In this post I have explained the construction of a 5000 watt inverter circuit which incorporates a ferrite core transformer and therefore is hugely compact than the conventional iron core counterparts.

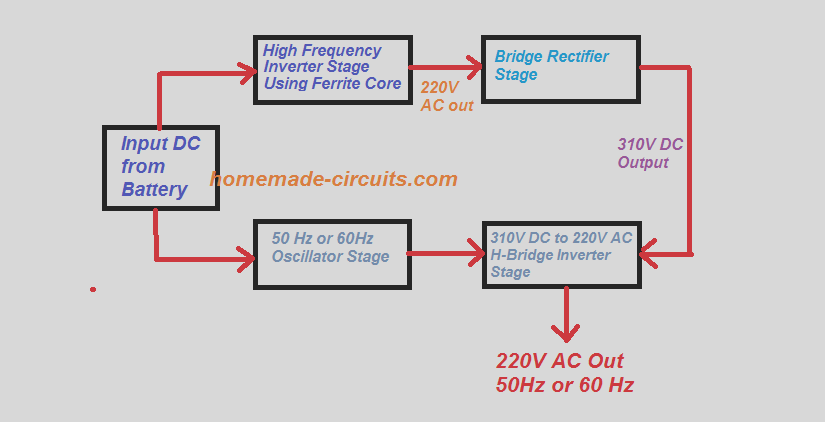

Block Diagram

Please note you can convert this ferrite core inverter to any desired wattage, right from 100 watt to 5 kva or as per your own preference.

Understanding the above block diagram is quite simple:

The input DC which could be through a 12V, 24V or 48V battery or solar panel is applied to a ferrite based inverter, which converts it into a high frequency 220V AC output, at around 50 kHz.

But since 50 kHz frequency may not be suitable for our home appliances, we need to convert this high frequency AC into the required 50 Hz / 220V, or 120V AC / 60Hz.

This is implemented through an H-bridge inverter stage, which converts this high frequency into output into the desired 220V AC.

However, for this the H-bridge stage would need a peak value of the 220V RMS, which is around 310V DC.

This is achieved using a bridge rectifier stage, which converts the high frequency 220V into 310 V DC.

Finally, this 310 V DC bus voltage is converted back into 220 V 50 Hz using the H-bridge.

We can also see a 50 Hz oscillator stage powered by the same DC source. This oscillator is actually optional and may be required for H-bridge circuits which do not have its own oscillator. For example if we use a transistor based H-bridge then we may need this oscillator stage to operate the High and low side mosfets accordingly.

UPDATE: You may want to jump directly to the new updated "SIMPLIFIED DESIGN", near the bottom of this article, which explains a one-step technique for obtaining a transformerless 5 kva sine wave output instead of going through a complex two-step process as discussed in the concepts below:

A Simple Ferrite Cote Inverter Design

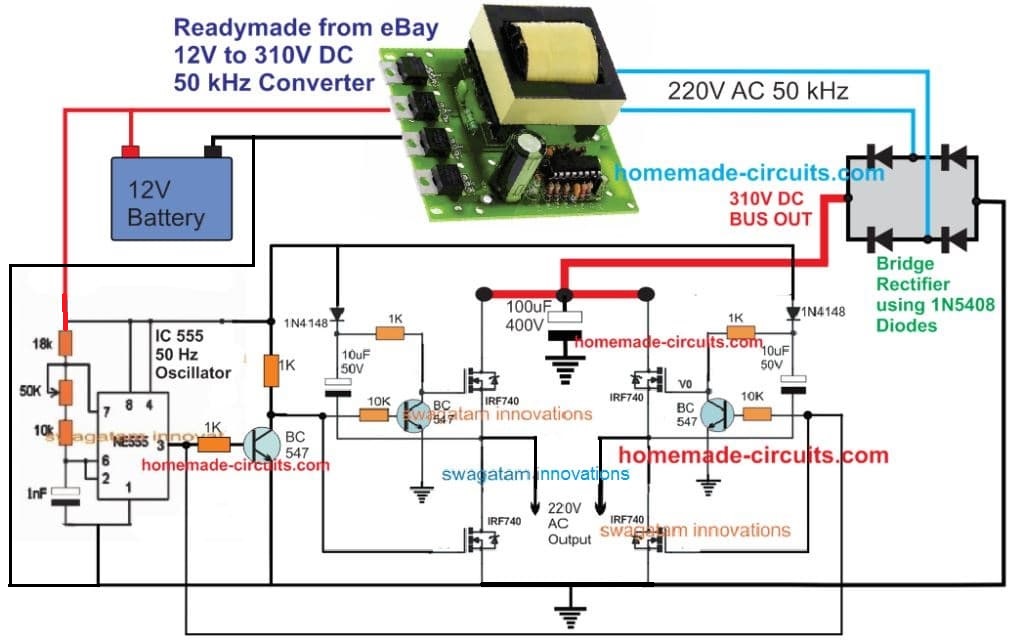

Before I have explained the 5kva version here's a simpler circuit design for the newcomers. This circuit does not employ any specialized driver IC, rather works with only n-channel MOSFETS, and a bootstrapping stage.

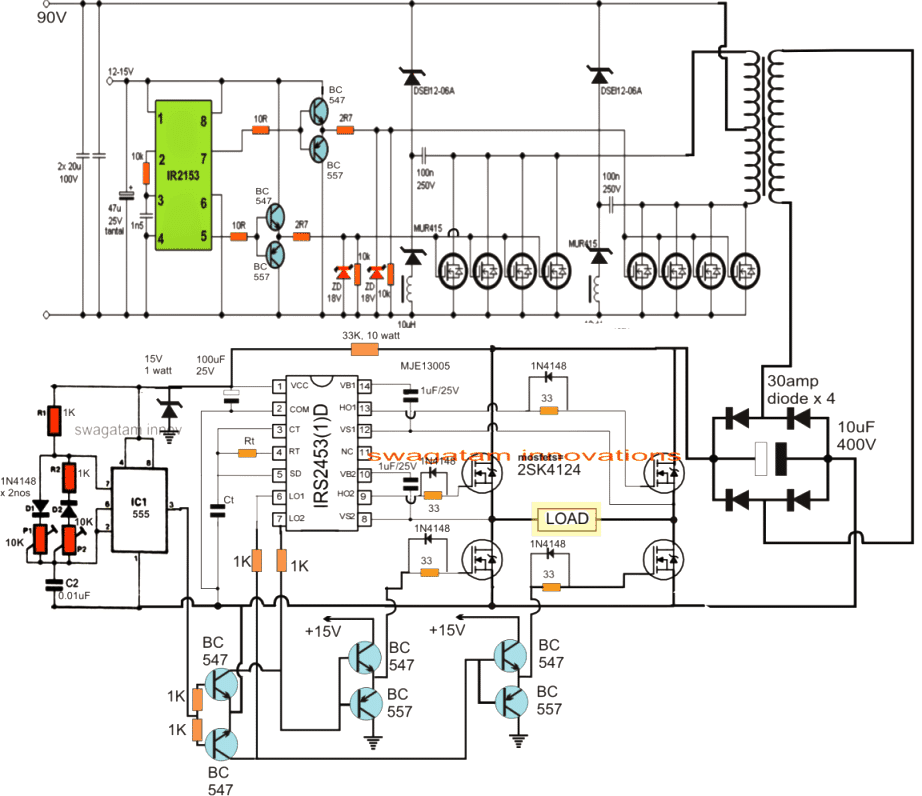

The complete circuit diagram can be witnessed below:

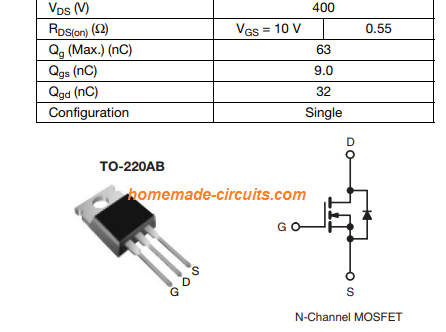

400V, 10 amp MOSFET IRF740 Specifications

In the above simple 12V to 220V AC ferrite inverter circuit we can see a ready made 12V to 310V DC converter module being used. This means you don't have to make a complex ferrite core based transformer. For the new users this design may be very beneficial as they can quickly build this inverter without depending on any complex calculations, and ferrite core selections.

5 kva Design Prerequisites

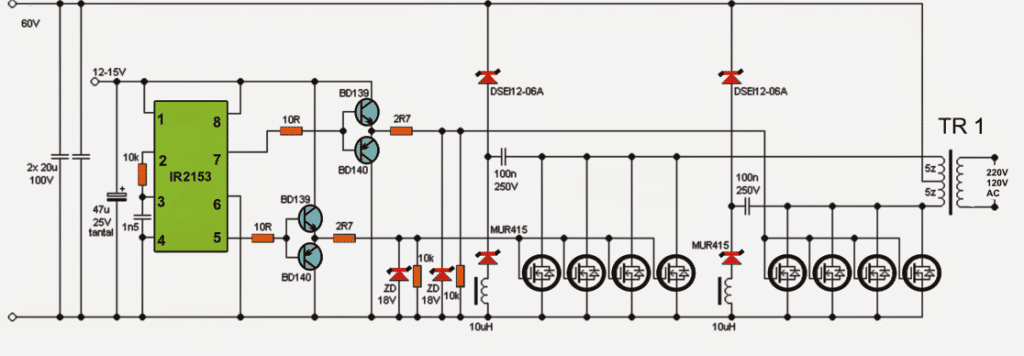

First you need to find 60V DC power supply for powering the proposed 5kVA inverter circuit. The intention is to design a switching inverter which will convert the DC voltage of 60V to a higher 310V at a lowered current.

The topology followed in this scenario is the push-pull topology which uses transformer on the ratio of 5:18. For voltage regulation which you may need, and the current limit – they are all powered by an input voltage source. Also at the same rate, the inverter expedites the current allowed.

When it comes to an input source of 20A it is possible to get 2 – 5A. However, the peak output voltage of this 5kva inverter is around 310V.

Ferrite Transformer and Mosfet Specifications

In regard to the architecture, Tr1 transformer has 5+5 primary turns and 18 for secondary. For switching, it is possible to use 4+4 MOSFET (IXFH50N20 type (50A, 200V, 45mR, Cg = 4400pF). You are also free to use MOSFET of any voltage with Uds 200V (150V) along with least conductive resistance. The gate resistance used and its efficiency in speed and capacity must be excellent.

The Tr1 ferrite section is constructed around 15x15 mm ferrite c. The L1 inductor is designed using five iron powder rings that may be wound as wires. For inductor core and other associated parts, you can always get it from old inverters (56v/5V) and within their snubber stages.

Using a Full Bridge IC

For integrated circuit the IC IR2153 can be deployed. The outputs of the ICs could be seen buffered with BJT stages. Moreover, due to the large gate capacitance involved it is important to use the buffers in the form of power amplifier complementary pairs, a couple of of BD139 and BD140 NPN / PNP transistors do the job well.

Alternate IC can be SG3525

You may also try to use other control circuits like SG3525. Also, you can alter the voltage of the input and work in direct connection with the mains for testing purpose.

The topology used in this circuit has the facility of galvanic isolation and operating frequency is around 40 kHz. In case if you have planned to use the inverter for a small operation, you don’t cooling, but for longer operation be sure to add a cooling agent using fans or large heatsinks. Most of the power is lost at the output diodes and the Schottky voltage goes low around 0.5V.

The input 60V could be acquired by putting 5 nos of 12V batteries in series, the Ah rating of each battery must be rated at 100 Ah.

High Frequency 330V Stage

The 220V obtained at the output of TR1 in the above 5 kva inverter circuit still cannot be used for operating normal appliances since the AC content would be oscillating at the input 40 kHz frequency.For converting the above 40 kHz 220V AC into 220V 50 Hz or a 120V 60Hz AC, further stages would be required as stated below:

First the 220V 40kHz will need to be rectified/filtered through a bridge rectifier made up of fast recovery diodes rated at around 25 amps 300V and 10uF/400V capacitors.

Converting 330 V DC into 50 Hz 220 V AC

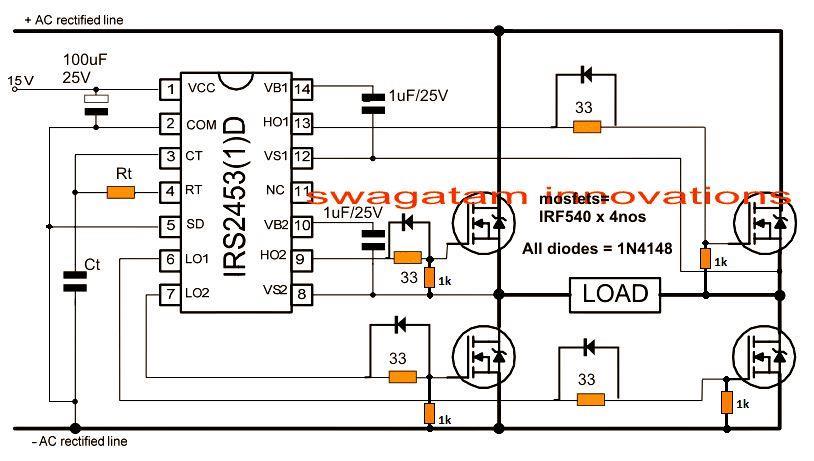

Next, this rectified voltage which would now mount up to around 310V would need to be pulsed at the required 50 or 60 Hz through another full bridge inverter circuit as shown below:

The terminals marked "load" could be now directly used as the final output for operating the desired load.

Here the mosfets could be IRF840 or any equivalent type will do.

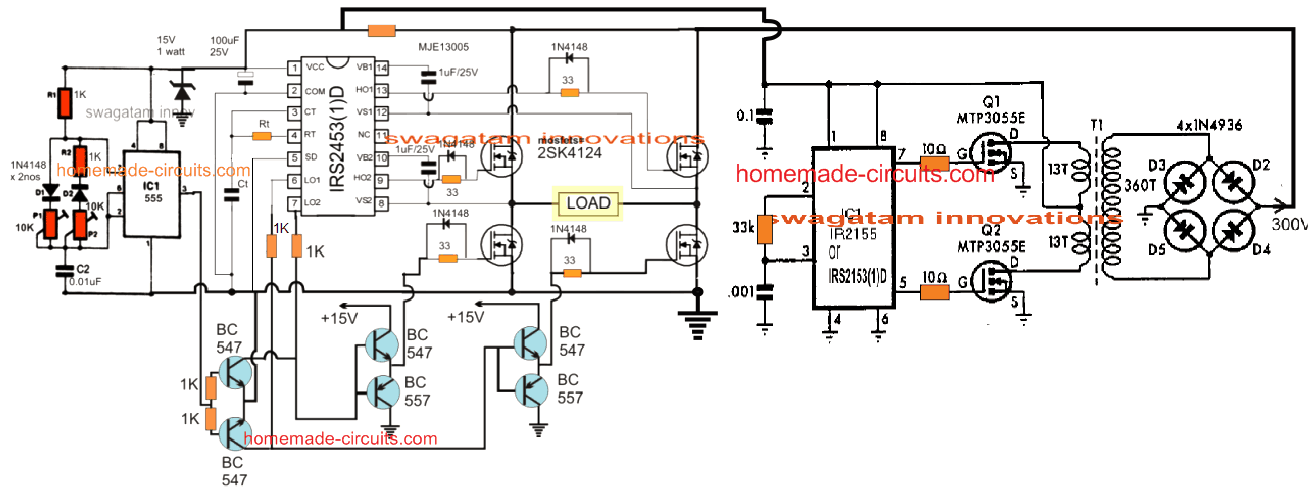

How to Wind the Ferrite Transformer TR1

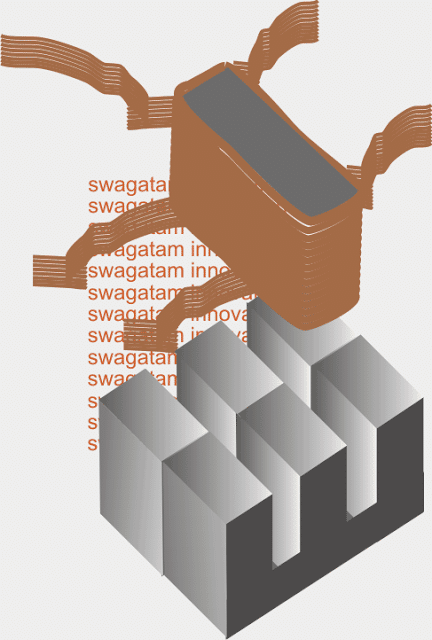

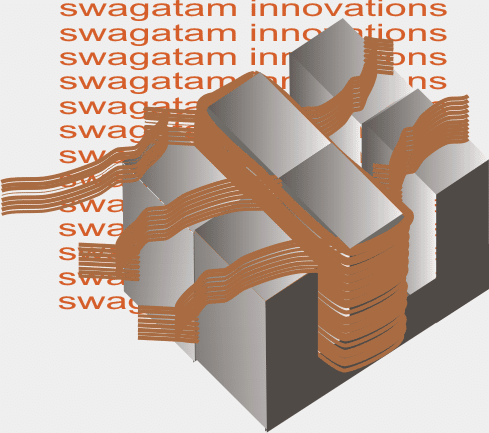

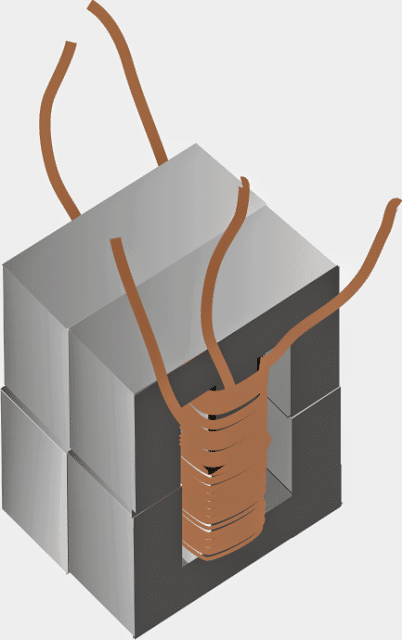

The transformer TR1 is the main device which is responsible for stepping up the voltage to 220V at 5kva, being ferrite cored based it's constructed over a couple of ferrite EE cores as detailed below:

Since the power involved is massive at around 5kvs, the E cores needs to be formidable in size, an E80 type ferrite E-core could be tried.

Remember you may have to incorporate more than 1 E core, may be 2 or 3 E-cores together, placed side by side for accomplishing the massive 5KVA power output from the assembly.

Use the largest one that may be available and wind the 5+5 turns using 10 numbers of 20 SWG super enameled copper wire, in parallel.

After 5 turns, stop the primary winding insulate the layer with an insulating tape and begin the secondary 18 turns over this 5 primary turns. Use 5 strands of 25 SWG super enameled copper in parallel for winding the secondary turns.

Once the 18 turns are complete, terminate it across the output leads of the bobbin, insulate with tape and wind the remaining 5 primary turns over it to complete the ferrite cored TR1 construction. Don't forget to join the end of the first 5 turns with the start of the top 5 turn primary winding.

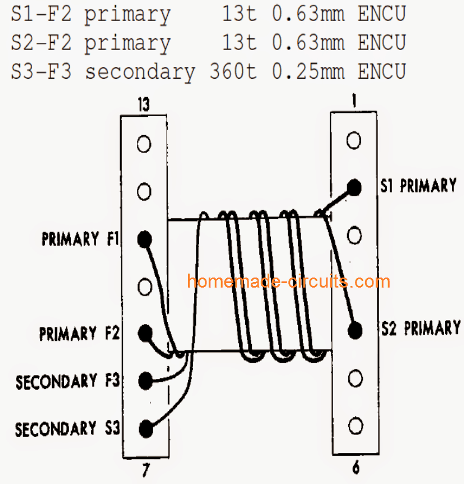

E-Core Assembly Method

The following diagram gives an idea regarding how more than 1 E-core may be used for implementing the above discussed 5 KVA ferrite inverter transformer design:

E80 Ferrite core

Feedback from Mr. Sherwin Baptista

Dear All,

In the above project for the transformer, i did not use any spacers between the core pieces, the circuit worked well with the trafo cool while in operation. I always preferred an EI core.

I always rewound the trafos as per my calculated data and then used them.

All the more the trafo being an EI core, separating the ferrite pieces were rather easy than doing away with an EE core.

I also tried opening EE core trafos but alas; i ended up breaking the core while separating it.

I never could open an EE core without breaking the core.

As per my findings, few things i would say in conclusion:

---Those power supplies with non-gaped core trafos worked best. (i am describing the trafo from an old atx pc power supply since i used those only. The pc power supplies do not fail that easily unless its a blown capacitor or something else.)---

---Those supplies that had trafos with thin spacers often were discolored and failed quiet early.(This i got to know by experience since till date i bought many second hand power supplies just to study them)---

---The much cheaper power supplies with brands like; CC 12v 5a, 12v 3a ACC12v 3a RPQ 12v 5a all

Such types ferrite trafos had thicker paper pieces between the cores and all failed poorly!!!---

In FINAL the EI35 core trafo worked the best(without keeping air gap) in the above project.

5kva ferrite core inverter circuit preparation details:

Step 1:

- Using 5 Sealed Lead Acid batteries of 12v 10Ah

- Total voltage = 60v Actual voltage

- = 66v fullcharge(13.2v each batt)voltage

- = 69v Trickle level charge voltage.

Step 2:

After calculation of battery voltage we have 66volts at 10 amps when full charged.

- Next comes the supply power to ic2153.

- The 2153 has a maximum of 15.6v ZENER clamp betwen Vcc and Gnd.

- So we use the famous LM317 to supply 13v regulated power to the ic.

Step 3:

The lm317 regulator has the following packages;

- LM317LZ --- 1.2-37v 100ma to-92

- LM317T --- 1.2-37v 1.5amp to-218

- LM317AHV --- 1.2-57v 1.5amp to-220

We use the lm317ahv in which 'A' is the suffix code and 'HV' is the high volt package,

since the above regulator ic can support input voltage of upto 60v and output votage of 57 volts.

Step 4:

- We cannot supply the 66v directly to the lm317ahv package sice its input is maximum of 60v.

- So we employ DIODES to drop the battery voltage to a safe voltage to power the regulator.

- We need to drop about 10v safely from the maximum input of the regulator which is 60v.

- Therefore, 60v-10v=50v

- Now the safe maximum input to the regulator from the diodes should be 50 volts.

Step 5:

- We use the regular 1n4007 diode to drop the battery voltage to 50v,

- Since being a silicon diode the voltage drop of each is about 0.7 volts.

- Now we calculate the required number of diodes we need which would buck the battery voltage to 50 volts.

- battery voltage = 66v

- calc.max input voltage to regulator chip = 50v

- So, 66-50=16v

- Now, 0.7 * ? = 16v

- We divide 16 by 0.7 which is 22.8 i.e., 23.

- So we need to incorporate about 23 diodes since the total drop from these amounts to 16.1v

- Now, the calculated safe input voltage to the regulator is 66v - 16.1v which is 49.9v appxm. 50v

Step 6:

- We supply the 50v to the regulator chip and adjust the output to 13v.

- For more protection, we use ferrite beads to cancel out any unwanted noise on the output voltage.

- The regulator should be mounted on an appopriate sized heatsink in order to keep it cool.

- The tantalum capacitor connected to the 2153 is an important capacitor that makes sure ic gets a smooth dc from the regulator.

- Its value can be reduced from 47uf to 1uf 25v safely.

Step 7:

- Rest of the circuit gets 66volts and the high current carrying points in the circuit should be wired with heavy guage wires.

- For the transformer its primary should be 5+5 turns and secondary 20 turns.

- The frequency of the 2153 should be set at 60KHz.

Step 8:

The High frequency ac to low frequency ac converter circuit using the irs2453d chip should be wired appropriately as shown in the diagram.

Finally completed.

Making a PWM Version

The following posting discusses another version of a 5kva PWM sinewave inverter circuit using compact ferrite core transformer. The idea was requested by Mr. Javeed.

Technical Specifications

Dear sir, would you please modify its output with PWM source and facilitate to make use such an inexpensive and economical design to World wide needy people like us? Hope You will consider my request. Thanking you.Your affectionate reader.

The Design

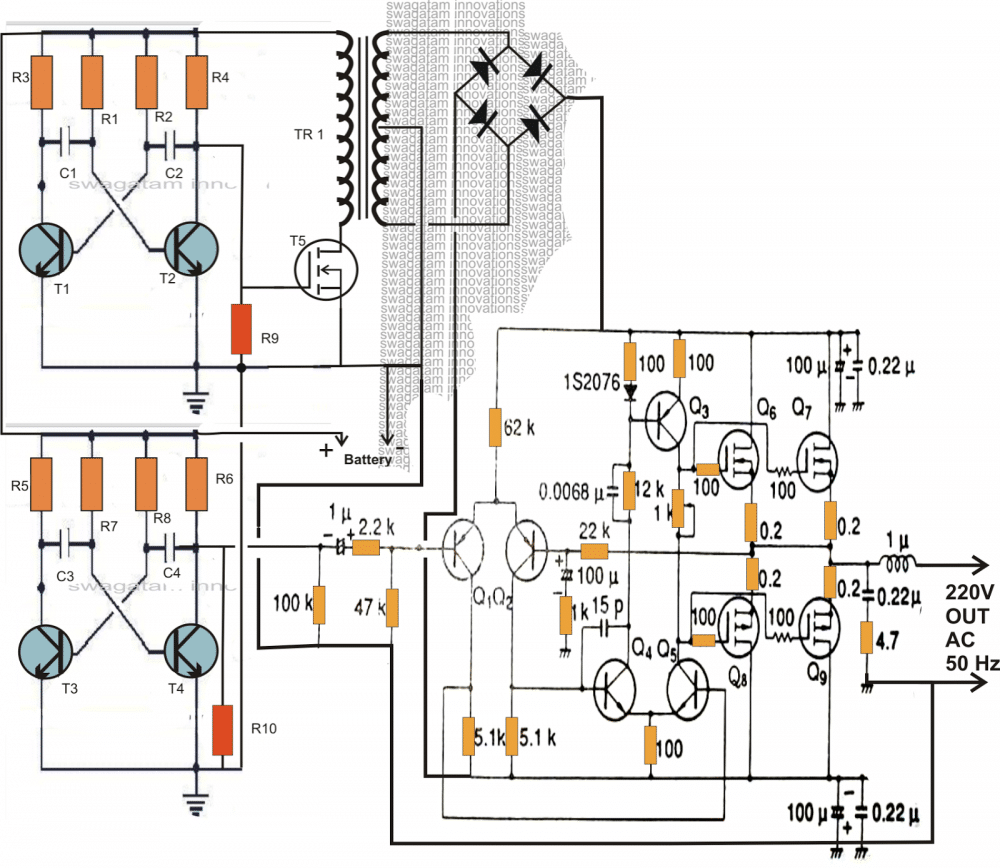

In the earlier post I introduced a ferrite core based 5kva inverter circuit, but since it is a square wave inverter it cannot be used with the various electronic equipment, and therefore its application may be restricted to only with the resistive loads.

However, the same design could be converted into a PWM equivalent sine wave inverter by injecting a PWM feed into the low side mosfets as shown in the following diagram:

The SD pin of IC IRS2153 is mistakenly shown connected with Ct, please be sure to connect it with the ground line.

Suggestion: the IRS2153 stage could be easily replaced with IC 4047 stage, in case the IRS2153 seems difficult to obtain.

As we can see in the above PWM based 5kva Inverter circuit, the design is exactly similar to our earlier original 5kva inverter circuit, except the indicated PWM buffer feed stage with the low side mosfets of the H-bridge driver stage.

The PWM feed insertion could be acquired through any standard PWM generator circuit using IC 555 or by using transistorized astable multivibrator.

For more accurate PWM replication, one can also opt for a Bubba oscilator PWM generator for sourcing the PWM with the above shown 5kva sinewave inverter design.

The construction procedures for the above design is not different to the original design, the only difference being the integration of the BC547/BC557 BJT buffer stages with the low side mosfets of the full bridge IC stage and the PWM feed into it.

Another Compact Design

A little inspection proves that actually the upper stage does not need to be so complex.

The 310V DC generator circuit could be build using any other alternate oscillator based circuit. An example design is shown below where a half bridge IC IR2155 is employed as the oscillator in a push pull manner.

Again, there's no specific design that may be necessary for the 310V generator stage, you can try any other alternative as per your preference, some common examples being, IC 4047, IC 555, TL494, LM567 etc.

Inductor Details for the above 310V to 220V Ferrite Transformer

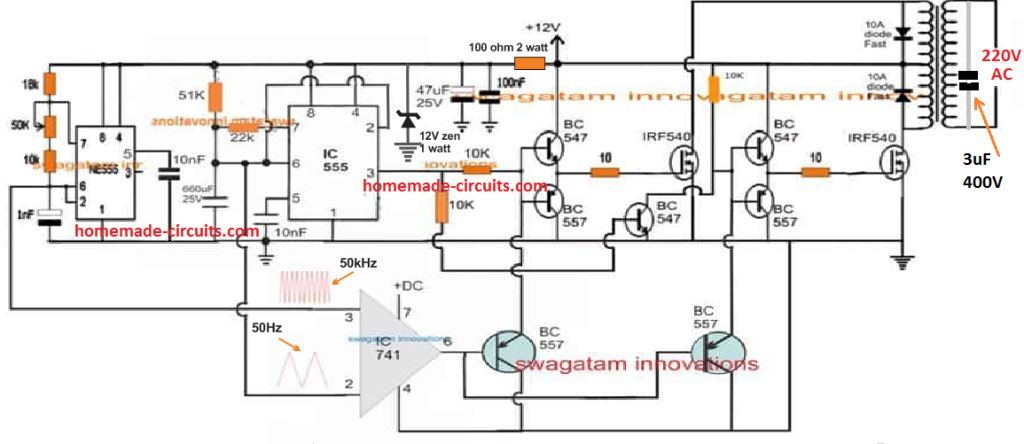

Simplified Design

In the above designs so far we have discussed a rather complex transformerless inverter which involved two elaborate steps for getting the final AC mains output. In these steps the battery DC is first needed to be transformed into a 310 V DC through a ferrite core inverter, and then the 310 VDC has to be switched back to 220 V RMS through a 50 Hz full bridge network.

As suggested by one of the avid readers in the comment section (Mr. Ankur), the two-step process is an overkill and is simply not required. Instead, the ferrite core section can itself be modified suitably for getting the required 220 V AC sine wave, and the full bridge MOSFET section can eb eliminated.

The following image shows a simple set up for executing the above explained technique:

In the above design, the right side IC 555 is wired to generate a 50 Hz basic oscillatory signals for the MOSFET switching. We can also see an op amp stage, in which this signal is extracted from the ICs RC timing network in the form of 50 Hz triangle waves and fed to one of its inputs to compare the signal with a fast triangle wave signals from another IC 555 astable circuit. This fast triangle waves can have a frequency of anywhere between 50 kHz to 100 kHz.

The op amp compares the two signals to generate a sine wave equivalent modulated SPWM frequency. This modulated SPWM is fed to the bases of the driver BJTs for switching the MOSFETs at 50 kHz SPWM rate, modulated at 50 Hz.

The MOSFEts in turn, switch the attached ferrite core transformer with the same SPWM modulated frequency to generate the intended pure sinewave output at the secondary of the transformer.

Due to the high frequency switching, this sine wave may be full of unwanted harmonics, which is filtered and smoothed through a 3 uF/400 V capacitor to obtain a reasonably clean AC sine wave output with the desired wattage, depending on the transformer and the battery power specs.

The right side IC 555 which generates the 50 Hz carrier signals can be replaced by any other favorable oscillator IC such as IC 4047 etc

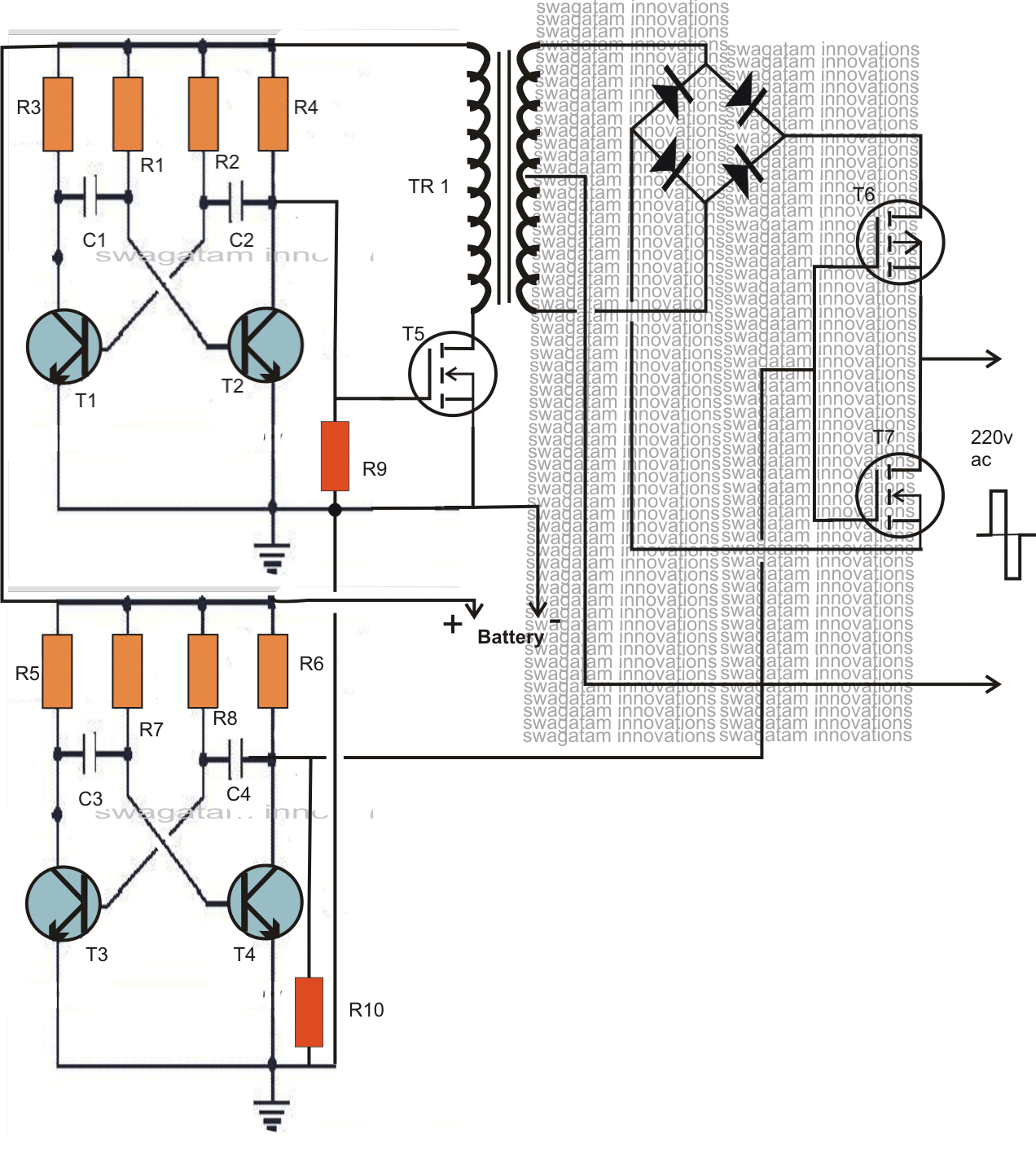

Ferrite Core Inverter Design using Transistor Astable Circuit

The following concept shows how a simple ferrite cored inverter could be built using a couple of ordinary transistor based astable circuit, and a ferrite transformer.

This idea was requested by a few of the dedicated followers of this blog, namely Mr. Rashid, Mr, Sandeep and also by a few more readers.

Circuit Concept

Initially I could not figure out the theory behind these compact inverters which completely eliminated the bulky iron core transformers.

However after some thinking it seems I have succeeded in discovering the very simple principle associated with the functioning of such inverters.

Lately the Chinese compact type inverters have become pretty famous just because of their compact and sleek sizes which make them outstandingly light weight and yet hugely efficient with their power output specs.

Initially I thought the concept to be unfeasible, because according to me the use of tiny ferrite transformers for low frequency inverter application appeared highly impossible.

Inverters for domestic use requires 50/60 Hz and for implementing ferrite transformer we would require very high frequencies, so the idea looked highly complicated.

After some thinking I was amazed and happy to discover a simple idea for implementing the design. Its all about converting the battery voltage to 220 or 120 mains voltage at very high frequency, and switching the output to 50/60 HZ using an push-pull mosfet stage.

How it Works

Looking at the figure we can simply witness and figure out the whole idea. Here the battery voltage is first converted to high frequency PWM pulses.

These pulses are dumped into a step up ferrite transformer having the required appropriate rating. The pulses are applied using a mosfet so that the battery current can be utilized optimally.

The ferrite transformer steps up the voltage to 220V at it output. However since this voltage has a frequency of around 60 to 100kHz, cannot be directly used for operating the domestic appliances and therefore needs further processing.

In the next step this voltage is rectified, filtered and converted to 220V DC. This high voltage DC is finally switched to 50 Hz frequency so that it may be used for operating the household appliances.

Kindly note that though the circuit has been exclusively designed by me, it hasn't been tested practically, make it at your own risk and on;y if you have sufficient confidence over the given explanations.

Circuit Diagram

Parts List for 12V DC to 220V AC compact ferrite core inverter circuit.

- R3---R6 = 470 Ohms

- R9, R10 = 10K,

- R1,R2,C1,C2 = calculate to generate 100kHz freq.

- R7,R8 = 27K

- C3, C4 = 0.47uF

- T1----T4 = BC547,

- T5 = any 30V 20Amp N-channel mosfet,

- T6, T7 = any, 400V, 3 amp mosfet.

- Diodes = fast recovery, high speed type.

- TR1 = primary, 13V, 10amp, secondary = 250-0-250, 3amp. E-core ferrite transformer....ask an expert winder and transformer designer for help.

An improved version of the above design is shown below. The output stage here is optimized for better response and more power.

Improved Version

Comments

The 5KVA FERRITE CORE Transformer TR1, that You use here is it center tap transformer

Then I think you should refer to the following article for all the details:

https://www.homemade-circuits.com/how-to-design-and-calculate-ferrite-core-transformers-for-inverters/

Thank you sir for your kindness, please I want to build 5KVA FERRITE CORE Transformer TR1… how can I connect the output of the primary coil 5+5 turns of 10 strands and 18 turns of 5 strands of secondary coil all in parallel, the 10 strands of primary coil and 5 strands of secondary coil, will I connect all the strands together as one or connect separately at the output of the transformer AND What is the thickness, diameter of the FERRITE CORE that I should use.Thanks

No problem Ola, here’s how you can do the winding…you must hold all the strands together as one, and then wind them together over the bobbin.

The E-core size can be estimated as per the info given in the following article:

https://www.homemade-circuits.com/smps-transformer-calculator-2/

sir pls can I use a toroidal ferrite transformer for this inverter?I have few of them laying around may b I can put them to use

Hi Abubakar,

Yes, you can use any ferrite type core for this project…

hello swagatam, nice work you’re doing here. but most of the Ic’s you used here are not available here. do you have a much more simplier desgn? and secondly i’m still still new in this high frequency ferrite core inverter, and what i have available is a 12vdc do you have a design for 12vdc battery?

Thank you Christopher, I appreciate your kind words.

The first design is the simplest one you can have. It may not be possible to create a simpler design that the first concept…

The first design uses a readymade converter module so the ferrite transformer does not need to be built by you…

Hi Swagatam, thanks for your response. I’ve got every other thing here for the first design except the reaadymade converter module. Can’t I build the converter module or something similar to it myself? if yes, please give me a guide or link to one that will be compatible with first design.

secondly, how many watt does this your first design deliver?

thirdly, what waveform does it produce at the 220vac output? can this be used with loads like fans etc?

please I’m still new to this type of design , so forgive my plenty questions.

thank you.

Hi Christopher,

I understand your problem, but unfortunately it may not be possible to build the top converter circuit for you or any newcomer because of the presence of the ferrite core transformer, which requires high expertise to build and optimize the winding and the core.

The first design is only a basic concept which can be upgraded to any required power level just by modifying the converter power output, battery and the number of MOSFETs in parallel.

It is a square wave design, fan will humming noise with this design.

thank you for your explanation and response. actually, I’m a bit familiar with winding the ferrite core transformers. I’ve got a couple of EE’s and ED core types that I can rewind.. it’s just that I had never thought I’d be interested in building a ferrite core inverter until now. So if there’s any circuit to replace the reaadymade converter module, I’ll really appreciate, as that is the main challenge i have now. Thank you Swag 😎

I completely understand Chris, that you want to build the transformer yourself, and you have some experience in this field, but winding a ferrite transformer requires elaborate calculations. If you can do those calculations then you can certainly rewind one using the available data, as suggested in the following article:

https://www.homemade-circuits.com/how-to-design-and-calculate-ferrite-core-transformers-for-inverters/

Thanks for responding so far. since the issue of the ferrite core transformer has been settled. how about the circuit diagram for the 12vdc to 310vdc converter?

Sure, here is an article which you can refer to for building a boost converter from the scratch:

https://www.homemade-circuits.com/how-to-make-simple-boost-converter-circuits/

Thank you, Swag. For your response. So, I’ve got some questions.

1. Concerning the first circuit diagram on this page, can I replace the ready-made boost converter with a boost converter I built using SG3525?

2. You mentioned before that the waveform of the inverter is a square wave. If I replace the readymade boost converter with that built from SG3525 while maintaining the other components, would it change the waveform of the inverter to a much better one(e.g modified sine wave), or would the waveform remain the same?

3. If the waveform would remain the same even after replacing the readymade boost converter to an Sg3524 boost converter, what and where do I need to make changes to get a better waveform output?

Thank you

Thank you for your response. I had already gotten all other components before I saw your last response.

Can the IRS2453 IC be replaced too? I’ve spent some days looking for it in this area, but it’s not available. If yes, which more readily available IC would I use that would still maintain the sine waveform, and how do I incorporate it into the circuit? Thank you so far for all your responses.

Please Search for “H-bridge driver ICs”, you may find some other good options also, or you can try the following simple circuit instead:

https://www.homemade-circuits.com/wp-content/uploads/2020/08/simple-ferrite-core-inverter.jpg

Hello Chris, here are the answers:

1. You can replace the boost converter with any equivalent DC to DC boost converter you want.

2. The boost converter output is supposed to be DC, so waveform cannot be achieved from this converter.

3. For a sine waveform, you can consider trying the last design using IC 555 and Ic 741.

Sir how Irs2453 voltage feeback work I can’t fine vb pin

Hello Islahuddin,

To add a feedback voltage control to Irs2453 IC, you will need to configure either its CT pin or the SD pin with the feedback transistor or the opamp…..the Vb pin is not required.

Good day sir

I love your work, please how can I get the GERBER PCB FILE OF THE PROJECT

THANKS

Thank you Russell, however, sorry I do not have the GERBER files for this project. I would rather suggest you to try the project on a strip-board first, and test the results, before designing a PCB.

Hello Mr Swagatam how much would it cost to order components from your country to Maseru Lesotho. Most of the components I need to build my projects are not available in my country.

Hi Poloko, sorry, I have no idea how much it would cost to procure parts from India to your country, you may have to inquire this with the part supplier.

Hi there! That is a very interesting circuit that I intend to try soon after locating the elusive high power, adequately sized ferrite transformer. Here clarity is not given for winding the transformer for running the unit off 24v (2X12/150A, a very common battery combination in many households.) as this info wasn’t available although it was suggested. One suggestion worth examining is that you’ve used a high wattage resistor to create 15v to power the low voltage section from high voltage Dc. A more elegant solution is to use a common 12v wall adaptor that are used in many applications can be taken apart and the Hi voltage Dc can be connected across the Hv Filter cap that is on the unit. The 12v Dc output can now be connected instead of the previous arrangement although 15v is suggested I feel it should be satisfactory or a 15v adaptor could be used. This is more efficient and will give out much less heat also.

Hi, thanks for the feedback!

A 24V DC would call for a huge amount of current from the transformer and the battery. To be precise we would need around 5000/24 = 208 amps, that is why 60V source is selected to minimize the current spec as far as possible.

The article provides the transformer details for a 60 V ferrite transformer.

Yes, the 12V or 15V DC can be obtained from an SMPS source or from a buck converter circuit such as the following design:

https://www.homemade-circuits.com/simple-220v-smps-buck-converter-circuit/

Hello how r u

I want to know that transformerless 5 kva circuit will work satisfy or just for ..

It will work satisfactorily if you build it correctly.

Block diagram and its function

Thank you very much for the kind information, appreciate it.

Hi Seagatam,,,I built a tl494 circuit,,,I made use of z44,,,,,but they keep getting hot with or without load

Hi Md, read the following article, and try implementing them as required:

https://www.homemade-circuits.com/mosfet-protection-basics-explained-is/

IN IRS2453 CIRCUIT FOR 50HZ WHAT IS RT AND CT

Rt is the timing resistor and Ct is the timing capacitor, these parts determine the output frequency.

Rt,100k ρυθμιζόμενο ct100n ,όλα εντάξει αλλά τα ,hz παρά πολλά.

Your detailed step by step teaching is awesome and simply top notch! Keep up the good work!

I will need your advice on two things

1. Need to purchase a low power variable single phase high frequency AC supply. Can you recommend one for me please?

2. I need already built inverters with the high frequency intermediate state as shown in your design. I need your recommendation please.

Kind Regards

Thanks a lot Swagatam for your good works. I’ll appreciate if you can give me a circuit to convert my 110 VAC 5kva Colman inverter to 220 VAC. And I’ll also like to get a circuit design for 12 VDC car battery charger. Thanks once again.

phanyessence@gmail.com

Thank you Epiphany,

You will need an external 100V to 220V transformer for converting your 110V to 220V.

For the battery charger you can investigate the circuits provided in the following articles:

https://www.homemade-circuits.com/opamp-low-high-battery-charger/

https://www.homemade-circuits.com/high-current-10-to-20-amp-automatic/

Hi, Thank you and Glad you liked the post!

Sorry to say this, but since I have not used any readymade VFD or inverter so suggesting a specific brand may not be possible for me.

Thanks very much Swagatam. I really do appreciate your sacrifice of time. Please I will need your support to deliver on this project. even if it is for a fee. You have my email address, do message me privately please.

You are welcome Achor! I above circuit is recommended only for the experts in electronics, not for the newcomers. If yu are well versed with electronic circuits and ferrite inverters then you can try this circuit.

Thanks very much. With respect to the 5Kva system , on no load condition, please what amount of power loss do we incur on the ferrite core with the high frequency(50-100khz) input supply?

I am not exactly sure about it, but the efficiency should be around 90% for the above designs without a load or with load.

OK, thanks very much. That gives one an idea of the power loss.

Kind Regards

No problem!

Good details…i like your work..I am interested in making an altenator using microwave transformers iron core,by welding them in multiple together to form three octagons from those cores and join them together, then winding as many turn of copper as possible to produce lets assume around 310v with frequency higher than 50/60hz as the rpm of neodymium magnet inside the core shall be aim high to increase the output….then rectify it to high Vdc…and then inverting it to 220v ac at 50hz…Asking for any assistance and guidance to best approach ….thanks

Thank you for your question. Please let me know what help exactly you need from me, if it is possible I will surely try to solve it for you.

Swagatan, well-done and thank you for your services and contributions to the spread of knowledge in electronics. I was designing a 3KVA inverter using SG3524 as PWM pulse generator and 2N7000 for the driver stage. I discovered that the biasing resistor one side of the driver stage was always getting hot. Initially I used 1/4watt resistor and later changed it to1/2watt resistor but the result was still the same. Kindly advise me on what to do. Thank you.

Thank you Oyekan,

That is very strange because 2N7000 is a MOSFET and MOSFETs have a high gate impedance, which means the bias resistor connected with the gate have negligible flow of current through it.

It seems your MOSfET is burned or faulty, otherwise the gate should provide a high impedance to the resistor and it shouldn’t become hot under any circumstances.

Try replacing the MOSFET with some other mosfet and check the response.

a narrow width and a large width when passed through photochromic retainers, while passing through ferritic transformers do not retain the essence, so the project using ferrite transformers will not be successful because when smoothing it doesn’t produce a sine wave