A fast battery charger circuit charges a battery with enhanced speed so that it is charged in less time than the specified period. This is usually done through a step wise current optimization or control.

While looking for a fast charger circuit that would charge a battery quickly, I came across a couple of designs which were not only useless but misleading too. It seemed that the concerned authors had no idea what a fast charger actually needs to be like.

Objective

The main objective here is to accomplish rapid charging in lead acid batteries without causing any harm to its cells.

Normally, at 25 degrees Celsius atmospheric temperatures , a lead acid battery is supposed to be charged at C/10 rate which would take at least 12 to 14 hours for the battery to get fully charged. Here C = Ah value of the battery

The objective of the concept presented here is to make this process 50% quicker and enable the charging to finish within 8 hours.

Please note that an LM338 based circuit cannot be used to boost the charging rate of a battery, while it is a great voltage regulator IC, enhancing the charging rate requires a special step wise changeover in current which cannot be done using an LM338 IC alone.

The Circuit Concept

When we talk about how to charge a battery quickly we obviously are interested to implement the same with lead acid batteries, since these are the ones which are used extensively for almost all general applications.

The bottom line with lead acid batteries is that these cannot be forced to charge rapidly unless the charger design incorporates an "intelligent" automatic circuitry.

With a Li-ion battery obviously this becomes quite easy by applying the full dose of the specified high current to it and then cutting off as soon as it reaches the full charge level.

However, the above operations could mean fatal if done to a lead acid battery since LA batteries are not designed to accept charge at high current levels continuously.

Therefore in order to pressure current at a rapid pace these batteries need to be charged at a stepped level, wherein the discharged battery is initially applied with a high C1 rate, gradually reduced to C/10 and finally a trickle charge level as the battery approaches a full charge across its terminals. The course could include a minimum of 3 to 4 steps for ensuring maximum "comfort" and safety to battery life.

How this 4 Step Battery Charger Works

For implementing a 4 step fast charger circuit, here we employ the versatile LM324 for sensing the different voltage levels.

The 4 steps include:

1) High Current Bulk Charging

2) Moderate Current Bulk Charging

3) Absorption Charging

4) Float Charging

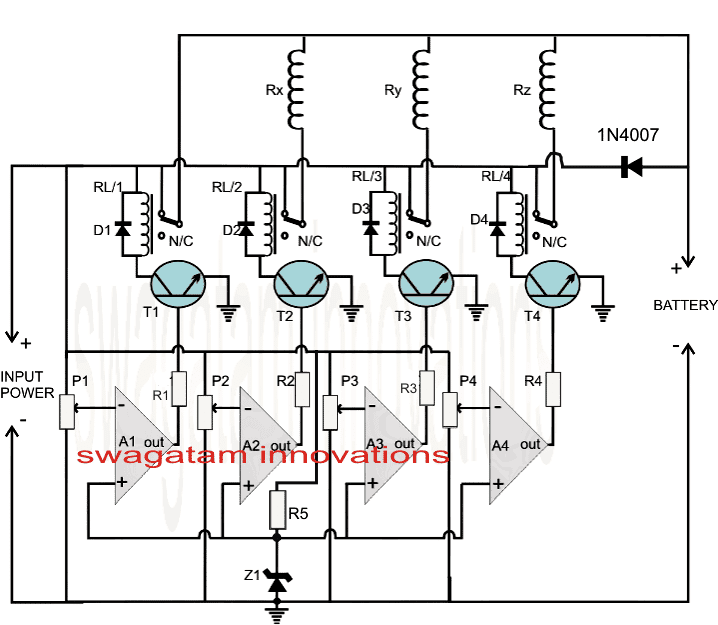

The following diagram shows how the IC LM324 may be wired up as a 4 step battery voltage monitor and cut off circuit.

Circuit Diagram

NOTE: Battery must be connected first before switching ON the input, to ensure that the circuit works correctly.

The IC LM324 is quad opamp IC whose all the four opamps are used for the intended sequential switching of the output current levels.

The proceedings are very easy to understand. opamps A1 to A2 are optimized for switching at different voltage levels during the course of the stepped charging of the connected battery.

All the non-inverting inputs of the opamps are referenced to ground through the zener voltage.

The inverting inputs are tied with the positive supply of the circuit via the corresponding presets.

If we assume the battery to be a 12V battery having a discharge level of 11V, P1 may be set such that the relay just disconnects when the battery voltage reaches 12V, P2 may be adjusted to release the relay at 12.5V, P3 may be done for te same at 13.5V and finally P4 could be set for responding at the battery full charge level of 14.3V.

Rx, Ry, Rz have same values and are optimized to provide the battery with the required amount of current during the various charging voltage levels.

The value could be fixed such that each inductor allows a current passage rate that may be 1/10th of the battery AH.

It may be determined by using ohms law:

R = I/V

The values of Rx, alone or Rx, Ry together could be dimensioned a little differently for allowing relatively more current to the battery during the initial stages as per individual preferences, and is tweakable.

How the circuit responds when switched ON

After connecting the discharged battery across the shown terminals when power is switched ON:

All the opamps inverting inputs experience a correspondingly lower voltage levels than the reference level of the zener voltage.

This prompts all the outputs of the opamps to become high and activates the relays RL/1 to RL/4.

In the above situation the full supply voltage from the input is bypassed to the battery via the N/O contacts of RL1.

The discharged battery now starts charging at a relatively extreme high current rate and rapidly charges upto a level above the discharged level until the set voltage at P1 exceeds the zener reference.

The above forces A1 to switch OFF T1/RL1.

The battery is now inhibited from getting the full supply current but keeps charging with the parallel resistances created by Rx, Ry, Rz via the corresponding relay contacts.

This makes sure that the battery is charged at the next higher current level determined by the the three parallel inductor net value (resistances).

As the battery charges further, A2 shuts down at the next predetermined voltage level, switching OFF Rx and rendering Ry, Rz only with the intended charging current to the battery. This makes sure that the amp level is correspondingly reduced for the battery.

Following the procedures as the battery charges to the next calculated higher level, A3 switches OFF allowing only Rz to maintain the required optimal current level for the battery, until it gets fully charged.

When this happens, A4 finally switches OFF making sure that the battery is now gets completely switched off after attaining the required full charge at the specified fast rate.

The above method of 4 step battery charging ensures a rapid charging without harming the battery internal configuration and makes sure the charge reaches at least at 95%.

Rx, Ty, Rz may be replaced with equivalent wire wound resistors, however it would mean some heat dissipation from them compared the inductor counterparts.

Normally a lead acid battery would need to be charged for about 10 to 14 hours for allowing at least 90% of charge accumulation. With the above rapid battery charger circuit the same could be done within 5 hours of time, that's 50% quicker.

Parts List

R1---R5 = 10k

P1---P4 = 10k presets

T1---T4 = BC547

RL/1---RL/4 = SPDT 12V relays 10amp contact rating

D1---D4 = 1N4007

Z1 = 6V, 1/2 watt zener diode

A1---A4 = LM324 IC

PCB design

This the original size PCB layout, from the track side, the high watt resistors are not included in the PCB design.

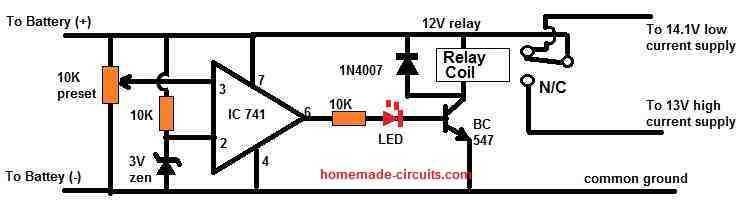

Simplest Single Op amp Fast Charger Design

The following diagram shows how a single op amp can be used to create a decent fast charger circuit for a 12V battery.

A discharged battery will be initially charged at a high current rate using the 13V supply, through the N/C contact of the relay. This will allow the battery to be charged quickly at the 13V mark within a few hours.

When the battery is charged up to 13V, the relay will changeover to the 14.1 V supply and the battery will start charging through the 14.1 V low current charging supply, until it is fully charged.

How to Set

- Initially keep the 10k preset wiper to the ground level.

- Connect a 13V fixed DC supply with the pin7 and pin4 supply lines of the IC.

- Next, adjust the preset until the relay just clicks ON from N/C to N/O, and the red LED turns ON.

- That's all, this single op amp fast charger circuit is all set now.

Simplest 2-Step Fast Battery Charger Circuit

In this section I will discuss a very simple yet effective battery charger circuit, which will charge your battery at a relatively faster rate than the normal charging methods.

This battery charger circuit can be used for fast charging of all types batteries, however make sure to adjust the current and the voltage of the charger according to the specifications of your battery.

That said, this fast charger circuit employs a step-charging process and therefore is specifically suitable for lead acid batteries and SMF batteries, since these batteries strictly require a step-charging method for implementing the fast charging effect. Li-ion batteries have no such restrictions, and can be quickly charged directly through a relatively high current input, and therefore do not strictly depend on step charging.

Now, let's understand how the circuit is designed to work.

How the Circuit Works

If you do not want to read the explanation below, you can simply watch this video instead:

Referring to the circuit diagram below, we can see that is basically a two step battery charger circuit, which will allow an initial high current charging for a lead acid battery, until the battery voltage has reached around 75% of its full charge level, wherein the circuit will switch the current to a lower level and continue the charging process until the battery attains the full charge level.

Here, the circuit is configured for fast charging of a 12 volt lead acid battery.

The NPN transistors works like a voltage sensor.

The Zener diode at the base decides at what voltage threshold the transistor needs to switch ON.

Here, the Zener diode is fixed at a 13.5 volt level, which means that the transistor will turn ON when the battery has charged up to the 13.5 volt level.

When the transistor turns ON, the connected relay also turns ON, causing its contacts to shift from its initial N-C contact to its N-O contact.

Initially, while the voltage level of the battery is below the 13.5 volt changeover threshold, the battery is allowed to charge with a relatively high current through the N-C contacts of the relay.

With this initial high current, the battery starts charging at a faster rate and quickly reaches the 13.5 volt level, wherein the transistor switches ON and causes the relay to changeover from its N-C contact to its N-O contacts.

The N-O contacts of the relay can be seen configured with a current limiter stage which consists of a high watt resistor, whose value determines the amount of current that needs to be reduced for the last phase of the charging process.

The battery now continues to charge but with a reduced current until finally it reaches its full charge level.

Please note that here the full charge level for the 12 volt lead acid battery must be restricted to a maximum of 14 volt which is around 0.3 volt lower than its actual maximum full charge level of 14.3 volts.

This reduced full charge level of 14 volt is intentionally chosen to ensure that the battery never reaches its highest 14.3 volt level, which in turn allows the battery to be connected with the reduced supply current indefinitely, without the need of an automatic cut off mechanism.

For a 12 volt lead acid battery, the initial high current charging may be done by using a maximum current which could be around 30% of its A-h rating.

For the current limiting, the above current may be reduced to around 7% of the battery A-h rating.

Calculating the Current Limiting Resistor Rx

The current limiting resistor must be calculated accordingly, using Ohm's law, as shown below:

Rx = V/I = (14 - 13.5)/Ah * 10%

Remember, the initial charging current which is selected here as 30% of the battery A-h must be thoroughly examined. If you find your battery warming up significantly with a 30% initial charging rate, you must reduce this level until the warming of the battery reduces to an acceptable level.

If you have any further questions regarding the above design please feel free to comment below with your queries.

if i want to use it for charging multiple battery 3.7 V 10000mAH about 10 pieces at a time, what to modify ?? please do guide me..

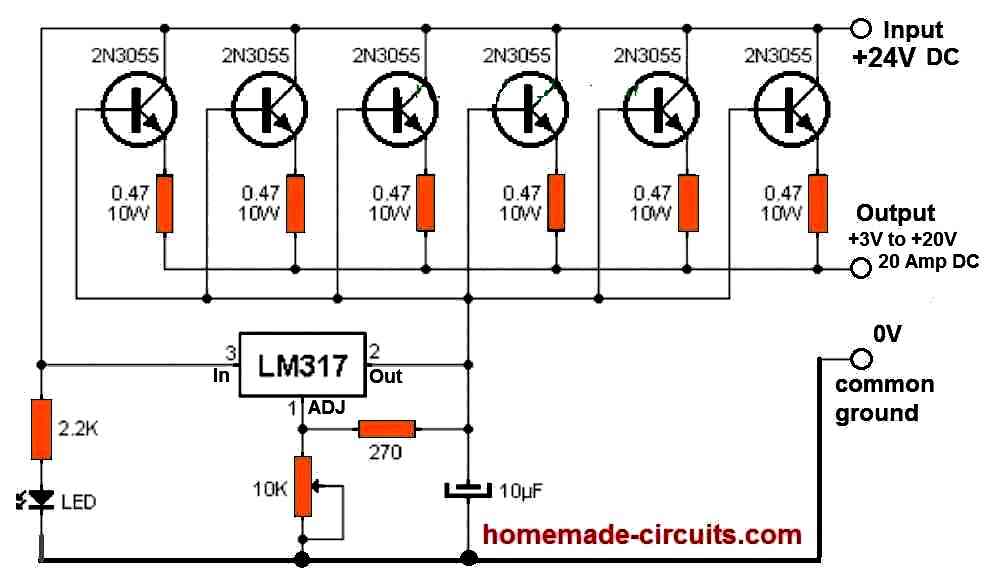

For a 3.7v li-ion battery you don’t need this complex step charger circuit, because you can charge it directly with a parallel lm338 ic regulator, with its output voltage set at 4.1v.

Hi

Sorry i am new to the electronics please help the inductors Rx, Ty and Rz what size should i use or ohm and what type of inductor can i use just not sure what to use the charger wil be used to charge 40ah to 120ah battries can i do it like that.

Thanks

Hi,

You can try 20 ohm 10 watt resistors for the Rx, Ry, Rz inductors. Just make sure the input current does not exceed 20% of the battery Ah rating.

Thanks so much ill do so

What is the Rx, Ry, Rz

Those are current limiting resistors which can be in the form of inductor or coil of iron wire.

What can we use as input power?

Hello sir, like you said( The 10K preset is for adjusting the output voltage to 14V for the battery. Now my question is where can one put multi meter while adjusting the the 10k preset for getting the 14v for the battery. Secondly, increasing the number of 2n3055 can the amp also increases in other to reduced the charging hours let say to get fully charge in 6hours.

Youngking, you can measure the output across the points marked as output 3 to 20V and common ground. Number of 2N3055 can be increased to increase the output amps but the maximum output amp will not be higher than the maximum amp from the solar panel. Remember the recommended current to the battery must never increase over 15% of its Ah value….and the battery must be allowed to charge for at least 10 hours, otherwise the battery condition may slowly deteriorate

Sir I have seen the image you shown me concerning using 20v/400watts solar panel for charging 12v/150ah battery, here is the link you refer me to. https://www.homemade-circuits.com/lm317-with-outboard-current-boost/. The one with 6 number of 2n3055. Now my question is as follows. –1- the upper right hand side which is +24v input DC, from where will I drive the 24v DC input from, let say if I add an add itional 12v automobile battery to my exit ing 12v deep cycle battery will I achieve this 24v DC input. -2- what is the purpose of the 10k preset and the light lED.

The 24V DC is the input supply which supposed to come from the solar panel. The 3 to 20 V is the output where the battery is supposed to be connected.

The 10K preset is for adjusting the output voltage to 14V for the battery.

The LED is power ON indication, it can be eliminated.

Good morning sir, I have seen the last circuit that uses ic 741.now question is as follows. 1-the setup you made is for 13v through pin #4and pin#7 what of the 14v full charge. 2- how many hours will it take to fully charge the 12v/150ah. 3.- should I upgrade the 3v zener diode and and the relay will be how many amps. 4 – the right hand side has three terminal so where will I connect the solar panel.

Youngking, 14V full charge does not require a any cut-off because 14V is already way below the full charge level of the battery. The full charge level of the battery is supposed to be 14.3V….so no cut off is required….you can keep the battery charging with 14V forever, no harm will be done to the battery. It can take around 6 to 9 hours for the battery to get fully charged with this circuit.

3V zener diode does not need any upgrade. Relay can be a 30 amp automobile relay.

The two voltages to the relay contacts has to come from the same solar panel through two separate voltage and current regulators, now this is again quite complicated to configure. The 14V regulator will come through a 14V/10amp regulator, while the 13V source will come from a 13V 20 amp regulator. Both from the same solar panel.

I would rather suggest you to use a single 14V 20 amp regulator and charge the battery directly through it….no other options would be required, but the charging could take around 10 hours.

Hello sir, ok I will go for 400 watts solar panel, but the buck converter will be difficult for me to construct. Won’t this 4step charger serve my purpose.i just want the one that I can construct easilyeasily. I would have post this comm ent via this play form(https://www.homemade-circuits.com/how-to-make-solar-battery-charger/ and is like the place is filled up.

Youngking, You can build the above explained circuit with a 15V 20 amp solar panel. However the above explained 4 step charger can be difficult unless you have the Rx, Ry, Rz current limiter with you. These can be difficult to obtain since their wattage values could be large for the 20 amp current. Instead I would suggest you to build the last circuit from the above article which is a two step charger and easier to configure and this will also charge your battery faster.

Okay sir.

Hello sir, sorry to quota you like you said. you can connect the LEDs in parallel with the relay diodes, make sure all the LEDs have a 1K limiting resistor in series. Now my question is , so the LEDS cathode will go together with the diode cathode. The 1k resistor to be connected in series, please I don’t understand how the connection will go please explain sir.

Hello Youngking, The LED connections must be exactly opposite to that of the diode. The anode of the LED will go towards the cathode of the rectifier diode and the cathode of the LED will go towards the anode of the rectifier diode. The resistor can be either in series with cathode or the anode of the LED.

Can you sell this PCB design for us.? also I want to know the how much time it will takes to charge a phone battery?

Sorry, I can’t provide PCBs. The charging time will depend on the current selected across the 3 steps.

does the input voltage stable?

hi sir, i have done the circuit now with Rx, Rz, and Ry values is 5.8ohms.

now how do i have to start this? how can i adjust the relays to trigger at specific voltage? do i connect the input voltage only then set the P1,P2,P3,P4? or what? there is no procedure where to start with a battery or without.

Hi Alitot,

the procedure has been elaborately explained in the earlier comments, anyway, here’s what you should do.

first slide down the wiper of all the presets towards the ground level

from the left side connect a variable power supply input and switch it ON, you will see all the relays clicking ON, adjust the variable supply to the full upper charging level, and then begin adjusting P4 such that RL4 just clicks OFF.

Now reduce the input supply the next lower level, and adjust P3, until RL3 just clicks OFF.

Similarly, adjust the P2, P1 for the subsequent lower charging levels to switch OFF RL2, RL1 respectively.

The setting up procedure is complete.

When you charge a battery make sure the input current is strictly 1/10th of the battery AH.

Example the full current flow to the circuit is 15 amp and the battery is 150ah .

When the battery voltage reach 12 volt 1st relay activated no here the Rx valve allow to flow 7.5 amp charge the battery 2nd relay activated

batt voltage 13 volt Ry allow 3.6 amp

3rd relay activated voltage 14.3 volt Rz allow 1.8 amp

15 amp which is 1/10th of 150AH should be for the 3rd relay.

for the 1st relay it should be around 40 amps, for the 2nd relay it could be around 30 amps, for the 3rd around 15 amp and with the 4rth relay OFF it could be around 1 amp (float)

so it should be Rx + Rz + Ry = 30 amps

Rz + Ry = 15 amps

Rz = 1amp

the suggested rates are not absolutely crucial…you just need to taper it down proportionately with each switching of the relay…

But if the input is maximum 15 ampere how manage 40 amp?

if you are having 15amp for 150ah, then no need of this fast charger, you can connect it directly with the battery and wait for 15 hours to charge. the fast charger is designed to facilitate an initial high current charging, and thus enable a quicker charging

Can this circuit handle 30 amp current?

it can handle any amp, just modify the relay stage accordingly

Sir, I wamted to make fast charger for 12V 35Ah lead acid battery, what is max charging current and how to identify maximum current? What is input supply rating? Cant this be applied to to charge any rating of batteries or what chages required?

Thanks in advance

Deepak, I do not have the calculations for the bulk charge current or the initial high current value for a lead acid battery, however I think around 50% of the battery Ah value can be used until 12.8 V is reached, then it must appropriately reduced as per the setting of the circuit.

The circuit can be used for any battery, by setting up the current changeovers appropriately

So those 3 resistors are not the same values? Are those gonna get really hot? Even if my regulator circuit can outstand 15Amps? I can send you my final variable voltage regulatr circuit thru email if u would like to inspect.

Thank you

They have different values and need to be calculated roughly as explained in the earlier comments. yes the resistors will get a lot warm…..sorry due to lack of time inspecting your design will be difficult at the moment.

Sorry im lost.

In the procedure you said "Rx, Ry, Rz have same values and are optimized to provide the battery with the required amount of current during the various charging voltage levels".

I really dont understand it. Does they have same value? Or different values? If you dont mind giving me an example. I computed R = 12V/7A = 1.714 then multiplied to 3 as per your comment that results in using the closest resistor available to 5.1 which is 5.8 ohms 10 watts

OK, sorry, I just forgot that all the 3 resistors remain connected in parallel initially and as they are switched OFF sequentially by the relays the line resistance increases proportionately

so yes they can be of similar values, but it is not necessary you can still use different values as per preference to allow the required amount of current during the charging process

The aim is to allow full current at onset, then may be 1/5 AH value when the second relay is activated, next it can be 1/10 AH for the second relay activation, 1/20 AH for the 3rd relay, and finally 1/40 AH for the last relay activation.

Hi, i got a transformer that supplies 25volts @20A.

i made a variable voltage regulator circuit that vary voltage from 0 to 25volts and can handle 15Amps with the help of 5pcs 2N3055 Transistors and LM317.

However, the circuit is done. now i want to integrate this battery charger to it.

i have a range of batteries to charge vary from 50Ah to 70Ah.

is it possible to use this circuit to charge any between the range without changing the values of the Resistors?

1 thing i dont understand is the Rx Ry and Rz. How many watts should those resistors be? I can only purchase those with 10 Watts rate. and if im about to use Inductors, what should be the values?

Hi, you can use a single design for al those batts.

just make sure that the last resistor Rz is calculated as per the 50AH battery.

here watts = R x Isquare, if you are using 10 watt then you may have to fix it on a large aluminum heatsink.

inductor must also have same resistance value as resistors

All my resistors are 6.8ohms 5w

use different values, as explained in the previous comment

So Because of that Im forced to try and modify the windings to get 14.3v after rectification.

If the current is 1/10th of battery AH then 16V will also work, but auto cut-off at 14.3V must be functional….

OK if it's 1/10th the battery Ah then I guess when the battery is connected the voltage will drop since it's of a lower amp.

The power resistors I'm using are 6.8ohms 5w If I wanted to increase the rate of charge or reduce it i would have to reduce or increase the size of those resistors?

the 1/10th rule is a general rule if the battery was directly connected with the supply source, it cannot be applicable for the above 4 step design, here the initial current can be high at arounf 50% of the battery AH value.

I got confused when you said your battery voltage was reaching 14V quickly, that cannot happen because the RL/1 is supposed to operate at 12V reducing the current, then RL/2 at 13V, and finally RL/3 at 14V where the float charge is initiated

the resistors must be calculated accordingly to reduce the current at 25% AH value for Rx, 10% AH value for Ry, and 1% AH value for Rz

My 12v transformers are close to 13v actually after rectifying I get 16v or even 17v

What voltage transformer should I use

you must use a 0-12V transformer, rectified with a full bridge diode network, and filtered with possibly a 6800uF/35V or higher value capacitor.

this will allow the required 14.3V after rectification for charging the 12V battery

OK ill reduce the amp transformer. What's the crew that rating transformer to use though, it's seems to be somewhere around 10v for a 12v battery

sorry I did not understand your question.

The way i have the transformer wrapped now I'm getting 10v, after its rectified I'm getting 13v.

The battery was at 12.3v and after 2 hours its at 12.7v.

The transformer is a 5amp transformer and the battery is a 7ah battery, the circuit is pulling just a little over 1/2 amp from the low voltage side of the transformer.

Notes sure why the amp is so low could it be the power resistors that I'm using reducing the current or is it that the supply voltage is too low.

you mean to say the problem was in the transformer?

but anyway 5amp is too high for a 7AH battery, you must use a 1.5 amp instead, and charge the battery for 10/12 hours, that's the right way of charging any lead aid battery

By the way after filtering the ac voltage from the transformer what voltage should be sent to the input of the circuit?

14v most likely?

for a 12V battery it should be 14.3V

That's how I done it but for some reason when I connect the battery the voltage is lowered a bit like it's suppose to but it doesn't go as low as the actual voltage of the battery.

After that it quickly Rises to 14.4v and the battery doesn't charge.

connect your power supply directly with the battery and check the voltage, if it still rises to 14,4V quickly then either your battery is faulty or your charger current is dangerously high.

and make sure you have connected the opamp input polarity correctly…the (-) goes to the preset

I'm trying this circuit out again.

When setting the voltage cut off levels I'm suppose to use a variable power supply, where should I add the variable output? to battery or input power to set the limits?

connect it from the left side that is from the "input power" side

Well that's the issue then with my circuit the battery is below 12v and when I apply the battery charger circuit to the battery none of the relays came on, the only way it comes on is when I lower the supply voltage to the charger slightly to about 14.2v then only 1 relay will come on

after connecting the battery check input point voltage where the supply needs to be applied….it must show the battery voltage….after confirming this connect the input supply which must immediately settle down to the existing battery voltage…if this is not happening and the input voltage is not settling to the battery voltage then may be your battery is faulty.

Yes after connecting the batter the supply points show the battey voltage but after connecting the supply it doesnt settle back down to the battery voltage

your battery can be faulty in that case.

The video I sent it's showing that when I set the power supply voltage to 14.4v then all relays are off, if I reduce the voltage a little then the a4 relay comes on, the only way all relays comes is if I reduce powersupply voltage to 12v. So the circuit isn't working as it should. Shouldn't the voltage be set a 14.4v max then when it's connected to the discharged battery then it's suppose to sense the batteries Voltage then turn on all 4 relays and as the voltage climbs then each relay turns off 1 by 1.

With the circuit I have if I set the voltage to 14. 4v then the circuit doesn't send any voltage if I reduce it then only 1 relay comes on and if that is the case then it will be 14v at a low current.

once you set the presets and confirm all the relays switched OFF, after this you can remove the input power supply and attach the battery.

with the battery connected the relevant relays can be expected to switch ON.

Now you can connect the power supply back at the input, on doing this you will find the power supply voltage settling down to the battery voltage level and then rising slowly in the course of time as the battery gets charged…this will in turn switch OFF the relays one by one until the battery is fully charged (last relay off)…it's as simple as that.

Ok then I understand the operation, in which connecting the batteries all relays come on but applying supply power after only a4 relay comes on so I guess my problem is that I havent left it there to settle long enough? If thats the case it because the powersupply I am using cant manage the power draw so the regulators get extremely hot quickly.

I wanted to use a powersupply I was building without regulators but If I do that when the battery receives 25v wont that be too much for the batteries? I know the ic can handle it and I could use a regulator for the relays but what about the battery since the voltage supplied to the input would also be at the output.

If the battery voltage is say 10.5V, the input supply will INSTANTLY settle down to this voltage as soon as its connected at the input….which will enable all the relays to activates.

Please make sure this happens with your charger functioning.

You can keep the voltage regulators attached, it has nothing to do with the above mentioned condition

24V can be harmful for a 12v battery and relay

I am facing a problem I now have 14.45 volts entering the circuit and I set all the values I added a led across the coils to know when the transistor is on. So when I send 12v I adjusted the p1 to activate the first coil then shifted to 12.5v but the light on a1 turned off, then after adjusting p2 so that led comes on when moving to 13.5v a2 led turned off and it when it that same order, all 4 stages were set, but applying 14.5v and then connecting to my battery of 10.5v nothing happened all replays staged off and no voltage was applied to the battery, I assume that reducing the voltage on the input a little a4 will enegergise.

So the only way that makes sence is if I am the one not understand how the circuit works fully, I was assuming that the input should be 14v because my battery is 12v battery (deep cycle) and setting all the parameters correctly then It would sence the battery voltage different from input voltage and if its lower than 12v then all relays would be on to fast charger then as it reaches each threshold set by me then a each relay would turn off accordingly, could I get some help?

your LED response is correct so the setting up procedure is also correct.

yes initially you can lower the voltage slightly and once the relays are activated, you can raise the voltage to 14.4V….but this should be done with the discharged battery connected.

Ok I did that but only the a4 relay activated, if I went down with the volt gradually then all the relays would come on, but once I increased the voltage then they would turn off again. So I dont know if the sensing section of the circuit is working, 1 problem I think would cause it is that I couldnt get a 6v zener diode so I used a 6.8v zener, Would that be the issue?

please connect the 1N4007 diode from the battery positive to the relay positives as shown in the updated diagram and check the response….

remember battery should be connected first and then the supply input

Ok I will add the diode later and let you know, I think that was an issue aswell since connecting the battery would activate a relay without applying power to the circuit.

I connected the diode just as you have it in the schematic but I am having the same issue. I made a quick video to show an example.

https://www.dropbox.com/s/h1svuujackydd4g/20160314_191207.mp4?dl=0

as the battery gets charged and its terminal voltage rises the relays will sequentially get deactivated until all the relays are switched OFF, and then the battery can be removed

I was thinking about that but wouldnt that be low current at 12v and even if I powered the coils with the regulator would the battery be getting the 20v from the circuit just the same? I am just asking for knowledge, I actually made a more powerful adjustable power supply just now to use.

The current limiting resistors will take care of the excess voltage and adjust it as per the battery requirements. Don't use filter capacitor with the power supply bridge to control the excess voltage at the output

I built this circuit just now and I used a variable powersupply I built to set all the relays. to do the charging I will now need a more powerful power supply I was planning to do a simple design using a 10amp transformer and a rectifier stage I wouldnt use a regulator and I think the output would be about 18 to 20v dc, since the opamp can manage that voltage and the relay is set to turn off at 14v max I was wondering if I could use it.

18V or 20V won't be a problem for the IC since the IC LM324 can handle upto 32V. however the relay might become quite hot at 18V, so may be you may want to add a 7812 regulator for the relay coils

Update:

R5 was missing in the original diagram, now it has been added in the diagram…If anybody was having problems with this circuit then probably it was because of this mistake….I regret it a lot.

Hi Swagatam, I have been looking at building this circuit to charge a 12 V 7AH sealed lead battery. Would it be suitable for this battery? If it is, the values of Rx, Ry and Rz would they be 18 ohms based on the battery and Ohms Law. I can obtain them in 5 or 10 watts as wire wound resistors.

Regards

Geoff

Hi Geoff, The above circuit can be used for charging almost all types of batteries including Lipo batts.

The Rx, Ry, Rz values are not too critical, just needs to be calculated such that the procedure allows a sequentially decreasing charging rate as the battery reaches its full charge level.

So the combined value of the ersistors must be such that they allow 5amp current to your battery initially….

R = V/I = 12/5 = 2.4 ohms….multiplying this by three gives…..7.2 ohms

Therefore you could probably use 7 ohms for each resistors.

Ooops, thanks for that clarification, still wondering how I obtained my answer. Kakooza asked earlier about swapping the relays for mosfets, I have some IRFZ44N's could I use these?

Regards

Geoff

OK..no issues..

I think relays are better suited to this application and much easier to configure, mosfets can make the design much complex and difficult to optimize or troubleshoot if anything goes wrong….

HI sir, I have doubt that is, diode to be connected at positive terminal of circuit? before or after circuit? As current can flow in reverse direction when Battery will be connected to this circuit.

Thank u very much

Hi Kaustubh, you can connect a diode in series with the battery positive terminal.

Thank you very much sir…..

Thanks you so much Sir..

Well done sir, what if I want to replace the relays with mosfet to make da system silent, how can I make it?

thanks kakooza, replace the BC547s with mosfets, remove the relays, connect the pole wire of the relays with the mosfet drains, connect the coil common end with the battery negative and connect the battery positive directly with positive line….

Wat about da burrialHello sir, which voltage should Iuse to set the relays?

Is it the charger voltage or battery voltage?

you'll have to set up the levels by applying the specified voltage levels through a variable power supply without connecting a battery at the output.

the relevant presets can be set across these voltage levels supplied from the variable power supply…the voltage levels are not critical

… could be like:

at 12V A1 relay switches ON,

at 12.5V A2 relay switches ON

at 13.5V A3 relay switches ON

and at 14.4V A4 relay switches ON

Thank you very much sir.

While to set preset,

initially p1 to p4 pot slider arm should be ground side & then gradually increase to activate relay, is that so?

Also p1 to p4 preset common connected terminal to be removed from I/p & connected to variable voltage power supply pot? Should I do this

the points marked " input power" should be connected with the variable supply input and P1…P4 adjusted as per the explained procedure

Hello sir,

I am new to circuits, & I am trying to implement the fast battery charger circuit. Please guide me to how & when to set preset values??.. preset value to be set before battery connected to circuit or after that??…please help me.

I connected the circuit on breadboard as given , Now I am giving supply of 13.5vdc, 2.5amp(max) to circuit. 1st preset(P1) is set to 12.0vdc, 1st relay(only) is gets on when i/p given to circuit. BUT 2nd,3rd,4th PRESET CAN'T SET, ALSO 2nd,3rd,4th RELAY NOT ACTIVATED when i/p is given to circuit. So please please guide me. THANKS

Hello Kaustubh,

you may set the other presets too in the same manner by supplying incrementing voltage levels.

for example 2nd relay can be set to activate at 12.5V… 3rd at 13V, fourth at 13.5V and so on.

this must be done without any battery connected and with the help of a variable power supply.

THANK YOU FOR IMMEDIATE REPLY………

Variable power supply means, as per given in BATTERY CURRENT INDICATOR CIRCUIT OF YOURS (How to set up the circuit)?

http://www.www.homemade-circuits.com/2015/04/battery-current-indicator-circuit.html

Thanks in advance

we want to set the presets with respect to the different voltage levels, so the power supply should be a variable voltage power supply…

use the variable voltage power supply to feed the relevant voltage levels to the circuit and adjust the presets accordingly so that relays click on those voltage levels.

current will need to be adjusted by using coils or resistors as explained, which will need to be calculated depending upon the battery AH rating.

Thank you once again..

Hello Hazrat,

making a 12V 70amp SmPS cannot be simple…it could be in fact quite complex..you can refer to the following article for more info:

https://www.homemade-circuits.com/2014/07/adjustable-0-100v-50-amp-smps-circuit.html

Hello sir,

want to convert 230 volt AC current into 12 volt DC current but i am new to electronics stuff i want to get some help from professionals to give me a circuit diagram with guide notes i like to make my power supply variable amp output power supply which can give me from 20 amp to 70 amp and i also want to keep my supply simple and cheap. please give me the details. Thanks

Meaning I should replace the inverting & non-inverting of TLC2272CP with those of LM324 and also the same to the outputs?

don't use LM324..Use TL072 it will directly fit with the TLC227CP pinouts.

Hello sir, how can I replace IC TLC2272CP with LM324 & is it possible to get equal functioning results?

just verify and interchange the inverting (-) and the non-inverting (+) inputs with each other…. and do the same with their supply and the output pins also.

Hi sir, I have a 55W panel & a 45AH flooded type battery bt the PV max output is 21V, how can I regulate the voltage using IC 555 & a P-mosfet to get 15 V output so that I can use the above 4 step charger,thanks.

Hi Kakooza, you will need to incorporate a buck converter circuit for the step down, or you can also go for a linear regulator such as a LM338 which is much easier than a buck circuit but a little inefficient due to significant heat generation.

How long does it takes to get to 95% with 15 amps suply? will this work with a four pin battery? I did an experiment with a 25 amp suplier and I connected the positive and the negative an dit did not work why? Thank you sir in advance thanks.

if correctly optimized, it won't take more than 6 hours to get to the 95% mark.

please provide the complete specification of the battery for proper understanding

sir/ what is input volts

for 6V battery it should be 7V, for 12V > 14V and for 24V > 28V

Sir i have 50 amp acid battery. i want charger circuit for this. please give me . thanks

kashif you can use any LM338 circuit for this

can I use the circut, if input given 12v 30amp

to charge 100ah battery?

yes it can used, but for a 100AH battery just 15amp input would be quite sufficient

sir dont mind for my questions..

and plz reply

I have make the two circuts,both are make with the help of ur blog

one of simple mppt (solar)

and the other is fast battery charger

this one..

now I have 150w 24vdc solar panel and I want when voltage come from solar panel just connect mppt circut and his output now connect input of fast battery charger circut and after this now the output connect to 12v 150ah battery.

so plz reply me can this work perfect?

and want when relay activate ,indication led on how connect led?

simply connect the solar panel out with the input of the MPPT circuit, then connect the MPPT output with the input of the above fast charger, that's all

sir I have use 12v dc 7amp spdt relay because 10amp relay not available in market

can work fine?

if your battery is less than 60AH then 7amp relays will do.

thanks a lot sir..

sir I want to connect leds,when the relays activate the led on..

help for this to complete my project .

you can connect the LEDs in parallel with the relay diodes, make sure all the LEDs have a 1K limiting resistor in series

all the circut made with jumper brcause I have no etchant pcb facility and dont no about pcb layout so I make all the line connect with jumper plz sir reply with my last question

OK, understood.

I done this project with jumper saloution .using of this circut 150ah 12v battery how much time fully charged?

and between ( ) and (-) terminal show 4k resistance do not show open. I worried about that can they have show resistance and not show open?

where did you use the jumpers?

ok thanks

can the transistor emitter connect the nagative (-) terminal or just to leave ground?

connect with battery (-) line

ok thanks I try to make pcb layout

can I replace wire wound resistors to normal resistor and much resistor use

yes you can do it, no issues.

…(Rx, Ry, Rz) those are not wire wound resistors, those are copper coils, you can replace them with wirewound high watt resistors.

sir u r good honest and like a super man.my english is not good but I think u are understand. u have share u r knowledge to people for free this is a big job very big job I regularly studied ur posts.and u prove ur self with quick reply also so great job.

thanks a lot Inayat.

thanks alot of thanks for reply sir I have buy all these component but I want to make pcb layout to parmanent marker because I have no printer facility and I have less experince of eletronics there for I request for pcb layout of this schematic plz sir help for this

Inayat, I am sorry it'll be difficult for me to provide a PCB design due to lack of time, you'll have to take the help of a PCB designer for this.

how set preset pz give me some informotion

for a 12V battery set P1 to make RL1 activate at 12V, set P2 to activate RL2 at 12.5V, P3 to make RL3 activate at 13V, and P4 to activate 14V

how set preset plZ give me detail

what is the voltage of input power as it show DC sign is it a 24v transformer?

Input could be anything between 6V and 30V depending upon the battery used, the relay will also need to be rated at this voltage