In this post I have explained 2 easy to build induction heater circuits which work with high frequency magnetic induction principles for generating substantial magnitude of heat over a small specified radius.

The discussed induction cooker circuits are truly simple and uses just a few active and passive ordinary components for the required actions.

Update: You may also want to learn how to design your own customized induction heater cooktop:

Designing an Induction Heater Circuit - Tutorial

Induction Heater Working Principle

An induction heater is a device that uses a high frequency magnetic field to heat up an iron load or any ferromagnetic metal through eddy current.

During this process electrons inside iron are unable to move as fast as the frequency, and this gives rise to a reverse current in the metal termed as eddy current. This development of high eddy current ultimately causes the iron to heat up.

The generated heat is proportional to current2 x resistance of the metal. Since the load metal is supposed to be made up of iron, we consider the resistance R for the metal iron.

Heat = I2 x R (Iron)

Resistivity of Iron is: 97 nΩ·m

The above heat is also directly proportional to the induced frequency and that's why ordinary iron stamped transformers are not used in high frequency switching applications, instead ferrite materials are used as cores.

However here the above drawback is exploited for acquiring heat from high frequency magnetic induction.

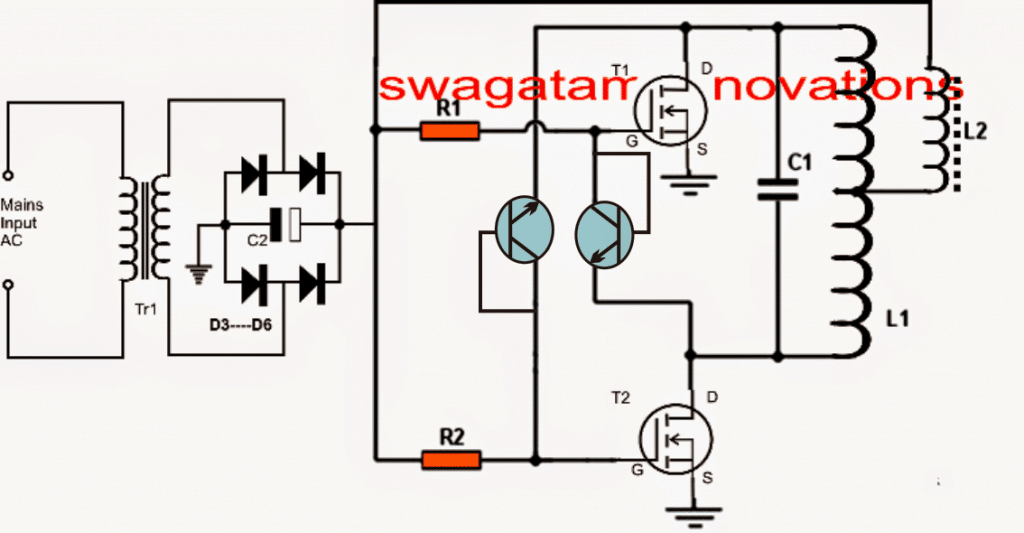

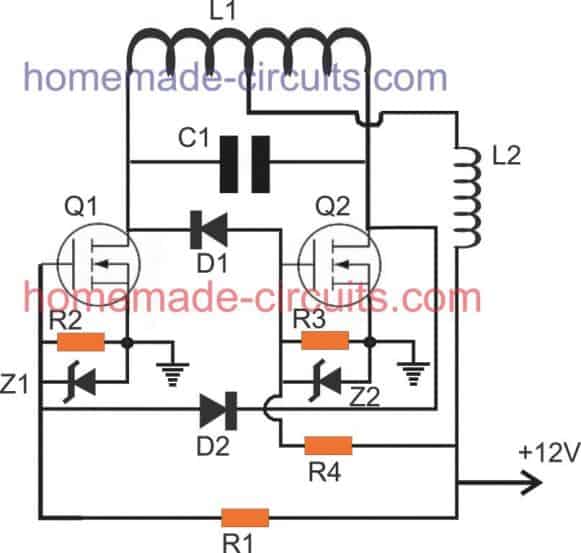

Referring to the proposed induction heater circuits below, we find the concept utilizing the ZVS or zero voltage switching technology for the required triggering of the MOSFETs.

The technology ensures minimum heating of the devices making the operation very efficient and effective.

Further to add, the circuit being self resonant by nature automatically gets sets at the resonant frequency of the attached coil and capacitor quite identical to a tank circuit.

Using Royer Oscillator

The circuit fundamentally makes use of a Royer oscillator which is marked by simplicity and self-resonant operating principle.

The functioning of the circuit could be understood with the following points:

- When power is switched ON, positive current begins flowing from the two halves of the work coil towards the drains of the mosfets.

- At the same the supply voltage also reaches the gates of the mosfets turning them ON.

- However due to the fact that no two mosfets or any electronic devices can have exactly similar conducting specifications, both mosfets do not turn on together, rather one of them turns ON first.

- Let's imagine T1 turns ON first. When this happens, due to heavy current flowing through T1, its drain voltage tends to drop to zero, which in turn sucks out the gate voltage of the other mosfet T2 via the attached schottky diode.

- Here, it may seem that T1 might continue to conduct and destroy itself.

- However, this is the moment when the L1C1 tank circuit comes into action and plays a crucial part. The sudden conduction of T1 causes a sine pulse to spike and collapse at the drain of T2. When the sine pulse collapses, it dries down the gate voltage of T1, and shuts it down. This results in a rise in voltage at the drain of T1, which allows a gate voltage to restore for T2. Now, its the turn of T2 to conduct, T2 now conducts, triggering a similar kind of repetition that occurred for T1.

- This cycle now continues rapidly causing the circuit to oscillate at the resonant frequency of the LC tank circuit. The resonance automatically adjusts to an optimal point depending on how well the LC values are matched.

However the main downside of the design is that it employs a center tapped coil as the transformer, which makes the winding implementation a bit trickier. However the center tap allows an efficient push pull effect over the coil through just a couple of active devices such as mosfets.

As can be seen, there are fast recovery or high speed switching diodes connected across the gate/source of each mosfet.

These diodes perform the important function of discharging the gate capacitance of the respective mosfets during their non-conducting states thereby making the switching operation snappy and quick.

How ZVS Works

As I have explained earlier, this induction heater circuit works using the ZVS technology.

ZVS stands for zero voltage switching, meaning, the mosfets in the circuit switch ON when they have minimum or amount of current or zero current at their drains, we have already learned this from the above explanation.

This actually helps the mosfets to switch ON safely and thus this feature becomes very advantageous for the devices.

This feature could be compared with the zero crossing conduction for triacs in AC mains circuits.

Due to this property the mosfets in ZVS self resonant circuits such as this require much smaller heatsinks and can work even with massive loads upto 1 kva.

Being resonant by nature, the frequency of the circuit is directly dependent on the inductance of the work coil L1 and the capacitor C1.

The Frequency could be calculated using the following formula:

f = 1 / ( 2π * √[L * C] )

Where f is the frequency, calculated in Hertz

L is the inductance of the Main Heating Coil L1, presented in Henries

and C is the capacitance of the capacitor C1 in Farads

Solving a Practical Example:

If the tank circuit consists of:

- Lt = 10 µH (Inductor)

- Ct = 0.1 µF (Capacitor)

The resonant frequency is:

f = 1 / (2 * π * √(Lt * Ct))Substitute the values:

f = 1 / (2 * π * √(10 x 10-6 * 0.1 x 10-6))

Simplify:f = 1 / (2 * π * √(1 x 10-12))f = 1 / (2 * π * 10-6)

f ≈ 159.15 kHzImportant Notes:

You may find that the actual operating frequency may deviate slightly due to:

- Non-ideal values in the components (e.g. parasitic resistance in the capacitors or MOSFETs).

- Loads variations (for e.g. placing a metal object in the work coil alters the Lt).

- The influence of the current-limiting inductors.

The circuit will lock onto the resonant frequency automatically through the ZVS feedback mechanism ensuring an efficient operation.

For precise design you must measure the inductance (Lt) and capacitance (Ct) using an LCR meter, or adjust the capacitor bank, to fine tune the frequency.

The MOSFETs

You can use IRF540 as the mosfets which are rated at good 110V, 33amps. Heatsinks could be used for them, although the heat generated is not to any worrying level, yet still it's better to reinforce them on heat absorbing metals. However any other appropriately rated N channel MOSFETs can be used, there are no specific restrictions for this.

The inductor or inductors associated with the main heater coil (work coil) is a kind of choke that helps eliminating any possible entry of the high frequency content into the power supply and also for restricting the current to safe limits.

The value of this inductor should be much higher compared to the work coil. A 2mH is generally quite enough for the purpose. However it must be built using high gauge wires for facilitating a high current range through it safely.

The Tank Circuit

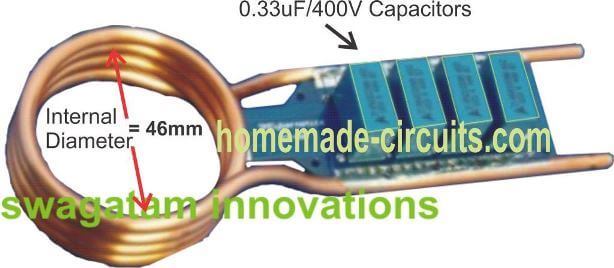

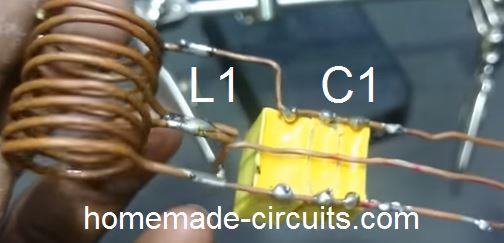

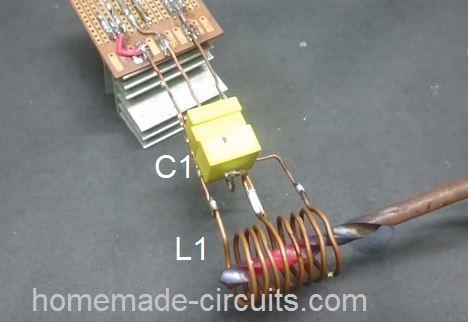

C1 and L1 constitute the tank circuit here for the intended high resonant frequency latching. Again these too musts be rated to withstand high magnitudes of current and heat.

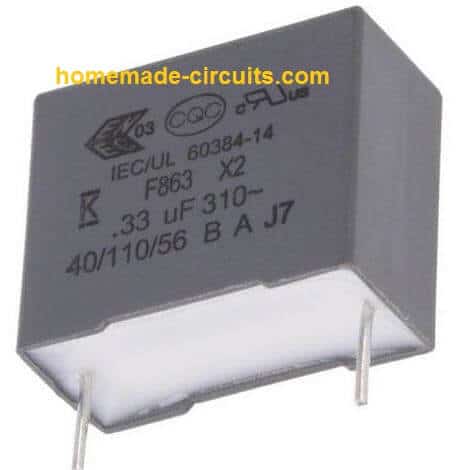

Here we can see the incorporation of a 330nF/400V metalized PP capacitors.

1) Powerful Induction Heater using a Mazzilli Driver Concept

The first design I have explained below is a highly efficient ZVS induction concept based on the popular Mazilli driver theory.

It uses a single work coil and a two current limiter coils. The configuration avoids the need of a center tap from the main work coil thus making the system extremely effective and rapid heating of load with formidable dimensions. The heating coil heats the load through a full bridge push pull action

The module is actually available online and can be easily bought at a very reasonable cost.

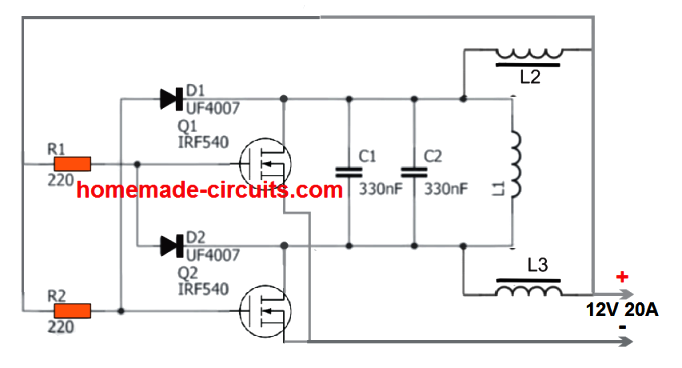

The circuit diagram for this design can be seen below:

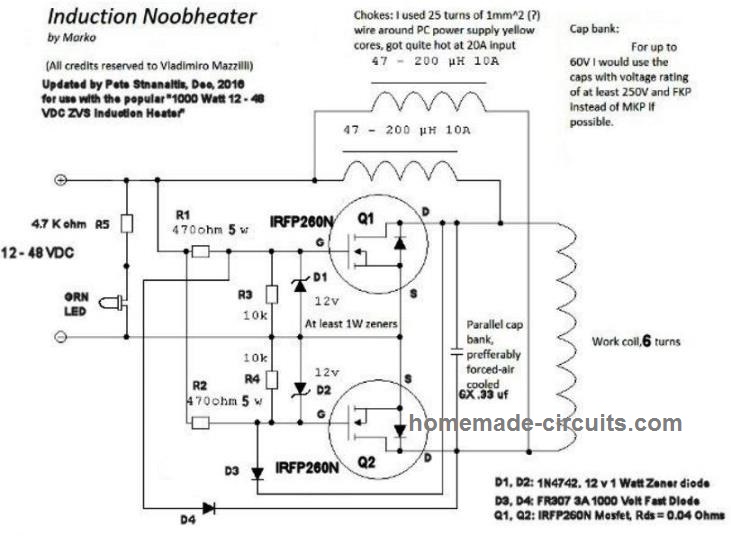

The original diagram can be witnessed in the following image:

The working principle is the same ZVS technology, using two high power MOSFETs. The supply input can be anything between 5V and 12V, and current from 5 amps to 20 amps depending on the load used.

Power Output

The power output from the above design can be as high as 1200 watts, when the input voltage is raised up to 48V, and current up to 25 amps.

At this level the heat generated from the work coil can be high enough to melt a 1 cm thick bolt within a minute.

Work Coil Dimensions

Video Demo

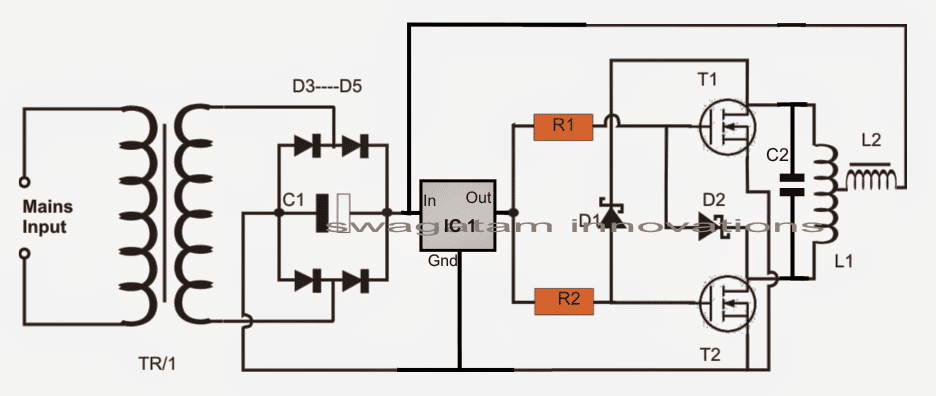

2) Induction Heater using a Center Tap Work Coil

This second concept is also a ZVS induction heater, but uses a center bifurcation for the work coil, which may be slightly less efficient compared to the previous design.

The L1, which is the most crucial element of the whole circuit. It must be built using extremely thick copper wires so that it sustains the high temperatures during the induction operations.

The capacitor as discussed above must be ideally connected as close as possible to the L1 terminals. his is important for sustaining the resonant frequency at the specified 200kHz frequency.

Primary Work Coil Specifications

For the induction heater coil L1, many 1mm copper wire may be wound in parallel or in bifilar manner in order to dissipate current more effectively causing lower heat generation in the coil.

Even after this the coil could be subjected to extreme heats, and could get deformed due to it therefore an alternative method of winding it may be tried.

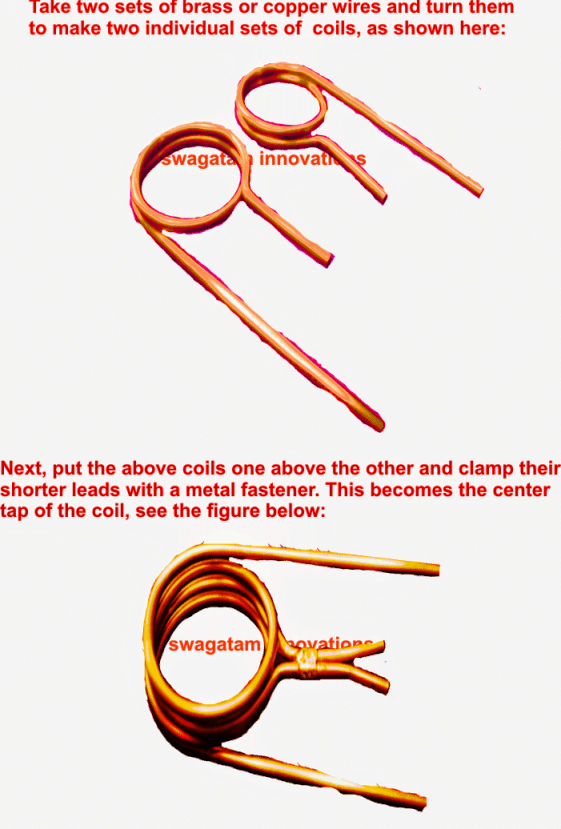

In this method we wind it in the form of two separate coils joined at the center for acquiring the required center tap.

In this method lesser turns may be tried for reducing the impedance of the coil and in turn increase its current handling capability.

The capacitance for this arrangement may be in contrast increased in order to pull down the resonant frequency proportionately.

Tank Capacitors:

In all 330nF x 6 could be used for acquiring a net 2uF capacitance approximately.

How to Attach Capacitor to the Induction Work Coil

The following image shows the precise method of attaching the capacitors in parallel with the end termianals of the copper coil, preferably through a well dimensioned PCB.

Parts list for the above induction heater circuit or induction hot plate circuit

- R1, R2 = 330 ohms 1/2 watt

- D1, D2 = FR107 or BA159

- T1, T2 = IRF540

- C1 = 10,000uF/25V

- C2 = 2uF/400V made by attaching the below shown 6nos 330nF/400V caps in parallel

- D3----D6 = 25 amp diodes

- IC1 = 7812

- L1 = 2mm brass pipe wound as shown in the following pics, the diameter can be anywhere near 30mm (internal diameter of the coils)

- L2 = 2mH choke made by winding 2mm magnet wire on any suitable ferrite rod

- TR1 = 0-15V/20amps

- POWER SUPPLY: Use regulated 15V 20 amp DC power supply.

Using BC547 transistors in place of high speed diodes

In the above induction heater circuit diagram we can see the MOSFETs gates consisting of fast recovery diodes, which might be difficult to obtain in some parts of the country.

A simple alternative to this may be in the form of BC547 transistors connected instead of the diodes as shown in the following diagarm.

The transistors would perform the same function as the diodes since the BC547 can operate well around 1Mhz frequencies.

Another Simple DIY Design

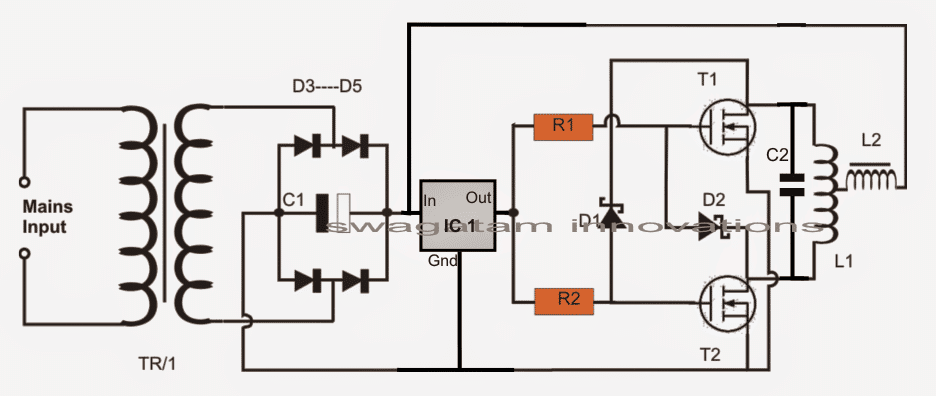

The following schematic shows another simple design, similar to the above, which can be constructed quickly at home for implementing a personal induction heating system.

Parts List

- R1, R4 = 1K 1/4 watt MFR 1%

- R2, R3 = 10K 1/4 watt MFR 1%

- D1, D2 = BA159 or FR107

- Z1, Z2 = 12V, 1/2 watt zener diodes

- Q1, Q2 = IRFZ44n mosfet on heatsink

- C1 = 0.33uF/400V or 3 nos 0.1uF/400V in parallel

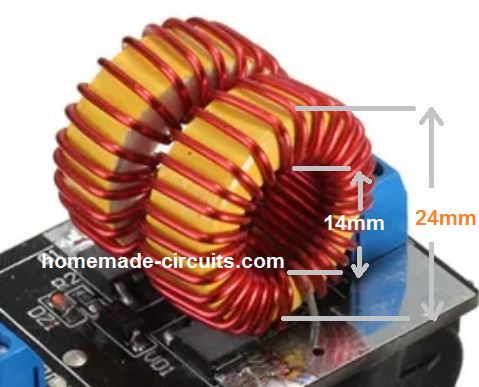

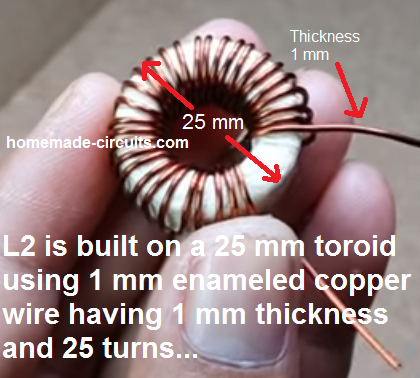

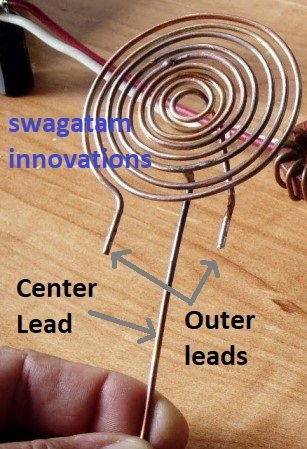

- L1, L2, as shown in the following images:

- L2 is salvaged from any old ATX computer power supply.

How L2 is Built

Modifying into a Hot Plate Cookware

The above sections helped us to learn a simple induction heater circuit using a spring like coil, however this coil cannot be used for cooking food, and needs some serious modifications.

The following section of the article explains, how the above idea can be modified and used like a simple small induction cookware heater circuit or an induction kadai circuit.

The design is a low tech, low power design, and may not be on par with the conventional units. The circuit was requested by Mr. Dipesh Gupta

Technical Specifications

Sir,

I have read ur article Simple Induction Heater Circuit - Hot Plate Cooker Circuit And was very happy to find that there are people ready to help youngsters like us to do something ....

Sir I am trying to understand the working and trying to develop an induction kadai for myself ... Sir please help me understanding the designing as I m nt so good in electronics

I want to develop an induction to heat up a kadai of dia 20 inch with 10khz frequency at a very low cost !!!

I saw your diagrams and article but was a bit confused about

- 1. Transformer used

- 2. How to make L2

- 3. And any other changes in the circuit for 10 to 20 kHz frequency with 25ams current

Please help me sir as soon as possible ..It will be help full if u could provide with the exact components detail needed .. PlzzAnd lastly u had mentioned to use POWER SUPPLY: Use regulated 15V 20 amp DC power supply. Where is it used ....

Thanks

Dipesh gupta

The Design

The proposed induction kadai circuit design presented here is just for experimental purpose and may not serve like the conventional units. It may be used for making a cup of tea or cooking an omelet quickly and nothing more should be expected.

The referred circuit was originally designed for heating iron rod like objects such as a bolt head. a screwdriver metal etc, however with some modification the same circuit can be applied for heating metal pans or vessels with convex base like a "kadai".

For implementing the above, the original circuit wouldn't need any modification, except the main working coil which will need to be tweaked a bit to form a flat spiral instead of the spring like arrangement.

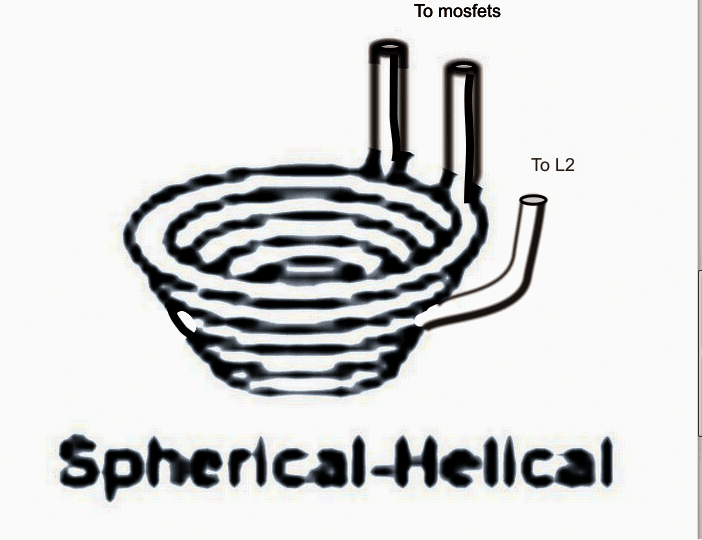

As an example, in order to convert the design into an induction cookware so that it supports vessels having a convex bottom such as a kadai, the coil must be fabricated into a spherical-helical shape as given in the figure below :

The schematic would be the same as explained in my above sevction, which is basically a Royer based design, as shown here:

Designing the Helical Work Coil

L1 is made by using 5 to 6 turns of 8mm copper tube into a spherical-helical shape as shown above in order to accommodate a small steel bowl in the middle.

The coil may be also compressed flat into a spiral form if a small steel pan is intended to be used as the cookware as shown below:

Designing the Current Limiter Coil

L2 may be built by winding a 3mm thick super enameled copper wire over a thick ferrite rod, the number of turns must be experimented until a 2mH value is achieved across its terminals.

TR1 could be a 20V 30amp transformer or an SMPS power supply.

The actual induction heater circuit is quite basic with its design and does not need much of an explanation, the few things that needs to be taken care of are as follows:

The resonance capacitor must be relatively closer to the main working coil L1 and should be made by connecting around 10nos of 0.22uF/400V in parallel. The capacitors must be strictly non-polar and metalized polyester type.

Although the design may look quite straightforward, finding the center tap within the spirally wound design could pose some headache because a spiral coil would have an unsymmetrical layout making it difficult to locate the exact center tap for the circuit.

It could be done by some trial and error or by using an LC meter.

A wrongly located center tap could force the circuit to function abnormally or producing unequal heating of the mosfets, or the entire circuit may just fail to oscillate under a worst situation.

Reference: Wikipedia

Comments

Hi, I am a complete novice in electronics and have no plans to build what I need. A lot of the information I find onlie is quite over my head.

What I am wanting to to do is to melt a small amount of lead inside a copper tube. The tube would be 1 1/2″ x 5/16″ dia. The lead would be a wire of about 15 grams or even less.

I am pondering one of the many Chinese made units from online but I have no idea how many Kw would be required or what frequency or another item called coil ratio.

The coil I plan to use would be a linear parallel coil about 20 ” long in total. It would run alongside a line of the copper tubes about 10″ long and then loop over top and back down along the other side. Thus about 20″ of coil heating length.

I would like the melt to take not more than a minute or so for 10 t0 15 pieces of the copper lead cylinders.

Any help would be appreciated.

Hey, thanks for your interesting question…First of all lead melts at only 327°C, copper survives that easily. 15 grams of lead is actually very small heat energy, the real problem is heating copper, not melting lead. Induction heaters heat conductive metals efficiently, but copper is harder to heat than steel or iron since resistance is low. So heater must be rated for copper, not for lead…

Now power is the big question. For what you described, copper tube 1.5″ long, 5/16″ diameter, lead inside around 15 grams, quantity 10–15 pieces, time target around 1 minute, realistically 800 W to 1500 W induction heater is enough. Most small Chinese induction heater boards rated 1 kW at 24–36 V will already do this comfortably.

For copper tubing of that size, typical working frequency 50 kHz to 150 kHz. Most ready made induction boards automatically operate in this range. Avoid units that require manual tuning if you are not building electronics yourself.

You can ignore coil ratio, what matters instead is coil must be close to copper, not touching. Spacing about 3–6 mm gap. Coil should be shorter than what you described. Your proposed 20″ long coil is too long. Induction heating works best when coil length is approximately same as heated object length.

For your case, ideal coil length 2″ to 3″. Heat one tube at a time, or small batch very close together. Trying to heat 10″ of tubing uniformly with single coil will need much higher power and is inefficient.

If you want this to work without headaches, buy a 1–1.5 kW Chinese induction heater. Use 24–36 V DC supply. Use short parallel or helical coil, 2–3 inches long. Process tubes one by one, or 2–3 at a time. Each piece will melt internally in 20–40 seconds, easily under your 1 minute target.

Thanks so much for the info! I was really hoping to do say 10 pieces at at time in a line with each piece spaced about 3/8″ apart. I have seen commercial units that do 18 or 20 ” at a time but those are automated units priced in the $100,000 range. Way out of my budget.

Would using a 5 KW or even 10 Kw unit allow that?

You are welcome Al, yes I think 5kW should be enough to fulfil your current target successfully..

Thank you so much for your help, Swagatam! Induction heating is a somewhat obscure subset of electronics and what I am doing is an obscure subset of induction heating. Inofrmation is hard to comeby on a basic level. If I had the ability to do all the calculations it might be different. But alas…

Anyway, you have been most helpful. If you are interested I can update you on my results once I get it set up.

Blessings on you.

Al

You are most welcome AL, there’s no need to do the calculations manually, you can take the help of the following calculators, and feel free to share the results here…

https://www.homemade-circuits.com/induction-heater-calculator/

https://www.homemade-circuits.com/zvs-induction-heater-tank-calculator/

https://www.homemade-circuits.com/induction-heater-work-coil-calculator/

Hello engineer, can you introduce me to an induction furnace circuit with an EGBT module that also has a drive, at least 5000 watts?

Sure, you can try the circuit explained in the following article, IGBTs are not required, you can use MOSFETs, they will never burn:

https://www.homemade-circuits.com/zvs-induction-heater-tank-calculator/

First design a 500 watt unit, if everything works good, the yoou can slowly try increasing it to 5000 w by modifying the MOSFETs and the input current.

I would like to heat about 1 g of coal inside a quartz tube, which is placed around the induction heating coil. The tube diameter is roughly 50–60 mm. My goal is to heat only the 1 g sample in the center to around 900 °C.

In what power range should the induction heater be for this application? Also, if I use a ZVS driver that is much too powerful, is there a risk that the sample will overheat?

ok thanks Do you think a ZVS circuit is suitable for this kind of project, or would another circuit design be better for the small amount I want to heat? If I use a 1000 W ZVS driver, will it be fine to run it at around 25% power, or could that damage the driver because of the lower frequency? I can’t seem to find any drivers in the 250–500 W range.

Ok thank you very much. I found some 500 W and 1000 W ZVS drivers. Now I one last question about temperature regulation. I want to reach 900–1000 °C to burn the coal, with a temperature ramp of about 50 to 200 K/min.

Is simple regulation by limiting the input DC current sufficient, or do I need another method to control the heat? I was considering using a K-type thermocouple for feedback and regulating the input DC power. Do you know of other solutions that would allow me to achieve stable, regulated temperature heating?

I think regulating the input current is the easiest and a reliable method of controlling the heat.

Another method is to deviate from the resonance point and reduce heat. Because as we know at resonance we get maximum heat and highest current, so deviating away from resonate can also proportionately reduce heat.

For more info on this you can refer to this post:

https://www.homemade-circuits.com/zvs-induction-heater-tank-calculator/

ZVS would be a better option because it is a very efficient topology.

1000 watt can be adjusted to run at 50% power, simply by limiting the input DC current to the desired lower level.

However, 500 watt kits are easily available on amazon and flipkart, did you check them there…?

If you want to heat 1 gram coal to 900 °c inside quartz tube by induction, then you must use small susceptor like graphite or steel piece because coal is not conductive.

Power range should be around 200 to 500 watts, not more. If you use too powerful zvs driver without control then susceptor will overheat very fast and may burn coal or crack quartz tube.

So better start with low power and heat in short pulses, watch temperature carefully. Do not just run full power directly.

Hello from France. How to chose the frequency? 10KHz? 20KHz? 50Khz? 100KHz? 1MHz?

Hi, the resonant frequency is automatically adjusted by the circuit, depending on the values of the coil and the capacitor. For more info, you can check out the following articles:

https://www.homemade-circuits.com/?smartsearch=induction+heater

yes I know, but what is the interest of high (1MHz) or low frequency (10KHz)?

High frequency will allow to achieve the results with maybe a tiny single turn, whereas 10kHz will require you to have a larger coil with more number of turns…

hi again

on the last circuit can i increse the wolatege and amps to incraese the power or not?

You can do it by suitably upgrading and calculating the MOSFETs, L1, L2, and the input power supply capacity.

Is there any point in adding water colling to the last circuit. Because im making a school project and this circuit is a littel to simple so i need to add something to it.

water cooling won’t be required for the coils, however I would rather recommend the first concept from the above article, since it is a tested design….

Can i ask what would you recomend that i add to the circuit because my proffesor said the design is a littel bit too simple

Please ask your professor, what more he wants in the circuit?

hi swagatam

could you please tell me how would i make a control station that controls the power do i just do this with potenciometer or is there other ways?

Hi Aleks, to control the power you just have to control the input current of the power supply.

can you please provide link where i can buy the last circuit?

If you are referring to the helical work coil, you can simply modify the coil of the first design on top, to make it flat and helical. Just make sure the inductance value of the modified helical coil matches with the original cylindrical coil.

I use a zvs circuit on powerful mosfet transistors, but I can’t get the frequency above 50 kHz, I would like to raise it to 400 kHz, could you advise in which part of the zvs circuit I need to make changes to increase the operating frequency, in addition to changing the inductance of the heating coil itself?

The frequency of a ZVS circuit depends on the LC values of the tank circuit. I have updated an example calculation in the above article, you can refer to it and modify your circuit’s tank LC values for getting the intended 400 kHz.

Thank you! Will see what I can do =)

No problem!

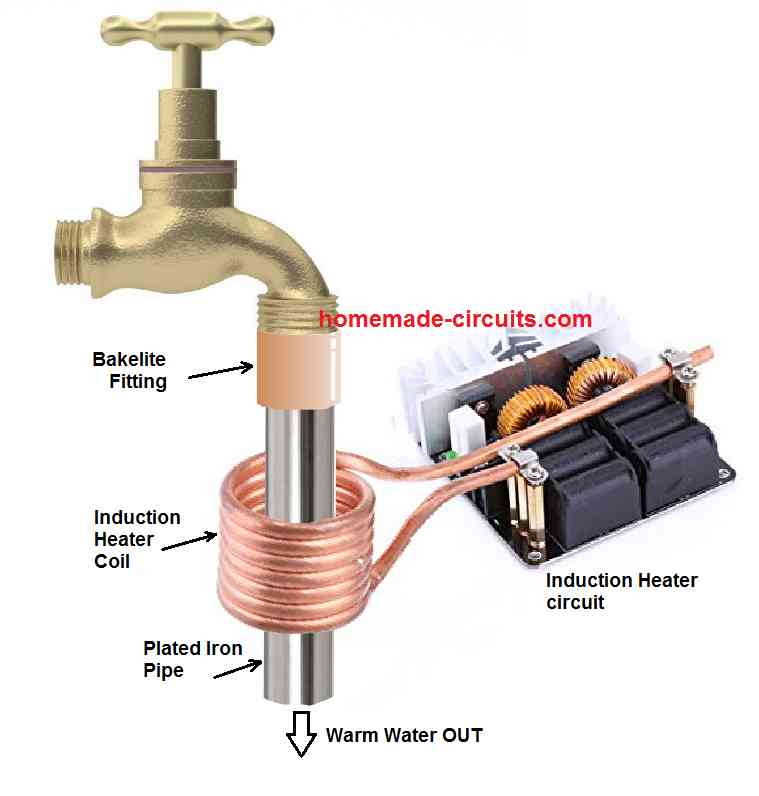

Hi

I have built heaters per your design and it melts iron. However I wish to heat a 15mm galvanised pipe with flowing water in the pipe to heat a radiator. It keeps blowing up. Can you assist?

My power supply is 12-24V 30 amps.

Your advice will be most welcome.

Regards

Richard

Thank you for the question.

Can you please tell me what blows up? Are you referring to the MOSFETs?

In that case you can consider using higher rated MOSFETs such as IRFP2907.

Let me know your thoughts on this?

Hi

Yes the mofets blew. Also one capacitor.

I am using Z44 mofets. will try again with IRFP2907.

What is the diff between the 2?

Z44 max current handling capacity is 36 amps at 100 degrees Celsius case temperature.

For IRF2907 it is 148 amps at 100 degrees Celsius.

Please make sure to add a good heatsinks to the MOSFETs.

Also, for the first circuit above, the voltage must not exceed 15V, 12V is optimal.

For the capacitors try adding more in parallel, however make sure to adjust the values so that the total capacitance value remains equal to the original value, as given in the diagram.

Hi dear! at the osilator part, you said that when Q1 ON the drain current of Q1 will decrease but can I ask why? Is it bc the electrical characteristic of mosfet or the other components? thanks

Hi, current does not decrease, the voltage decreases.

sorry It was my mistake 🙂 btw thanks to very fast reply! and also all of this articles

So than can I ask why the drain voltage decreases?

Thanks for your interest in this article.

When a transistor conducts, its drain or collector tends to be grounded via its source or the emitter pin, due to this the drain or the collector volage tends to drop towards zero, so it decreases.

If we combine at least 4 boards from the second photo without the capacitors, with a total of 15 capacitors SIEMENS MKP B32650 CAPACITORS 0.22uF 1000V with a coil of copper 6 mm pipe by running water through the coil, you also need fans for the verites and 5 watt resistors. You can melt copper silver in a ceramic pot. You need a 45 volt 50 amp power supply.

Thank you very much for sharing your valuable feedback.

You can set the operating frequency to 10MHz.

hii sir i want to make a 10kw induction heater can you tell me a how to calculate a L,R,C in resonant tank and how to calculate a transformer turn at resonant side please you give a calculation with any example

Hi Harshit,

I do not have tested calculations for induction LC tank circuit. However you can do it with some trial and error method.

You can buy a ready made 1000 watt induction heater unit and then through some experimentation upgrade it to 10kva. I can help with this experimentation.

hi dear sir i want to find out prenciple in zvs please

sir, I want to design a induction heater so how to calculate a L, C, R and transform ratio

Hi Sedigh, The ZVS principle is explained in the above article, please read it again, and let me know if you have any further questions.

Hi Randy, can I ask if your questions are solved? cuz I’m also the one who want to know that 🙂

The number of turns is fixed and cannot be changed. It has to be exactly as specified in the diagram or in the readymade unit. In the readymade unit which I tested had 10 turns, and it could make a 4mm screwdriver rod red hot within 20 seconds.