In this article we study a simple 3.7V li-ion battery charger circuit with auto-cut off, which can be charged from your computer USB port or any other 5 V regulated source.

Simplest 3.7V Li-ion Battery Charger with Auto Cut-off using LM393 IC

If you do not wish to read the following long explanation, you can just watch the same in this video:

How it Works

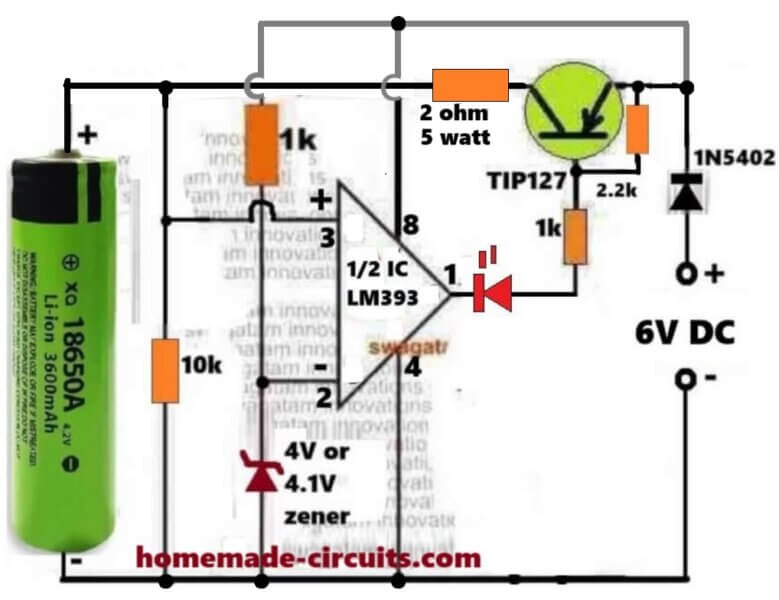

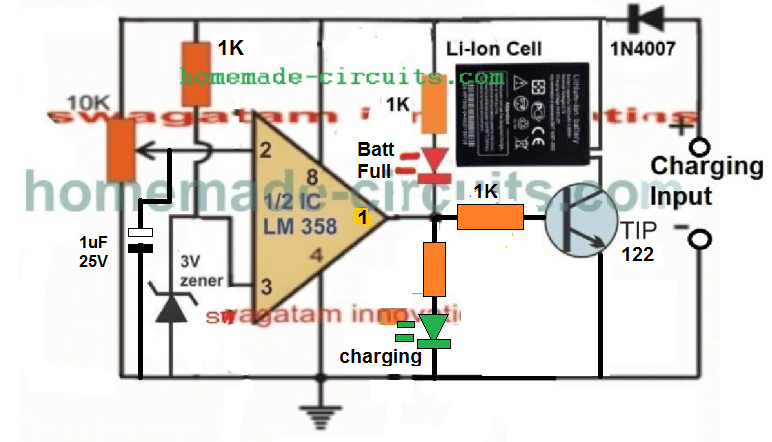

Here we see that this small circuit is made for charging one 3.7V Li-Ion cell like 18650 type, and we also see that it automatically stops the charging when the cell voltage becomes full around 4.1V or 4.2V.

So we can say that this is an automatic over charge protector using one half section of LM393 and one PNP transistor TIP127 which is working like a main current switch.

How The Whole Circuit Works Step By Step

Power Source And Battery Connection

We start by giving 6V DC supply to the circuit which acts like the charging input. The 3.7V battery is connected on the left side, so that the current flows from 6V supply through the TIP127 transistor to the battery for charging purpose.

Voltage Divider For Sensing Battery Level

The pin#3 of the LM393 is connected directly to the battery positive so it can sense the battery volatge level directly. So this way pin3 can sense the present battery level.

Reference Voltage From Zener Diode

We have one 4V or 4.1V zener diode connected to the inverting input pin2 of LM393. That zener is giving a fixed reference voltage which stays constant even if the battery voltage changes. So we can say that pin2 is having fixed 4.1V reference while pin3 is showing actual battery sample voltage.

Comparator Working Principle

Now we understand that LM393 is acting like one comparator, so it is comparing the voltages present at pin3 and pin2.

Case 1: Battery Voltage Is Low Or Discharged (below 4V or 4.1V)

So now that battery voltage is less than 4.1V, so voltage at pin3 is lower than voltage at pin2. Then the LM393 output transistor from inside becomes ON and it pulls pin1 to ground.

Because of this, pin1 becomes low and that low goes to the base of TIP127 through one 1k resistor. Since TIP127 is a PNP transistor, so its base getting low will make it conduct hard, so the current now starts flowing from emitter to collector and reaches the battery and the battery begins to get charged.

The LED also turns ON in this time because its cathode at pin1 goes to ground.

So we can now say in this condition:

LM393 output = LOW (Ground).

TIP127 = ON.

LED = ON.

Battery = Charging.

Case 2: Battery Voltage Is Full (4.1V Or 4.2V)

Now after sometime the battery gets almost charged, so that the voltage at pin3 becomes slightly higher than pin2. Then in this situation the internal transistor of LM393 turns OFF and its pin1 becomes open collector, that means pin#1 is now floating, without any logic level (open).

Now since pin1 is open, it cannot pull low anymore, so in this situation the 2.2k resistor now becomes active. That 2.2k resistor is connected from +6V to TIP127 base node so it pulls the base of TIP127 towards positive potential.

So when the base is pulled high and becomes near the emitter voltage, forces the TIP127 hard to stop conducting completely. So current cannot flow anymore from emitter to collector. The battery is disconnected from the charger. The LED also turns OFF because now there is no current path to ground through pin1.

So we can say now:

LM393 output = OPEN.

TIP127 = OFF.

LED = OFF.

Battery = Cut Off.

Role Of The 2.2k Resistor

Now we explain that 2.2k resistor which is very important here. It is actually working like a pull-up resistor, so that resistor is keeping the TIP127 base in one correct position depending on the output of LM393.

So when LM393 output is low, then that resistor becomes inactive because LM393 is grounding the base through the 1k resistor. So charging goes ON.

But when LM393 output is open then that 2.2k resistor pulls the TIP127 base high towards the emitter potential. So the transistor gets turned OFF strongly and it cannot conduct any leakage current. So this resistor ensures that the base never floats and the transistor never stays in half ON condition.

If that resistor is not there then the base of TIP127 may stay floating after LM393 goes open and this may allow some small leakage current to flow continuously, and the battery may keep trickle charging which is unsafe for Li-ion cell. So this 2.2k resistor saves the battery from such leakage problem.

Step By Step Summary Table

| Battery Condition | Pin3 Vs Pin2 | LM393 Output | Role Of 2.2k | TIP127 | LED | Battery |

|---|---|---|---|---|---|---|

| Low Or Discharged | Pin3 < Pin2 | Pin1 = Ground | Inactive | ON | ON | Charging |

| Fully Charged | Pin3 > Pin2 | Pin1 = Open | Active | OFF | OFF | Cut Off |

Main Points To Remember

So we now understand that LM393 works as one precise voltage comparator. The 4.1V zener sets the final cut-off limit. TIP127 handles the charging current. The LED gives visual indication of the charging status. The 2.2k resistor ensures proper base pull-up. And the diode 1N5402 stops the reverse current flow from battery to the circuit whenever the charger is unplugged.

Summary Of The Operation

We can now say everything in one line like this:

When the battery is below 4.1V then the LM393 output becomes low, then the TIP127 conducts, then the battery charges and LED glows. When the battery becomes full near 4.1V or 4.2V then the LM393 output becomes open, then the TIP127 stops conducting, then charging stops, and LED goes OFF.

So it works fully automatic and safe for 3.7V Li-ion cells.

How to Set up

It is actually very Easy.

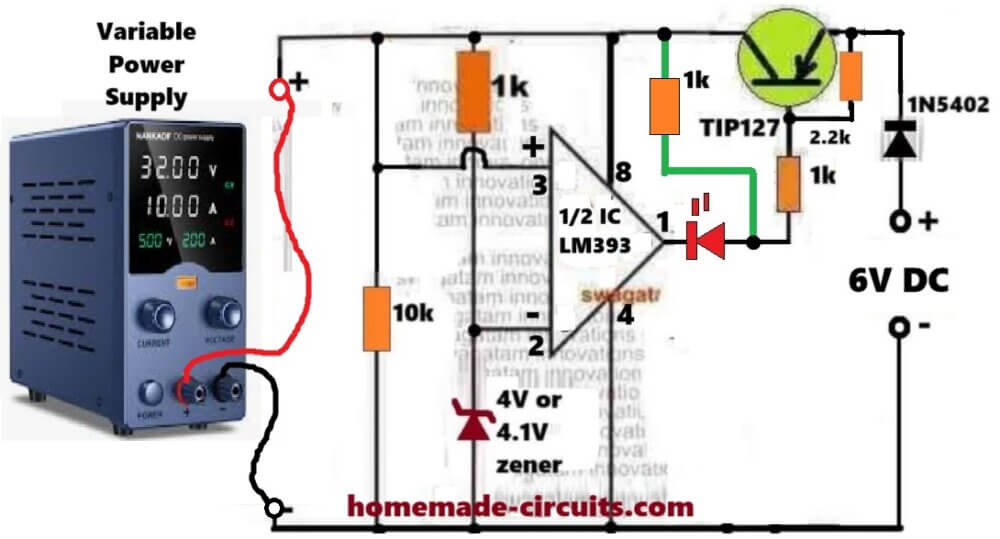

During the setup procedure, do not connect any battery, instead, connect a variable power supply DC input on the battery side, meaning replace the battery points with this variable power supply DC input.

Connect a 1k temporary resistor between pin#8 of the IC and the anode of the red LED.

Keep the supply at zero volts and gradually increase it, until it reaches above 4.1V, or 4V.

At around 3V, you must see the LED turning ON.

Keep increasing the variable power supply voltage until it is above 4V or 4.1V. At this point you must see the LED shutting off.

That's all, this will prove that you LM393 based auto cut off is working correctly.

Now you can remove the above mentioned temporary resistor, and start charging any discharged 3.7V Li-ion battery using the normal configuration, as depicted in the above image.

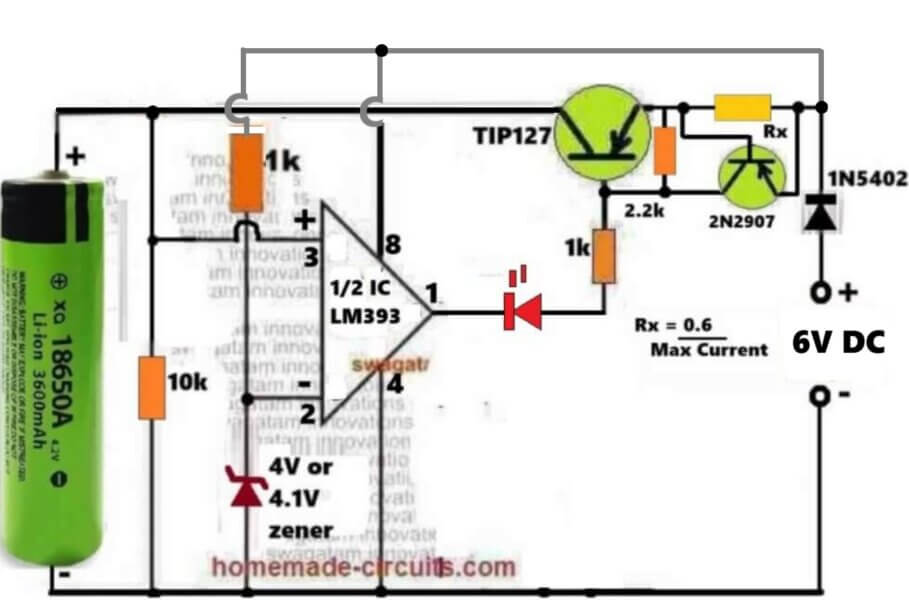

Constant Current Version

The above circuit can be further upgraded into a constant current version, as shown in the following diagram:

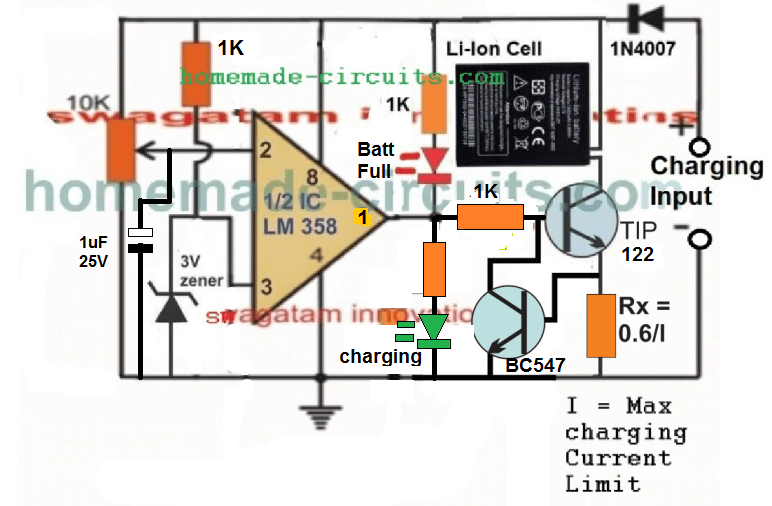

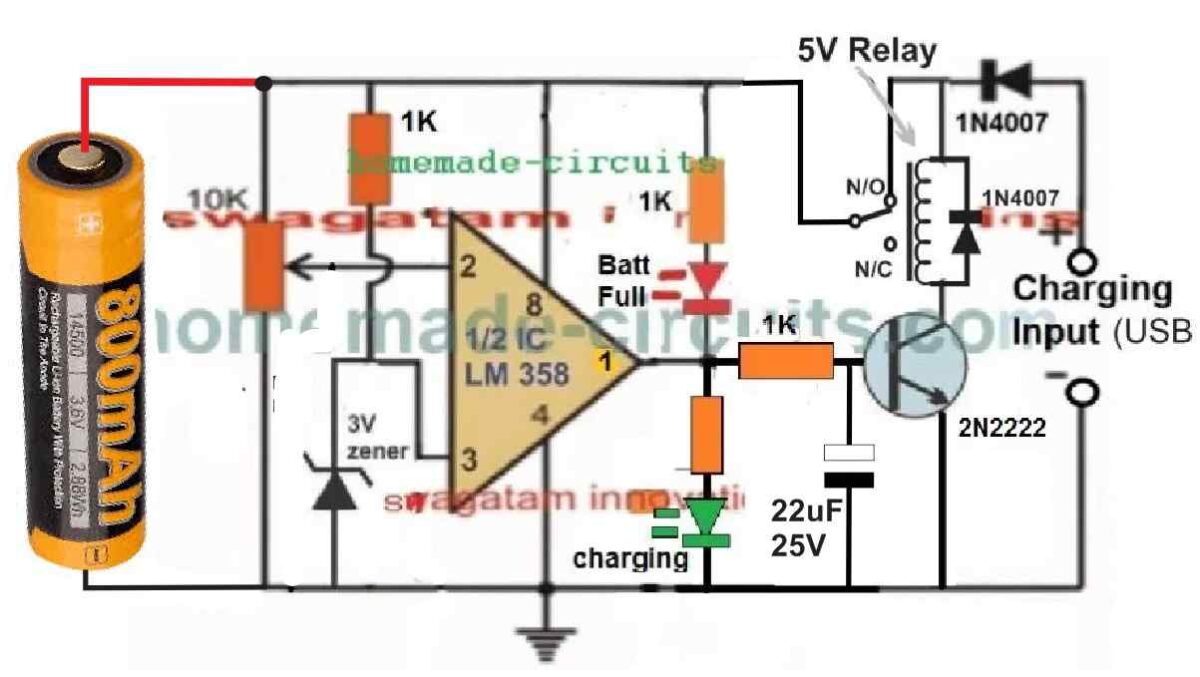

3.7V Auto Cut-off Circuit using IC 741

The following IC 741 auto cut off Li-ion battery charger circuit can be understood with the help of the following description:

The IC LM358 is configured as a comparator. The IC LM741 is not used since it is not specified to work with voltages lower than 4.5V.

Pin#2 which is the inverting input of the IC is used as the sensing pin and is attached with a preset for the required adjustments and setting.

Pin#3 which is the non-inverting input of the opamps is reference at 3V by clamping it with a 3V zener diode.

A couple of LEDs can be seen wired across the output pin of the opamp, for detecting and indicating the charging condition of the circuit. Green LED indicates the battery is being charged while the red illuminates as soon as the battery is fully charged, and supply is cut off to the battery.

How to Charge using USB Port

Please remember that the charging process can be quite slow and may take many hours, because the current from USB of a computer is normally very low and may range between 200 mA to 500 mA depending on which number port is used for the purpose.

Once the circuit is assembled and set up, the below shown design can be used for charging any spare Li-Ion Battery through the USB port.

First connect the battery across the indicated points, and then plug in the USB connector with your computer's USB socket. The green LED should instant become ON indicating the battery is being charged.

You can attach a voltmeter across the battery to monitor its charging, and check whether the circuit cuts off the supply correctly or not at the specified limit.

Since the current from a computer USB can be quite less, the current control stage can be ignored and the above design can be much simplified as shown below:

Video Clip showing the automatic cut off action, when the Li-Ion cell is charged upto 4.11V:

Please note that the circuit will not initiate charging unless a battery is connected prior to power switch ON, therefore please connect the battery first before connecting it to a 5 V supply source.

An LM358 has two opamps which means one opamp is wasted here and remains unused, therefore LM321 may be tried instead to avoid the presence of an idle unused opamp.

How to Set up the above 3.7 V Li-ion Charger Circuit:

That's extremely easy to implement.

- First, make sure the preset is moved at the ground side fully. Meaning, the pin#2 should be at ground level through the preset initially.

- Next, without any battery connected, apply an exact 4.2 V across the +/- supply lines of the circuit, through an accurate adjustable power supply.

- You will see the green LED coming ON instantly.

- Now, slowly rotate the preset, until the green LED just shuts OFF, and the RED LED switches ON.

- That's all! The circuit is now all set to cut off at 4.2 V when the actual Li-Ion cell reaches this level.

- For the final testing, connect a discharged battery to the shown position, plug-in the input power through a 5 V source, and have fun watching the cell getting charged and cut-off at the stipulated 4.2 V threshold.

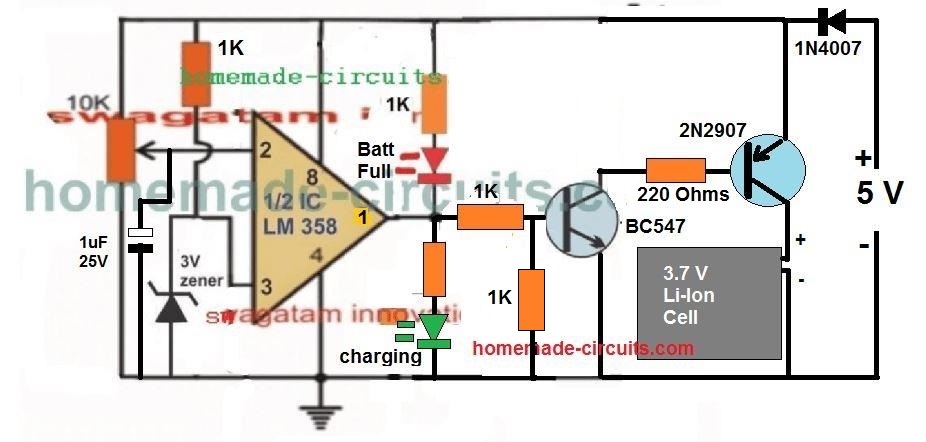

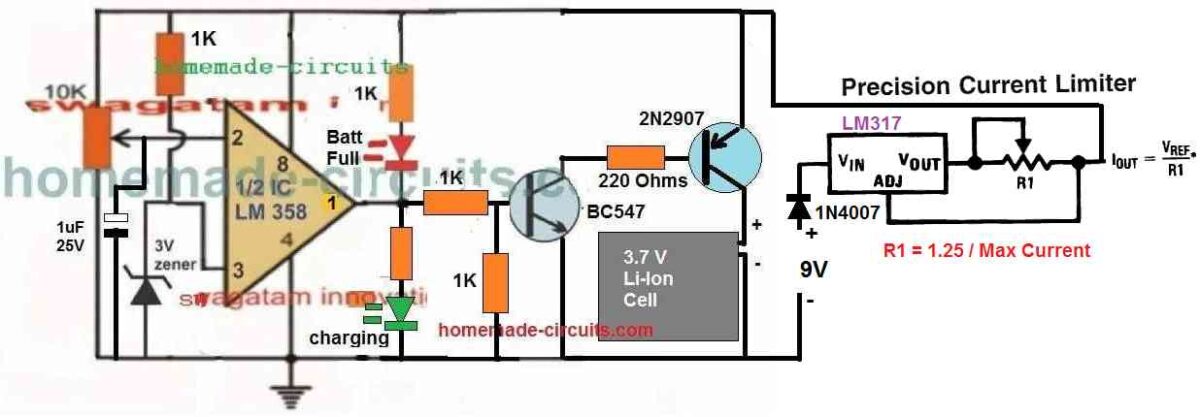

Constant Current CC Feature Added

As can be seen , a constant current feature has been added by integrating the BC547 stage with base of the main BJT.

Here the Rx resistor determines the current sensing resistor, and in case the maximum current limit is reached, the potential drop developed across this resistor quickly triggers the BC547, which grounds the base of the driver BJT, shutting down its conduction and charging of the battery.

Now, this action keeps oscillating at the current limit threshold, enabling the required constant current, CC controlled charging for the connected Li-ion battery.

Current Limiting not Required for USB Power

Although a current limiting facility is shown, this may not be required when the circuit is used with an USB since the USB already is quite low with current and adding a limiter may be useless.

The current limiter should be used only when the source current is substantially high, such as from a solar anel or from another battery

Improving the Circuit Further

After some testing it appeared that the Darlington transistor was unable to switch sufficient current to a Li-Ion cells, especially which were deeply discharged. This resulted in a difference in voltage levels across the cell, and across the supply rails of the circuit.

To combat this issue, I tried to improve the design further, by replacing the single Darlington BJT with a pair of NPN/PNP network, as given below:

This design improved the current delivery significantly, and resulted in a reduction in the margin of difference between the battery terminal voltage level and the actual supply voltage level, and therefore false cut-off switching.

The following video, shows the test result using the above circuit:

Adding Current Control to the above Design

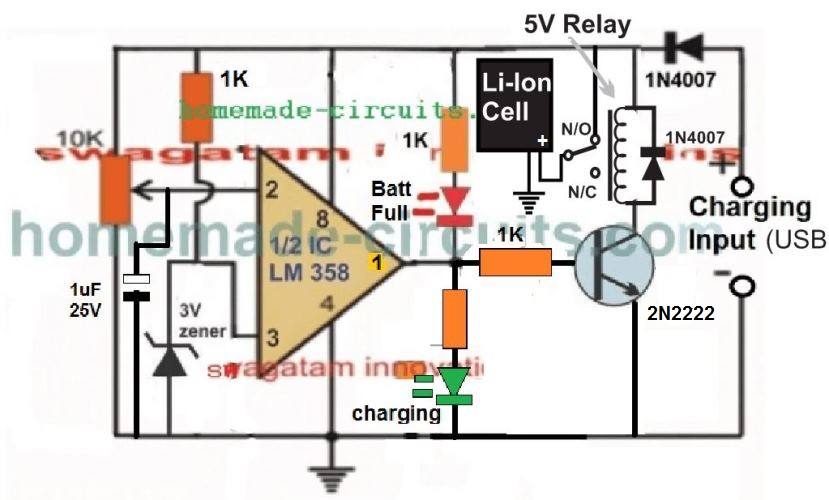

Using a 5V Relay

The above designs can be also built using a 5V, which will ensure the best possible current delivery to the cell and faster charging. The circuit diagram can be seen below:

Please Note:

This article was substantially changed recently and therefore the older comment discussions may not match with the circuit diagram shown in this present updated design and explanation.

Another Ideal 3.7 V Battery Charger Circuit with Auto Cut-off

Here's a 3.7 V Battery charger circuit which looks perfect in for the automatic cut-off and a self-monitoring of the 3.7 V battery.

In the relay based circuit previous to the above design, there seems to a serious drawback.

In the previous design the battery needs to be connected first, before applying the input power. This is crucial, otherwise the relay can start chattering, if the power is switched ON first without a battery connected.

But in the above new design where the battery can be seen connected on the left side, the chattering of relay problem is completely eliminated.

Moreover, this design has an added advantage. The circuit will be able to continuously monitor the battery level and self-regulate the circuit to ensure that the battery is automatically disconnected when it reaches full charge level, and automatically connected to the supply when it is discharged to some lower level.

The input supply can can be from any 5V regulated source. However make sure the current spec of the supply is restricted to 0.5 C. Meaning the current of the 5V source must not be 50% of the battery mAh value.

How to Adjust the Preset

The auto cut off preset setting up is easy.

Initially, do not connect any battery or the input supply, and rotate the preset wiper to the ground level.

Next, take a variable DC power supply. Adjust its output to precisely 4.1 V, which is the optimum full charge level of a standard 3.7 V battery.

Connect this supply to the circuit from the left side, across the points where the battery is supposed to be connected.

You will see the GREEN LED illuminating. At this stage the relay must switch ON, however it won't since there's no 5V supply from the right side of the circuit. No worries, we can still setup the circuit by looking at the LEDs.

After this, slowly adjust the preset until the GREEN LED just switches off and the RED LED just switches ON.

That's all, the auto cut off set up is complete for the circuit.

Now, to test the circuit LIVE, you can connect a discharged 3.7V cell across the indicated points, and a 5 V supply from the relay side and see the actually cut-off happening, as soon as the battery is fully charged at 4.1 V.

Comments

The 118650 battery charger is voltage-controlled, NOT current-controlled. I question the validity of the entire article due to this simple, but crucial and important mistake.

Please explain your point, I will let you know where you are going wrong…

Dear Sir Swagatam

Hello, it is my duty to thank you for your kind assistance and the time you dedicated to responding to me and redrawing the circuits.

Your kindness is always present before my eyes.

I am 100% sure that the circuit is perfect and the semiconductors are indeed faulty.

God bless you

With warmest regards,#

Moe

Hello, Dear Moe,

I am extremely sorry and I admit that the previous circuit which I suggested you had a big problem and i am extremely sorry about all the hassles you had to face while testing the circuit.

I really don’t know how I missed this basic issue in the design.

In the previous circuit the 4V zener diode was linked with the battery, so how could the pin#2 of the LM393 get a fixed reference of 4V if the battery voltage was below 4V, so the IC could never do the comparison, and that’s why it kept failing.

The 4V zener resistor side must be connected directly with the input supply DC, and not with the battery so that pin#2 is able to get a fix reference, which could be compared with the battery voltage.

If you have time in near future then you can check this updated circuit and see if it works or not:

https://www.homemade-circuits.com/wp-content/uploads/2013/12/current-controlled-3.7V-li-ion-auto-cut-off-charger-circuit.jpg

Again, I am extremely sorry about all the trouble you had to face with the previous faulty design, due to my silly mistake…

It is my great pleasure Dear Moe, thank you so much for your kind words!!

God bless you too!!

Dear Sir engineer Swagatham

Hello

would you please tell me how much is the amount of the resistor which is connected to the positive pole of the green LDR? 1k?

Truly yours

Ali

Hi Ali, yes both the LED resistors are 1k.

Dear Sir

which N channel MOS i will choose. does it logic level or which is best?

Nitesh,

yes a logic level MOSFET would be better, such as this one:

https://www.digikey.com/en/products/detail/vishay-siliconix/IRLZ44STRRPBF/856860

Thanks

Dear Sir

i want to pass Power Bank 5V@9000 maH voltage to mobile device via Mosfet & gate of that mosfet is connected with mcu ( for on / off) . I am find out best method how can mcu &mosfet connetion each other May i ground one resistor also from Mosfet Gate ? there is facilities inside software for do logic high or logic low for mosfet operate at the time on timer & off timer.so pl give schamatics.

Hi Nitesh,

You can configure the circuit in the following manner:

Connect the N-channel MOSFET gate directly with the MCU output. No need of any pull down resistor.

Connect the source with the ground line of the MCU.

Connect +5V of the power bank with MCU (+) and connect the negative of the power bank supply with the MCU ground.

Connect this +5V also with the mobile charging input (+) and connect the mobile ground with the drain of the MOSFET.

What can be the substitute for the 150E resistor in the project in the link

https://www.homemade-circuits.com/wp-content/uploads/2024/11/3.7V-auto-cut-off-battery-charger-circuit.jpg

There is no substitute for this resistor, you can make it by adding a few assorted resistors in series parallel, slight difference is OK…

Which circuit (in your opinion) is best in factors like time taken for charging, safety

The following circuit is the best:

https://www.homemade-circuits.com/wp-content/uploads/2024/11/3.7V-auto-cut-off-battery-charger-circuit.jpg

Can we use a 1.67A Samsung adaptor

Yes, definitely you can use it…

Hi,

Does these circuits only work in fully empty batteries, 0V?

I assembed the 3rd circuit, for the 4th time, calibrated, with the preset at ground level (0homs), turn it on, green LED was on, move the preset until red LED becomes on, turning OFF green LED.

Connected a battery with only 2.3V, plug it to a 5V DC adapter and the red LED came ON, implying that the battery was charged….

Hi,

The circuit can be used to charge any 3.7V battery discharged below the set level (4.1V).

While setting up the preset, the supply input to the IC must be exactly adjusted at 4.1V.

I hope you have connected 1uF at pin#2.

Also, the input power supply current must be rated at 50% of the battery Ah.

If you are having difficulty setting up this circuit you can try the following one:

https://www.homemade-circuits.com/wp-content/uploads/2024/11/3.7V-auto-cut-off-battery-charger-circuit.jpg

Hi,

When you say preset to the ground, means that the resistor value between the center point and ground is 0 (zero).

Right?

If that is so, meassuring between the entry point of the adjustable resistor and the center point is about 3K, leaving 7K between the center point and ground.

Nélio Abreu

Hi Nelio,

Yes, that refers to resistance value between the center point and ground, which should be 0 (zero).

This is to be done during the setting up procedures of the preset. initially we must keep the preset fully towards ground and then slowly adjust it until the LEDs just changeover. This sets up the op-amp cut-off threshold.

There’s no need to measure the preset resistance, you can confirm the changeover through a variable power supply voltage and LED switching.

Hi, Swagatam,

I’m currently testing the 2nd circuit, with 2 minor changes:

Using TIP41C and without the base resistor and so far is working fine.

The 3rd circuit didn’t work

Best Regards.

Nélio

Hi Nelio,

A base resistor is strictly recommended for all BJTs, so please do not remove the base resistor.

The 3rd circuit should work, because it has been tested by me, you can see the adjoining video.

However, here’s another design which is very basic and very good, and virtually failproof, you can try it:

https://www.homemade-circuits.com/wp-content/uploads/2024/11/3.7V-auto-cut-off-battery-charger-circuit.jpg

Hi, the LED in the failproof circuit, is what? Charging LED or Charged LED?

How to I set the trimmer?

Best Regards.

Nélio

That LED indicates the battery is Charging, when it is shut-off means battery is fully charged.

To ensure that the LED does not blink ON-OFF at the threshold, you can connect a 100uF capacitor across the pin#2 of the IC, and ground.

Hi Swagatam,

Thanks for all the work you do here to help us all out.

I have a couple questions:

Thanks,

-G

Thank you Gee,

1) Yes, the last circuit can work with a solar panel. You can use any solar panel between 9V and 36V and use a 5V buck converter to optimize the solar panel output to 5V and then feed this 5V to the op amp circuit.

2) You can charge any number of batteries in parallel depending on the buck converter capacity.

il manque l’indication de la valeur de la résistance concernant la diode verte , est-elle

aussi de 1k ohms ? Merçi

Yes, the resistor connected with the green LED can be also 1k, but if you find the brightness low then you can decrease it to 470 ohms.

Hi Swagatam,

Is there a possibility that you have the LED’s identification wrong?

I mean, When it says Full should be charging and vice-versa.

Hi Nelio,

The LEDs are correctly configured to identify the results.

Initially when the battery is low, pin2 voltage is lower than pin3, so the output pin1 is high causing the green LED to illuminate and red to remain shut off.

When the battery is fully charge, the pin2 voltage becomes higher than pin3 voltage, causing pin1 to go low and the RED LED illuminates and the green is shut off.

So as per the above functioning the LEDs are labelled correctly.

I’m currently testing the 3rd circuit with 2N2907 and BC547. The results are the same. RED LED (in your schematic) is ON and GREEN LED if OFF.

Well that’s not that is happening in my circuit. When I connect the circuit with Battey in it, the RED LED (in your schematic) is ON and the green OFF (in your schematic)

That means you have either connected the pin2 and pin3 oppositely, or your preset adjustment is not done correctly.

What happens when you check with a power supply?

If the power supply result works then the battery result should also work.

You can see the video it worked perfectly for me.

With my PSU the result is the same. However it’s is charging, although I don’t if it’s correct.

I have an imagem but I can’t share it with you since your blog don’t allow it.

The opamp comparator works with a simple principle. When the battery is connected and power is switched ON, the battery immediately SINKS the current and causes the voltage to drop to its discharged level. When this happens the pin#2 voltage becomes lower than pin#3. So this is the crucial aspect. In your circuit when you switch ON power with the battery connected, is the pin#2 voltage dropping below pin#3???

This must happen, If this does not happening then the RED LED will never shut off.

If with PSU the same is happening then you might be missing something with the setting up procedure. Please follow the steps as explained under How to “Set up the above 3.7 V Li-ion Charger Circuit”

If you are having problems with the above circuits, you can try the following alternative design. For setting up, please replace the battery with the input DC from a variable power supply. Adjust the voltage to 4.1 V, keep the preset wiper arm to ground level, initially the RED LED will remain illuminated, now slowly adjust it until the LED just shuts off. Setting up is finished.

https://www.homemade-circuits.com/wp-content/uploads/2024/11/3.7V-auto-cut-off-battery-charger-circuit.jpg

Hi Swagatam,

I have assemble the 2nd circuit, calibrat it.

Put a 3.7V Li-Ion battery, type 16340 of 4800mAH to charge, connect a 5V adapter of 1A of current maximum output.

Left the battery there to charge with a capacity monitor and it hasn’t stop charging, after 2 days.

The capacity monitor indicates 4,338V, 99%. I have measure the voltage, to be the same.

The calibration was done using an adjustable PSU, set to 4.2V and 1A.

Hi Nelio,

The op amp has to operate and switch OFF the transistor if the 10K preset is correctly adjusted to 4.2 or 4.1 V. You can do one thing, connect another LED in series with the base 1K resistor of the transistor and monitor this LED response. This will ensure that no leakage or offset voltage from the op amp output can falsely keep the transistor switched ON.

Also while setting up the preset did your LEDs shut off correctly?

I would recommend you to set the cut off at 4.1V, so that it cannot exceed at the most 4.2V.

Yes. When I adjust the preset, the LED’s switch status. The RED turned OFF and the GREEN turned ON (in my circuit Colors are switched, since RED is consider danger, don’t touch, and Green is consider Ok).

I will try your sugestion of the 3rd LED and 1K resistor.

Thanks.

N.A.

OK, that means your op amp is good and working. Now you can just put another LED in series with the transistor base resistor and check the response.

Hi Swag,

In these circuits the capacitor is 1uF 25V.

Should it be these values?

Can I use 1uF 50V?

Thanks.

Best Regards.

Nélio Abreu

Hi Nelio,

As a rule of thumb, the capacitor voltage value must be two times the supply voltage, so for these circuits it can be any value higher than 12 V or 25 V. 50 V is fine.

Hi Swag,

Thanks

Best Regards.

Nélio Abreu

You are welcome Nelio!

Hi Angelo,

If you are using 4.2V DC as the full charge voltage, then it should reach 4.2V, if not then your battery could be having problems. However, if you are using 4 V then if the battery settles at around 4V then it is absolutely fine…even at 4V the charging can be considered optimal and it will ensure longer life for the battery and enhance charge discharge cycles.

Good day sir. I’m having issues in charging the 3.7 V 9900 mAh LiON battery. It can’t be fully charged even I left it charging for about 4-5 hours. Then I measured the terminal voltage of the battery which is about 4.04 V only. But it should be 4.2V right?

Thank you Binoj,

I appreciate your useful observations and feedback.

Yes, indeed a base/emitter resistor must be included for the relay driver transistor to eliminate the offset voltage which is normally present at the output of most op amps.

This offset voltage is actually a small level of leakage voltage which continues to hang even while the output has turned low….this voltage is in the range of 1V or 1.5V which is enough to keep the transistor switched ON.

The base emitter resistor creates an appropriate resistive divider which effectively eliminate this leakage voltage and allows the transistor to be switched OFF correctly.

Sir, thanks for your help and there is excellent current control when using LM317 as suggested by you.. And continuing my experimentation, i have also tried the relay cutoff circuit using 2n2222. But when the preset is adjusted to effect the cut off, the lm358 is going low but the relay is not being cutoff and the battery continues to be in charging mode. And then i added the 1k resistor across the base and emitter of 2222,which you have only included in the previous circuits and eliminated in this particular circuit. Now the correct cutoff is happening as required. Can you pls tell what is happening when the 1k is present and when it is not there.

That’s great Binoj, glad you could make it successfully.

3.3V will also work since the cut off value is 4.2V. However, instead of 3.3 V zener you can use 3nos of 1N4148 diodes connected in series in place of the zener diode, but with opposite polarity.

Connecting the load at collector enables maximum current transfer due to minimum resistance and also there’s no voltage drop of 0.6 V.

For the current control, the best way id to add a LM317 current limiter at the input source. Here’s the complete diagram:

https://www.homemade-circuits.com/wp-content/uploads/2023/03/adding-current-limit-to-a-3.7-V-charger-circuit-1200×417.jpg