The IC 4017 can be considered as one of the most useful and versatile chip having numerous electronic circuit applications.

About IC 4017

Technically it is called the Johnsons 10 stage decade counter divider. The name suggest two things, it’s something to do with number 10 and counting/dividing.

The number 10 is connected with the number of outputs this IC has, and these outputs become high in sequence in response to every high clock pulse applied at its input clock pin out.

It means, all its 10 outputs will go through one cycle of high output sequencing from start to finish in response to 10 clocks received at its input (pin#14). So in a way it is counting and also dividing the input clock by 10 and hence the name.

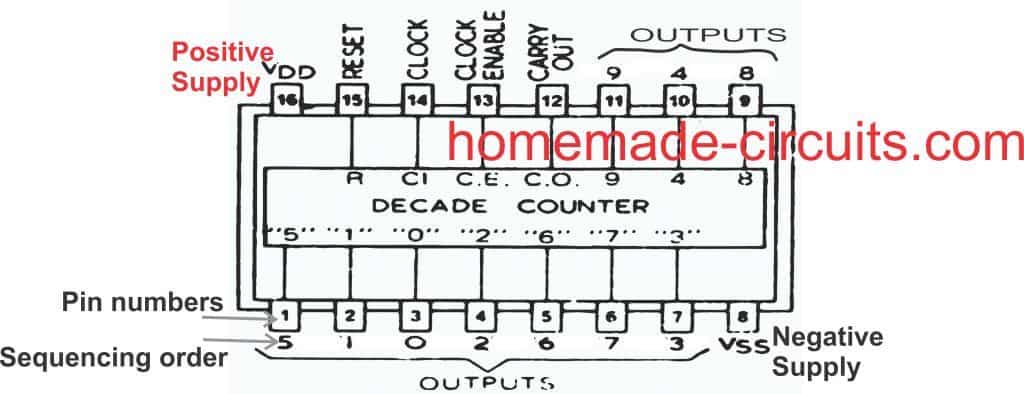

Understanding pinout Function of IC 4017

Let’s understand the pin outs of the IC 4017 in details and from a newcomer’s point of view: Looking at the figure we see that the device is a 16 pin DIL IC, the pin out numbers are indicated in the diagram with their corresponding assignment names.

What do Logic High, Logic Low Mean

The pinout which are marked as outputs are the pins which are rendered logic "high" one after the other in a sequence in response to clock signals at pin#14 of the IC.

"Logic high" simply means attaining a positive supply voltage value, while "logic low" refers to attaining zero voltage value.

When the IC 4017 is initially switched ON, it gets reset, and a logic high appears at pin#3 by default. We will discuss the resetting process in the later paragraphs.

In this position, when the first clock pulse is applied at pin#14, the existing logic high at pin#3 jumps from pin#3 to the next pinout that is pin#2. The logic high remains locked on pin#2 until the next clock is applied on pin#14, which causes the high logic at pin #2 to jump from pin#2 to the next output pinout that is pin#4, and this sequencing of logic high goes on until it reaches the last pinout of the IC which is pin#11, after which the logic high sequence jumps back to pin#3, and the cycle repeats again.

What is the Output pin Sequencing order?

To be precise, the sequencing movement happens through the pinouts: 3, 2, 4, 7, 10, 1, 5, 6, 9, 11...

After pin#11 the IC internally resets and reverts the logic high at pin #3 to repeat the cycle.

Why Pin 15 Should be Grounded

This sequencing and resetting is successfully carried out only as long as pin#15 is grounded or held at a logic low, otherwise the IC can malfunction. If it is held high, then the sequencing will not happen and the logic at pin#3 will stay locked.

Please note that the word “high” means a positive voltage that may be equal to the supply voltage of the IC, so when I say the outputs become high in a sequential manner means the outputs produce a positive voltage which shifts in a sequential manner from one output pin to the next, in a “running” DOT manner.

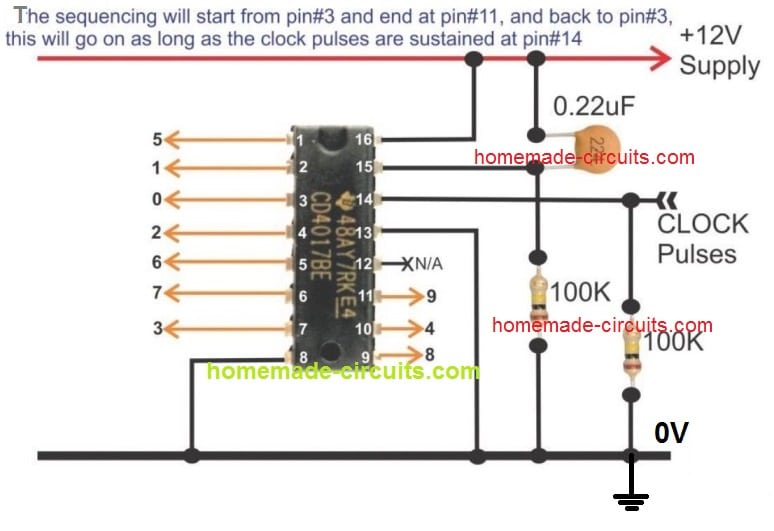

Pin 14 Needs External Frequency (Clock Signal)

Now the above explained sequencing or shifting of the output logic from one output pin to the next output is able to run only when a clock signal is applied to the clock input of the IC which is pin #14.

Remember, if no clock is applied to this input pin#14, it must be assigned either to a positive supply or a negative supply, but should never be kept hanging or unconnected, as per the standard rules for all CMOS inputs.

The clock input pin #14 only responds to positive clocks or a positive signal (rising edge), and with each consequent positive peak signal, the output of the IC shifts or becomes high in sequence, the sequencing of the outputs are in the order of pinouts #3, 2, 4, 7, 10, 1, 5, 6, 9, 11.

Pin 13 is Opposite of Pin 14

Pin #13 may be considered as the opposite of pin #14 and this pin out will respond to negative peak signals. Meaning if a negative clock is applied to this pin will also produce the shifting of "logic high" across the output pins

However normally this pin out is never used for applying the clock signals, instead pin #14 is taken as the standard clock input.

Therefore pin #13 needs to be assigned a ground potential, that means, must be connected to the ground for enabling the IC to function.

In case pin #13 is connected to positive, the whole IC will stall and the outputs will stop sequencing and stop responding to any clock signal applied at pin #14.

How Pin 15 Works Like reset Pin

Pin #15 of the IC is the reset pin input. The function of this pin is to revert the sequence back to the initial state in response to a positive potential or supply voltage.

Meaning, when a momentary positive voltage hits pin 15, the output logic sequencing comes back to pin #3 and begins the cycle afresh.

If the positive supply is held connected to this pin #15, again stalls the output from sequencing and the output clamps to pin #3 making this pinout high and fixed.

Therefore to make the IC function, pin #15 should always be connected to ground.

If this pinout is intended to be used as a reset input, then it may be clamped to ground with a series resistor of 100K or any other high value, so that an external positive supply now can be freely introduced to it, whenever the IC is required to be reset.

Using Pin#15 to Reduce the Number of Output Sequence

As I have explained above, there are 10 outputs in the pinout order of 3, 2, 4, 7, 10, 1, 5, 6, 9, 11.

The sequencing begins from pin#3 and ends at pin#11, where the IC resets and the sequence reverts to pin#3 to begin a new cycle.

However, suppose you do not want to use all the 10 output sequences, instead want to limit the sequence to 5 numbers only. Meaning, you want to use the output sequencing in order of 3, 2, 4, 7, 10. The sequence is supposed to begin from pin#3 and end at pin#10 and return back to pin#3.

However, this cannot happen as long as pin#15 is connected to ground. To limit the sequencing to a desired lower count, the pin#15 should be disconnected from the ground line, and connected to output pin which comes just after the last sequence pinout.

In the above example, where we want the sequence to end at pin#10, the next pinout that comes after pin#10 is pin#1, so pin#15 must be connected to this pin#1, to ensure that whenever the sequencing hits pin#1, it is instantly reverted to pin#3 for a new cycle, and the maximum output sequencing is limited to 5 count only.

In the above manner you can limit the output sequencing to any other desired count below 10.

Ground pin and Carryout Pin

Pin #8 is the ground pin and must be connected to the negative of the supply, while pin #16 is the positive and should be terminated to the positive of the voltage supply.

Pin #12 is the carry out, and is irrelevant unless many ICs are connected in series, I will elucidate it some other day. Pin #12 can be left open.

Have specific questions?? please feel free to ask them through your comments...all will be thoroughly addressed by me.

Basic IC 4017 Pinout Connection Diagram

Application LED Chaser Circuit using IC 4017 and IC555

The following example GIF circuit shows how the pinouts of a IC 4017 is usually wired with an oscillator for obtaining the sequential logic high outputs. Here the outputs are connected to LEDs for indicating the sequential shift of the logics in response to each clock pulse generated by the IC 555 oscillator at pin#14 of the IC 4017.

You can see that the logic shift happens in response only to the positive clock or positive edge at pin#14 of the IC 4017. The sequence does not respond to the negative pulses or clocks.

IC 4017 Working Simulation

Video Clip:

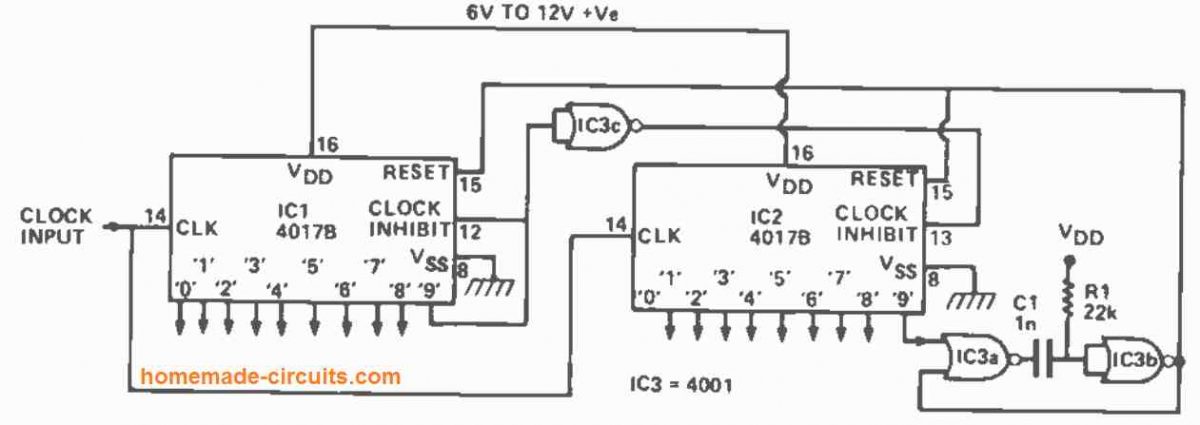

How to Cascade Two 4017 ICs for Getting 17 Sequencing Outputs

The diagram above shows how to connect two 4017s together to create a 10-to 17 stage counter/decoder. It shows how to cascade two 4017 ICs to get 17 sequencing outputs instead of only 10 from a single IC. The circuit is shown configured to divide by 17.

The clock signal is supplied in parallel to IC1 and IC2. As soon as the count falls below 9, the '9' output of IC1 turns low, causing the clock inhibit pin of IC2 to be set high through IC3c, preventing IC2 from being impacted by the clock signals.

The '9' output of IC1 rises high when the 9th clock pulse comes, inhibiting IC1 from further clocking action, while simultaneously driving the clock inhibit terminal of IC2 low through IC2c, allowing IC2 to respond to further clock signals.

When the 17th clock pulse arrives, the '9' output of IC2 swings high for a brief period, triggering the IC3a -IC3b 15uS monostable. This 15us pulse resets both counters to the empty or '0' states.

After that, the counting sequence starts again by itself. Because the '9' output of IC1 and the '0' and '9' outputs of IC2 are "lost" in the counting process, the circuit only has 17 counter/decoder stages available. By connecting the "free" input pin of IC2a to the matching output pin of IC2, the circuit can be made to count by any number between 10 and 17.

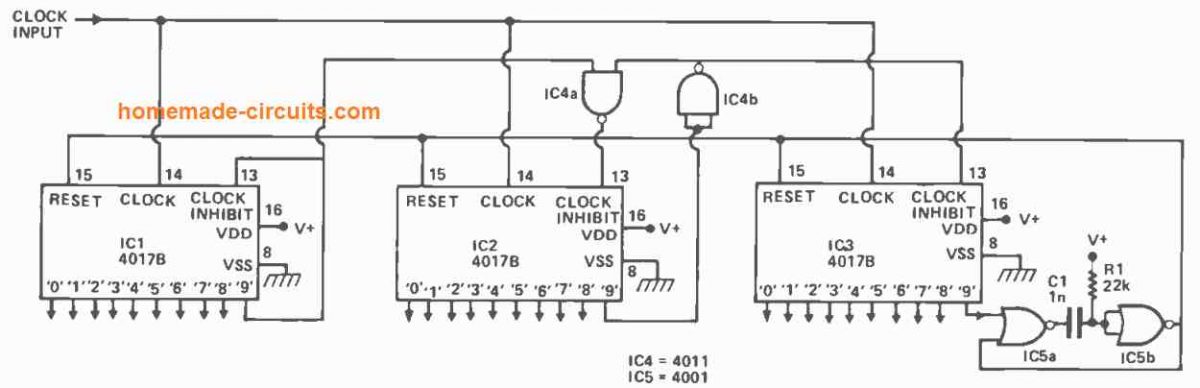

How to Cascade Three IC 4017 for Getting 25 Sequencing Outputs

The configuration for creating an 18 to 25 stage counter/decoder from three 4017s can be seen in the diagram above. IC3 is inhibited by IC4b and IC2's low output '9,' whereas IC2 is inhibited by IC4a and IC1's low output '9,' until the 9th clock pulse. Between the 10th and 17th clock pulses, IC1 is inhibited by its high '9' output, while IC3 is inhibited by IC4b and IC2's low output '9'.

Subsequently, between the 18th and 25th clock pulses, IC1 is inhibited by its high '9' output, and IC2 is inhibited through the high '9' outputs of IC1 and IC2 using IC4c, and the whole circuit is reset to the '0' state by means of the IC5a and IC5b monostable.

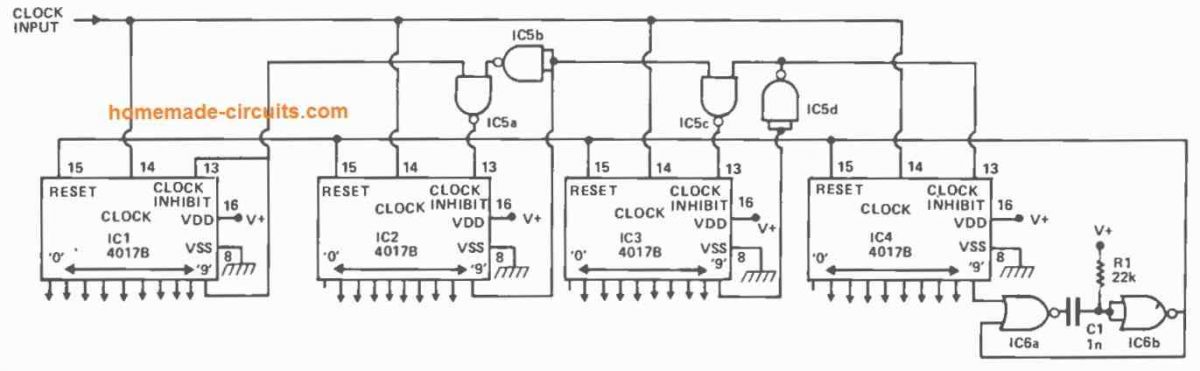

How to Cascade Four IC 4017 to get 33 Sequencing Outputs

Using a divide-by-33 operation, the above setup shows how to make a 26 to 33 stage counter/decoder set. By interposing extra IC2-1C5a-1C5b stages between 1C2 and 1C3, this design may be extended to provide a ny number of decoded output stages. Each subsequent 40178 stage adds eight decoded outputs to the system.

Comments

disculpen la molestia , pero lo que deseo saber es que tipo de circuitos integrados son los que aparecen en el diagrama: IC3a, IC3b, IC3c, IC4a, IC4b, IC5a, IC5b POR EJMPLO

The IC numbers are given in the diagram, IC 4001 and IC 4011…

buen dia

En los diagramas mostrados aparecen los circuitos IC1, IC2, IC3, IC4 E IC5. Quiero saber que tipo de circuitos so esos (555, otro?) Y COMO ES SU CONEXXION

555 IC is used as an oscillator IC to feed the clock signals, or the ON/OFF alternate pulses to pin14 of the 4017 ICs.

hi, my name is hank, my question is the 18 to 25 count circuit schematic at the top is connected for the divide by 18 or is it 25… I need a system that give me a 1 output only every 18 pulses ….which pin of the cd4017 do I need to use….12-13-25 @ 4:AM thank you hank…..

Hi Hank, that circuit is divide by 25 circuit…

Please go on counting from 1st to the last pin of IC1, IC2, IC3, to get the 12, 13, 25 outputs serially.

I have built many fine circuits with your advice; I just did one as an LED driver for mini-Christmas lights on a dollhouse. I was thinking about adding a small capacitor to each of the 4 outputs I am using to act as a delay bleed down to the gate of the 2222 transistors I am driving. I am thinking this will give me a more incandescent look to the lights as they switch off.

My question is will this cause any issues with the chip if I do not first install a diode on each output before the cap?

Sounds great! Yes, adding a slight delay will certainly give the LEDs an incandescent filament bulb type of lagging ON/OFF switching appearance.

nice one. thanks. but in my circuit, for the first counts 3, 2,and 4 also, the pin 12 is high. seems they must be low . i have let the pin12 floating as i do not use it in my applicaiton. also, after 3 counts, i want to reset the IC to restart from pin3 onwards. but it is not happening. can you help me.

Greetings, dear friend, probably the base connection of an ic555 is not connected to the negative

Thanks Babu, that is correct, pin#12 will be high for the first 3 counts and then become low until pin#9, then again high until pin#4. You can keep it floating or open if you don’t need it.

If you want to reset the IC after pin#4, then just connect the pin#15 with pin#7.

To make sure the IC starts always from pin#3 during power ON, make sure to connect the above mentioned pin#15 with pin#7 through a 10k resistor, and then connect pin#15 with positive rail through a 0.1uF capacitor.

hi, Swagatam its long time follower of you, Need Led Chaser for making aerrow of 10 sets of coloured 5mm led x 2 set for both side. The Led arrange sequence in no. 1-3-3-3-3-3-3-3-3-3 which is same in another side. Lighting Sequence needed blinking start from right and End in 1 and after that total set glowing at a time for 20 sec and again the sequence repeat. Can it be possible in 12 volt 1-2 amp max besic smps driver because it used in road and housing would be 32 mm or maz 40 mm waste pipe housing. Again Besic 4017 and 555 IC Circuit can Perform this. Basically I need this With Showing your regular cheap circuit. Thank You. Waiting For Your Circuit review with Components and Diagram by which I Can make It. Waiting for your convenient.

Thank you Rajib,

So you want the chasing effect on the LED string by initially flashing of the single LED then remaining groups of 3 LEDs chasing forward? Do you want the 3 LED groups to shut off after each 3 LED lights up, or to hold the illumination until the whole array lights up and then shut off together?

If you want them to hold until the whole string is lit up, then you may want to do something as explained in the following article:

https://www.homemade-circuits.com/welcome-chasing-led-display-circuit/

Let me know your opinion….

Hi Swagatam,

In cascading, why can’t I cascade the chips directly as shown in this website

https://www.homemade-circuits.com/wp-content/uploads/2025/03/how-to-cascaade-4017-ICs.jpg

Using the CarryOut pin?

Thanks.

Hi Nelio,

The pin#12 of the IC 4017 is HIGH for 5 clock pulses and LOW for the next 5 clock pulses in one complete cycle of 10 counts.

So I don’t know how this cascading can cause a continuous sequential flow across the outputs of the two ICs to generate 20 continuous output sequences. If that would be so simple then i wouldn’t have used such complex methods to cascade the 4017 ICs.

But I could be wrong, so I would request you to try this method and let us know if that works or not?

Hi, Swagatam,

I have assembled the circuit Cascade with 3 chips 4017, making the stop at Output 3 of the 3rd 4017, since I’m only lighting 20 LED’s, but I have a situation: LEDs connected to Output 0 of 2nd 4017 and Output 0 of 3rd 4017 are always ON, turning OFF when the sequence passes through them, but lighting ON again when reset occurs.

How can I solve this?

Nélio

Hi Nelio,

Did you modify the IC5a input which is connected to pin#9 of IC3 4017? You might need to connect it to pin#4 of IC3 4017?

But I think these circuits are overkill, they can be much simplified using BJTs.

Hi, Swagatam,

Has I mentioned, «making the stop at Output 3 of the 3rd 4017» Output 3 which is pin 4 of the 3rd 4017 is connected to the input of IC5a.

I have reviewed the connections several times, but the LED’s connected at Output 0 (pin #3) of 2nd and 3rd 4017 are always ON, turning OFF when the sequence passes by them, but turning back ON when resets occur.

Hi Nelio,

Yes, pin#3 is always ON by default whenever the IC 4017 is in the “standby” position.

So, while your 1st 4017 is operating the other two are “waiting” and in the standby position, which means its pn#3 will be ON.

The easiest way to eliminate this is simply not use the pin#3 of the 2nd and the 3rd ICs.

Or the other method is to power ON the subsequent ICs only when the previous IC has finished counting upto 10. In this way if the ICs have no power in the standby mode, their pin#3 will be off.

If you want this method, I can draw it for you…

I’ll probably try another approach…. will test the cascade configuration of the datasheet of the 4017, using a single AND chip.

Thanks anyway.

Nélio.

Ok, great! let me know how it goes…

Hi, Swagatam,

The cascade works but not in full sequence.

As soon as the 1st 4017 reaches Output 9, the next 4017 advances from Output 0 to Output 1, and the 1st 4017 resets.

The second 4017 only advances whenever the first 4017 reaches Output 9

Thank you Nelio,

So the results are not correct, and that cascading is not effective.

Hi Swagatam,

I cannot get a simple 4017 5 LED chaser to work. Have checked and checked and still cannot see what is wrong. All LEDs flash together and sometimes change but not in the expected order. Same problem I had with previous 4017s but have replaced witha brand new one today and see the same problem. Any ideas what may be causing this? I have pin#1 connected to pin#15 to only cycle the first five outputs. Also have input from 555 to pin 14 with 100K ohms pin #14 to ground…

Do I need to put 1K from the unused pins to ground?

Thanks for any help.

Cheers

Hi Michael,

You just need the following basic setup, please try it with a push button first and check whether the output logic sequences or not in response t each pressing of the push button:

https://www.homemade-circuits.com/wp-content/uploads/2024/10/4017-test-set-up.jpg

Please keep a pause of at least 2 seconds between each pressing.

If it works then your IC is good, and now you can remove only the 1uF capacitor and keep everything else as is, and integrate the 555 oscillator’s pin#3 with pin#14 of the 4017

Hi Swagatam,

This has been a work in progress for a little while but now that I have a handle on the 4017 circuit I need to incorporate it into a circuit you provided called “motor-control-using-photo-interruptor”. You may recall it was triggered by a flash/pulse and was to run for only a few revolutions.

I can send the image you linked if you cannot locate it. I actually need to trigger the 4017 circuit simultaneously with the pulse that starts the motor and stop the motor after the number of revolutions counted by the 4017 circuit (this is done by a microswitch on a cam driven by the motor. Each rev will increment the counter like in the push button option you sent earlier). So I need to also add a switch which will replicate the pushbutton and after 5 revs turns off the power to the circuit. Does this make sense?

Hi Michael,

Yes I remember it, and it make sense, however when do you want the 4017 outputs to advance, is it when the light of the photo interrupter is just blocked or after it is just released?

Let me know about it, I will try to figure it out.

Hi Swagatam

I am removing the photointerrupter and replacing it with a microswitch – closed when pushed otherwise open – so it will be the switch circuit that inputs to pin14 on the 4017IC.

Thanks

Thank you Michael,

So after 5 revs you want the power supply to the 4017 IC circuit should be shut off automatically and permanently, which can be reset back manually through a separate push button maybe, is that right?

Hi Swagatam.

So after 5 revs when the microswitch is closed by the cam on the motor, the power to the motor should go off until another starting pulse is sent to the main circuit. At 5 revs as I understand it, the 4017 should already be reset so the next time the motor starts it will be at the start of rev 1.

Hope this helps

Ok, understood, so it looks pretty easy actually.

We simply drive the motor through a PNP Darlington transistor whose base is controlled by the 5th output from the 4017 IC.

As soon as this 5th output becomes high, the PNP driver transistor is turned OFF, which turns off the motor.

Hi Swagatam,

Thanks for the new circuit design. It makes sense. I will look into the reed switches a little more – seems they may have an issue with longevity though?

Problem – I have breadboarded the circuit you sent and have sent 7 ICs and a few PNPs to the graveyard. I am using a 12V power source but would think they should handle it. I do need the 12v for the motor to run.

Hi Swagatam,

Still persisting with this. Have fried numerous 4017s I will send you the full circuit schematic once I get it finalised and perhaps you can why its popping my ICs. In the whole circuit its only the 4017 that cant handle it. Can I send the KiCad file or do I just send a image? What is the best email for this?

Hi Michael, you can send the image of the schematic too my email, I will check it out and continue the discussion under this comment…

homemadecircuits

@gmail.com

Hi Michael,

The circuit which I provided you is perfect and 100% correct.

12V is the correct and preferable supply DC for any CMOS IC, I hope you are using a CMOS version of the 4017 IC, otherwise it could instantly burn.

The transistor can burn if it is not rated as per the motor current.

Since you said your motor was very small, i assumed that BD140 would be enough for it, nevertheless you can upgrade the transistor to TIP127 for better safety, if required.

Let me know if you happen to troubleshoot the issue…

Its just a small motor. Testing so far indicates there is virtually no inertia once the power goes off. In fact I am thinking I will need a small capacitor to actually push it past the microswitch. Well fingers crossed anyway 🙂

In that case you can try replacing the microswitch with a reed switch for a frictionless operation.

The following diagram should do the job:

https://www.homemade-circuits.com/wp-content/uploads/2024/10/4017-motor-control-circuit.jpg

Ahh good. Forgot the reset will happen at the same time pin1 goes high. The “looping” circuit is also basically triggered by the starting pulse for the motor. So I need the following circuits to work together (a small challenge for you … well maybe not) :-

a) a circuit that has slow fading/glowing LEDs which are on/off with main power source so this happens regardless of any pulse to the circuit (I have this already)

b) a pulse initiated circuit to power the motor which is only active while pin3 on the 4017IC is low (will this control the start of the motor if the initial pulse is also sent to pin14?)

c) a pulse initiated circuit to count 5 revs (each count is manually triggered by a cam on the motor closing a microswitch at zero degrees rotation)

d) a flashing LED circuit that only has power while the motor is rotating (I have this already).

Does this all make sense and can they work together?

Thanks again for your efforts with this project.

All the above things can be designed, but I am wondering how would you stop the motor rotational inertia. Even if the motor supply is turned off at pin#3, the motor shaft may keep rotating due to inertia and keep triggering the microswitch and never turn off?

Does that mean there will be only 4 revs? Do the pin assignments need to be advanced by 1?

It will be 5 revs:

3 to 2 = 1 rev

2 to 4 = 2 rev

4 to 7 = 3 rev

7 to 10 = 4 rev

10 to 1 and reset to 3 = 5 rev

So I assume then that because 4017 pin1 then goes low, the next pulse will be able to start the motor again for 5 revolutions. Correct?

Oh, I forgot that at the 5th pulse at pin#14, the 4017 needs to reset also, which means the PNP transistor would switch OFF only momentarily and then turn ON again instantly.

OK, so we can do one thing, instead of pin#1 we can use the pin#3 with the PNP base to shut off the motor, and let pin#1 be solely for the resetting purpose, connected with pin#15.

This should take care of everything perfectly.

Sorry. Was using a 10uF capacitor. 1uF works for each push to advance. I will try converting to the 555 input and let you know.

Ok no problem, just make sure to remove the 1uF after you connect the pin#3 of 555 with pin#14 of the 4017.

Hi Swagatam,

Actually interesting thing now but I think I have worked out what has been happening…

When I remove the capacitor all the LEDs start flashing in sync with the input at pin14. So same problem returns. Capacitor back in and it works nicely.

My 555 circuit has been adjusted to a 50/50 duty cycle so I am guessing that this has been the reason for the strange behaviors I have been seeing. Must be related to how the 4017 handles the pin14 input.

Thanks Michael, for the updates,

CMOS ICs can be specifically sensitive to RF noise and disturbances, the pin#14 being a sensitive input of the IC might be getting rattled by some sort of RF noise existing in your setup, it is not due to 555 IC’s 50/50 duty cycle.

Anyway, glad the problem is solved now through a capacitor.

Thanks for the quick reply. No luck. I added the push button. The circuit starts with pin3 on but nothing happens when I press the button. But all the LEDs have stopped flashing when the button is pressed (=output from 555).

Hi,

the ON/OFF time is not critical because the 4017 pin#14 will respond and trigger only to the switch-ON rising edge of each pulse…

Hi again

Just wondering about the 555 LED. Should it be more OFF and flash ON, or mostly ON and blink OFF (which is what it’s doing now).

Thanks