In this post I will explain 8 easy methods of building touch sensor switch circuits at home, which can be used for switching 220 V appliances ON/OFF with mere finger touch operat

ions. The first one is a simple touch sensor switch using a single IC 4017, the second one employs a Schmidt trigger IC, the 3rd one work with a flip flop based design and there's another one which uses the IC M668. I will explain the procedures in detail.

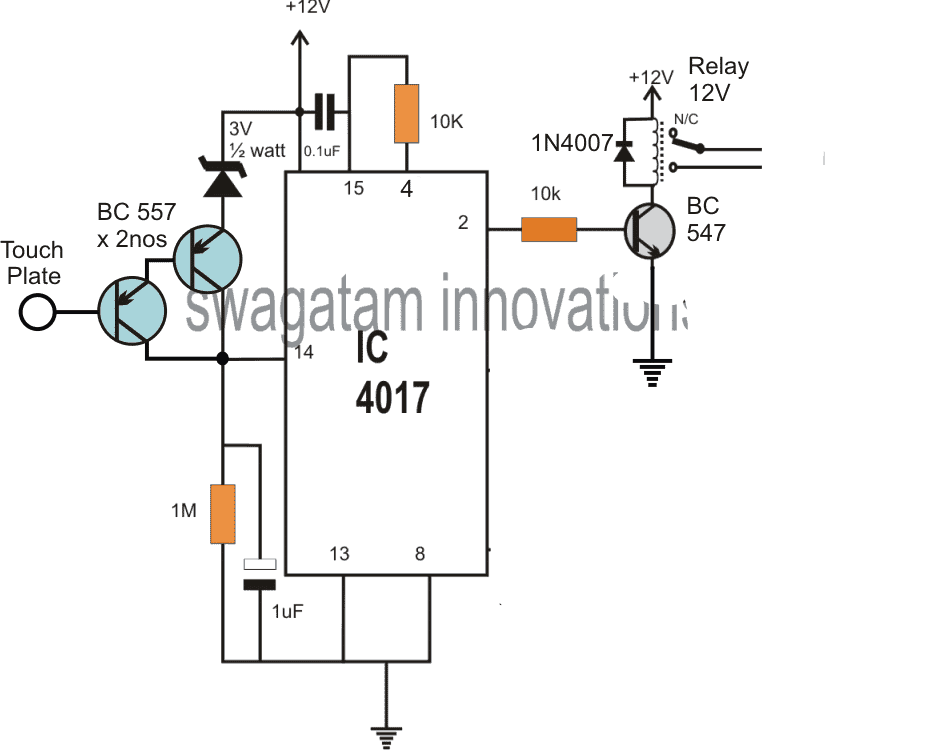

1) Using a 4017 IC for the Relay Touch Activation

Referring to the below given circuit diagram for the proposed first simple touch activated relay circuit, we can see that the entire design is built around the IC 4017 which is a 10 step johnson's decade counter divider chip.

The IC basically consists of 10 outputs, starting from its pin#3 and randomly ending at pin#11, constituting 10 outputs which are designed to produce a sequencing or shifting high logics across these output pins in response to every single positive pulse applied at its pin#14.

The sequencing does not need to finish at the last pin#11, rather could be assigned to stop at any desired intermediate pinout, and revert to the first pin#3 to initiate the cycle afresh.

This is simply done by connecting the end sequence pinout with the reset pin#15 of the IC.

This makes sure that whenever the sequence reaches this pinout, the cycle stops here and reverts to pin#3 which is the initial pinout for enabling a repeat cycling of the sequence in the same order.

For example in our design pin#4 which is the third pinout in the sequence can be seen attached to pin#15 of the IC, implies that as the sequence jumps from pin#3 to the next pin#2, and then to pin#4 it instantly reverts or flips back to pin#3 to enable the cycle again.

How it Works

This cycling is induced by touching the indicated touch plate which causes a positive pulse to appear at pin#14 of the IC each time it's touched.

Let's assume at power switch ON the high logic is at pin#3, this pin is not connected anywhere and is unused, while pin#2 can be seen connected with the relay driver stage, therefore at this moment the relay stays switched OFF.

As soon as the touch plate is tapped, the positive pulse at pin#14 of the IC toggles the output sequence which now jumps from pin#3 to pin#2 enabling the relay to switch ON.

The position is held fixed at this point, with the relay in the switched ON position and the connected load activated.

However as soon as the touch plate is touched again, the sequence is forced to jump from pin#2 to pin#4, which in turn prompts the IC to revert the logic back to pin#3, switching OFF the relay and the load and enabling the IC back to its standby condition.

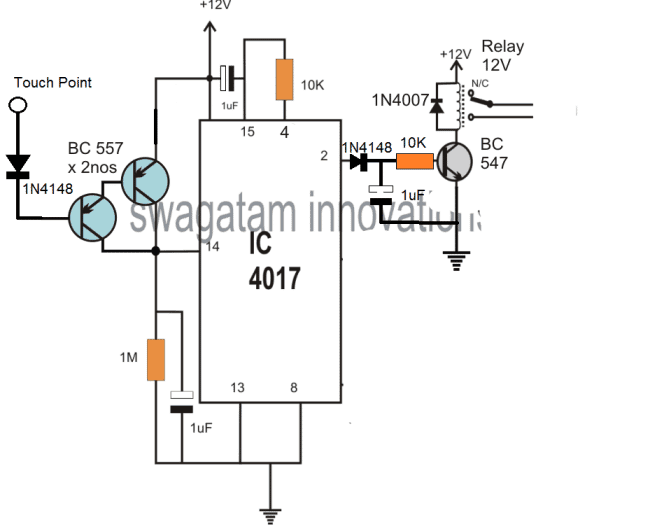

Modified Design

The above touch operated flip flop bistable circuit might show some oscillation in response to finger contact, leading to relay chattering.

To eliminate this issue, the circuit should be modified as given in the following diagram.

Or you may also follow the diagram which is shown in the video.

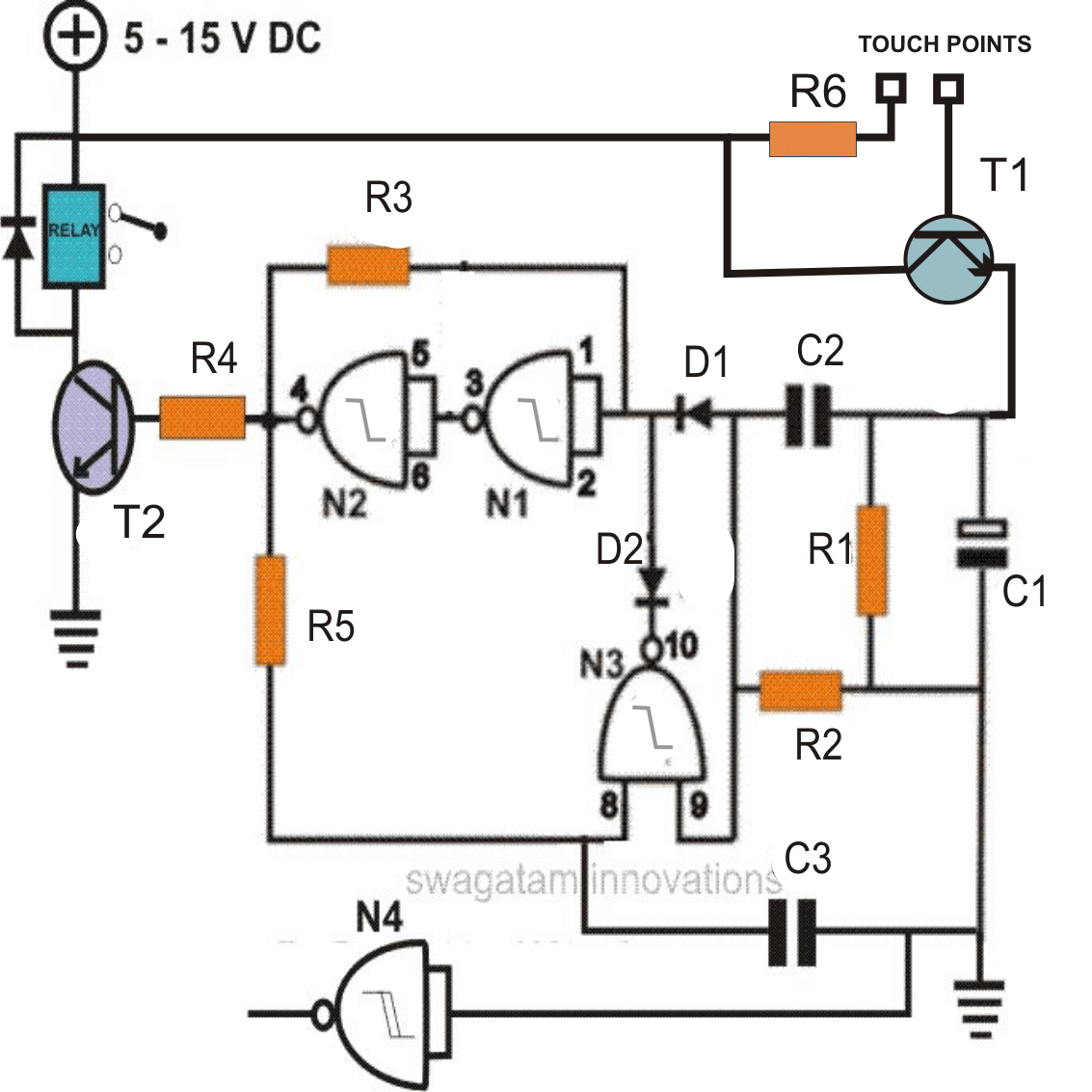

2) Touch Sensitive Switch Circuit Using IC 4093

This second design is another accurate touch sensitive switch can be built using a single IC 4093 and a few other passive components.

The shown circuit is extremely accurate and fail-proof.

The circuit is basically a flip-flop that may be triggered through manual finger touches.

Using Schmitt Trigger

The IC 4093 is a Quad 2-input NAND Gate with Schmidt trigger. Here we employ all the four gates from the IC for the proposed purpose.

How the Circuit works

Looking at the figure the circuit may be understood with the following points:

All the gates from the IC are basically configured as inverters and any input logic is transformed into an opposite signal logic at the respective outputs.

The first two gates N1 and N2 are arranged in the form of a latch, the resistor R1 looping from the output of N2 to the input of N1 becomes responsible for the desired latching action.

Transistor T1 is Darlington high gain transistor which has been incorporated for amplifying the minute signals from the finger touches.

Initially when power is switched ON due to the capacitor C1 at the input of N1, the logic at the input of N1 is pulled to ground potential making N1 and N2 feedback system latch with this input producing a negative logic at the output of N2.

The output relay driver stage is thus rendered inactive during initial power switch ON.

Now suppose a finger touch is made at the base of T1, the transistor instantly conducts, driving a high logic at the input of N1 via C2, D2.

C2 charges instantly and blocks any further faulty triggers from the touch, making sure the de-bouncing effect does not disturb the operation.

The above logic high instantly flips the condition of N1/N2 which now latches to produce a positive at the output, triggering the relay drive stage and the corresponding load.

So far the operation looks pretty straightforward, however now the next finger touch should make the circuit collapse and return to its original position and for implementing this feature, N4 is employed and its role becomes truly interesting.

After the above triggering is done, C3 gradually gets charged (within seconds), bringing a logic low at the corresponding input of N3, also the other input of N3 is already held at logic low through the resistor R2, which is clamped to ground.

N3 now becomes stationed in a perfect stand by position “waiting” for the next touch trigger at the input.

Now suppose the next subsequent finger touch is made at the input of T1, another positive trigger is released at the input of N1 via C2, however it does not produce any influence over N1 and N2 as they are already latched in response with the earlier input positive trigger.

Now, the second input of N3 which is also connected to receive the input trigger via C2 instantly gets a positive pulse at the connected input.

At this instant both the inputs of N3 goes high. This generates a logic low level at the output of N3.

This logic low immediately pulls the input of N1 to ground via the diode D2, breaking the latch position of N1 and N2.

This causes the output of N2 to become low, switching OFF the relay driver and the corresponding load. We are back into the original condition and circuit now waits for the next subsequent touch trigger in order to repeat the cycle.

Parts List

Parts required for making a simple touch sensitive ON/OFF switch circuit.

- R1, R2 = 100K,

- R6 = 1K

- R3, R5 = 2M2,

- R4 = 10K,

- C1 = 100uF/25V

- C2, C3 = 0.22uF

- D1, D2, D3 = 1N4148,

- N1---N4 = IC 4093,

- T1 = 8050,

- T2 = BC547

- Relay = 12 volts, SPDT

The above design can be further simplified using just a couple of NAND gates, and a relay ON OFF circuit. The entire design can be witnessed in the following diagram:

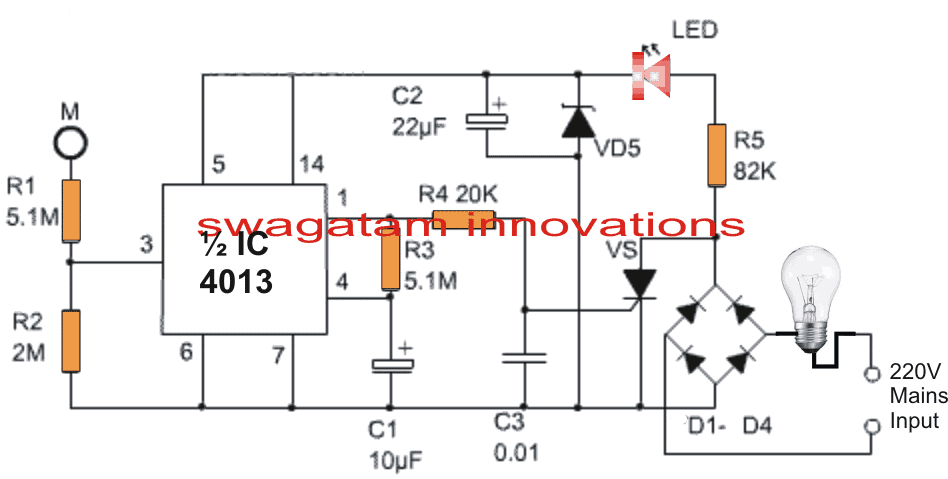

3) 220V Electronic Touch Switch Circuit

It may be now possible to convert your existing mains 220V light switch circuit with the electronic touch switch circuit explained in this 3rd configuration.

This third idea is built around the chip M668 and it employs just a handful of other components for implementing the proposed mains touch switch ON/OFF application.

How this simple mains electronic touch switch circuit works

The indicated 4 diodes form the basic bridge diode network, the thyristor is used for switching the mains 220V AC for the load, while the IC M668 is used for processing the ON/OFF latching actions whenever the touch switch is touched.

The bridge network rectifies the AC into DC through R1 which limits the AC current to safe level for the circuit, and VD5 regulates the DC suitably.

The final outcome is a rectified, stabilized 6V DC which is applied to the touch circuit for the operations.

The touch plate is connected with a current limiting network using R7/R8 so that no shock sensation is felt by the user while putting finger on this touch pad.

The various pinout functions of the IC can be learned from the following points:

The supply positive is applied to pin#8 and ground to pin#1 (negative) The touch signal on the touch pad is sent to pin#2, and the logic is transformed into an ON or OFF at the output pin#7.

This signal from pin#7 subsequently drives the SCR and the connected load into either ON or OFF states.

C3 makes sure that the SCR is not false triggered due to multiple pulses in response to an improper or inadequate touching on the touch pad. R4 and C2 forms an oscillator stage for enabling the required processing of the signals within the IC.

A synchronization signal from R2/R5 is divided internal through pin#5 of the IC. Pin#4 of the IC has a very crucial and interesting function.

When connected with the positive line or Vcc, the IC enables the output to alternately toggle ON/OFF, allowing the light or the load to switch ON and OFF alternately in response to every touch on the touch pad.

However when pin#4 is connected to the ground or the negative line Vss, it transforms the IC into a 4 stage dimmer circuit.

Meaning in this position every touch on the touch pad causes the load ( a lamp for example) to reduce or increase its intensity sequentially, in a gradually dimming or gradually brightening manner ( and OFF at the ends).

If you have any questions regarding the functioning of the above discussed mains touch switch circuit please write them down through the comment box...

4) Touch Activated Lamp Circuit with Delay Timer

The fourth design is a transformerless touch activated 220V delay lamp switch circuit enables the user to momentarily switch ON a table lamp or any other desired bed lamp during night time.

How the circuit Works.

Referring to the circuit above, the four diodes at the input form the basic bridge rectifier circuit for rectifying the mains AC into DC.

This rectified DC is stabilized by the 12V zener and filtered by C2 to acquire a fairly clean DC for the accompanying touch switch circuit.

R5 is used for limiting the input mains current to a much lower level suitable for operating the circuit safely.

An LED can be seen connected with this supply which ensures a dim light is always ON near the circuit for facilitating quick location of the touch switch pad.

The IC used in this transformers touch lamp with delay circuit is a double D flip-flip IC 4013, which has 2 flip flop stages built inside it, here we make use of one of these stages for our application.

Whenever the indicated touch pad is touched by finger, our body offers a leakage current on the point causing a momentary high logic on pin#3 of the IC, which in turn causes the pin#1 of the IC to go high.

When this happen the attached triac is triggered via R4, and the bridge rectifier completes its cycle powering the series lamp. The lamp now illuminates brightly.

Also in the meantime, the capacitor C1 gradually starts charging via R3, and when it gets fully charged pin#4 is rendered with a high logic which resets the flip flop in its original condition.

This instantly turns pin#1 low switching OFF the SCR and the lamp.

The value of the R3/C1 produces a delay of about 1 minute, this can be increased or decreased by suitably increasing or decreasing the values of these two RC components as per individual preference.

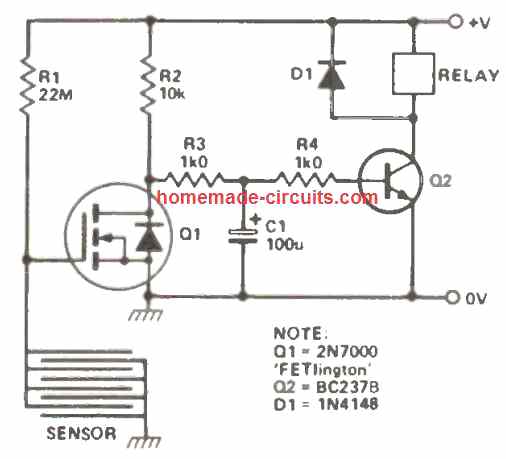

5) Touch Sensor Switch using a Single MOSFET

Just a single MOSFET and few additional passive parts are all that's needed to build this 5th touch sensor circuit.

The MOSFET gate can be seen connected with a 22M resistor, and a touch sensor built using a PCB with copper mesh on it.

With the indicated 22 M resistor, even breathing on the sensor mesh will be enough for the MOSFET to turn OFF momentarily.

If you find this sensitivity to high, you can reduce the 22M to 10M then it will allow the MOSFET to turn OFF with a finger touch on the copper sensor board.

During the absence of a touch on the sensor, the MOSFET remains in the switched ON condition, due to the positive voltage arriving from R1.

During this period the base voltage to Q2 via R2 remains grounded through the MOSFET drain which causes the Q2 transistor to remain switched OFF. With Q2 switched OFF, the relay also remains switched OFF.

As soon as the sensor plate is touched, it instantly causes a grounding of the R1 voltage through the finger, forcing the MOSFET to turn OFF.

When the MOSFET is turned OFF, the Q2 transistor gets the access to the potential from the R2, and it turns ON now, When Q2 turns ON, the relay coil gets the required amount of power, and it also turns ON, switching ON any load that may have been configured across its contacts.

Removing the finger from the touch sensor, restores the circuit to its original form, and the relay switches OFF.

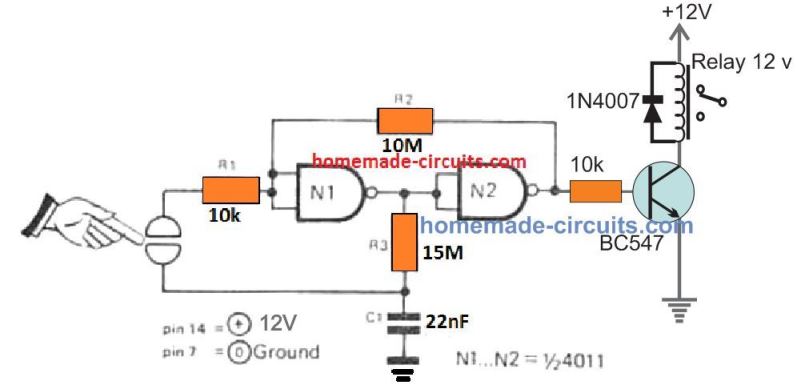

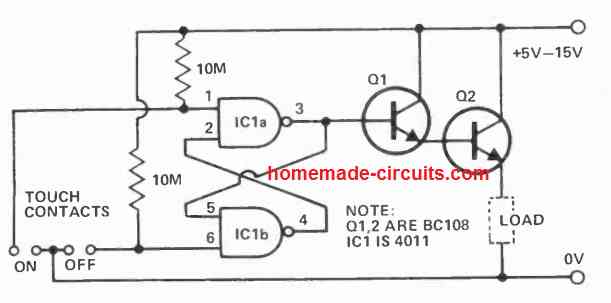

6) Using IC 4011

Working with just one 1 / 2 of an IC 4011, along with a few general purpose BJTs, this 7th touch operated switch could be designed which can be well suited for numerous battery powered circuits.

Considering that all the inputs to the leftover gates of the IC 4011 are connected to the ground line, the current consumed by the IC in the off state is practically zero which means the battery life will be long and unaffected.

When the 'on' contacts are touched with a finger causes pin 3 to become high, which turns on the darlington pair and power is supplied to the load.

When the 'off' contacts are touched, the opposite happens, and the action switches OFF the load.

Q1 needs to be a high gain transistor, and Q2 picked out according to the current specifications of the load.

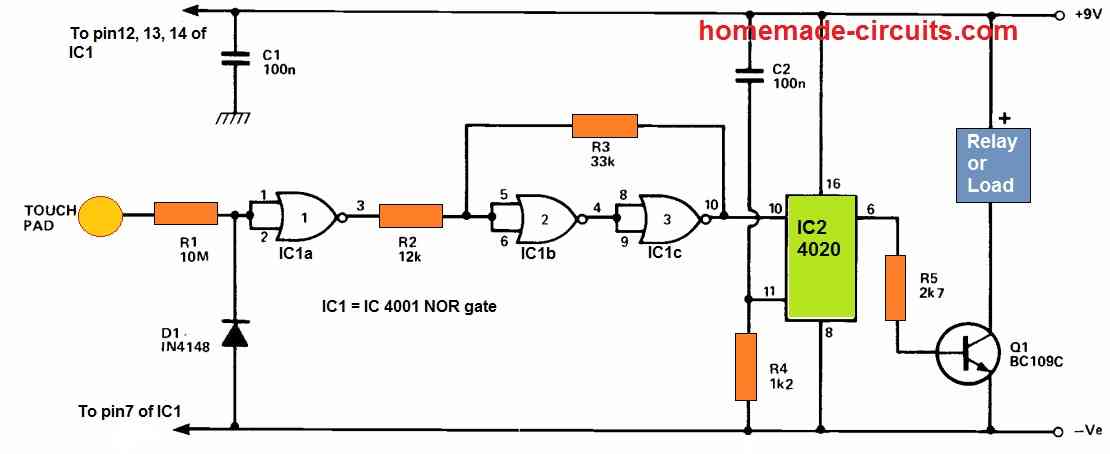

7) Using IC 4001 and IC 4020

In this 8th touch switch sensor idea, when the input contact of gate 1 (which, as the other three gates in the device, is linked to function as an inverter) is touched, stray mains hum is picked up and connected to the input of gate 1 (which, just like the other three gates in the device, is wired to function as an inverter) through R1.

The input signal is able to of switching gate 1 input from one logic level to the other since IC1 is a CMOS device with a very high input impedance.

Because the IC 4001 circuit's input impedance is so large, the backward resistance of D1 is utilized to connect the input to ground during idle situations, preventing erroneous activity.

In combination with the circuit's input capacitance, R1 works as a low pass filter, attenuating noise and interference that may be encountered on the 50Hz mains signal.

The output from gate 1 still has substantial amount of noise components and a rise time that is insufficient to operate the circuit's end stage.

The trigger circuit built around gates 2 and 3 is used to resolve this issue.

Due to the connection with R2, R3 tries to keep gate 2 input in almost the same condition as gate 3 output, preventing any change in logic state induced by gate 1 output.

Because R2 is smaller than R3, gate 1 can drive the trigger circuit if its output signal is large enough.

The main 50Hz signal will be powerful indeed, however the noise spikes may not, and therefore will be removed from the trigger's output.

The connection across R3 guarantees a fast shift whenever the trigger's output begins changing state.

IC2 is a 14-stage binary (division by 2) counter, and Q1 is operated from the output of the seventh stage via current limit resistor R5.

At power up, C2 and R4 send a positive reset pulse to the counter, causing the outputs to be low and Q1 to be turned off.

The load for transistor Q1 is formed by the regulated device, which apparently gets no substantial power.

A 50Hz signal is provided to IC2 when the touch contact is activated, and the 7th stage output swaps state after 64 pulses.

The load is turned on and off as this output swings high and low. In practice, the contact is held just long enough for the unit to transition to the ideal state (which the user wants to do automatically).

In the "off" position, the unit uses around 1uA, while in the "on" position, it draws roughly 3mA.

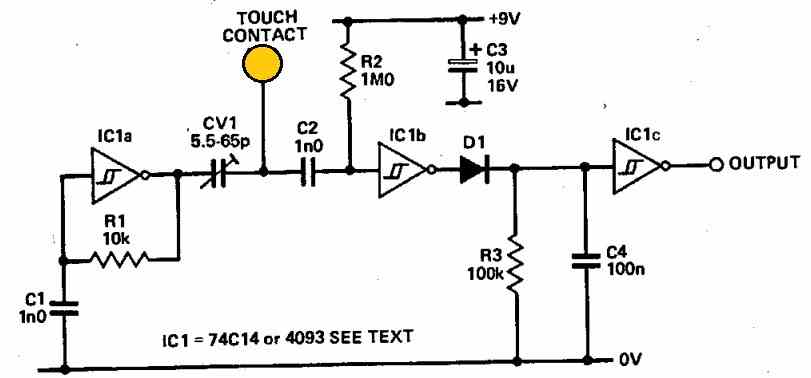

Using IC 4093

Presenting an innovative touch-sensitive switch configuration with broad applicability that relies solely on easily available components.

In its fundamental configuration, the output state rests at logic 0. Upon contact, an ingenious mechanism swiftly transforms the output to logic 1.

The core of the setup features IC1a operating within an oscillator arrangement generating an approximate 200 kHz frequency.

Throughout the periods when the contact remains untouched, a high-frequency signal of this oscillator circulates through CV1 and C2 before reaching the input of IC1b.

This Schmitt inverter synchronizes with the signal frequency, upholding the charge across C4.

However, when the touch plate encounters a finger touch, the signal transmitted to IC1b's input undergoes significant attenuation due to the combined influence of CV1's potential division and the finger's capacitance.

Consequently, IC1b's output ceases its oscillation, stabilizing at logic 0. Following this, C4 undergoes discharge via R3, leading IC1c's output to transition to logic 1.

To fine-tune sensitivity, optimal adjustments should be made to CV1.

Depending on the specific requirements, slight deviations in the value of C1 might be necessary due to the tolerances of the 74C14's Schmitt triggers.

The estimated operational frequency can be roughly calculated using the equation f = 2 / (R1 x C1).

Inclusion of C2 serves the purpose of suppressing potential hum-induced interference that might otherwise trigger IC1b erroneously.

As an alternative, one can opt for utilizing IC 4093 gates configured as inverters instead of the 74C14s for those who prefer that option.

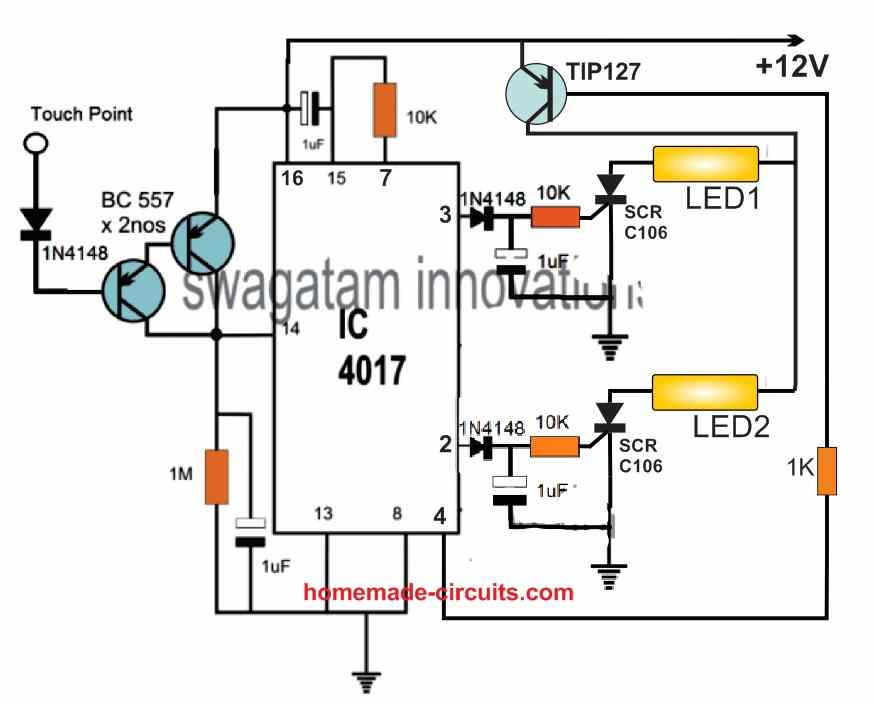

Touch Controlled Sequential LED Lamp Circuit

The following touch controlled sequential LED lamp will work in the following manner:

When power is switched ON, a short pulse is sent to pin#15 through the connected 1uF capacitor. The short positive pulse resets the IC such that a logic high is reached at pin#3.

With a logic high at pin#3 the connected SCR is switched ON and LED1 is also switched ON. Since the supply is DC, the SCR latches the LED1 permanently ON, and keeps it ON permanently.

After this, if the touch pad is touched once, the high logic at pin#3 jumps to pin#2.

The SCR on pin#2 similarly latches and switches ON LED2 permanently. Therefore now, both LED1 and LED2 are switched ON one after the other.

Next, if the touch pad is touched again, the logic high from pin#2 jumps to pin#4, which causes the TIP127 transistor to get a high logic at its base, so that it turns OFF.

When the TIP127 transistor is turned OFF, the DC supply to the LEDs is also turned OFF, which breaks the latching of the two SCRs. Both the SCRs now switch OFF and the LEDs also switch OFF.

At this position if the touch pad is touched yet again, causes the logic high at pin#4 to jump to the next output pin which is pin#7.

However, since pin#7 is connected to pin#15 of the IC this logic high resets the IC back. The resetting action causes the logic high to go back to pin#3, causing the relevant SCR to switch ON (latch)and the LED1 to illuminate. The process now repeats.

As we can see only two LEDs are used here, however since there are 10 outputs for the IC 4017, we can use a total number of 10 LEDs in this circuit.

The pinout sequence of the IC are in the order: 3, 2, 4, 7, 10, 1, 5, 6, 9, 11

As you will notice, in our circuit the first 4 sequencing pinout are used which 3, 2, 4, 7. Pin#4 is used to switch OFF the transistor and the SCRs, pin#7 is used to reset the IC back to pin#3.

It means, the two pinouts which comes immediately after the last LED in the sequence can be used for turning of the transistor and the resetting the IC respectively.

Let's say, we want to use 8 sequentially activating LEDs. For this we have to use the pinouts 3, 2, 4, 7, 10, 1, 5, 6 for connecting the SCR/LED networks.

In this situation, the two subsequent pinouts which comes after the pin#6 (which is the last LED pinout) can be used for turning off the transistor and for resetting the IC. These two pinouts are obviously pin#9 and pin#11.

This is how you can configure the pinouts of the IC 4017 for getting the desired number LEDs to illuminate sequentially, through touch activation.

Good afternoon my good friend Swagatam.Perhaps you know a circuit with which I could sequentially press the touch sensor and turn on this or that load.

For example, I have 4 rows(10 pieces) of 5050 smd LEDs. The task is to turn on one row with one touch, turn on the second row with the second touch, and so on, and turn it all off with the last touch.

Thank you in advance for your hint.

Thank you Jorge,

I will surely try to figure out the circuit and will update it soon in the above article!

Waiting for your help!

Thank you for waiting friend! Please see the following example design, I have shown two LED stages, but you increase it up to 10 LED stages. Note the connection of pin#4 and pin#7, you will have to change these pinout numbers depending on how many LED stages you use.

https://www.homemade-circuits.com/wp-content/uploads/2022/10/sequential-touch-LED-LED-lamp.jpg

Thank you, my friend!!!

But I need the explain of this circuit. How I can connect 4-6 stages of LED? How I need to change pin 4 and pin 7 for 5-6 stages? What type of LEDs you use in your circuit? I have smd5050 LED’s, is it sute?

My stupidity…Sorry…

No problem at all, I have explained the circuit at the bottom of the above article. You can check it out.

Yes you can use 5050 LEDs since they are 12 V modules.

Thank you, my friend! I’ll try to assemble this circuit, then send you report about it! It’s very useful for my aquarium illumination.

You are welcome my friend! let me know if you have any problems or doubts.

Thanks for your amazing work. Am designing a touch activated security alert system(cell phone speed dial, 4second on then off). Which of these do you suggest I use?

Hi, thanks! You can try the second design which is a tested one.

Hello, Swatagam ,

My problem is, when I use a long wire for the touch pad , the circuit becomes very sensitive et sometimes, it triggers without touching the touch pad . I mean I used a long wire between touch pad and the circuit. For example, the touch pad is connected to the door and the circuit itself is far away What to do in this case?

With many thanks.

Hello Mohamad, yes long wire will cause problems since it will work like an antenna and catch the unwanted hum signal from the atmosphere, so it is not recommended.

However, you an try adding a 0.22uF capacitor between the base of the BC557 and the positive 12V line and check the response! Hope it solves the issue.

Thanks very much for this prompt response

Greedings from Algeria

Thank you, I am glad to help!

i am trying to 3 circuit but IC is not available in market chennai then c3 and zener diode value and voltage not mentioned so please send me clear and details circuit diagram

If IC is not available to you, then you cannot build the circuit..

Touch Switch light Circuits

Thanks for your efforts in providing the touch activated switch. May I know why the 4th circuit is not published, or does one need to pay before getting the circuit diagram ?

4rth circuit is posted and clearly visible to me….please refreshing your page or try from some other browser…

Thanks for the urgency in reply. I actually used another browser (chrome) and I found the circuit.

My question now is that I will like to modify the circuit such that it will only operate on DC. If that be the case, I know the bridge rectifier, the 82k resistor and may be the 12v zener diode will be omitted…WHERE WILL I CONNECT THE ANODE OF THE SCR??

You are welcome! May I know the reason behind using an external DC, because with an SCR your circuit will not be isolated from mains anyway?

By the way you will need a triac instead of an SCR if you prefer to power the circuit from an external DC, and it won’t be isolated from mains

On 2nd circuit,

Left of pin 15,

Which connects to +12v.

Is it pin 16?

yes it is pin16

thx… works fine

Hello.

I built second circuit touch switch.(the one 1n4148 attached to touch plate).

Are the components correct and as it shows in the diagram?

Sadly not working…

Dear Sir,

I have mounted the touch circuit on a PCB and it works great. When I connected the touch pin to my main metal gate, it stays on.

I asked an electronics technician for advice, they told me the circuit was picking up all the signal around.

Can you please help me, how to mitigate all unwanted signals?

Cordially

Dear Henri, that is correct, the touch pate cannot be a large metallic object, otherwise it may pick up stray signals and causes problems. You can try putting a 0.22uF capacitor across the base and the positive supply line of the BC557 Darlington input transistors and see if that prevents the stray pick up

I have a weird question. I’m pretty novice when it comes to this stuff, so sorry in advance. I would like to make a momentary capacitive circuit that runs off a small wafer/watch battery, that turns on a surface mounted LED. But, instead of having one touch point that turns on the LED, I want several points touched at the same time, to complete the circuit. And, if only one point is touched, it would not turn on. Would this be possible? Thanks in advance for your help!

yes that seems possible by using multiple SCRs connected via separate diodes at the pin14 of the IC 4017, and SCR gates configured with separate touch switches

Hi Swagatam,

I am a newbie for this field but found myself very interested to enter this industry. The Option 3 from your designs is very interesting and I am trying to find for part, however, I could not see the IC M668 (also Google but failed). Can you please guide me where to find such IC with thanks.

I am thinking of making a small size switch that can be installed on the wall-plate for 220VAC lamp of 15-100W, Can you guide me on a smaller design of this Option 3 (small parts – not sure they are avaiable)

Thank you very much for your attention.

Ngoc – Vietnam

Hi Dang, the IC M668 is not one of the regular ICs so it seems unavailable at the moment. However, I think the second circuit can be be adapted for direct mains operation by using a capacitive power supply with it. In this case, the base of the BC557 will need to be to be connected with a 2M2 series resistor for safety. Finally, the IC pin2 could be configured with a triac for operating an low AC bulb.

Hi Swagatam,

Thank you for your quick response. What about the 4 options?

Ngoc

Hi Dang, yes the 4rth is even better, since 4013 is easily available, and you can two of these from a single iC

Thanks Swagatam,

So If I use the Option 4, can I remove the C1 and R3 to avoid the Lamp to be off and what should be modification to make the switch be permanent and only off at 2nd touch

Quoted [

Also in the meantime, the capacitor C1 gradually starts charging via R3, and when it gets fully charged pin#4 is rendered with a high logic which resets the flip flop in its original condition. This instantly turns pin#1 low switching OFF the SCR and the lamp.

The value of the R3/C1 produces a delay of about 1 minute, this can be increased or decreased by suitably increasing or decreasing the values of these two RC components as per individual preference.]

So this should need a bit of modification for it to activate the off procedure at 2nd touching of M. Please share with me on how to do that.

I am a total newbie.

Ngoc

Hi Dang, you seem to be correct, please refer to the IC 4013 circuits presented in the following article, it will give you a clear idea regarding its detailed pinout functioning, and you can easily modify the above circuit according to the given data:

https://www.homemade-circuits.com/build-these-simple-flip-flop-circuits/

Hi Swagatam,

I cant find IC 4013 with pin out as you stated on the Option 4. I previously made a comment asking you how to remove the timer R3, C1 and replace with certain combination so the circuit will toggle upon touches to turn on/off the bulb.

Please help with thanks.

Ngoc

Hi Dang, please go to the link which I provided in the previous comment, you will find all the details in it.

You can remove R3, C1, they are not required, you can remove them, connect pin4 to ground.

Sir thanks for quick reply and it works great.

Thanks Janak, I am glad it's working!

Sir i tried it using 1000mf cap with 1m resistor and also diode. but now it works only if switch is in off state. suppose before power goes if switch is off and power comes it remains off but if switch is ON and power goes and when power comes back it is off. Sir is there any other way to keep same state of switch even if main power goes and come it remains in previous state.

circuit description for two touch switch.

Ic used cd 4013. Two output taken from this Ic 1st output from pin 1 and 2nd from pin 13.Input given through M397 TTP223 Capacitive Touch Switch Button Self-Lock Moduleto both input pins 3 & 11 with 2k resistor to I/O of touch module other end of resistor goes to pin 3 of ic 4013 and one more resistor of 100k from pin 3 goes to ground. . short pins of Ic 2 with 5, 4 with 6&7, 12 with 9 and 10 with 8 which is then shorted to 7 as ground & 14 is vcc.

output of this Ic given to ULN2004 ic and output through this ic is given to relay circuit. Input supply is 5v

sir pls let me know if any other modification to be done so that switch remain in same previous state even if power goes and come.

Janak, please refer to the last diagram of the following article:

https://www.homemade-circuits.com/2012/05/make-this-easiest-flip-flop-circuit.html

did you connect the parts in the indicated manner?

Sir I made a touch switch using 4013 ic and its works fine but suppose if switch is OFF and main power goes and when power comes back again switch turns ON (vice versa). How can I avoid this. or how to keep the same state of switch when power goes OFF or comes ON.

Janak, to rectify the issue you can connect a high value capacitor across the ICs suply terminals via a 1M resistor, and also make sure to connect a 1N4148 from the supply to the (+) of the capacitor, that is at the junction of 1M and capacitor positive, cathode will go at this point, and the anode to the supply positive.

Dear sir,

Can this circuit may be used for fence for detecting intruder. If nor what changes needed in above circuit.

Abbas

Dear Abbas, no it cannot be used for fence, since the fence could act like an antenna and cause stray pick ups and spurious relay operations

The number of pin which is on the left of pin15 is not written. Is it pin16?

yes it's pin#16

Ok it worked..thank you…Is there simple touch on/off circuit working by 220V? Or can't we,for example, add bridge diode and condenser..? Have you got any simple/easy such circuit?

a capacitive power supply can be dangerous and lethal, so it's not recommended

what is that touch plate..is it an ordinary metallic plate to which base of transister is connected..sir im new to these type of circuits thats why i asked

it can be any metal end, even a small 1 inch stripped wire will do.

this wire should be as small as possible, longer wires might produce erratic results due to stray disturbance pick up

Sir good morning Hope you fine. I requested u to design a circuit for boost the heart beat sound from stethoscope via condensor mic to 8" speaker.Is there any chance to design.

Thank you

Sridhar

Sridhar, it is in my draft and I will post it soon, there's one article in the queue, next to that I will publish your article

Thank you sir,I will wait.

Sridhar, I think I already have this circuit in this website, you can see it here:

https://www.homemade-circuits.com/2016/01/electronic-stethescope-amplifier-circuit.html

alternatively you can try the following preamplifier circuit and use it with your STK amp circuit for amplifying the heart beats:

http://www.ti.com/lit/ug/tidu765/tidu765.pdf

it works perfectly u a great SWAGATAM, thanks

Thank you Davis! It's my Pleasure!

your welcome!!

sir

is there any progress in my request

can you tell me how to buy parts for making these projects online individually..i dont want bulk quantity.can you tell me any site..this ia because nowadays all parts are not available in my nearby electronic shops..please help me

NvD, can you please repeat your request, I have it my draft but it would be easier if you could say it again.

Parts can be purchased by placing an order through any online component dealer and by paying through your debit card or netbanking…the parts will reach the destination within the stipulated date.

OK, I think I have recently posted it here:

https://www.homemade-circuits.com/2016/07/simple-touch-sensor-switch-circuit.html

sorry the correct link is given below:

https://www.homemade-circuits.com/2016/07/touch-free-faucet-circuit.html

circuit it not working. im hooking up a simple LED to the relay and it wont turn on

remove the relay and check by connecting the LED across pin#2 and ground via resistor 1K…first confirm this.

Does the touch plate work when it is placed under a glass panel? LIke if we touch the particular area on the glass which is placed above the touch plate, the relay should response.

No, it needs to be touched physically to actuate…

for your application you can try the IC 555 capacitive switch circuit from this site

Could you please share link of the circuit which uses IC 555?

Thanks in advance

Here’s a circuit which can be modified as the touch sensor using IC 555

https://www.homemade-circuits.com/capacitive-switch-circuit-for-vehicle/