In this post I will explain the construction of a 5000 watt inverter circuit which incorporates a ferrite core transformer and therefore is hugely compact than the conventional iron core counterparts.

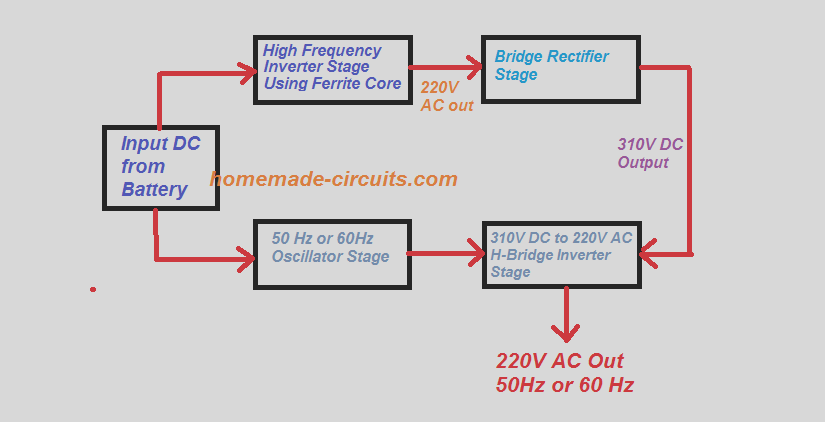

Block Diagram

Please note you can convert this ferrite core inverter to any desired wattage, right from 100 watt to 5 kva or as per your own preference.

Understanding the above block diagram is quite simple:

The input DC which could be through a 12V, 24V or 48V battery or solar panel is applied to a ferrite based inverter, which converts it into a high frequency 220V AC output, at around 50 kHz.

But since 50 kHz frequency may not be suitable for our home appliances, we need to convert this high frequency AC into the required 50 Hz / 220V, or 120V AC / 60Hz.

This is implemented through an H-bridge inverter stage, which converts this high frequency into output into the desired 220V AC.

However, for this the H-bridge stage would need a peak value of the 220V RMS, which is around 310V DC.

This is achieved using a bridge rectifier stage, which converts the high frequency 220V into 310 V DC.

Finally, this 310 V DC bus voltage is converted back into 220 V 50 Hz using the H-bridge.

We can also see a 50 Hz oscillator stage powered by the same DC source. This oscillator is actually optional and may be required for H-bridge circuits which do not have its own oscillator. For example if we use a transistor based H-bridge then we may need this oscillator stage to operate the High and low side mosfets accordingly.

UPDATE: You may want to jump directly to the new updated "SIMPLIFIED DESIGN", near the bottom of this article, which explains a one-step technique for obtaining a transformerless 5 kva sine wave output instead of going through a complex two-step process as discussed in the concepts below:

A Simple Ferrite Cote Inverter Design

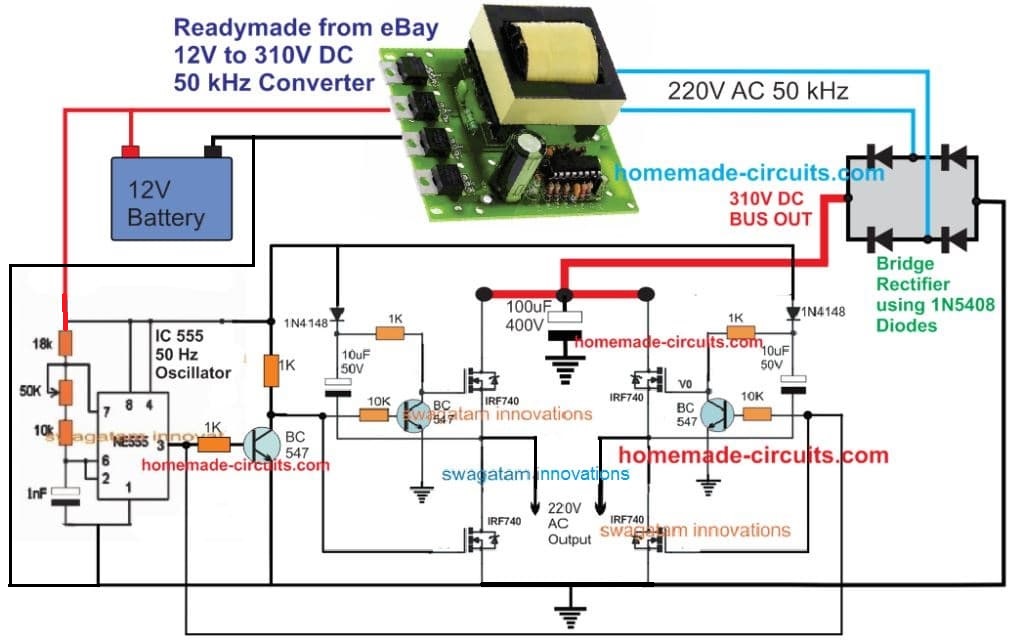

Before I will explain the 5kva version here's a simpler circuit design for the newcomers. This circuit does not employ any specialized driver IC, rather works with only n-channel MOSFETS, and a bootstrapping stage.

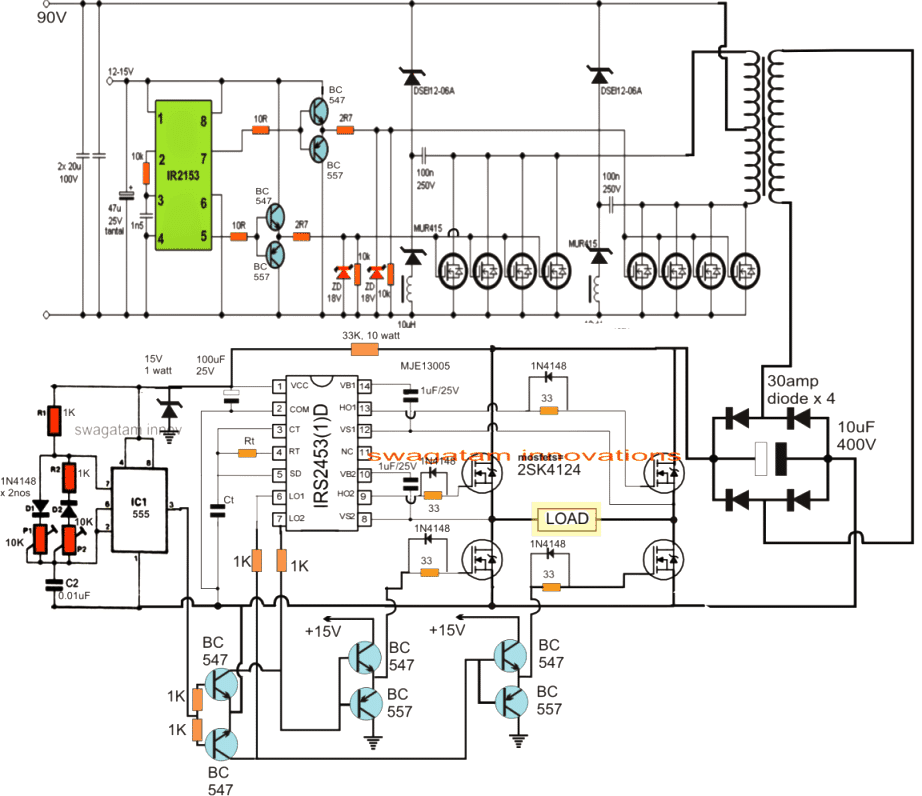

The complete circuit diagram can be witnessed below:

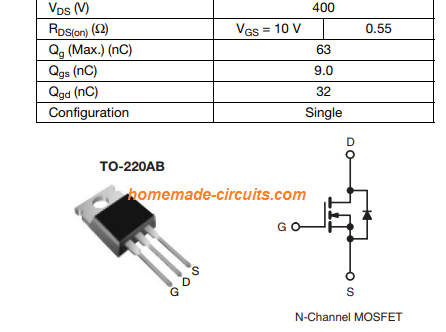

400V, 10 amp MOSFET IRF740 Specifications

In the above simple 12V to 220V AC ferrite inverter circuit we can see a ready made 12V to 310V DC converter module being used. This means you don't have to make a complex ferrite core based transformer. For the new users this design may be very beneficial as they can quickly build this inverter without depending on any complex calculations, and ferrite core selections.

5 kva Design Prerequisites

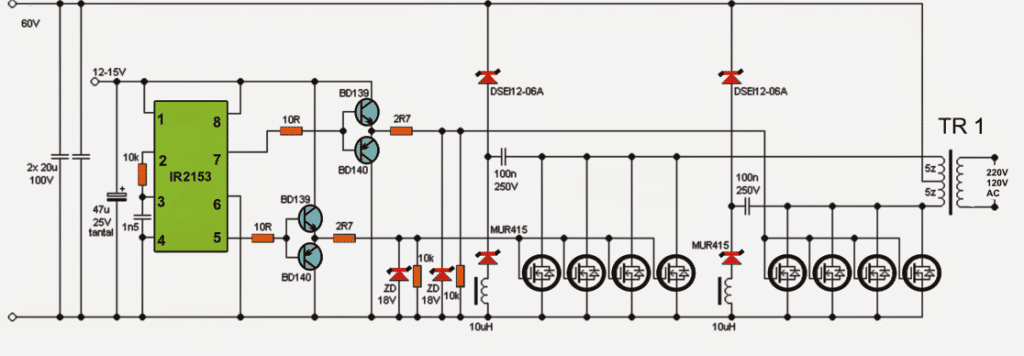

First you need to find 60V DC power supply for powering the proposed 5kVA inverter circuit. The intention is to design a switching inverter which will convert the DC voltage of 60V to a higher 310V at a lowered current.

The topology followed in this scenario is the push-pull topology which uses transformer on the ratio of 5:18. For voltage regulation which you may need, and the current limit – they are all powered by an input voltage source. Also at the same rate, the inverter expedites the current allowed.

When it comes to an input source of 20A it is possible to get 2 – 5A. However, the peak output voltage of this 5kva inverter is around 310V.

Ferrite Transformer and Mosfet Specifications

In regard to the architecture, Tr1 transformer has 5+5 primary turns and 18 for secondary. For switching, it is possible to use 4+4 MOSFET (IXFH50N20 type (50A, 200V, 45mR, Cg = 4400pF). You are also free to use MOSFET of any voltage with Uds 200V (150V) along with least conductive resistance. The gate resistance used and its efficiency in speed and capacity must be excellent.

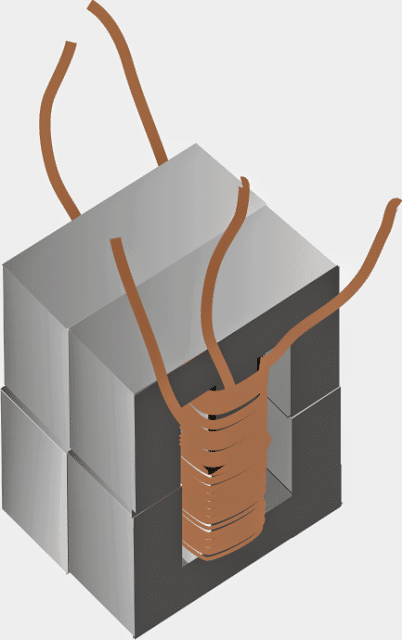

The Tr1 ferrite section is constructed around 15x15 mm ferrite c. The L1 inductor is designed using five iron powder rings that may be wound as wires. For inductor core and other associated parts, you can always get it from old inverters (56v/5V) and within their snubber stages.

Using a Full Bridge IC

For integrated circuit the IC IR2153 can be deployed. The outputs of the ICs could be seen buffered with BJT stages. Moreover, due to the large gate capacitance involved it is important to use the buffers in the form of power amplifier complementary pairs, a couple of of BD139 and BD140 NPN / PNP transistors do the job well.

Alternate IC can be SG3525

You may also try to use other control circuits like SG3525. Also, you can alter the voltage of the input and work in direct connection with the mains for testing purpose.

The topology used in this circuit has the facility of galvanic isolation and operating frequency is around 40 kHz. In case if you have planned to use the inverter for a small operation, you don’t cooling, but for longer operation be sure to add a cooling agent using fans or large heatsinks. Most of the power is lost at the output diodes and the Schottky voltage goes low around 0.5V.

The input 60V could be acquired by putting 5 nos of 12V batteries in series, the Ah rating of each battery must be rated at 100 Ah.

High Frequency 330V Stage

The 220V obtained at the output of TR1 in the above 5 kva inverter circuit still cannot be used for operating normal appliances since the AC content would be oscillating at the input 40 kHz frequency.For converting the above 40 kHz 220V AC into 220V 50 Hz or a 120V 60Hz AC, further stages would be required as stated below:

First the 220V 40kHz will need to be rectified/filtered through a bridge rectifier made up of fast recovery diodes rated at around 25 amps 300V and 10uF/400V capacitors.

Converting 330 V DC into 50 Hz 220 V AC

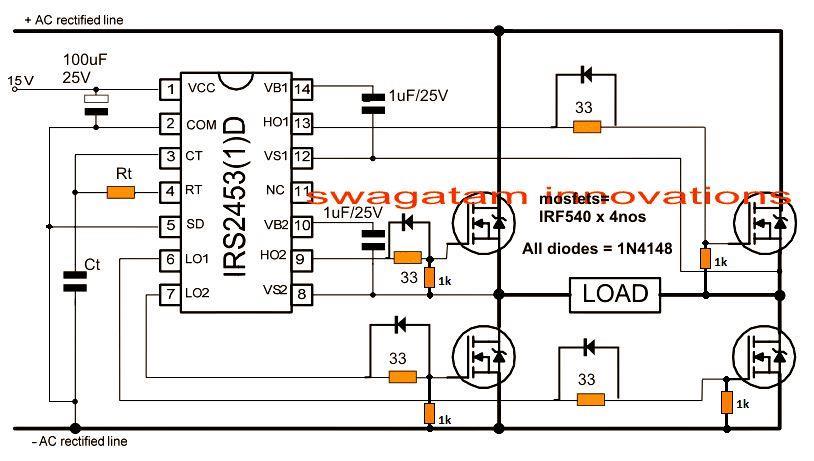

Next, this rectified voltage which would now mount up to around 310V would need to be pulsed at the required 50 or 60 Hz through another full bridge inverter circuit as shown below:

The terminals marked "load" could be now directly used as the final output for operating the desired load.

Here the mosfets could be IRF840 or any equivalent type will do.

How to Wind the Ferrite Transformer TR1

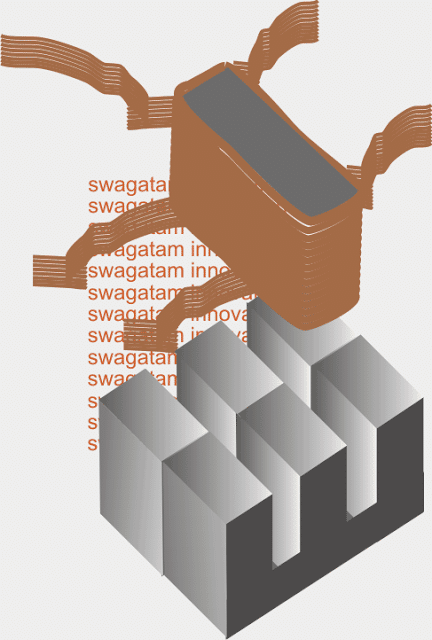

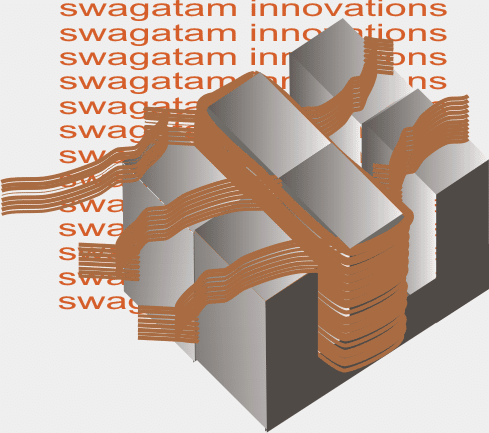

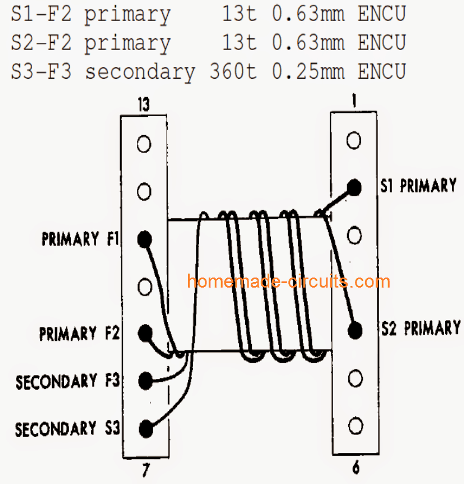

The transformer TR1 is the main device which is responsible for stepping up the voltage to 220V at 5kva, being ferrite cored based it's constructed over a couple of ferrite EE cores as detailed below:

Since the power involved is massive at around 5kvs, the E cores needs to be formidable in size, an E80 type ferrite E-core could be tried.

Remember you may have to incorporate more than 1 E core, may be 2 or 3 E-cores together, placed side by side for accomplishing the massive 5KVA power output from the assembly.

Use the largest one that may be available and wind the 5+5 turns using 10 numbers of 20 SWG super enameled copper wire, in parallel.

After 5 turns, stop the primary winding insulate the layer with an insulating tape and begin the secondary 18 turns over this 5 primary turns. Use 5 strands of 25 SWG super enameled copper in parallel for winding the secondary turns.

Once the 18 turns are complete, terminate it across the output leads of the bobbin, insulate with tape and wind the remaining 5 primary turns over it to complete the ferrite cored TR1 construction. Don't forget to join the end of the first 5 turns with the start of the top 5 turn primary winding.

E-Core Assembly Method

The following diagram gives an idea regarding how more than 1 E-core may be used for implementing the above discussed 5 KVA ferrite inverter transformer design:

E80 Ferrite core

Feedback from Mr. Sherwin Baptista

Dear All,

In the above project for the transformer, i did not use any spacers between the core pieces, the circuit worked well with the trafo cool while in operation. I always preferred an EI core.

I always rewound the trafos as per my calculated data and then used them.

All the more the trafo being an EI core, separating the ferrite pieces were rather easy than doing away with an EE core.

I also tried opening EE core trafos but alas; i ended up breaking the core while separating it.

I never could open an EE core without breaking the core.

As per my findings, few things i would say in conclusion:

---Those power supplies with non-gaped core trafos worked best. (i am describing the trafo from an old atx pc power supply since i used those only. The pc power supplies do not fail that easily unless its a blown capacitor or something else.)---

---Those supplies that had trafos with thin spacers often were discolored and failed quiet early.(This i got to know by experience since till date i bought many second hand power supplies just to study them)---

---The much cheaper power supplies with brands like; CC 12v 5a, 12v 3a ACC12v 3a RPQ 12v 5a all

Such types ferrite trafos had thicker paper pieces between the cores and all failed poorly!!!---

In FINAL the EI35 core trafo worked the best(without keeping air gap) in the above project.

5kva ferrite core inverter circuit preparation details:

Step 1:

- Using 5 Sealed Lead Acid batteries of 12v 10Ah

- Total voltage = 60v Actual voltage

- = 66v fullcharge(13.2v each batt)voltage

- = 69v Trickle level charge voltage.

Step 2:

After calculation of battery voltage we have 66volts at 10 amps when full charged.

- Next comes the supply power to ic2153.

- The 2153 has a maximum of 15.6v ZENER clamp betwen Vcc and Gnd.

- So we use the famous LM317 to supply 13v regulated power to the ic.

Step 3:

The lm317 regulator has the following packages;

- LM317LZ --- 1.2-37v 100ma to-92

- LM317T --- 1.2-37v 1.5amp to-218

- LM317AHV --- 1.2-57v 1.5amp to-220

We use the lm317ahv in which 'A' is the suffix code and 'HV' is the high volt package,

since the above regulator ic can support input voltage of upto 60v and output votage of 57 volts.

Step 4:

- We cannot supply the 66v directly to the lm317ahv package sice its input is maximum of 60v.

- So we employ DIODES to drop the battery voltage to a safe voltage to power the regulator.

- We need to drop about 10v safely from the maximum input of the regulator which is 60v.

- Therefore, 60v-10v=50v

- Now the safe maximum input to the regulator from the diodes should be 50 volts.

Step 5:

- We use the regular 1n4007 diode to drop the battery voltage to 50v,

- Since being a silicon diode the voltage drop of each is about 0.7 volts.

- Now we calculate the required number of diodes we need which would buck the battery voltage to 50 volts.

- battery voltage = 66v

- calc.max input voltage to regulator chip = 50v

- So, 66-50=16v

- Now, 0.7 * ? = 16v

- We divide 16 by 0.7 which is 22.8 i.e., 23.

- So we need to incorporate about 23 diodes since the total drop from these amounts to 16.1v

- Now, the calculated safe input voltage to the regulator is 66v - 16.1v which is 49.9v appxm. 50v

Step 6:

- We supply the 50v to the regulator chip and adjust the output to 13v.

- For more protection, we use ferrite beads to cancel out any unwanted noise on the output voltage.

- The regulator should be mounted on an appopriate sized heatsink in order to keep it cool.

- The tantalum capacitor connected to the 2153 is an important capacitor that makes sure ic gets a smooth dc from the regulator.

- Its value can be reduced from 47uf to 1uf 25v safely.

Step 7:

- Rest of the circuit gets 66volts and the high current carrying points in the circuit should be wired with heavy guage wires.

- For the transformer its primary should be 5+5 turns and secondary 20 turns.

- The frequency of the 2153 should be set at 60KHz.

Step 8:

The High frequency ac to low frequency ac converter circuit using the irs2453d chip should be wired appropriately as shown in the diagram.

Finally completed.

Making a PWM Version

The following posting discusses another version of a 5kva PWM sinewave inverter circuit using compact ferrite core transformer. The idea was requested by Mr. Javeed.

Technical Specifications

Dear sir, would you please modify its output with PWM source and facilitate to make use such an inexpensive and economical design to World wide needy people like us? Hope You will consider my request. Thanking you.Your affectionate reader.

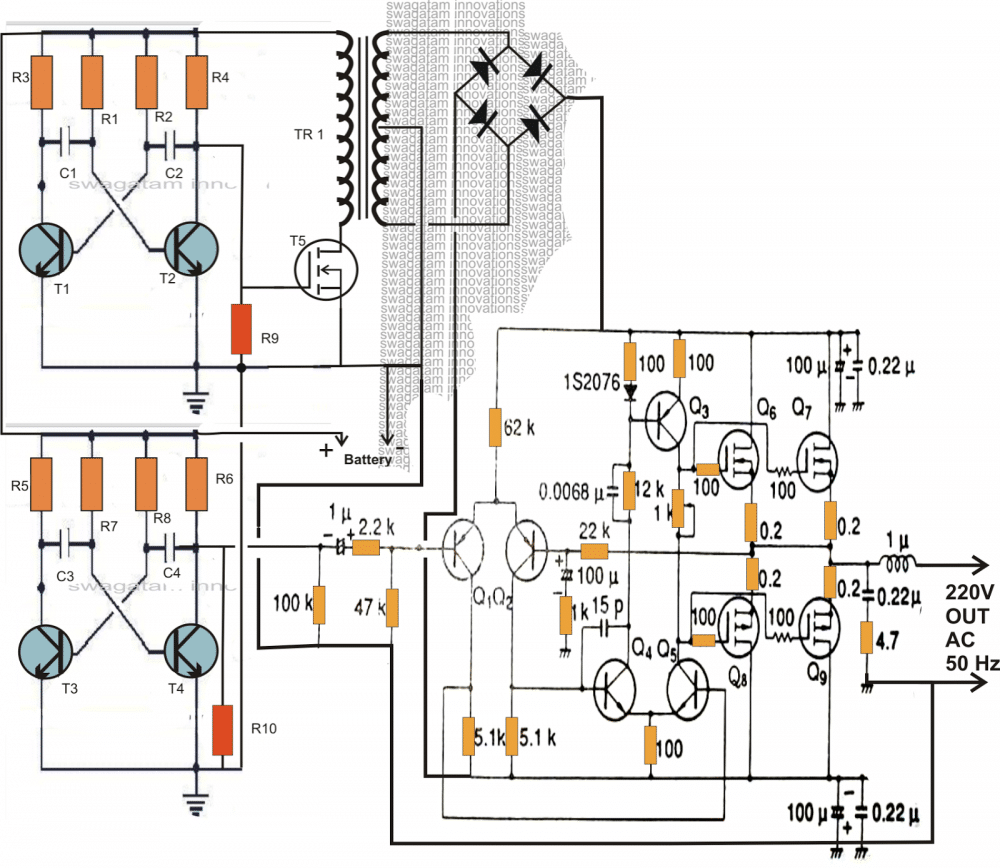

The Design

In the earlier post I introduced a ferrite core based 5kva inverter circuit, but since it is a square wave inverter it cannot be used with the various electronic equipment, and therefore its application may be restricted to only with the resistive loads.

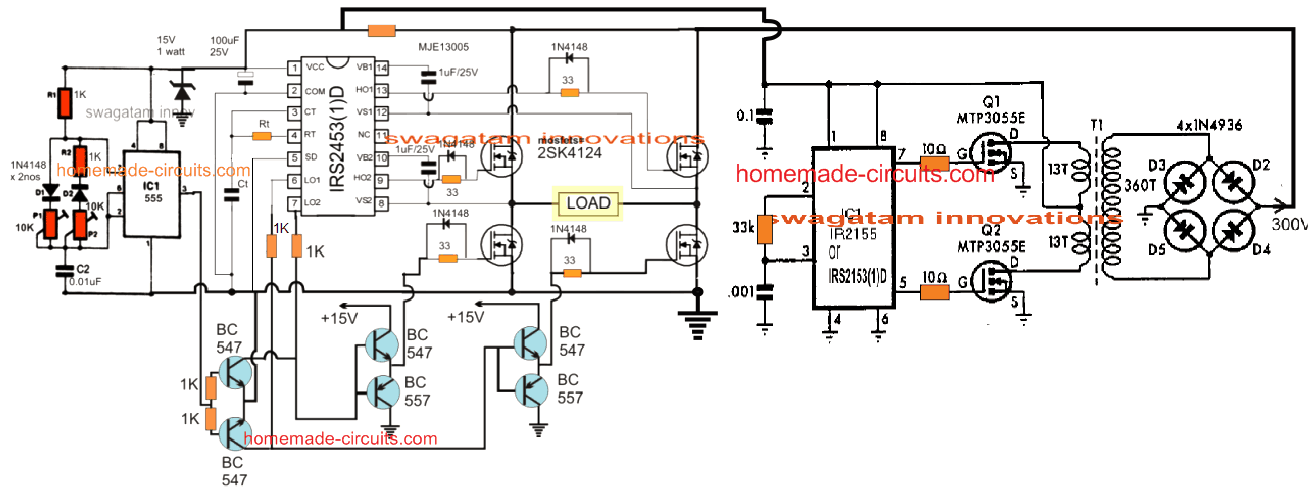

However, the same design could be converted into a PWM equivalent sine wave inverter by injecting a PWM feed into the low side mosfets as shown in the following diagram:

The SD pin of IC IRS2153 is mistakenly shown connected with Ct, please be sure to connect it with the ground line.

Suggestion: the IRS2153 stage could be easily replaced with IC 4047 stage, in case the IRS2153 seems difficult to obtain.

As we can see in the above PWM based 5kva Inverter circuit, the design is exactly similar to our earlier original 5kva inverter circuit, except the indicated PWM buffer feed stage with the low side mosfets of the H-bridge driver stage.

The PWM feed insertion could be acquired through any standard PWM generator circuit using IC 555 or by using transistorized astable multivibrator.

For more accurate PWM replication, one can also opt for a Bubba oscilator PWM generator for sourcing the PWM with the above shown 5kva sinewave inverter design.

The construction procedures for the above design is not different to the original design, the only difference being the integration of the BC547/BC557 BJT buffer stages with the low side mosfets of the full bridge IC stage and the PWM feed into it.

Another Compact Design

A little inspection proves that actually the upper stage does not need to be so complex.

The 310V DC generator circuit could be build using any other alternate oscillator based circuit. An example design is shown below where a half bridge IC IR2155 is employed as the oscillator in a push pull manner.

Again, there's no specific design that may be necessary for the 310V generator stage, you can try any other alternative as per your preference, some common examples being, IC 4047, IC 555, TL494, LM567 etc.

Inductor Details for the above 310V to 220V Ferrite Transformer

Simplified Design

In the above designs so far we have discussed a rather complex transformerless inverter which involved two elaborate steps for getting the final AC mains output. In these steps the battery DC is first needed to be transformed into a 310 V DC through a ferrite core inverter, and then the 310 VDC has to be switched back to 220 V RMS through a 50 Hz full bridge network.

As suggested by one of the avid readers in the comment section (Mr. Ankur), the two-step process is an overkill and is simply not required. Instead, the ferrite core section can itself be modified suitably for getting the required 220 V AC sine wave, and the full bridge MOSFET section can eb eliminated.

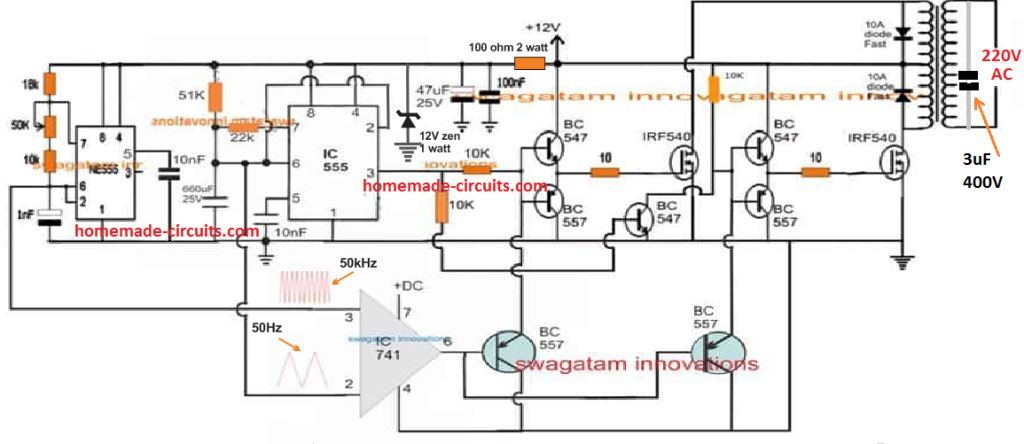

The following image shows a simple set up for executing the above explained technique:

In the above design, the right side IC 555 is wired to generate a 50 Hz basic oscillatory signals for the MOSFET switching. We can also see an op amp stage, in which this signal is extracted from the ICs RC timing network in the form of 50 Hz triangle waves and fed to one of its inputs to compare the signal with a fast triangle wave signals from another IC 555 astable circuit. This fast triangle waves can have a frequency of anywhere between 50 kHz to 100 kHz.

The op amp compares the two signals to generate a sine wave equivalent modulated SPWM frequency. This modulated SPWM is fed to the bases of the driver BJTs for switching the MOSFETs at 50 kHz SPWM rate, modulated at 50 Hz.

The MOSFEts in turn, switch the attached ferrite core transformer with the same SPWM modulated frequency to generate the intended pure sinewave output at the secondary of the transformer.

Due to the high frequency switching, this sine wave may be full of unwanted harmonics, which is filtered and smoothed through a 3 uF/400 V capacitor to obtain a reasonably clean AC sine wave output with the desired wattage, depending on the transformer and the battery power specs.

The right side IC 555 which generates the 50 Hz carrier signals can be replaced by any other favorable oscillator IC such as IC 4047 etc

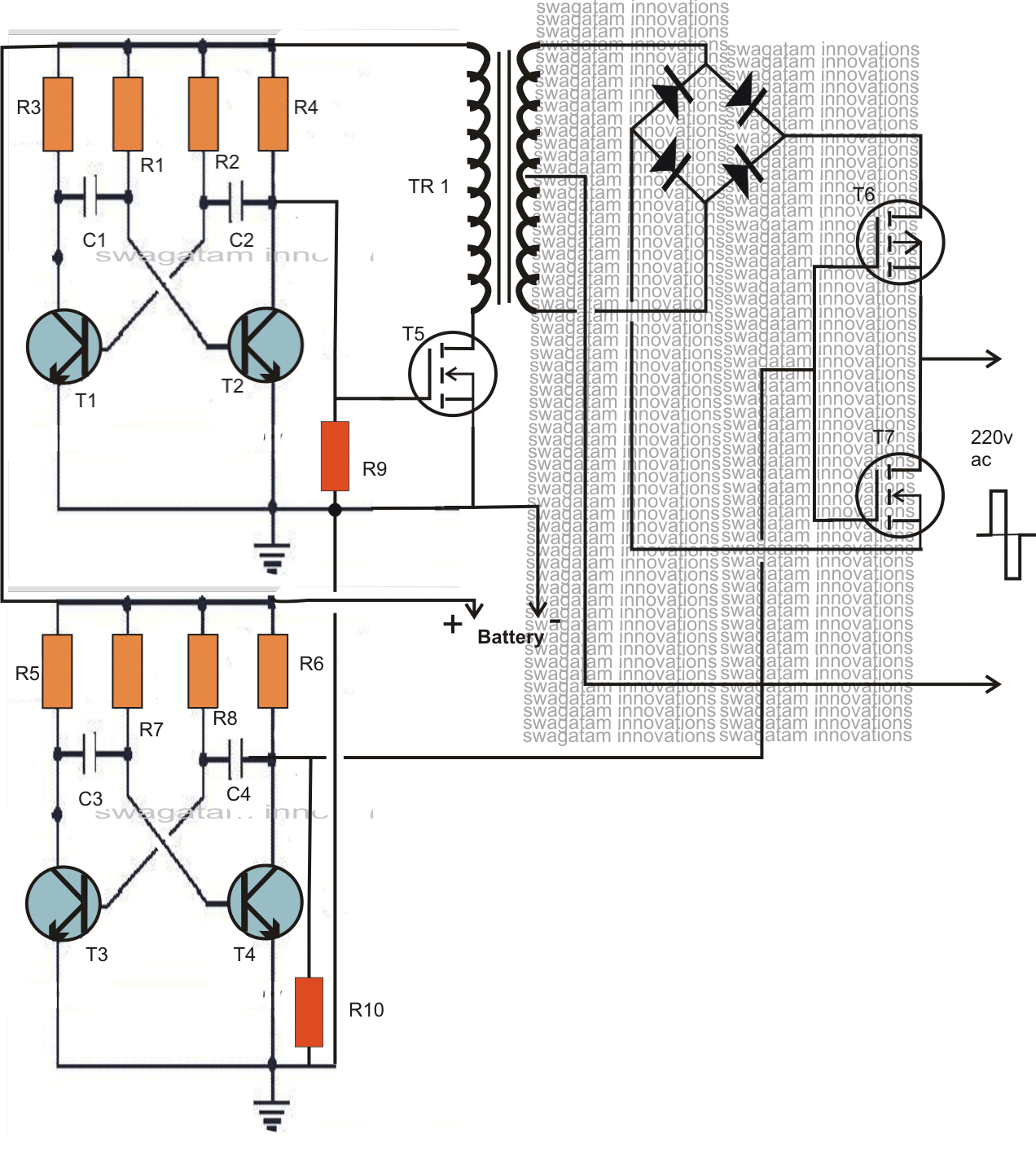

Ferrite Core Inverter Design using Transistor Astable Circuit

The following concept shows how a simple ferrite cored inverter could be built using a couple of ordinary transistor based astable circuit, and a ferrite transformer.

This idea was requested by a few of the dedicated followers of this blog, namely Mr. Rashid, Mr, Sandeep and also by a few more readers.

Circuit Concept

Initially I could not figure out the theory behind these compact inverters which completely eliminated the bulky iron core transformers.

However after some thinking it seems I have succeeded in discovering the very simple principle associated with the functioning of such inverters.

Lately the Chinese compact type inverters have become pretty famous just because of their compact and sleek sizes which make them outstandingly light weight and yet hugely efficient with their power output specs.

Initially I thought the concept to be unfeasible, because according to me the use of tiny ferrite transformers for low frequency inverter application appeared highly impossible.

Inverters for domestic use requires 50/60 Hz and for implementing ferrite transformer we would require very high frequencies, so the idea looked highly complicated.

After some thinking I was amazed and happy to discover a simple idea for implementing the design. Its all about converting the battery voltage to 220 or 120 mains voltage at very high frequency, and switching the output to 50/60 HZ using an push-pull mosfet stage.

How it Works

Looking at the figure we can simply witness and figure out the whole idea. Here the battery voltage is first converted to high frequency PWM pulses.

These pulses are dumped into a step up ferrite transformer having the required appropriate rating. The pulses are applied using a mosfet so that the battery current can be utilized optimally.

The ferrite transformer steps up the voltage to 220V at it output. However since this voltage has a frequency of around 60 to 100kHz, cannot be directly used for operating the domestic appliances and therefore needs further processing.

In the next step this voltage is rectified, filtered and converted to 220V DC. This high voltage DC is finally switched to 50 Hz frequency so that it may be used for operating the household appliances.

Kindly note that though the circuit has been exclusively designed by me, it hasn't been tested practically, make it at your own risk and on;y if you have sufficient confidence over the given explanations.

Circuit Diagram

Parts List for 12V DC to 220V AC compact ferrite core inverter circuit.

- R3---R6 = 470 Ohms

- R9, R10 = 10K,

- R1,R2,C1,C2 = calculate to generate 100kHz freq.

- R7,R8 = 27K

- C3, C4 = 0.47uF

- T1----T4 = BC547,

- T5 = any 30V 20Amp N-channel mosfet,

- T6, T7 = any, 400V, 3 amp mosfet.

- Diodes = fast recovery, high speed type.

- TR1 = primary, 13V, 10amp, secondary = 250-0-250, 3amp. E-core ferrite transformer....ask an expert winder and transformer designer for help.

An improved version of the above design is shown below. The output stage here is optimized for better response and more power.

Improved Version

Good day sir

I love your work, please how can I get the GERBER PCB FILE OF THE PROJECT

THANKS

Thank you Russell, however, sorry I do not have the GERBER files for this project. I would rather suggest you to try the project on a strip-board first, and test the results, before designing a PCB.

Hello Mr Swagatam how much would it cost to order components from your country to Maseru Lesotho. Most of the components I need to build my projects are not available in my country.

Hi Poloko, sorry, I have no idea how much it would cost to procure parts from India to your country, you may have to inquire this with the part supplier.

Hi there! That is a very interesting circuit that I intend to try soon after locating the elusive high power, adequately sized ferrite transformer. Here clarity is not given for winding the transformer for running the unit off 24v (2X12/150A, a very common battery combination in many households.) as this info wasn’t available although it was suggested. One suggestion worth examining is that you’ve used a high wattage resistor to create 15v to power the low voltage section from high voltage Dc. A more elegant solution is to use a common 12v wall adaptor that are used in many applications can be taken apart and the Hi voltage Dc can be connected across the Hv Filter cap that is on the unit. The 12v Dc output can now be connected instead of the previous arrangement although 15v is suggested I feel it should be satisfactory or a 15v adaptor could be used. This is more efficient and will give out much less heat also.

Hi, thanks for the feedback!

A 24V DC would call for a huge amount of current from the transformer and the battery. To be precise we would need around 5000/24 = 208 amps, that is why 60V source is selected to minimize the current spec as far as possible.

The article provides the transformer details for a 60 V ferrite transformer.

Yes, the 12V or 15V DC can be obtained from an SMPS source or from a buck converter circuit such as the following design:

https://www.homemade-circuits.com/simple-220v-smps-buck-converter-circuit/

Hello how r u

I want to know that transformerless 5 kva circuit will work satisfy or just for ..

It will work satisfactorily if you build it correctly.

Block diagram and its function

Thank you very much for the kind information, appreciate it.

Hi Seagatam,,,I built a tl494 circuit,,,I made use of z44,,,,,but they keep getting hot with or without load

Hi Md, read the following article, and try implementing them as required:

https://www.homemade-circuits.com/mosfet-protection-basics-explained-is/

IN IRS2453 CIRCUIT FOR 50HZ WHAT IS RT AND CT

Rt is the timing resistor and Ct is the timing capacitor, these parts determine the output frequency.

Rt,100k ρυθμιζόμενο ct100n ,όλα εντάξει αλλά τα ,hz παρά πολλά.

Your detailed step by step teaching is awesome and simply top notch! Keep up the good work!

I will need your advice on two things

1. Need to purchase a low power variable single phase high frequency AC supply. Can you recommend one for me please?

2. I need already built inverters with the high frequency intermediate state as shown in your design. I need your recommendation please.

Kind Regards

Hi, Thank you and Glad you liked the post!

Sorry to say this, but since I have not used any readymade VFD or inverter so suggesting a specific brand may not be possible for me.

Thanks very much Swagatam. I really do appreciate your sacrifice of time. Please I will need your support to deliver on this project. even if it is for a fee. You have my email address, do message me privately please.

You are welcome Achor! I above circuit is recommended only for the experts in electronics, not for the newcomers. If yu are well versed with electronic circuits and ferrite inverters then you can try this circuit.

Thanks very much. With respect to the 5Kva system , on no load condition, please what amount of power loss do we incur on the ferrite core with the high frequency(50-100khz) input supply?

I am not exactly sure about it, but the efficiency should be around 90% for the above designs without a load or with load.

OK, thanks very much. That gives one an idea of the power loss.

Kind Regards

No problem!

Thanks a lot Swagatam for your good works. I’ll appreciate if you can give me a circuit to convert my 110 VAC 5kva Colman inverter to 220 VAC. And I’ll also like to get a circuit design for 12 VDC car battery charger. Thanks once again.

phanyessence@gmail.com

Thank you Epiphany,

You will need an external 100V to 220V transformer for converting your 110V to 220V.

For the battery charger you can investigate the circuits provided in the following articles:

https://www.homemade-circuits.com/opamp-low-high-battery-charger/

https://www.homemade-circuits.com/high-current-10-to-20-amp-automatic/

Good details…i like your work..I am interested in making an altenator using microwave transformers iron core,by welding them in multiple together to form three octagons from those cores and join them together, then winding as many turn of copper as possible to produce lets assume around 310v with frequency higher than 50/60hz as the rpm of neodymium magnet inside the core shall be aim high to increase the output….then rectify it to high Vdc…and then inverting it to 220v ac at 50hz…Asking for any assistance and guidance to best approach ….thanks

Thank you for your question. Please let me know what help exactly you need from me, if it is possible I will surely try to solve it for you.

Swagatan, well-done and thank you for your services and contributions to the spread of knowledge in electronics. I was designing a 3KVA inverter using SG3524 as PWM pulse generator and 2N7000 for the driver stage. I discovered that the biasing resistor one side of the driver stage was always getting hot. Initially I used 1/4watt resistor and later changed it to1/2watt resistor but the result was still the same. Kindly advise me on what to do. Thank you.

Thank you Oyekan,

That is very strange because 2N7000 is a MOSFET and MOSFETs have a high gate impedance, which means the bias resistor connected with the gate have negligible flow of current through it.

It seems your MOSfET is burned or faulty, otherwise the gate should provide a high impedance to the resistor and it shouldn’t become hot under any circumstances.

Try replacing the MOSFET with some other mosfet and check the response.

a narrow width and a large width when passed through photochromic retainers, while passing through ferritic transformers do not retain the essence, so the project using ferrite transformers will not be successful because when smoothing it doesn’t produce a sine wave

đã ai thử thành công biến tần ferít chuyền trực tiếp sin pwm qua biến áp sung ra 220v sin cho mình tham khảo với. Mình đang muốn áp dụng đối với biến tần hòa lưới.xin chân thành cám ơn

bạn có thể chạy giả lập mạch biến tần ferit xem có hoạt động được không. dang tín hiệu sau khi làm mịn có thành sóng sin thuần túy không cám ơn bạn nhiều mọi người rất quan tâm điều này

Can you design a grid-tied inverter using arduino, won’t it help people to make their own small-capacity grid-tied inverter at a reasonable price, thank you very much

Sorry, My Arduino knowledge is not good, so it won’t be possible for me to provide the mentioned design

Can you tell me if the inverter uses a ferrite transformer to produce a sine modulation using a 3 mf loc capacitor to flatten out to 50hz is it possible. I can apply this to the grid-tied inverter IC 555 on the right, replace it with 50hz of grid power, ic 555 on the left, create 50khz and mix with 50hz to produce sine pwm to put into load-coupled power through the ferrite transformer

No, none of the above circuits uses a capacitor to flatten the 50 Hz….but if you want you can try it.

mình thấy có mạch này https://www.homemade-circuits.com/wp-content/uploads/2020/08/simple-ferrite-core-inverter.jpg

It is supposed to be a pure sine wave inverter, therefore the output capacitor is placed to smooth the SPWM into pure sine wave.

I made a post but I did not see it, anyway I have a different perception. I need some insight on the following design. I plan to connect 12, 48v solar panels in series which is 576VDC max. Therefore, I want to design an inverter with 600v input. A pure sine wave might not be that important because it will only be feeding resistive loads. Meaning water heaters, hot plates, solder irons, stoves etc. I can convert the AC output to my desire. I can place a sensing circuit to turn off when the power drops certain value. I will not use a battery backup, therefore, this is a standalone unit. It should shut off or turn on as the power drops to a certain threshold or when the sun rises the the next day. If 2, 300v inverters are better with 6 panels in series, please recommend that design.

Since resistive load is involved you can drive them easily DC supply also, why do you need an AC inverter? If you connect the 576V DC to the load they would still operate.

Thank you for your reply. Can you explain how can I connect the 576VDC to a hot water heater that uses 240VAC. I will connect 6 panels each in series, therefore, I will have two 288VDC and 8amps per phase. I am afraid that is too high for equipment that uses 120VAC per phase. I believe that I will not need a voltage sensing circuit, because the equipment will cool down when the power drops. Do you think that a restive load with low voltage or low current can harm a circuit. A circuit that reduces the voltage to a manageable level is the only device I might need.

You can reduce the number of series solar panels so that the DC becomes around 260 V for the heater. You can make some arrangement through which you can quickly adjust the number of panels in series or parallel to suit a particular device.

To reduce voltage you can try adding the following simple shunt regulator circuit

https://www.homemade-circuits.com/wp-content/uploads/2021/12/solar-panel-shunt.jpg

Thanks a million my brother, I finally have a plan to provide free energy to my relatives. In a couple of years, I plan to install an inverter to provide a clean sine wave. I will observe how this system work before I do any changes, anyway from me and my relatives, we appreciate your expertise.

I am glad you found my suggestions useful. I wish you all the best with your project!

I tested it with a 3-phase H-bridge because the motor is 3-phase AC . I will test next week with a single phase H-bridge . It would be great if I got +/- 12 V, ie V (p-p) = 24V from DC 12 V, I would basically have a voltage doubling. I am interested in getting 400 V DC from 100 V DC, so 2 H-bridge and filtering rectifier circuits would be enough, which is much simpler than that transformer. I want to thank you for your time and I will let you know the progress of the tests next week. Have a wonderful day !

For a 3 phase driver the case is different, and it will require 620 V peak as suggested by you in your earlier comments. It is because normally we use 440V RMS for a 3 phase load.

Presently I cannot figure out how 400V can be achieved from a 100V supply through a H bridge circuits…let’s hope it works.

I wish you all the best!

Congratulations on your impressive work ! However, after 7 years since you published the project, someone tells you that you made wrong calculations, it seems that no one has practically made this design. From the 310 V DC voltage you cannot get an AC voltage of 220 V but only 110 V with the H-bridge. You need 620 V DC to get 220 V AC. You can get 620 V DC from 220 V AC with a simple scheme with 2 diodes and 2 capacitors. If I manage to make the transformer, I want to make the part of 330V DC .

P.S. The same error is true for other H-bridge inverter schemes.

Congratulations, you are partially correct. For a square wave generator the output will be 115V from a 310V DC but if the H bridge is SPWM sine wave, then the output will be 220V from 310V DC

Actually NO….the AC output for a square wave will be equal to its peak value….in H bridge for a 310V DC, the output will also be 310 V AC.

I am also an electronics engineer since 1990 but I work in the IT field, electronics being a hobby. Recently I decided to make a VFD circuit to control an AC motor and I studied the theory again, when I found out that I need 650 V DC to get 230 V AC and I said wow, it can’t be possible … I can’t attach images that would be suggestive but we have this: the AC mains voltage has V(rms) 230V (for me), the peak voltage V(pk) = 325 V and the peak to peak voltage V(p-p) = 650 V. The V(p-p) voltage produced by the H-bridge cannot exceed the voltage V(p-p) from the power supply, so if V(p-p) = 310V then, after the H-bridge, we will have V(p-p) = 310V (maximum, real 300 V or less) , V(pk) = 155 V and V(rms) = V(pk)/1,414 = 110 V (sine) or V(rms) = V(pk) = 155V (rectangular). I wish I was wrong, but ….

I am afraid you are wrong. I don’t know what results you got from your VFD experiment, I just want to explain in a very simple term.

How does the H bridge function?

It simply switches the 310V DC supply alternately to the load. Meaning for one positive cycle the load gets the 310V DC, and for the next cycle the load gets -310V DC. So at any instant the load is getting the fully 310V DC, this means the peak and the RMS are both 310V for the load.

The 1.41 value does not apply for square wave AC, it applies only for sinusoidal wave AC.

Just rectify the output from the H-bridge through a bridge rectifier and check the voltage on a meter, that will tell you what RMS exactly are you feeding to the load.

I have already tested this with a 12V powered H-bridge and an oscilloscope. I invite you to do this. We’re not talking about a charge pump.

P.S. I wrote above: sine wave (sine) – 110 V and rectangular wave – 155 V.

Your scope may be giving wrong results, or your H bridge may be faulty….it is straightforward calculation….no scope is required. You must investigate why you are getting this result for a single phase H bridge??

for a 310V Dc bus, A Single phase H-bridge will produce 310V DC on one direction and then 310V DC on the other direction to create one positive half cycle of 310V peak and a negative half cycle of 310V peak, there’s nothing complicated in that.

The H bridge will not cancel or terminate any part of the DC for a square wave output….for sinewave some portion of the DC will be cancelled or chopped of that is why we have to consider the 1.41 factor.

650v để ra 220v soay chiều thì phải dùng mạch nửa cầu h không phải toàn cầu h điện áp lấy ra ở giữa 2 tụ và giữ nửa cầu h

sir,the third circuit with two 555timer and a ferrite transformer at the output,my question is can that work for domestic appliances because,to me ferrite core works at high frequence to turn on.or how can they work with home appliances at just single stage?please sir,i want to be clear with this.looking forward to your quick answer

Eniola, if you build everything correctly, then this circuit can be used for any electronic domestic appliance. The 555 circuit is a 50Hz circuit…with 20kHz PWM…so it will ultimately produce 50 Hz at the output

Okay, also the ferrite transformer will be calculated at what Khz? when calculating the turns ratio.

The frequency of the fast triangle waves which is fed to one of the op amp inputs

Please sir i need further explanation on ready made 12v to 310v to 5kv please thank you.

sir, thank you for the lecture .I don’t know what to do my 5kva 48 inverter when connected its will be working normal all of the sudden the out put voltage will just go up and burn some light what should I do to rectify it. Thanks

Isaiah, I think it may be due to malfunctioning of the feedback control, which may not be regulating the output voltage correctly. Or may be the there’s no feedback control present in your inverter…

hey how do you calculate the transformer for the first circuit with h bridge at the output? I mean by the some core information or inductance of the windings

Sorry I do not have the inductance value for the winding, I only have the number of turns, as mentioned in the article.

Good schematics dear swagatam

Isn’t it easier to put 19 12 V batteries in series to add up to 228 V and put them in the oscillator that creates the 50 or 60 Hz frequency? You protect the whole installation with automatic fuses and you have as many kw as you want.

That is what we usually do in most high voltage inverters, however, maintaining 19 numbers of batteries may not be easy.

Please sir how can I increase the power of my inverter up to 10000 watts

by upgrading the transformer, mosfets and the battery accordingly.

Hello sir khalid here how are you sir hope you well our prays with you. Sir i need help sir i change the winding of ferrite transformer i am using 3+3 EE80 cores now i am getting 145dc from from output and the frequency is 450khz before there zero volt and frequency was very as i said i am using 10k pot the frequency not decresing it is in last point still it can be incresed but not decreasing to get 50 htz what modification required with ic to get 50htz please need help sir.and now the transformer is giving output sir thankyou very much you are my teacher sir please reply i will try to get success by your help please waiting for your reply i will back with result thaks sir plesae take care.

Hello Khalid, the frequency of the first SMPS should be below 100 kHz, 450kHz is very high.

I think you should try the 555 IC version instead, which is much easier and will fulfill the same results:

https://www.homemade-circuits.com/wp-content/uploads/2020/08/simple-ferrite-core-inverter.jpg

Hello sir thank you very much for teply sir the osdilater is working its giving from 890.5 to 990 .5 kilo htz i checked with digital multimeter it has frequency reading option. Before joing the circuits all i was checked seperately it was working then i was joined together . Now i checked osdilater is working. The winding i did on bobbin i made by hand with plastic sheet.the voltages going but output not coming from transformer so we have to make another winding or what .please reply sir i am waiting your help thank you very much for your help and cooperation i will be back with result. Please take care .khalid.

Hello Khalid, 990kHz looks very high, almost 1MHz, I don’t think the IC is configured too produce this much frequency. It should not be more than 100 kHz. In the article it is clearly written the max frequency as 40 kHz, You should read the article fully for understanding its working.

Hand winding will not do, it should wound with machine and with great accuracy. The e-cores must have a paper gap between the edges. Please get it done from a professional transformer winder

As I cautioned you earlier this circuit is for people who are well versed with the basics of SMPS, it is not recommended for a newcomer.

If you are new to this, you must first try smaller SMPS circuits and study their working by experimenting with their transformer winding and the effect of frequencies on the number of turns.

Hello sir khalid here how are you sir i did the 5kva above reffering to 60v i got ferrite cores and i did it complete as it is in the drawing and for testing i used 14 o 14 v transformer it is 28 i used 4 diodes and 2500 uf capacitir after capacitor it is showing 40 volts and i am also using 22 diodes to reduce volt from 60 to 50 because i am using 317 ic to supply 12v to ic irs2453 after testing sucessfully i will use 60v supply but now i am using transfoer 28v so i adjust the supply to 12v for ic irs2453 its ok and also i am using same 12v to transisters pwm insertion which is plus 15 mark is there . Now every thing is good but the ferrite transformer is not giving outputi remove the connection from 30 amps diode and checked no output but another with centre tap i gave the supply ot is showing 40v but no output the tonnes and guage and strands i make all as you said 5+5 and 18 but no output what will be problem and the supply to pwm insertion transister with same 12v with ic irs2453 i connected so is this good or we have to connect different 12v. And the transformer i have change the again or what .please reply me about this two problems. Thank you very much for your help. And take care. I will be back .

Hello Khalid, solving a ferrite core SMPS problem can be very difficult without checking the circuit practically. So I cannot troubleshoot it correctly from here.

There are few basic things that must be checked.

Is your oscillator circuit oscillating correctly, and with what frequency?

Is the ferrite transformer correctly wound with a small gap between the ferrite core edges?

Are the MOSFETs conducting optimally?

So basically you must check all the stages for ensuring that they are working with perfection.

You must also have an ammeter connected with the supply to check if the current consumption to circuit is getting affected.

Even with a slight mistake your MOSFETs can blow and create more confusions.

Hi Swagatam,

Thank you for looking but that is not the one I was looking for.

I’ll keep looking.

Tom Kenefick

No problem Tom, hope you are able to find it quickly!

On thing I haven’t seen on youtube or your site (I hope I searched adequately) is a tutorial on how to smooth distortion from the typical brushed gas generators that people buy just about everywhere.

I saw one such video on youtube that smoothed the output by running it through an AC/DC charger, to a battery bank, on finally to a sine wave inverter. Not really what I would consider a video on “smoothing” gas generator output.

Any interest in giving this a few minutes with pen and paper? 🙂

You have a great site, BTW. Your efforts are much appreciated!

Thanks

Doug

I guess the intended output is a DC? In that case the output can be smoothed using a filter capacitor? A battery is also great compensator, and will smooth just about any form DC ripple and fluctuations, while also getting charged through those ripples.

So a large capacitor across the battery terminals along with the generator output connected across the same battery terminals can assure a clean and a smooth DC for the inverter.

Hello sir how are you hoping you well.khalid here thankyou for help your guide and and reply . After success of simulater circuit .now i recieved ee80 cores for 5kva inverter the circuit before was made but the ee80 core was not found but now i got from online and make bobbin i wanted to verify the bobbin from you buy sending the photos so how could i send the pictures. And i rapped 5tones primary and cut the wire after secondary 18 tonnes i will make another 5tonnes but i want to send the bobbin picture.and after completing complete transformer i will send again picture to you after assembling .so please reply .thankyou very much please take care i will back.

Hello Khalid, I appreciate your interest in this circuit, however it is duty to caution you that this is a complex SMPS circuit and is not recommended for newcomers in the field. Because if you are building it for the first time without prior knowledge SMPS and ferrite transformers, then you could run into problems, and it can be difficult for me to understand the fault and troubleshoot it through comments.

So I advise you to proceed with caution, if possible start with a smaller design first, gain some experience and then try this design.

You can send the pics to my email, which is given in the CONTACT page.

Hello Swagatam I am Kallol Bhuiya. I want the output 50 Hz 220 v AC will be pure sine wave. so kindly give me this type of circuit. it will be very helpful to me. (load approx 10kv max)

The circuit output mosfit transistor n channel or p channel?

Good sir. Please what is the power rating of the “simple ferrite inverter” designed above for the new comers..

It is around 100 watts

Hi Swagatam,

I am wondering why you don’t directly low pass filter the output of the high frequency transformer using a LC filter to obtain the 50Hz sine wave.

What is the point in rectifying the transformer output and then subjecting the DC obtained to an AC conversion. Why not just filter out the HF components at the Ferrite transformer output itself to obtain the sinusoid?

Regards

Ankur

Hi Ankur, I am not sure how an LC filter can be used to convert a 220 V 50 kHz signal to 220 V 50 Hz at 5 kva, please explain in more detail

Hi Swagatam, A PWM (eg. carrier at 100KHz) signal modulated by a 50Hz sinusoid will produce a spectrum with a peak at 50Hz along with its attenuated harmonics. These harmonics when filtered out by an LC filter at the HF transformer output will result in a 50Hz wave.

A ternary (3-level) PWM will have further attenuated harmonics.

Regards

Ankur

Thanks Ankur, that makes sense! If time permits I’ll try to update the design in the above article.

Dear sir, according to the schematic whether the 310VDC High frequency inverter has been tested and works well in providing 5KVA power, with 8 mosfets. this source determines the reliability of the inverter. if the DC supply from the battery available is 120v, it is necessary to calculate the number of primary turns of the HF transformer.

Regards,

Widiatmono

Dear Widiatmono, yes it is tested, but it is recommended only those who are experts with SMPS and flyback designs. Yes it is strictly necessary to calculate the ferrite transformer under all circumstances.

Dear Swagatam,

If you don’t mind, please correct the calculation for the number of turns of the inverter that I built, with a DC voltage of 120volts according to the formula, N = 120×100000000 / 4x50khzx1500x2.1 (etd59), the result is 20turns so that the primary is made CT 2x20turns. for mosfet using 8x IXFH50N60P3 and is being considered using igbt

Thank you for your help, I really appreciate it

Widiatmono hersan

Indonesia

Hi Widiatmono, It looks OK to me. Using MOSFET will be a better option initially, since they are cheaper than IGBTs and their datasheet is more familiar.

Hi. please can you help me. I use sg3525 ,I choose rt=22k, ct 1nf, rd=56ohms.which gives oscillator frequency at 64khz. so each mosfet switching at 32khz. My question is during calculation of primary turn of ferrite transformer, which frequency (F) I have to consider in the formula (vinx10^8/4×FxBmaxxAc) ? 32khz or 64khz? Many thank’s man

Hi, it is 32kHz which must be taken into account while calculating the primary turns

He sir khalid here hpe you are fine.i recieved irs2453 from online i did other corcuits completed for 5va inverter now H bridge i am doing i want to ask the caps connecter to ic irs2453 from pin 8 to 10

12 to 14 is this polarised or non polarised .and another doubt we can give directly 60 v to ic irs2453 as through 33k resister as shown in diagram no problem or is there any problem please im waiting for reply thanks .but now only remaing EE80 core online not avaluable also.but im in search may i can get until i finish the complete circuit.i am waiting for reply i will back take care.

Hi Khalid, those can be polar or non-polar, it is not critical.

you can also try the following circuit which is simpler than IRS2453

https://www.homemade-circuits.com/wp-content/uploads/2019/11/full-bridge.png

Hi Swagatam,

We’re working on solar-powered air conditioning and need a board similar to the one you have here. It’s up to 380v solar DC input or 120v alternating current input, and then it supplies 310v DC to the electronics in the air conditioner (compressor and fan motors). Is this anything you can help with, or can you advise who you can refer me to for this?

Thanks,

Dave

Hi David, A ferrite based transformer might require some serious calculations and some practical experimentation, so it can be difficult to suggest without doing these analysis in a lab, which may not be possible for me due to lack of time. Sorry, I do not have anybody else who may be willing to do the job for you.

Great design, Please confirm that this is a pure sine wave design .What changes is to be made if we are building a 1000w circuit ?. How can we include a EGS002 module into the design .

Thank you, it is not a sine wave design. For 1000 watt you will have to upgrade the transformer and the mosfet specs accordingly

Pls I need you help with these. Thanks in advance, you are the best.

1. How to incorporate a changeover/charger circuit to this existing circuit

2. How to incorporate a low battery shutdown circuit.

Thank you Chris, However, I would suggest you to build the unit successfully first, once you complete it then we can proceed with the further enhancements.

Wow, wow wow. Thanks a million Swagatam. You are the best

Good day sir, thanks for the informative article, I attempted building the inverter, I used sg3525 to generate a frequency of 50khz, I used mosfets irpf3205 in a push pull topology, I wound a ferrite core transformer 3 turns (twice to form center tap) on primary side using 6 strands of 0.45mm wire and I made 96 turns on secondary using 0.45mm wire..my challenge is that once I connect the center tap to my 12v 100AH battery, the battery voltage drops quickly and the negative trace of the circuits burns off causing a open circuit, I have rewound another ferrite core transformer but am getting same problem,the oscillator and mosfets work well without transformer but once I put the trasformer the negative rail melts and battery voltage reduces rapidly and stabilises back to 12v when the track is melted….pls sir how can I correct this.

Daniel, your described inverter is completely different to the one which is explained above. Moreover, ferrite inverters are always difficult to optimize, because they need many calculations and sophisticated gadgets to test, so it can be difficult for me to judge your design problem.

The IR2155 inverter section explained in the second last design is an easy option which you can probably try. You can replace the IC with sg3525

Dear Swagatam,

Am highly astonished at your knowledge of electronics circuits. Really grateful to come across your post. Under the section ” Making a PWM Version” I have a few questions;

1. How easy is it to incorporate to this existing circuit an input changeover/charger circuit?

2. How easy is it to incorporate a low battery shutdown circuit.

3. Lastly, to increase the duration the inverter can provide the power, can I cascade 12VDC batteries say four(4) together with this circuit ?

Looking forward to your anticipated response.

Thank you Dear Dyani, all those features can be easily included in the design, however making the inverter section is the most difficult part. Other features can be easily added once the inverter is built successfully and thoroughly tested.

Thanks ok but only confusion with negative lead of capacitors .negative will connect up or down side this i wants know .thank you very much sir for reply i am waiting.

Khalid, Capacitor negatives are connected with the MOSFET sources

Thanks a lot for reply sir khalid here. i want to ask the capacitor which is connected pin 10 and 14 of irs24531d where the negative leg to be connected please reply thanks .

they should connect on the spot where the black dots are shown…

Thankyou very much for reply sir i forget to ask where the negative leg shold be connected of cap

Ic ok but if ee80 not found so what other number of ee core mathes for this particular 5kva circuit please reply thanks. Khalid.

the full bridge circuit negative/positive will connect with bridge rectifier output. The bridge rectifier should be connected with TR1 output

the core should e such which comfortably accommodates the total winding of the transformer…

this circuit is for the EXPERTS ONLY, so please proceed with caution.

Hello sir hiw are you khalid here i got ic irs2453d but in diagram it is irs24531d is this ok and second thing in full bridge circuit 1uf 25v is this polarised or non polarised .please let me know i will be thankful. Now i got components but still EE80 not found inshallah until my circuit is complete i can get .only ee80 is required or we can use ee85 for the same data.thanks.

Hi Khalid, it is one and the same and will work.

1uF/25V can be polarized, but please try 10uF/25V instead which is more suitable for 50 Hz frequency. If the rating of the diodes are the same then you can use them.

Hai sir khalid here thank you for reply i have one question for 5kva inverter i am referring to 60v circuit . For high frequency circuit i used irf 740 as you mention but for full bridge inverter in irs24531d circuit can i use irf 640n 4pcs because it is avaluable with me. and for rt what value of potentio meter i can use plesae reply i will be thankful waiting for reply.

Hi Khalid, whenever you are in doubt about a MOSFET, you should check the datasheet of the device, and confirm whether its VDS (drain/source voltage) and ID (drain/source current) matches the supply voltage and load current respectively or not. If the datasheet specifications are higher than the required specifications, then the MOSFeT is OK, otherwise not.

Thanjs fir reply sir so i can use 10uf 50v non polarised instead of 1uf 50v is this ok please reply thanks because in circuit both legs showing black of 1uf 50v thats why i confused polarised or non polarised.

You can use polarized or non-polarized both will work.

Hello sir khalid here again hope you are fine.i have question. I make the circuit high frequency and oscillator but not tested because i am waiting for ic irs24531d may be i can this week online 1st question can i use different mosfets in full bridge side means 2 irf7460 and 2 irf 640n or should be all four same. And 2nd what is rt and ct value and if i want us a pontentio meter what should be value please i am want to the value of capacitor and resistor ct and rt of full bridge ic irs24531d .thanks waiting for reply.

Khalid, you can use any MOSFET as long as its rating matches the required output voltage and current specifications.

The Rt Ct formula is given in the following article, or you can also experiment it through trial and error using a frequency meter.

https://www.homemade-circuits.com/simplest-full-bridge-inverter-circuit/

Hai any have made this 5kva inverter because i cannot find EE80 F core and irs2453 ic in india and also online so please if got success making the circuit wheather same with the ic and F core or any substitute if suceeded please send the details of substite ic and Fcore please send picture and details o wil be thankfull to swagatam sir and others thanks.

Thanks Khalid, the above design is a tested one, but it was tested by other members not by me, so it can be difficult for me to provide precise suggestions.

Please can you help me with pic16f877a inverter Code + Simulation + PCB + Schematics + Gerber Files

You can refer to the following article…

https://www.homemade-circuits.com/sinewave-ups-circuit-using-pic16f72/

It is all that I have in this website…

Plz sir can I get the PCB details file for the 3kva ferrite based inverter? Thanks so much for your supports

I don’t have the PCB details at this moment, if possible I’ll try to update it in near future.

Good day sir…How can I generate a sinewave using this microcontroller 18f26k22?

Sorry Shilex, I have no idea about it…

Good day,

This is a great article. I’m interested to utilise the circuit to drive a 3kw load.

My energy source are PV solar panels.

My planned configuration is 6x320W panels in series (1920W rated energy, practical power is about 80% at 1536W)

with another 6 in parallel. The open circuit voltage is about 200V and under full load falls to about 180V at 8.5A.

With 2 sets in parallel its 180V at 17A.

If the input DC power from the solar drops, due to clouds or sunset/sunrise, what will be the effect on the primary boost phase? Will the circuit at maximum PWM just not be able to reach 310Vac@50kHz, causing the amplitude of the output to drop below 230Vac rms at 50Hz?

The transformer winding calculation resulted in 25 primary and 45 secondary turns. Are the number of turns still practical or won’t it fit on a ee80 core given the wire guage required to transfer 17A?

Hi, thanks, and glad you liked it…if the solar voltage drops, the output would also drop proportionately. I am not sure about the winding data, because it’ll need to be done with some calculations or with some trial and error.

Hi Swag, Thanks for all your interesting projects. I would like to know whether it would be possible to use two of these modules in tandem to produce a 1000 watt inverter. Also the input voltage must be 24v instead of 12 volts. Could you please give slow and understandable instructions and maybe a sketch to a guy like me who is not so smart in electronics? It would really be appreciated. Eric Smith.

Hi Eric, you can try that by modifying the transformer differently. I would recommend the 3rd circuit from bottom. Instead of 13+13 turns at the primary you can try 10+10 turn, using 2 numbers 20 SWG super enameled copper wire in parallel. For secondary you can use 24 swg 250 turns.

Build and test each section separately and stage-wise….having said that, this circuit is no way recommended for any newcomer, so please proceed with caution.

Dear Mr. Swagatam,

While making the ferrite core transformer I was using a cutting knife blade or a #180 sand paper to remove enamel coating of winding wires. This is tedious and time consuming. have you got a better way of doing it?

Thanks.

Hi Gamini, you get a special solution (chemical) for cleaning the super enamel of copper wires, you can inquire it online for the details.

Ok sir thank you very much i am reffering to pwm 90 supply volt seond circuit is resistor type 10uh inductor ok for it or not .and i bought diode of 40 amps because 30 amps not avaluable its good or not. And ds812 06a zener not avaluable so is there any equivalent for it.and ic ir2453 1d still not found but i am trying for ic may i can found. And ee80 ferrite transformer core i not found i am trying also for this.but for diodes and inductor i want your answer please reply and also the number ds812 06a zener is this number correct.iam waiting for answer thanks.

For the diode you can use the following:

https://www.digikey.bg/product-detail/en/ixys/DSEI12-06A/DSEI12-06A-ND/241965

yes the small resistor type induct0r will do

Hello sir thanks for reply.i bought inductor 10uh it is resister type not ferrite ring it will be ok or not or require ferrite ring type please reply thanks

Hello Khalid, which circuit are you exactly referring to? Please note that this circuit is very complex and is intended only for experienced engineers and needs to be built with sophisticated measuring equipment like oscilloscopes and digital meters, so please proceed with caution.

Ok Thank you very much but mosfets required to fix with mica between heatsink and mosfets to protect short with mosfets and heat sink or we can fix the mosfet without mica on heat sink . This is my question please let me know .thanks

Mica is recommended if you use a single common heatsink, if you use separate heatsinks then no need…

Hello sir khalid here i bought some components for 5kva inverter i am trying to build each circuit seperate one by one my questio is all resistors are 1 / 4 or any different watts available if there is which please tell me.and 2nd question is all bjt’s should be fixed with mica on heat sink or can be fixed without mica on heat sink please let me know .as i make the circuit i will send the picture each circuit thak you very much for your cooperation and help to us.

Khalid, yes all the resistors are 1/4 w 5%.

Only the MOSFETs will need to be mounted on heatsinks, not the BJTs.

Always use a heavy duty bulb in series with the MOSFET drains, this will ensure that the MOSfETs are never burned due to a mistake or some other fault.

Hai khalid here thanks gor reply i have some questions. If i am going the last circuit of 5kva with 360 tons inductor i want to the connecting points for batteries and the charger points from grid and if i suppose to make solar so where the connecting ponts please.and i saw your dual charger if that we wants to connecte how to be connected and what chages the dual charge circuit requirwd please this is the question .i am gathering parts if i get success i will send the images and result.thanks again.

Hello, this circuit is for the experts in SMPS projects, so please proceed only if you have prior knowledge and experience with ferrite based SMPS concepts, otherwise you may find it extremely difficult to succeed. Please first make the initial basic design successfully, afterwards we can discuss the other parameters.

Hai sir i am planing to make this inverte as you said in in the article the readymade module if we use it will be very easy the module i saw on net it is 500watts is this ok it operates only on 12 vots please reply.

Hi Khalid, if it’s rated at 12V then it must be operated with 12V only. It is OK to use it

Hello sir you are helping alm over the world its really a great help to us

Thank you khalid!

Dear Swagatam

May the almighty reward you for teaching the world free of charge. Ive been your student since 2014.

I will suggest you should establish an online electronic university which awards degrees so that you reward yourself rather than relying on peanuts from Google. Think about it.

I’ve some question as per the above 5kva inverter .

https://www.homemade-circuits.com/5kva-ferrite-core-inverter-circuit/

1. Stacking of two ee80 ferrite cores for larger power , how do I design the bobbin that will fit the winding? Or do I wind on the center arm of the core directly without bobbin ? Please explain.

2.If no ee80 cores available, How many ee55 cores can be stacked together to obtain such intimidating KVA?

3. Can you give me a link online where I can get more information on stacking of cores together for obtaining monster power ? I’ve googled my eyes out without any

Thanks.

Thank you Dear Davidson, I appreciate your thoughts.

As we know, ferrite transformers are not easy to calculate, so estimating something without calculations can be difficult.

Here, I am not sure how many of them can be stacked up, and even whether it is recommended or not.

For experimenting you can try 3nos of ee55 and check whether that satisfies the requirements or not.

You can create a hand made bobbin using a cardborad wrapped up on the center limb of the e core.

you can try this link for reference:

https://electronics.stackexchange.com/questions/96435/making-a-bigger-transfomer-core-by-stacking-multiple-smaller-cores

hello Sir,

Please do I need to design additional feedback control circuit for the low frequency oscillator which switches the 310VDC to 220VAC or will the output AC be automatically 220VAC due to the 310VDC rms?

Hello Kingsley, A feedback can be added for better output regulation. You can try the last concept discussed in the following article:

https://www.homemade-circuits.com/load-independentoutput-corrected/

The transistor collector can be connected to the Ct pin3 of the full bridge inverter IC.

Thank You Dear Swagatam.

Please I want to ask these question(s) that keep confusing me about the high frequency ferrite core inverter.

I want to know if the rectified high frequency 310Vdc will share the same GND with the H-bridge MOSFET in the 50Hz low frequency AC switching side? Again, will the GND of the two oscillators (the low frequency and the high frequency oscillator) connect together as common GND with the battery negative? Please help me I am using high frequency SG3525 oscillator to drive the ferrite transformer and everything works fine; the high frequency 310Vdc is obtained without trouble but each time I connect the obtained high frequency rectified 310Vdc to the common drain and common Source of the H-bridge MOSFET on the low frequency side, I ended up getting nothing at the AC output. I tried placing the digital multimeter at the +ve and _ve of the rectified 310Vdc to observe if the voltage remains the same after the connection and only find out that the voltage withdrwas to zero. This process has burnt My H-bridge MOSFETs on the low frequency side a couple of times and once i insist on checking the fault, it even get some of the MOSFETs on the high frequency push-pull side burnt too without separating the two(2) oscillators. I am using IR2110 * 2 to drive the H-bridge MOSFETs and have connected all the GNDs together including the GND of the rectified high ferquency 310Vdc, GND of the two(2) oscillators, and GND of battery. In the rectification, I used UF5408 ultra fast diode rated at 3Amps each.

Please help me sir. Thank you in anticipation of your response.

Hello Kingsley,

yes all the grounds or the negative s need to be joined in common. This is necessary so that the bootstrap capacitors associated with the IC is able charge through the low side MOSFETs while they are ON. If the grounds do not connect the bootstrap cap won’t respond and the circuit will fail to work

just make sure to connect a 1K across all the gate/source of the MOSFETs.

Thank You Sir. I already connect 10K from gate to source and 10R from gate to driving signal through IR2110. I used to do so for push-pull low frequency inverter that i have been designing for long and it works well there. Though I don’t know if that is the problem with the h-bridge counterpart associated with the high frequency.

Hi Kingsley, please make it 1K instead of 10K for fast discharging of the MOSFET capacitance

OK Thank you.

Please what is the acceptable range of values for the bootstrap capacitor? I am using 47uf. is that value acceptable or do I still have to reduce it?

Hi Kingsley, you can use any value between 0.1uF and 1uF if the frequency is above 20kHz

47uF is too high for 20 kHz and above, it may be OK for 50 Hz application

Hello sir, how do you determine the values of those components, say for example resistor and capacitor values for an arbitrary power output of a given design. For instance if I want to design a 5kva inverter

Hello Ken, it depends on which component it is being used, and under what V and I conditions. It will be different for a BJT, a capacitor, a MOSFet an IC etc…

1) actually sir i want to make half bridge with four mosfets each pulse with two mosfet without heating . i only have problem with two mosfets on single pulse that’s getting hot. how to solve the problem?

2) another problem is that once i have used two 47N60 super fet. each mosfet with single pulse of IR2110 they are not getting hot but also the smps not getting started and both pulse voltage of IR2110 dropped. i don’t know why the pulse dropped and the mosfet not turned on?

3) sir is it possible to make full bridge or half bridge with uc3843? as in the 555 inverter circuit diagram where single output drive full bridge with necessary transistor etc?

Hi Sheraz, connect a 1K resistor across gate source of each mosfet and check the response.

47N60 seems to have a separate source for the gate driver input, so make sure to use this separate source with the bootstrap capacitor of the high side MOSFETs.

You can try building a full bridge using any oscillator by using separate bootstrap stages for the external n channel mosfets, as shown at the end of this post:

https://www.homemade-circuits.com/simplest-full-bridge-inverter-circuit/

the 555 output pulse with bc547?

IR2110 is a half bridge driver IC, it must be used with two mosfets, single is not recommended. Use a 1K resistor across its gate/source and see if that stops heating of the IC.

Hi sir! dear sir i have the problem with driving two mosfet 20n60 with a single pulse of IR2110 driver. one mosfet get extremely hot. i made an IR2110 based smps it works fine with single mosfet on each pulse but can’t drive two 20n60 or 13n60 with single pulse. i have not added the buffer stage as shown in your IR2153 inverter circuit diagram. how can i drive multiple 20n60 or 13n60 mosfet with single pulse???. i connect two mosfet with single pulse of IR2110 with single 10R resistor at the gate pin but they getting hot and the pulse dropped not starting the smps. but fine with single mosfet. how to solve this problem?

Hi Sheraz, you must use the driver stage as suggested in the first diagram, otherwise the MOSFETs may heat up an blow. so please use the push pull stage and check again.

Dear Swagatam

Firstly very very thanks to you for your quick response.

Now my question is:-

01. Can I connect negative terminal of my home wall socket/grid line to output line of inverter’s any

one 220 VAC output line?

It might create a short circuit, because the LIVE from the inverter will try to short itself with the Grid neutral.

Thanks Swagatam, for your option.

I understand that it’s not possible to wiring China inverter’s

output line with mix to my home wiring.

But one thing I would like to inform you that, In my home IPS/UPS/Inverter system there is also two output line but when I check boths output line it shows one +VAC and another one is -VAC terminal.

My question is any difference is there for designing circuit for China Inverter System and other inverter/IPS/UPS system which is regularly used for backup system of power failure.

Dear Zahirul,

the UPS could be having an arrangement for a dedicated neutral line which allows the output to show 0V for the neutral wire, unlike ordinary inverters which do not have a special arrangement for the neutral.

Yes there will be a difference in the transformer winding specs and the switching specs.

The neutral line is basically a reference line, which enables the load to respond to the +220V and -220V alternating phases with reference to the neutral line…so the neutral by itself does not generate any current and therefore stays neutral.

So nice Swagatam, I understand all the matter.

My next topics is:-

I have two 1000 VA UPS which are run by two 12 VDC battery i.e input voltage is 24 VDC.

Now I want to convert this system to 12 VDC input system. If I use 12 volt transformer instead of 24 volt transformer for inverter system but circuit board is same as before then it will work or not?

If it is needed to convert circuit board also then how I convert the circuit board to 12 VDC input system.

Give me tips and topics

Thanks Zahirul, yes a 24V inveretr will work with 12V if the battery and the transformer are replaced with 12V equivalents. Changing the board may not be required but if it has 24V relays they also will need to be changed with 12V.

Awasom! I am very very please to you for your support.

Now I would like to know one thing is- if I make my inverter system is 12 VDC input system instead of 24 VDC by replace Transformer, Battery and Realys (if needed) then inverter’s VA/Watt rating will decrease or not?

My question to you-

01. If VA rating decreased then, Can I increase Watt/VA by adding more

MOSFET to circuit board?

02. Can I make 12v-0v-12v transformer by taking one connection from

between 24v and 0v of 24v-0v-24v transformer?

Swagatam, for your kind information I would like to inform you that-

I am making this type of inverter system for reduce the battery cost, why not already I have a one 12 Volt 160AH battery but my UPS required two battery. If I purchased more one battery then I have to spend more USD 150, now a time this is not possible for me. That’s why I am taking your suggestion for done the job nicely and correctly. Don’t fill boring.

Thanking you

Always, I will be stay with you.

Hello Zahirul,

The output wattage will depend on the input wattage.

The wattage is calculated by multiplying the transformer voltage with its current rating.

This transformer wattage must be satisfied by the battery otherwise the transformer will not be able to produce the rated power.

Mosfets are only like ON/OFF switches, they don’t generate power, they only switch power across the connected parameters. But they must be rated according to the transformer V and I rating otherwise they will burn.

The battery will need to be selected as per the required power output and the transformer wattage.

For a 160 Ah battery the typical wattage of the transformer can be 12 x 16 = 192 watts or 200 watts. Meaning the transformer primary must be rated at 12V, 16 amps or 20 amps.

Hello sir khalid here hope you well.sir now i assembled the circuut for rt i used 10k potentiometer is this ok and for ct from which value i should try and second thing it is electrolytic type or pf type please let me this 2 things .i will be waiting for reply and i will be back thanks please reply sir.

Hello Khalid, you will have to find the values either using the formula or with a frequency meter, Ct will be non-polar and a small value capacitor.

Hi I need u r help

Dear Sir

I am from Bangladesh. In my china 300 watt inverter system there is two ware for AC 220 out.

But problem is both two AC out line shows positive/alive (both wire light up the AC tester) that is I can not identify which one is positive terminal and which one is negative terminal. Why not I want to connect my inverter output to my home wiring because for power backup when grid line is off. For this purpose I will use auto cutoff relay system only for positive terminal of both grid and inverter system.

I need help from you for this problem.

Technical observation myself:-

When I check inverter circuit board I seen both VAC out line come out from two different MOSFET pairs

Source Pin.

Dear Zahirul, normally inverters do not have a neutral as our mains AC have. Inverters operate in a push-pull way which causes their output wires to swap between LIVE an Neutral alternately, therefore you may find LIVE on both wires since it is alternating across the output.

In utility mains, the distribution transformer has a common neutral and +310V/-310V phases which alternate with respect to the neutral producing positive cycle and negative cycles with respect to the neutral which always stays at zero potential.

What about using arduino to generate sinewave and voltage controller

Pls an you modified it to modified sine wave inverter

modified version is not possible because it will require modifying the dead time, which is not possible here.

Hi,

Thanks for this. It is very educative.

I am attempting to build an inverter of this capacity for everyday home use. The sources of power include AC mains (220v), Solar Panel (12-48v) and Lead Acid batteries. The most preferred source will be the solar panels, which can both charge the batteries and supply power at the same time. The next preferred will be to discharge the batteries when the solar panels don’t supply again; and then charge and supply power with AC mains should both initial sources are depleted.

I would be very grateful if you can give me a circuit for this. Thanks a lot!

Hi, please provide the details regarding the inverter wattage, battery voltage and Ah rating, and load rating, if possible I’ll try to help!

Thanks,

I’m looking at maximum of 5000watts inverter with multiple 12v 200Ah battery (the number of batteries will be flexible, but typically between 1-5 batteries of that rating), load will be between 1000 – 3000watts. Should be able to include one or two refrigerators (about 0.8-1A current rating, 220v) in the load, considering their starting power. Other appliances will be bulbs, TV set, laptop chargers, etc.

I would really be grateful for this!

Thanks for providing the details. The circuit provided in the above article is for experienced engineers, so I would rather recommend buying one from an online store and then configuring it through changeover relays and a battery charger.

Making the battery charger and the changeover stage can be constructed at home with my assistance.

I can attempt to build the above circuit, but my questions: the PWM version has 90v input according to the circuit diagram, can I use a 20A dc/dc converter and use with a 12v battery?

I also have a 1.5kva sine wave inverter, can I increase the capacity by changing the transformer and increasing the number of power transistors? What othe components of the circuit do I need to replace?

For a 5kva if you use 12V then the current will be 5000/12 = 416 amps which looks impracticable, that’s the reason why 90V and above is suggested for this design.

You can put many 12V batts in series for getting 90V or 60V

I am not sure whether it would be a good idea to modify a ferrite transformer of an existing inverter, because ferrite transformer require proper calculations for the turns and the core size, so I can’t suggest much on this.

In this circuit the rms voltage is 220v . It is aligned with preset

Yes that’s right!

Hi sir , I have seen your 5kwatt transformer less inverter circuit . I tried it using ic 3525 (because i can’t get ic 2453 ),gate ic 2110 and igbt kgf40n120kda with snubber of 10ohm 5watt and 10kpf 2kv.i have solar cell for 350v DC and it is used for input for this circuit. For stablized output , feedback also given through opto isolater 4n35. It’s all refered from your circuit. It’s good for up to 1.5 hp motor .

But, in case of electronic loads

TV get harmbars , tube light chokes gets fault ,phone charger,etc,.

Please reply me the solution sir .

Hi Sageyu, for sensitive electronics you will need to employ SPWM so that the output is turned a pure sinewave. I have many examples published in this website related to SPWM inverter which you can refer to for more info.

Hi sir good afternoon

Sir ,in some of your circuits additional pwm is given instead of spwm. Is it good for motor and electronic appliances. But its output (after filter),i have seen is not sinusoidal on CRO.

Sir do you have any camparator circuits for spwm.if you have please send me the http.