive and negative.

The output from the power supply is directly applied to the battery which requires to be charged.

The next stage consists of an opamp 741 IC voltage comparator, which is configured to sense the battery voltage while it is being charged and switch its output at pin #6 with the relevant response.

Pin #3 of the IC is rigged with the battery or the supply positive of the circuit via a 10K preset.

The preset is adjusted such that the IC reverts its output at pin #6 when the battery becomes fully charged and reaches about 14 volts which happens to be the transformer voltage at normal conditions.

Pin #2 of the IC is clamped with a fixed reference via a voltage divider network consisting of a 10K resistor and a 6 volt zener diode.

The output from the IC is fed to a relay driver stage where the transistor BC557 forms the main controlling component.

Initially, power to the circuit is initiated by pressing the "start" switch. On doing this, the switch bypasses the contacts of the relay and powers the circuit momentarily.

The IC senses the battery voltage and since it will be low during that stage, the output of the IC responds with a logic low output.

This switches ON the transistor and the relay, the relay instantly latches the power via its relevant contacts such that now even if the "start" switch is released, the circuit remains switched ON and begins charging the connected battery.

Now as the battery charge reaches about 14 volts, the IC senses this and instantly reverts its output to a high logic level.

The transistor BC557 responds to this high pulse and switches OFF the relay which in turn switches of the power to the circuit, breaking the latch.

The circuit gets completely switched OFF until the start button is pressed once again and the connected battery has a charge that's under the set 14 volt mark.

How to set up.

It's very easy.

Do not connect any battery to the circuit.

Switch ON power by pressing the start button and keep it depressed manually, simultaneously adjust the preset such that the relay just trips or switches OFF at the given rated transformer voltage which should be around 14 volts.

The setting is complete, now connect a semi discharged battery to the shown points in the circuit and press the "start" switch.

Due to the discharged battery, now the voltage to the circuit will drop under 14 volts and the circuit will instantly latch, initiating the procedure as explained in the above section.

Circuit Diagram for the proposed battery charger with high ampere capacity is shown below

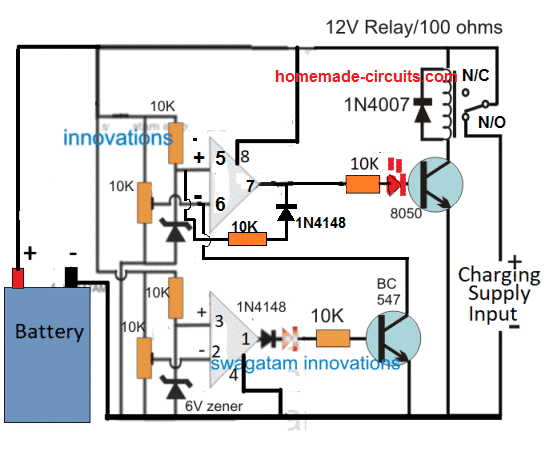

2) 12V, 24V / 20 amp Charger Using two opamps:

The second alternative way of achieving battery charging for a lead acid battery with high amperage can be observed in the following diagram, using a couple of op amps:

The working of the circuit can be understood through the following points:

When the circuit is powered without a battery connected, the circuit does not respond to the situation since the initial N/C position of the relay keeps the circuit disconnected from the charging supply.

Now suppose a discharged battery is connected across the battery points. Let's assume the battery voltage to be at some intermediate level, which may be between the full charge level and the low charge level.

The circuit gets powered through this intermediate battery voltage. As per the setting of the pin 6 preset, this pin detects a low potential than the pin 5 reference level. which prompts its output pin 7 to go high.

This in turn causes the relay to activate and connect the charging supply to the circuit and the battery via the N/O contacts.

As soon as this happens, the charging level also drops to the battery level and the two voltages merge at the battery voltage level. The battery now begins charging, and its terminal voltage begins increasing slowly.

When the battery reaches it full charge level, the pin 6 of the upper opamp becomes high than its pin 5 causing its output pin 7 to go low, and this switches off the relay, and the charging is cut off.

At this point another thing happens. The pin 5 is connected to the negative potential at pin 7 via the 10k/1N4148 diode, which further lowers the pin 5 potential compared to pin 6.

This is called hysteresis, which ensure that even if the battery now drops to some lower level that won't trigger the op amp back to charging mode, instead the battery level now has to drop significantly down until the lower op amp is activated.

Now, suppose the battery level keeps dropping due to some connected load, and its potential level reaches the lowest discharge level.

This is detected by pin 2 of the lower op amp whose potential now goes below its pin 3, which prompts its output pin 1 to become high and activate the BC547 transistor.

The BC547 grounds the pin 6 of the upper op amp competely. This causes the hysteresis latch to break due to pin 6 potential dropping below pin 5.

This instantly causes the output pin 7 to go high and activate the relay, which yet again initializes the charging of the battery, and the cycle repeats the procedure as long as the battery remains connected with the charger.

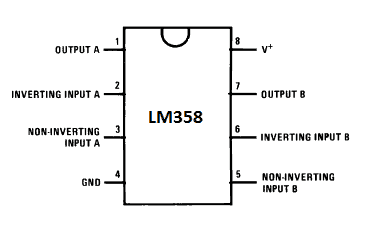

LM358 Pinout

For more auto cut-off charger ideas, you can read this article regarding opamp automatic battery charger circuits.

Video Clip:

The set up of the above circuit can be visualized in the following video which shows the cut off responses of the circuit to the upper and the lower voltage thresholds, as fixed by the relevant presets of the opamps

3) Using IC 7815

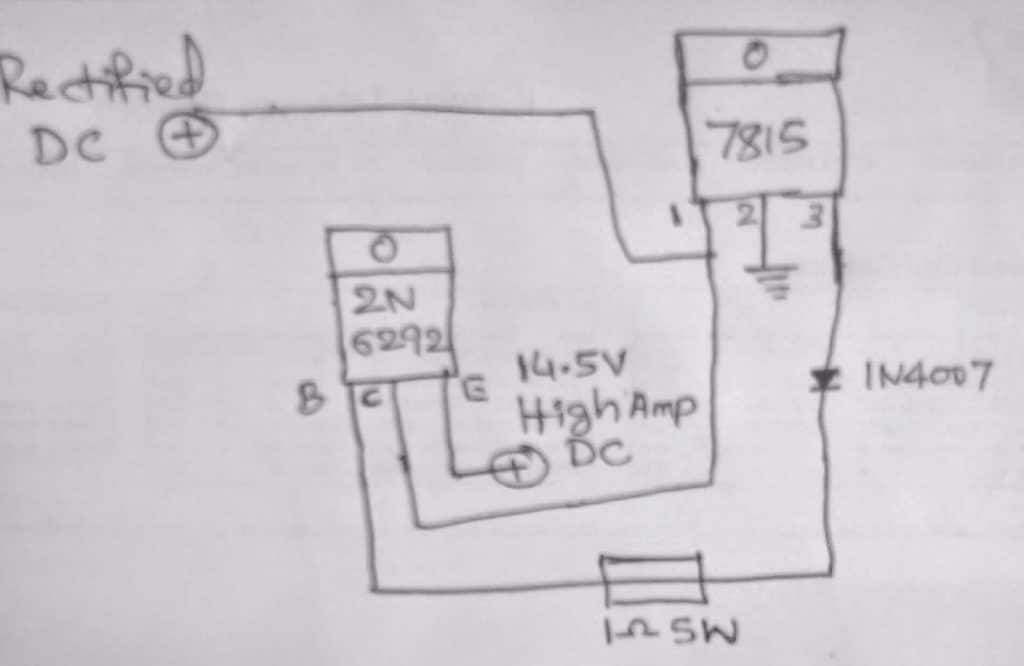

The third circuit explanation below details how a battery may be charged effectively without using any IC or relay, rather simply by using BJTs, I will explain the procedures:

The idea was suggested by Mr. Raja Gilse.

Charging a Battery with a Voltage Regulator IC

I have a 2N6292 . My friend suggest me to make the simple fixed voltage high current DC power supply to charge an SMF battery.

He had given the attached rough diagram. I don't know anything about the above transistor. Is it so ?

My input is 18 volt 5 Amp transformer. He told me to add 2200 uF 50 Volt capacitor after rectification. Is it works ?

If so , is there any heat sink necessary for transistor or/and IC 7815 ? Is it stops automatically after battery reaches 14.5 volt ?

Or any other alteration needed ? Please guide me sir

Charging with an Emitter Follower Configuration

Yes it will work and will stop charging the battery when around 14 V is reached across the battery terminals.

However I am not sure about the 1 ohm base resistor value...it needs to be calculated correctly.

The transistor and the IC both may be mounted on a common heatsink using mica separator kit.

This will exploit the thermal protection feature of the IC and will help safeguard both the devices from overheating.

Circuit Diagram

Circuit description

The shown high current battery charger circuit is a smart way of charging a battery and also achieving an auto shut off when the battery attains a full charge level.

The circuit is actually a simple common collector transistor stage using the shown 2N6292 power device.

The configuration is also referred as an emitter follower and as the name suggests the emitter follows the base voltage and allows the transistor to conduct only as long as the emitter potential is 0.7V lower that the applied base potential.

In the shown high current battery charger circuit using a voltage regulator, the base of the transistor is fed with a regulated 15 V from the IC 7815, which ensures a potential difference of about 15 - 0.7 = 14.3 V across the emitter/ground of the transistor.

The diode is not required and must be removed from the base of the transistor in order to prevent an unnecessary drop of an extra 0.7 V.

The above voltage also becomes the charging voltage for the connected battery across these terminals.

While the battery charges and its terminal voltage continues to be below the 14.3 V mark, the transistor base voltage keeps conducting and supplying the required charging voltage to the battery.

However as soon as the battery begins attaining the full and above 14.3 V charge, the base is inhibited from a 0.7 V drop across its emitter which forces the transistor to stop conducting and the charging voltage is cut off to the battery for the time being. As soon as the battery level begins going below the 14.3 V mark, the transistor is switched ON again...the cycle keeps repeating ensuring a safe charging fr the connected battery.

Base resistor = Hfe x battery internal resistance

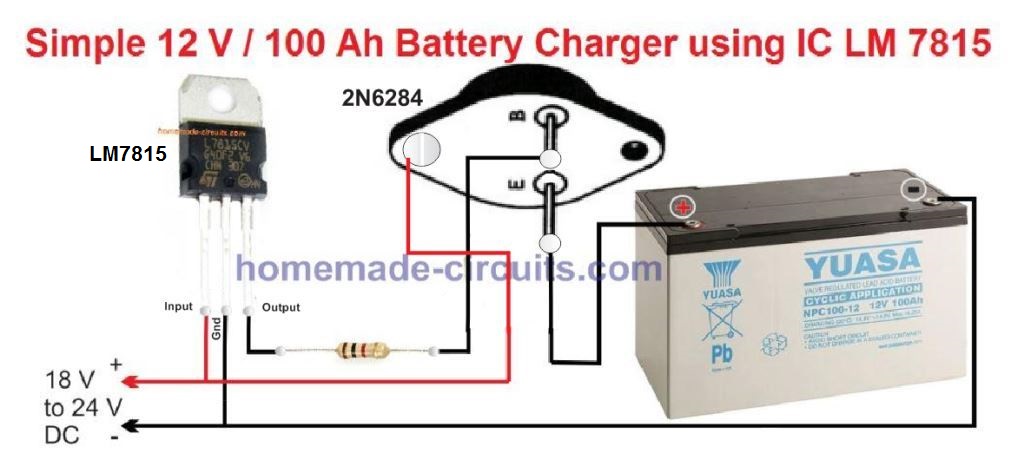

Here's a more appropriate design which will help to achieve optimal charging using IC 7815 IC

As you can see, a 2N6284 is used here in the emitter follower mode. This is because 2N6284 is a Darlington transistor with high gain, and will enable optimal charging of the battery at the intended 10 amp rate.

This can be further simplified by using a single 2N6284, and a potentiometer as shown below:

Make sure that you adjust the pot to get a precise 14.2 V at the emitter of the battery.

All the devices must be mounted on large heatsinks.

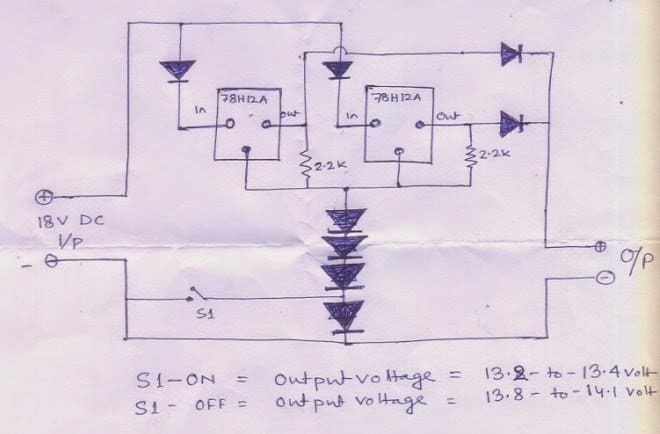

4) 12V 100 Ah Lead Acid Battery Charger Circuit

The proposed 12V 100 ah battery charger circuit was designed by one of the dedicated members of this blog Mr. Ranjan, I will explain more regarding the circuit functioning of the charger and how it could be used as a trickle charger circuit also.

The Circuit Idea

My self Ranjan from Jamshedpur, Jharkhand. Recently while googling I came to know about your blog, and become a regular reader of your blog. I learned a lot of things from your blog. For my personal use I would like to make a battery charger.

I have a 80 AH tubular batery and a 10 Amps 9-0-9 volts transformer. So I can get 10 amps 18-0 volts if I use the two 9volts leads of transformer.(Transfomer is actually obtained from an old 800VA UPS).

I have constructed a circuit diagram based on your blog. Please have a look on it and suggest me. Please note that,.

1) I am belonging to very rural area hence there is a huge power fluctuation it varies from 50V ~ 250V. Also note that I will draw very less amount of current from the battery( Generally using LED lights during power cuts) approx 15 - 20 Watt.

2) 10amps transformer i think safely charges 80AH Tubular Battery

3) All diodes used for the circuit are 6A4 dides.

4) Two 78h12a used as parallel to get 5+5 = 10 amps output. Although I think Battery must not draw full 10 amps. as it will be in charged condition in day to day use so internal resistance of battery will be high and will draw lesser current.

5) A switch S1 is used thinking that for normal charge it will be kept in off state. and after fully charging the battery it switched to on state to maintain a trickle charge with lower voltage. NOW question is that is this safe for the battery to kept in charge unattended for long time.

Please reply me with your valuable suggestions.

100 Ah battery charger circuit diagram designed by Mr. Ranjan

Solving the Circuit Request

Dear Ranjan,

To me your high current VRLA battery charger circuit using IC 78H12A looks perfect and should work as expected. Still for guaranteed confirmation it would be advisable to check the voltage and current practically before connecting it with the battery.

Yes, the shown switch can be used in the trickle charge mode and in this mode the battery can be kept permanently connected without attending, however this should be done only after the battery has been fully charged upto around 14.3V.

Please note that the four series diodes attached with the GND terminals of the ICs could be 1N4007 diodes, while the remaining diodes should be rated well over 10amps, this could be implemented by connecting two 6A4 diodes in parallel at each of the shown positions.

Also, it is strongly recommended to put both the ICs over a single large common heatsink for better and uniform thermal sharing and dissipation.

Caution: The shown circuit does not include a full charge cut-off circuit, therefore the maximum charging voltage should be preferably restricted between 13.8 to 14V. This will ensure that the battery is never able to reach the extreme full charge threshold, and thus remain safe from over charge conditions.

However this would also mean that the lead acid battery would be able to attain only around 75% charge level, nevertheless keeping the battery undercharged will ensure longer life for the battery and allow more charge/discharge cycles.

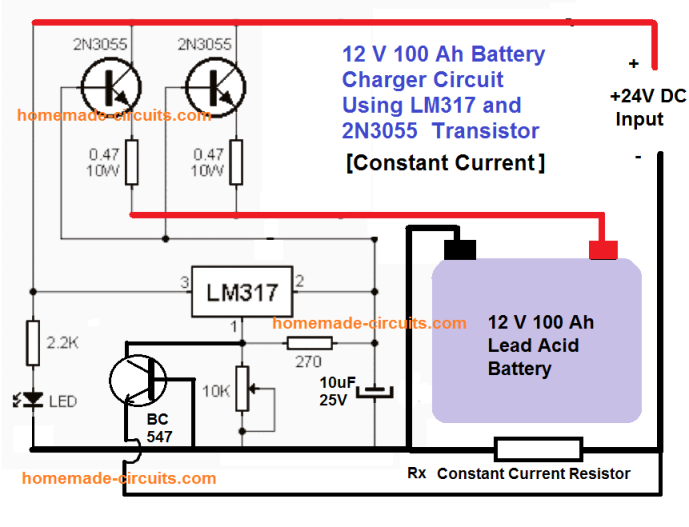

Using 2N3055 to Charge a 100 Ah Battery

The following circuit presents a simple and safe alternative way of charging a 100 Ah battery using 2N3055 transistor. It also has a constant current arrangement so the battrey can e charged with the correct amount of current.

Being an emitter follower, at the full charge level the 2N3055 will be almost OFF, ensuring the battery is never over charged.

The current limit can be calculated using the following formula:

R(x) = 0.7 / 10 = 0.07 Ohms

Wattage will be = 10 watts

How to Simply Add a Float Charge

Remember other sites may present unnecessarily complex explanation regarding float charge making it complex for you to understand the concept.

Float charge it simply a small adjusted current level which prevents self discharge of the battery.

Now you may ask what's self discharge of the battery.

It's the declining level of charge in battery as soon as the charging current is removed. You can prevent this by adding a high value resistor such as a 1 K 1 watt across the input 15 V SOURCE and the battery positive.

This will not allow the battery to self discharge and will hold the 14 V level as long as the battery is attached to the supply source.

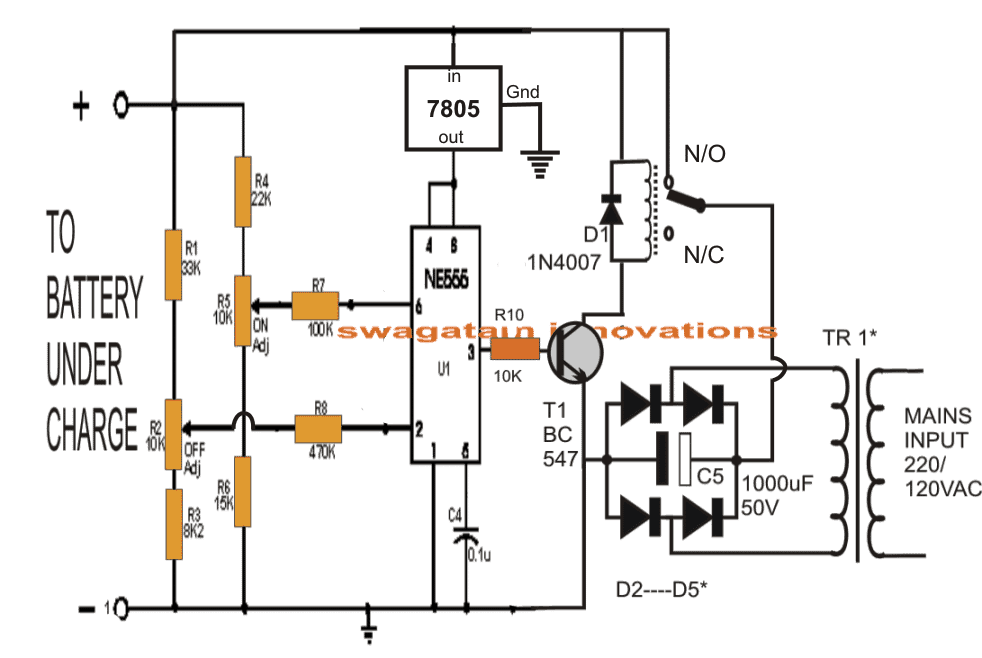

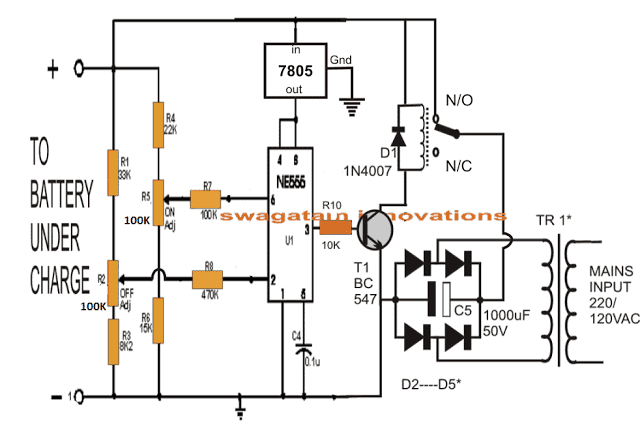

5) IC 555 Lead Acid Battery Charger Circuit

The fifth concept below explains a simple, versatile automatic battery charger circuit. The circuit will allow you to charge all types of lead acid battery right from a 1 Ah to a 1000 Ah battery.

Using IC 555 as the Controller IC

The IC 555 is so versatile, it can be considered the single chip solution for all circuit application needs. No doubt it's been utilized here too for yet another useful application.

A single IC 555, a handful of passive component is all that's needed for making this outstanding, fully automatic battery charger circuit.

The proposed design will automatically sense and keep the attached battery up to date.

The battery which is required to be charged may be kept connected to the circuit permanently, the circuit will continuously monitor the charge level.

If the charge level exceeds the upper threshold, the circuit will cut off the charging voltage to it, and in case the charge falls below the lower set threshold, the circuit will connect, and initiate the charging process.

How it Works

The circuit may be understood with the following points:

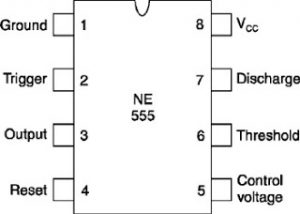

Here the IC 555 is configured as a comparator for comparing the battery low and high voltage conditions at pin#2 and pin#6 respectively.

As per the internal circuit arrangement, a 555 IC will make its output pin#3 high when the potential at pin#2 goes below 1/3 of supply voltage.

The above position sustains even if the voltage at pin#2 tends to drift a little higher. This happens due to the internal set hysteresis level of the IC.

However if the voltage continues to drift higher, pin#6 gets hold of the situation and the moment it senses a potential difference higher than 2/3rd of supply voltage, it instantly reverts the output from high to low at pin#3.

In the proposed circuit design, it simply means that, the presets R2 and R5 should be set such that the relay just deactivates when the battery voltage goes 20% lower than printed value and activates when the battery voltage reaches 20% above printed value.

Nothing can be as simple as this.

The power supply section is an ordinary bridge/capacitor network.

The diode rating will depend on the charging current rate of the battery. As a rule of thumb the diode current rating should be twice that of the battery charging rate, while the battery charging rate should be 1/10th of the battery Ah rating.

It implies that TR1 should be around 1/10th of the connected battery Ah rating.

The relay contact rating should be also selected as per the ampere rating of TR1.

How to set the battery cut off threshold

Initially keep the power to the circuit switched OFF.

Connect a variable power supply source across the battery points of the circuit.

Apply a voltage that may be exactly equal to the desired low voltage threshold level of the battery, then adjust R2, such that the relay just deactivates.

Next, slowly increase the voltage up to the desired higher voltage threshold of the battery, adjust R5 such that the relay just activates back.

The setting up of the circuit is now done.

Remove the external variable source, replace it with any battery which needs to be charged, connect the input of TR1 to mains, and switch ON.

Rest will be automatically taken care of, that is now the battery will start charging and will cut off when its fully charged, and also will get connected to power automatically in case its voltage falls below the set lower voltage threshold.

IC 555 Pinouts

IC 7805 Pinout

How to Set Up the Circuit.

The setting up of the voltage thresholds for the above circuit may be done as I have explained below:

Initially keep the transformer power supply section at the right hand side of the circuit completely disconnected from the circuit.

Connect an external variable voltage source at the (+)/(-) battery points.

Adjust the voltage to 11.4V, and adjust the preset at pin#2 such that the relay just activates.

The above procedure sets the lower threshold operation of the battery. Seal the preset with some glue.

Now increase the voltage to about 14.4V and adjust the preset at pin#6 to just deactivate the relay from its previous state.

This will set up the higher cut off threshold of the circuit.

The charger is now all set.

You may now remove the adjustable power supply from the battery points and use the charger as explained in the above article.

Do the above procedures with lot of patience and thinking

Feedback from one of the dedicated readers of this blog:

Hi, you have made a mistake on preset R2 and R5, they should not be 10k but 100k, I just made one and it was a success, thank you.

As per the above suggestion, the previous diagram may be modified as shown below:

Wrapping it up

In the above article I will explained 5 great techniques which could be applied for making lead acid battery chargers, right from 7 Ah to 100 Ah, or even 200 Ah to 500 Ah, simply by upgrading the relevant devices or the relays.

If you have specific questions regarding this concepts, please feel free to ask them through the comment box below.

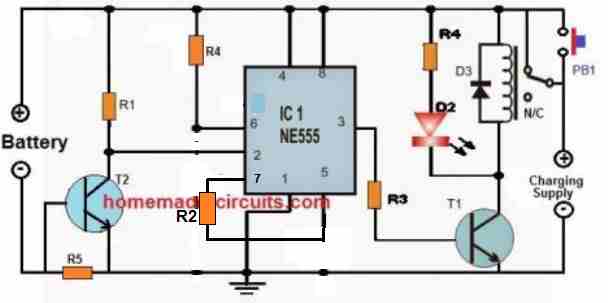

IC 555 Current Dependent Battery Charging

The IC 555 lead acid battery charger circuit could be also built using a current sensor at its pin#2.

The complete circuit diagram is shown below:

- R1, R3 = 10k

- R2 = 100k

- LED resistor can be 1k

- Pin#6 resistor R4 can be shorted with jumper link

- R5 = 1 / max charging current

- Relay = 12V relay for 12V battery.

- Relay diode = 1N4007

- T1, T2 = BC547

How it Works

The circuit is actually configured as a set/reset latch circuit.

The R4 can be replaced with a wire short.

At the start when power is applied, the relay contact being at the N/C, the circuit does not respond.

Pressing the PB1 push button, initializes the circuit by momentarily supplying the current throgh the PB1 to the battery.

The battery acts as the load, and creates a voltage drop across R5, which triggers ON the T2.

With T2 conducting pin#2 of the IC is held low, which prompts the output pin#3 to become high, and switch ON the relay.

The relay contacts now changes to N/O point and the circuit gets latched. The PB1 pressing is thus only required momentarily, and then it can be released.

As the battery gets charged, the voltage across R5 keeps getting lower, until the point when the battery is almost fully charged, when the R5 voltage drop is unable to hold the T2 ON any longer.

T2 switches OFF, causing pin#2 to go high again, and this in turn causes the pin#3 to go low, and turn OFF the relay and turn OFF the charging supply to the circuit and the battery.

Hi,

Your circuit diagrams and explanations are excellent and I really appreciate you putting up this page.

My question is how do I modify the “Using IC 555 as the Controller IC” charging circuit to provide 30 amps of charging current to the battery?

You said to upgrade the relay and the components but I’m not sure exactly what I would need to do.

I thank you very much in advance for any guidance you can give me.

Ted

Hi, Thanks very much, and glad you found the post useful!

The relay contacts are responsible for handling the battery current so the relay must be upgraded to have a contact rating of at least 35 amps to handle 30 amp current. So for 30 amp current you would a relay whose contacts are rated at 35 amps, 40 amps or maybe 50 amps.

However, there are much easier ways to charge a battery using transistors and ICs only, without involving relays. I would recommend these instead.

Let me know if you need any further assistance.

Good day sir. For the 555 timer based 12v charger, can I replace the resistors at pin#6 and pin#2 with a series 1k resistor 5.1v zener and 4.7 v zener respectively? Will it work and is there any disadvantage?

Hello Emmanuel,

I am not sure about it, you will have to test it through a practical experimentation.

Ok sir

Thanks for your reply sir. But my second doubt still not cleared by you sir. I wanted to know whether this 555 circuit i refered to can be used for cutting of the charging process alone without making it to auto charge the battery? I want it for an emergency lamp circuit without automatic charging, but only employing auto cutoff only..and what changes need to be done for that.. pls help me sir

Binoj, If you do not want an automatic low battery detection and charging, then you can remove the pin#2 preset entirely and instead connect a push button across pin#2 and ground. Make sure to have a 10K resistor connected between pin#2 and the positive line.

But please note that I have not tested the 555 circuit yet. If you want a tested alternative you can try an op amp version which will only do automatic cut off but no automatic recharging.

Simple 3.7 V Li-Ion Battery Charger Circuit

Hlo sr, regarding the ic 555 battery charger circuit, i cant figure out how the voltage regulator actually gets the power if the output from bridge is fed through the NO contact of relay. Or is there any mistake in the diagram? Can u pls clarify the relay contacts connection. And another thing is that shall this circuit be used only for auto cutoff function and not for auto charging. If so what changes are to be made??

Hello Binoj. there’s no mistake in the diagram, it is correct.

When the battery is low. pin#2 is below 1/3rd Vcc which causes pin#3 to go high and it switches ON the relay. The relay contacts shift to N/O and start supplying power to the regulator and the battery.

Initially, at the start, when the relay contacts are at N/C, the regulator and the IC get the power from the battery.

The circuit can be used for auto cut off and also for auto charging.

Hello Sir, I have a DC supply which is 26v,52amps but I just need 24v, 17 amps to charge my 24v ,170AH battery . Can you please help me with a charger I can regulate the current and voltage?

Hello Chris, for charging a 24V lead acid battery fully you will require a minimum of 28 V. So even 26V is insufficient.

Hello sir thanks for your assistance and correction but I also have a Delta rectifier module which is 100-240v input and 54vdc-53.7A Output. Can you please assist with a charger circuit I can use with this to charge my 24v battery?

Hi Chris,

First you will need a buck converter to drop the 54V to 28V Dc, only after this you will be able to charge your battery. I don’t have this circuit with me at this moment.

Thanks for your support

hi swagatam can I implement the current sensor from the second IC555 to the first IC555 circuit?

Hi Sam, both current and voltage cut off is not recommended, you can use either of them for the cut off. Using both will not make sense!

Hello Swagatam I was talking about the first circuit in this article. Can it be ok for the 200ah 12v battery and can I use 6.2v zenar instead of 6v zena? Secondly, I was asking to know if high current Mosfet’s of about 150amp are better and makes the inverter more efficient than low current Mosfet’s?

Hello Morris, I guess you are referring to the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2011/12/high2Bcurrent2Bbattery2Bcharegr2Bcircuit.png

Yes 6.2V zener will also work instead of 6V zener.

Yes, higher the current the better will be the performance of the mosfet

Ok sir. But does MOSFETs with high current consume more power from the battery faster? Secondly in an inverter circuit is it the oscillator stage design that makes inverter consume voltage Faster or the MOSFETs used in the amp stage. Thanks in advance my teacher.

The current rating of the mosfet suggests its maximum capacity to handle the current, its breakdown limit. The consumption of the mosfet depends on the wattage of the load connected across its drain, which is a transformer for an inverter. Yes the oscillator duty cycle determine how much average current the mosfet will consume.

Ok sir thanks for the response. Do u hv inverter charger circuit design that uses is mosfet as diode to charge battery whn battery gets low without bridge diode. I tried a separate transformer with bridge diodes to charge the 200ah battery but the four metal bridge diodes gets too hot???? pliz guide me

Hi Morris, yes I have one related post on how to use mosfet body diode for charging battery, you can read it here:

https://www.homemade-circuits.com/using-mosfet-body-diodes-to-charge-battery-in-inverters/

Hae Swagatam I built the first circuit and charged the battery. I used also an digital battery indicator to show me if around 14.4v it will trip the relay. The two voltages merged and started indicating 11.7 upto 14.6v without tripping the relay. Whn I disconnected the battery now reads 13.3v. Does it reads upto around 15v up for the real voltage itself to reach 14.4 to trip? Advise

Hi Morris,

14.6V is too high, you must not use more than 14.3V. Actually 14.1 V is the recommended level. If you adjust the preset correctly to trip at 14.3V or 14.1 V then the circuit surely trip at that point. Remember at the full charge level, the pin#3 voltage of the IC should become slightly higher than pin#2, this is when the op amp output will become high and the BC557 will shut off, switching OFF the relay. You can replace the 3V zener with an LED for the indication. Cathode will go to pin#6 of the IC and anode towards the resistor.

When you remove the battery after the full charge, the battery voltage will slowly drop to 12.8V and this is perfectly normal, do not expect it to stay at 14V permanently, because in the idle state the a fully charged 12V battery will show a voltage level of around 12.8v.

And what will happen if I remove also the diode to the battery terminal (6A4)? I used the circuit without it coz the 6a4 I had exploded????????.

6A4 can handle only upto 5 amps so it won’t work. You can remove it. But after full charge remove the battery from the charger otherwise it might self discharge through the op amp 10K resistor

Hello Swagatam,pliz check the first circuit in this article if it is really that way. Thi is how i set it: I first tweaked my supply to around 14.0v. Then loaded it to the circuit before connecting a battery…..tweaked again the 10k preset until the relay comes to N/O because whn it comes to N/C u will find that u just continue holding the start button for it to come on. So whn it’s tweaked to activate u just find is coming on whn u press the button once but u will wait for the relay to cut off until u see he’ll my friend???????? pliz try circuit the way it is and see then tell me. I just unplug it and find the battery is full but not cutting off

Hello Morris,

I will explain you the right process for adjusting the preset.

1) Replace the 3V zener with an LED. Cathode will go to pin#6

2) Keep the 10k preset slider to ground level.

3) Keep the push button shorted.

4) Supply around 14.1V DC across the positive and the negative lines of the 741 circuit.

5) You will find the LED switching ON, and the relay clicking to the N/O side contacts.

6) Now, slowly adjust the 10K preset until the LED just shuts off and the relay switches off to N/C contacts.

Your circuit is all set now. You can now remove the push button shorting and test the set up with an actual battery.

Hello sir can u get me the procedure of setting the second circuit in this article to function as expected.

Hello Swagatam, I have original 24v automatic charger which has two led indicators ie one for float charge and the other for quick charge. Now I bought two 100ah battery which I connected in series. Whn I connected them to that charger the red led for quick charge indicates then upon full charge or whn nearing full charge it shifts to float charge indicator. My question is that is that how the charger should be working? Can that cause any harm to the batteries? Thanks!

Hi Morris, from your description it looks like your charger controller is working correctly.

So I should not worry any harm to the bad? Now whn it shifts to float charge what happens at that time to the battery and should I just leave it to stay unplugged? Thanks sir.

Float charge is like trickle charging, using very low current, just to ensure that the battery does not self discharge. It is perfectly safe, you can keep it plugged.

Dear Swagatam

I am very thankful to you for the reply, and I suggest removing the old circuit and build a simple one without attaching the other accessories only working on AC &DC is it possible to get such a circuit .

I would like to thank u for the second part also.

You are welcome Nabeel, it is not possible to know or judge what circuit was used in your fan, because different fans have different circuits, there’s no standard circuit available in the market

Dear Sir,

I am from Iraq, I need your help with many things in the electronic field first is a circuit for the fan that can work on mains (ac) and a battery, that means when the AC is available it works normally but when AC goes off it will switch to the battery, in fact, the fan has a circuit and due to fluctuation of

electricity the Ic in charge burnt up In the power section and I don’t know the number or any think on it so I had to go for changing the circuit I could replace the bridge

and the Optocoupler but I can not read any number on it

second – I would like to learn how to design a PCB with easy aid

Hello Nabeel, If the fan has a circuit then it can be difficult to troubleshoot the issue without checking it practically.

To learn how to design PCB you can refer to the following article:

How to Make PCB at Home

Thanks for the detail and various different designs. I am trying to mimic what we commonly get off the shelf these days (smart charging, float, trickle, reverse connection protection, etc.) with the exception that i need it to have a continuous running capacity of 70A or more at 14.2 (up to 14.4V) . Is it possible to mod one of these? I am a electronics enthusiast with no formal training and have completed several small projects following plans. Thanks for your help.

Hi, the only advantage of a smart charger is that it allows a fast charging of the battery compared to the ordinary chargers. However, if the charging at normal speed is acceptable then smart charger is absolutely not required, moreover charging any battery at a standard slow rate is the most recommended since it promises longer life to the battery.

A Smart charger basically comprises of fast charging through 3 step charging, float charging or trickle charging, and temperature compensation.

In contrast, a normal good charger will have a constant current constant voltage charging, with float charging and trickle charging, which is extremely easy to implement yet is very safe.

If possible I will design a smart charger circuit soon and post in my blog, with all the above mentioned features.

I will make the IC 555 Current Dependent Battery Charging. Please i will like you to guide me. Thanks

No problem, you can ask your questions, I will try to answer them.

Hi.

Could you please share an example formula for calculating the 7.pin output for circuit 2?

I do not know how to calculate because hysteresis is made in the circuit

Hi, For hysteresis formula you can read the following article:

Opamp Hysteresis – Calculations and Design Considerations

Hai sir,

I have a few doubts regarding this circuit (5 IC 555 Lead Acid Battery Charger Circuit)

I need to design a charger for 4v 1.5AH lead-acid battery

1.Instead of using Relay we can use Transistor BD139 or BD140.

2.Preset R2,R5 value 100k for 12v battery . We can use the same value for 4v battery or need to change.

3.In this circuit the 555IC power supply is taken from Battery. Instead of taking the power supply from the battery, we can use the transformer output power supply. If we take transformer output power supply When power failure appears the IC will remain in the same state or reset.

pls guide me sir

Hi Kesavaraj,

You can replace the relay with transistors as given in the following diagram:

The IC 555 has to be connected on the battery side so that it is able to detect the battery voltage and implement the required switching of the charging input….if it is connected at the charging supply then the output will be immediately switched OFF on power switch ON

Sorry, actually the IC 555 Vcc supply can be easily shifted on the input supply side, by simply connecting the IC 7805 input to the emitter of the TIP127

Ok sir

Thank you sir

Offer of cooperation on the production of Ultra fast chargers.

I have achieved a new method by which I can charge lipoly and other types of high C batteries in up to 5 minutes without heating the battery to destruction in the battery.

Please send all the data, I’ll pot it with your credentials

hello sir I’m sorry I asked outside the contents, but this question is important for me what diode (UB02 diode.) What kind of diode is it, sir?

I am talking about circuit No:2 (12V, 24V / 20 amp Charger Using two opamps:)

And also asking the use of veriable resistor connected to pin 2 of the IC

Upper preset is for adjusting the full charge threshold, lower preset for setting the lower discharge restoration.

I mean the 10k veriable resistors

In the 3rd circuit? 3rd circuit with the relay does not have a low detection, it is only for over-charge cut off protection

For the circuit number 2 please which preset is for the set of low charge it is the preset connect to the pin 6 if yes. What is the use of the preset connected to the pin 2??? Please explain to me

I cannot see any preset? Do you want to connect a preset?

Dear Swagatam,

What is the best charger for 12 V 30 Ah Tubular Lead Acid Solar Battery with over charge protection and charging current should be within 10Amp so that the battery always will be in a good condition.

Hi Sayem,

the following circuit is perhaps the most recommended design for any lead acid battery:

https://www.homemade-circuits.com/regulated-car-battery-charger-circuit-for-garage-mechanics/

Good day Sir,

On my observation of the above; two-Opamps-in-one battery charger circuit.I think the normally open [NO] should initiate charging while[ Nc] disengages it based on the diagram.The two charge -status LEDs are not labeled ie charging and fully charged.Are they the ones close to the 10kohm at the base of the transistor?.Can the circuit be used for 8-10amp current requirement?.

Pls make a video or article on dead battery revival as i would like to learn more on epson salt.

Thank You.

Hi Patrick, you are right, the explanation needs a correction, I’ll do it soon. Yes the charger can be used for charging any battery, by suitably upgrading the relay specs.I already have an article regarding treating sulfated batteries, however I do not have the necessary calculations for getting guaranteed results, it might require some experimentation.

2 Simple Battery Desulfator Circuits Explored

Hi sir, between 15.5v and 14.4v charging voltage with auto cut off , which one do you recommend.

Hi Sheun, If you are referring to the input supply, then both will work since the auto cut-off is in operation, however for better safety 14.4V is preferable.

My dearest engineer Sir

I really appreciate your assistance regarding the battery charger.it was a success.tnk u

I have a issue at work .the 3phase 110vdc battery charger we are using got burnt and av been tasked with you must do it.am thinking of designing a controller circle for controlling the charging of the charger.the voltage I have a battery 92cells series together at low voltage it gives 110vdc and at full voltage it gives 120vdc approximately.each cell at low voltage is 1.19vdc and at full is 1.30.the transformer is 7.5kva.pls I need a controller circuit diagram for it having short circuit protection polarity protection and overcharging protection.making it full automatic.pls help me out.i want to incorporate display with it.if possible can I have ur direct mail?

Thanks Oladimeji, you can try implementing the following concept by suitably adjusting the input parameters.

https://www.homemade-circuits.com/high-voltage-360v-battery-charger/

The input supply must have a constant voltage and constant current features in-built.

Dear Sir,

Pls assist me I need an automatic battery charger circuit for 24v charger with with overcharging ,polarity protection and Auto cut off with relay, it’s o be use to charge 100 amps to 500amps pls help me out.from oladimeji

Oladimeji, you can use any one of the designs mentioned in the following article;

Op amp Battery Charger Circuit with Auto Cut Off

Replace the relay with a 24 V 50 amp relay, and transistor with a 2N2222

Hello sir tanx for your reply,if I may ask how do I set the low battery cut off and full battery cut of.also how do i determine the R6 for the automatic 24v battery charger as advertised

Tnx

Oladimeji, I have updated the setting up procedure in the op amp battery charger article, you can check it out

– What is the purpose of the 3v zener diode at the ouput of the IC741 ( Using a Single Op amp project)?

– I have replaced it with a led and it works BUT it doesn’t work if i replace it with a diode (1n4148 for instance). Have you an explanation? Thanks.

It is two block the offset leakage voltage from the op amp output, 1N4148 will work if two are used in series, cathode should be towards the op amp output pin6

Hello sir swagatam, have you ever thought how internal mosfet diodes can be used as bridge rectifiers? If so then try to figure out how this auto cut with Lm358 can be connected to a mosfet system to control charging process of a ups charging 2nos 200Ah batteries. Assume a mosfet system using 4nos mosfets say irfp3006 and design a full circuit and help me design one with an aid of a circuit diagram.

Hello Evans, I remember talking about this concept with another follower of this blog, but I can’t recall under which article the whole discussion is posted?

However, there is a similar concept is published in the following article, which probably you can modify for fulfilling your application needs

https://www.homemade-circuits.com/solid-state-relay-ssr-circuit-using-mosfets/

It has been a little while since this covid-19 lockdown and I want to say, ‘Hi’ to you. I hope you are fine.

Please continue to keep safe.

Thank you I am fine! You too keep safe.

Thanks but which configuration gives the highest current output?

Thanks.

It is common emitter which gives maximum current but needs to be cut off with an op amp at full charge

First I commend your fast responsiveness making your blog highly active. Secondly, I have been carrying out some researches on battery charging system for some days now because the life of an inverter depends to a large extent on the battery and I find your blog has the best in the world. Congratulations!

I again I want you to please explain why the emitter pin of 2N6292 and 2N6284 goes to the anode of the battery under charge in the lm7815 but it is grounded in some other configuration i.e. common emitter. Which mode, emitter follower or common emitter is the best for current amplification in charging system with 2Nxxxx family?

When the load is connected on the transistor emitter, it is called emitter follower or common collector circuit, when the load is connected on the transistor collector, it is called common emitter circuit. The advantage of emitter follower is that it allows the emitter voltage to be controlled by adjusting the base voltage, whereas in common emitter this advantage is not there. Even a 0.7V at the base will cause the whole supply to reach the load when connected at the collector side. But on the emitter side, the emitter voltage to the load will follow the base voltage and will be always 0.7 V lower than the base.

Considering the third battery charger design above using IC7815 and 2N6284, how can a BJT whether Darlignton transistor or not deliver 10amp without faulting the law of conservation of energy since the person who made the circuit-request said, ‘My input is 18 volt 5 Amp transformer.’

Input is 18Vx5A=90W

Output is 14.3Vx10A=134W.

Pls., how can this be possible? I think this transformer should be changed. I’m trying to go through again before I recommend this site to more people because it is educating.

It is basic knowledge that the output from any system will be lower than the input, so just upgrade the input according to the load requirement. It is the working concept that is important, upgrading as per personal specifications is just a matter of minutes. By the way I cannot see where I have mentioned that a 5 amp input can be used to get 10 amp output

Hello Swagatam, I have been following u since last year and I must say, ‘I like u for ur work,’

God bless u.

Don’t u think an extra diode at the anode end will help to prevent battery self-discharge? Although, I think it may prevent the system from reactivating the relay since it won’t prevent current from flowing back into the system.

Thanks.

Emmanuel.

Thanks Olamide, are you referring to the op amp transformer based design? It is supposed to be a one shot off design, so detecting the low battery is not included in the design

No, that one already has a diode at the anode. I’m referring to the fifth one having IC555. I have tested almost all the designs and I think that fifth one is most suitable for Nigerian Grid system or any other situations with unstable voltage but I suspect a slow current discharge which is taken care of by a diode but won’t allow the operating amp to detect low voltage which does still allows it to detect the 14.4v and deactivates the relay.

Thanks.

The resistor values are very high so the discharge will be extremely slow and negligible…

You are correct sir I was just thinking about complete elimination of the discharge.

Lastly I think it should work normally with regulated solar panel of correct voltage like the special one you designed with 48v. If a regulated voltage between 14-15v is fed into this fifth design in question I THINK IT SHOULD WORK to power a 12Vx10A=120w battery from a 150w panel (Energy losses considered with 5-6hrs insolation).

Have a nice Sunday.

Sir,in this high capacity charger,if one don’t want to use Relay but transistor in place of the relay what can you recommend? Thanks

Andy, you can try the following concept

Good day Swag, last year I was involved in the repair of the charging system of an imported inverter of a friend by just replacing the fuse. It also happened to the charging system of the inverter I personally built, by replacing the fuse within 2 weeks.

Please what could be responsible, sir.

Adeyemi, a fuse will blow when there’s an overload or a short circuit, you can put a current limiter in series with the supply line to make sure the fuse never blows.

Please sir, how can I get a current limiter circuit for it

You can try any of the MOSFET based designs explained in the following article:

https://www.homemade-circuits.com/universal-high-watt-led-current-limiter/

Good day sir, I bought used battery, charged it to full, but blew the inverter 2-3 times maybe due to battery short circuit. But thereafter, it worked well with the inverter. Please explain to me the principle.

Hi Adeyemi, if the battery voltage is as per the inverter specs then the inverter can never blow. Either your inverter is faulty, or the battery voltage is much higher than the inverter voltage.

Please post inverter related comments under inverter only.

Please sir, can high value capacitor used to filter the output cause overload or short circuit.Thanks Swag

No, it is fine to use a capacitor at the battery terminal.

Thanks for being always there, please what is advice on either getting a Grade A battery of 65ah and grade B of 100ah 12v battery which are same price for powering a load of 140watts.

Thanks Ademyei, I won’t be able to suggest much on this since I am not a battery expert, perhaps the manufacturer will be able to explain better.

Thanks for your reply, please to 200w freezer which set up is better in terms of efficiency, durability for 400ah battery, 200ah/24v or 100ah/48v using appropriate inverters

100Ah/48V option will be the most efficient.

Hi.

How can I use inverted power regulator for charging 100Ah battery?

i have 24V from solar panel and i need to have to charge 2 x 12V battery which is in series.

i guess the best method is using 7915 and 2N6287 a PNP version for 2N6284, but how to connect PNP darlington, with C to output and E from IC output, or viceversa?

thank you

Hi, for 24V solar panel, you don’t need any regulator, simply connect the two batts in series. Connecting them in parallel will reduce the efficiency drastically. Make sure the panel current is 5 times less than the Batt Ah value.

i connect 2 batt’s in series, but on one batt i get 14.8V (sometimes worst about 15V) and to the second 14V (or 13.8V). That’s i need to charge individualy. i didnt put batt’s in parallel, is in series, but from your excelent article, i intend to make schematic with 7815 and NPN Darlington, but i need schematic for the negative batt charger with PNP Darlington and 7912.

Thank you, also for great article!

Thanks Criss, you can try the following option, If possible I’ll update using 7912 also soon

https://www.homemade-circuits.com/wp-content/uploads/2019/10/pnp-battery-charger.jpg

Thank you Swagatam.

Your link is what i wanted.

I found many interested article on your web site, inverters, tutorials…

You are great, thank you for your work!

Thank you Criss, Glad you liked my posts, wish you the best!

Hi sir,

I have some sort of questions regarding the auto cut off battery charger. is there any of your ideas on how to auto turn off back the relay from N-Open to N-Close position to auto recharge again the battery during low voltage at about 10 vdc? In this case I don’t have to worry about the full or the discharge of the battery and can continuously supply to my dc to ac inverter?.

I’m hoping you could share some of your good ideas regarding this matter.

Jing G. Amora from Philippines!

Thank you very much Sir!

Hi Jing,

the 3rd design from top is designed for both high and low cut offs.

You can also try the concepts presented in the following article:

https://www.homemade-circuits.com/opamp-low-high-battery-charger/

hello sir,

yes I’ve missed to read the third part of the article just before sending my text message, and

the circuit for me was so easy to understand. I’ve tried it on actual with my own pcb layout and it’s working so far right now only there are few that I have to modify about the circuit, two of the 6 volts zener diode was replaced to a bit higher 6.8 volts and all of the resistors, I replaced it to 8.2K but the 2 trimmers were as is 10K. my cut off voltage charging settings is set to 12.9 volts the relay goes to (N/C) and when the battery voltage drops to 11 volts the relay goes back to (N/O). one more idea had come to my mind is that I’ve replaced the relay to DPDT one pole is for the charging and one pole is for the ac line, so during the relay charging goes off the ac line also goes to off position.

Thank you very much Sir, you have broaden my mind and I will keep on following your good circuit designs. More Power!

Thanks Jing for your interesting feedback, I am glad the two opamp version is working for you.

However modifying the relay contact wiring may cause rapid ON/OFF vibration if the circuit is powered without a battery connected.

Anyway appreciate your involvement very much…keep up the good work!

Hi Swagatam. Thanks a lot for sharing your knowledge.

In this page there are several designs and circuits labelled as follows :

1) Using a Single Op amp

2) 12V, 24V / 20 amp Charger Using two opamps

3) Using IC 7815

4) 12V 100 Ah Lead Acid Battery Charger Circuit

5) IC 555 Lead Acid Battery Charger Circuit

My question is simple : I am planning to construct a charger for my batteries car witch are 12v – 60AH to 80AH capacity (several batteries). What are the suitable circuits i have to use witch are fully working and already tested by yourself.

Thanks.

Thanks Hedi, It will depend on a few things regarding the selection of the designs presented in the above article.

Whether you are interested to have a quicker charging, optimal charging, higher back up time and lower life, and/or the level of experience and knowledge you have in the field of practical electronics.

I would recommend the SMPS option given at the beginning of the article, since it will do the job without any fuss.

Just plug it and forget it, as it says. However all easy things come with a slight disadvantage, in this case the charging will be slightly lower than the full charge level and therefore a lower backup time. But the good thing is that it will ensure a longer life and an increased number of charge discharge cycles for your battery, provided the discharging conditions also complement the charging procedure.

So finally, just buy one 12 V 10 amp SMPS, adjust the preset to 14.1V, connect it to the battery and that’s it. Keep checking from time to time, once it reaches the set 14.1V , you can remove it and use it for the required purpose.

Thanks a lot for the quick reply . I have enough knowledge in the field of practical electronics and what i am looking for is an optimal charging design with automatic cut off circuit for 12v batteries with a capacity around 60 AH to 80 AH (this is the important criteria).

Actually as a hobbyist i don’t like to buy ready “plug and forget it” devices. As i said i have enough knowledge in electronics and a great part of the components needed for the designs listed in this page are already available in my “electronic component box”. Have as well several home made arduino uno if required. Thanks again .

OK, then you can try the first circuit using a single op amp. replace the 3V zener with a red LED, for getting the cut off indication. Cathode will go to pin#6. Make sure the transformer current is not more than the 12 amps, and the voltage can be 0-12V. Adjust the preset to get a cut off at 15V, which will produce a cut off at 14.4V for the battery due to the series diode..

By using this design, is it safe to apply directly 16.8 v at 12amps to the battery? You have mentioned in your tutorials that it is important to respect the charging voltage of a battery as well as the charging current?

Honestly i feel more confident when using voltage regulators and apply the exact charging voltage to the battery witch have also the advantage of having a larger choice of transformer voltage . Don’t you?

It is absolutely safe because the current is limited to 10 amps which is quite low for a 100 Ah battery, and moreover the cut off is set at 14.4.

If you still want to include a voltage regulator, you can use a LM396 IC after the bridge.

Another aspect is the 100uF filter which is very low and will cause the average voltage to drop even lower than 14V. If required you can eliminate the 100uF cap.

The peak voltage may become crucial when the there’s no cut off.

Absolutely clear. Thanks a lot for the explanation. I’ll give it a try and let you know how it goes.

Thanks again.

No problem, wish you all the best!

Actually i discover that it is very hard to find this kind of transformers here. My question is : can i use a 12v/10A smps power supply tweaked to 14v in replacement of the transformer and its rectifier diodes?

Yes an SMPS will also work as described in the first diagram. Adjust to 14.4V if you are use the op amp cut off

I have made the first project (auto cut off) and done the preset voltage procedure without problem (cut off at 13,8v) by using a variable voltage supply for this purpose . Till here all is ok. BUT as soon as i connect the powered circuit using a main power supply (15v at 10A) to the actual car battery (12v / 80AH) the relay enter in a big vibration mode (switching between N/O and N/C at high frequency) same thing for the leds. What may be the issue?

PS : As main power supply i am using an ATX pc power supply modified to get the 15v/10A as output.

Do you see this happening even if the push button is held depressed continuously? Also, please check whether the voltage is dropping to the battery discharge level or not. Because the if voltage is dropping then the opamp output will produce a zero voltage at its output enabling the PNP to conduct and latch the relay ON. Alternatively, you can try connecting a 1000uF capacitor right across the relay coil and check whether this solves the issue.

Also please replace the 3V zener at the op amp output with an LED for getting a direct indication of the situation, Cathode will go to the op amp pin6

No if the push button is held depressed continuously this is no more happening. I have also made the second project (automatic charger with double op amp) and successfully achieved the preset task (11,9v / 13,6v) but the issue is the same. Have replaced the relay with another brand without success. Have also put a 1500uf capacitor across the relay coil and then the switching ON/OFF frequency have decreased (the relay switch itself between ON and OFF every one second now).

ps : Have from the beginning replaced the 3v zener diode with an led.

That looks strange, I’ll check it tomorrow myself and let you know!

After several tests here are my conclusion : The vibration issue have been solved after installing the 6A4 diode at the Battery + connector (haven’t installed it initially to avoid the voltage drop across it) but now and after connecting my car battery and switching ON the power supply, the relay is never triggered when pressing the push button . In fact the system works very well when using laboratory psu without connecting a battery BUT in real life as soon as a battery AND a power supply are connected you have either a relay vibration issue if the 6A4 diode is not installed or Nothing if it’s installed.

Your conclusion is not correct. Electronics is about understanding and solving, it’s as simple as that. Some concepts are too simple and does not require testing, but they might sometimes have some minor hidden issue..and that’s why I am here… to diagnose and solve it for the needy hobbyists.

I checked the circuit and yes it was oscillating, due to the one simple issue.

As soon as the relay switches OFF at the full charge threshold, the input supply is cut off. Now the filter capacitor across the bridge begins discharging and as soon as it drops below the cut off threshold, the relay energizes again, and this continues.

The remedy is to remove the filter capacitor from the power supply, and keep a 1000uF capacitor connected across the relay coil.

If filter capacitor cannot be removed, then simply place a 1000uF capacitor across pin#3 and ground. Or add an additional 10K resistor in series with the existing base 10 K of the transistor and connect a 100uF across the junction of these 10K and ground line.

Remember, since the capacitor will initially charge, it will keep the relay ON even after the push button is released, but once the capacitor charges, the relay will switch OFF…and this result will be when battery is not connected….with battery connected everything will run normally

Swagatam have you tested one of these projects in REAL LIFE ?

Thanks a lot for the explanation witch is clear and logic. I’ll do the modification and let you know how it goes.

Meanwhile i have a question : in what cases the circuit voltage does not drop to the battery discharge level but remain at the power supply level and what is the reason of this?

Again thanks a lot for helping.

You are welcome! The voltage will not drop under two conditions, if the battery is dead, and not accepting the charge, or the battery is already fully charged. Under all circumstances the input current must be substantially low compared to the battery Ah value.

If a high current is used for a good battery, the voltage will drop initially but will rise quickly, as the battery fluid boils and the battery gets slowly destroyed and dead.

Why not use a low current threshold (battery full charged) for the cut off instead of voltage threshold?

Current based is also possible, but voltage control is the conventional and the easier option. If possible I’ll update the current based design also soon…

Thanks a lot.

I’m asking for a current based cut off circuit because i’m actually using a constant voltage battery charger (an ATX power supply modified to get 14.5 v as output connected to a current limiting resistor ) . It is working very well. But i’m obliged to verify continuously the charging current and to manually power off the psu when the charging current decreases to let’s say 100mA to avoid unnecessary loss of energy especially if I am absent. Is there a solution for this. Thanks again.

OK, You can try the following circuit for deactivating the battery charging when current reaches almost 0V:

https://www.homemade-circuits.com/wp-content/uploads/2019/10/battery-current.jpg

Thanks a lot Swagatam. That’s exactly what i’m looking for. You are the best.

My pleasure Hedi, I have also updated the circuit description in the article.

Thank You Very Much

TIP 147 is PNP darlington transistor.On emiter will be plus 16-24 V in and on colector is plus out.In picture is wrong.

Thank you for pointing it out, I have replaced the image with the proper one.

Good evening, is it possible to charge three 12v lead acid batteries connected in series using number 5 battery charger, if not how can I improve it to be able to charge 36v batteries.

Hello,

sorry I could not understand what you meant by “number 5 battery charger”

I mean the lead acid battery charger with 555 timer

I would recommend the second circuit, not IC 555, because I have not yet tested the IC 555 design

You are welcome!

No it is not safe to charge a 12V 5 Ah battery with 22V, 5 amp supply.

You can use an LM317 IC regulator circuit for controlling the 22V, 5 amp to 14V 500 mA, as explained in the following artcile:

12V Battery Charger Circuits [using LM317, LM338, L200, Transistors]

Thanks for taking your time sir.

I have a 1500w rated sine wave UPS I want to convert. It is designed to use 2x12v 9Ah SLA batteries (24v circuit). I want to know how possible it is to adapt it for 24v 200Ah SLA batteries, and then increase the load capacity to 5000w. I know I can increase the mosfets and change to a bigger transformer for the load (hope it’s safe), but I’d also want to upgrade the charging circuit to 20A. Please what do you recommend sir?

Hi Foxy, assuming it is a 12V UPS, you can upgrade it to 24V by replacing the transformer and the MOSFETs accordingly with matching specs, and make sure the circuit gets a regulated and stable 12V. It is perfectly safe to do this. But 24V 200 Ah will not give you 5 kva, the battery will get damaged very quickly. You may require 24V, 500 Ah for this. The charger will be 25 Ah in that case.

Good day sir! I have question about IC 555 Lead Acid Battery Charger Circuit number 5 in this article. I want to add a 5mm LEDs. 1 red led for charging and 1 green led when its done and what are the resistors in each led. Is it possible sir?

Good Day Michael, Add one LED in series with T1 base, add another LED across pin#4/8 and pin#3 through a 1K resistor

Olá amigo.

Estou tentando fazer um carregador ajustável para baterias de litio, com corte automatico de carga de 1,4V até 4,2V com um relé de 5V, um trimpot 1K e um 2n2222a. É possivel? Você tem um diagrama?

obrigado

Oi amigo, você pode fazer isso usando dois transistores como mostrado abaixo:

https://www.homemade-circuits.com/battery-full-charge-indicator-circuit/

Você pode usar 2N2907 para o transistor de LED e substituir o resistor de LED por uma bobina de relé. Certifique-se de adicionar diodos em paralelo com a bobina do relé

Sir in the 2nd circuit can i use 555 timer instead of lm358? it is not available here in our place..

Paul, sorry that is not possible because the the two ICs have different pinout arrangement.

You can try two separate IC741, or use 2 opamps from the IC LM324

sir which rating transformer is used in this circuit.

in using two opamp ckt what is charging supply input (from transformer?).

and in two opamp ckt what u use before 8050 thansistor which u show a diode sign with different colour and before bc547

Imran, the red color thing is a RED LED.

The transformer rating should match the battery voltage rating and current should be preferably 10 times less than the Ah rating of the battery if it is a Lead acid battery, or 50% less if it’s a li-ion battery

I thing there is a small mistake on this circuit.

PIN number 2 is mention next to PIN number 8. I think it should be pin 7.

thank you paaker for pointing out the mistake, I have corrected it now, please check it

Both circuits work perfect,

I hav assemble and using it.

Thanks Swag.

Thanks Paaker, I am glad it’s working!

again sir.

I am needing this automatic charge cutoff for my solar installations, if it can work well for both solar and windmill it would be great!

yes it will work for kinds of sources between 3V and 30V, for higher voltages just make sure that the IC supply is restricted below 30V (for the last circuit)

Thanks for directing me here sir… now i have some questions, can i replace IC LM358 with TL072? can i replace transistor 8050 With any darlington pair or any high voltage transistor such as tip transistor? please i will take your advice from here if i have anymore questions.

thanks for the help sir.

Youre amazing teacher for real

Thanks Nkwenti, yes you can replace LM358 with TL072, just make sure the pinouts are correctly exchanged.

The relay driver transistor can be replaced with other types but preferably it should be selected as per the rating of the relay, having said this any transistor such as a TIP122 will also work

hi sir, can this circuit be used to charge a 12v 60AH battery. thanks

Hi Joseph, yes it can used!

dear sir,

on the second circuit in the link you provided,i am asking if LM338 input is connected to battery input?

and what formular should i use when calculating resistor in parallel with the LEDS?

Regards

Jude,

yes the input is connected to the supply source (+), the output is connected to the LED (+), the negative goes directly to the LEDs. The formula is

R1 = 1.25 / LED safe current (max current)

Dear Sir,

is it proper to just connect all my bulbs(dc bulbs) directly to the positive and negative terminal of the battery without any damage to the bulbs? using the bottom charging circuit diagram.

or advise on how best i can handle this.

Thanks

It will need to be calculated with formulas, give me the V and I specs of the LED and the supply input, I’ll show you how to do it.

Dear Sir,

i have five(5) 12V , 4watts bulbs already, and i have 12V, 200AH battery for this purpose,

Thank you so much while i await your response

Jude, the total wattage of your becomes 4 x 5 = 20 watts,

You may have to include a current limiter circuit in between the supply and the LED assembly.

You can opt for the following current limiter design and use it for the purpose

https://www.homemade-circuits.com/universal-high-watt-led-current-limiter/

This will allow the supply current to pass through the above circuit and limit current before entering your LEDs

Dear Sir,

i appreciate so much for the kind responses.

i will be building the charger circuit at the bottom article this weekend.

i need a simple dc emergency light circuit diagram where i have to go straight and connect my load(i.e DC bulbs) through the charging circuit..

i just need to power five DC bulbs of 5Watts each.

Humble regards

You are welcome Jude!

I wish you all the best!

Dear Sir,

i want to build this circuit,but i want to use it to charge 12V, 200AH battery.

My questions are:

1-what are needed to be modified in the circuit to be able to charge this battery comfortably?

2-will the battery discharge after power outage when the battery is not in use,if yes,how do i prevent this?

3-how can i set up this circuit to power dc bulbs without having to build extra circuit for it.

4-i want it in such a way where i have to switch to DC for lighting in my home when there is power outage from the utility,how do i achieve this?

5-how do i wire it so that when the utility restores the light and i switches to utility,my battery starts charging automactically.

Best regards

Hi Jude,

If you want to have an automatic load switch ON, then you can try the following concept

https://www.homemade-circuits.com/make-this-automatic-10-watt-to-1000/

Only the relay will be required to be changed with a 30 amp relay.

Dear Sir,

thanks for your quick response.

i have checked the link and this questions to ask;

i am a newbie and i don`t want to make a lot of mistakes while building this circuit…does the circuit in the link has charging capacity?,

i want to build a kind of DC project where i have to power ten dc bulbs like 4watts each,through my 12V, 200AH battery.

i need a clearer explanation on how i can achieve this project in such a way that the battery will keep charging automatically when there is AC and won`t give out power except the AC is OFF.

Please note i don`t want the battery to discharge when it is not in use.

i appreciate your assistance.

regards