In this post I have explained s few simple DC to DC buck-boost converter circuits which can be used for either stepping up the input DC voltage or stepping down the input DC voltage to specific output DC voltage levels.

Since a buck-boost converter allows the input voltage to be either stepped up or stepped down, hence it is named as buck and boost converter or buck-boost converter.

Basic Working principle

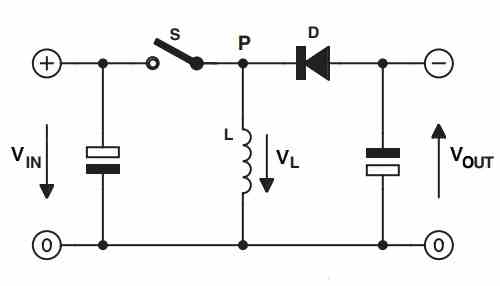

The basic working principle of a buck-boost converter can be understood with the help of the following explanation.

Referring to the basic buck-boost topology diagram above, when the switch S is closed, the input voltage VIN is blocked by the diode D, since D is reverse biased. Therefore the voltage has no other option but to flow through the inductor L.

The inductor L due to its inherent reluctance property initially tries to block the current. Due to this, initially the voltage drop across L is high. However, slowly as the reluctance of the coil decreases and the current through the inductor increases.

During this phase the inductor L stores the energy (voltage and current) inside its winding.

Ideally this the point when the switch S needs to be opened.

When switch S is now opened, the voltage VL stored inside the inductor reverses direction, and it passes through the diode D which is now forward biased. In the process VL also passes through the output capacitor and charges it fully.

During this phase the output capacitor stores energy inside it and gets fully charged, simultaneously the load across VOUT also gets the energy from the inductor for ts operation.

Next, at this point if the switch is closed again, the process repeats as explained above, however now the capacitor provides its stored energy to the load.

Depending how how fast or how slow the switch S is closed and opened, the output DC can be a stepped up or boosted output, or it can be a stepped down or buck output.

In a real life electronic buck-boost circuit, the switch S is replaced with a BJT or a MOSFET and this device is switched ON/OFF through an external PWM for generating a buck or a boost output.

Simple Two Transistor Buck-Boost Converter Circuit

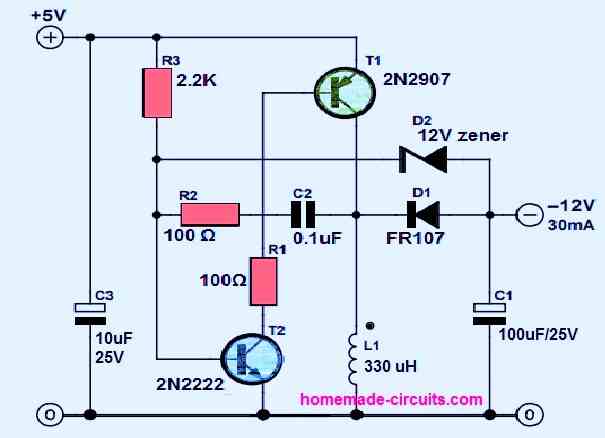

The following figure shows how a very simple buck-boost converter could be built using just a couple of transistors and a few other passive parts.

The working of the circuit can be understood from the following points:

Here the circuit is configured to provide a negative boosted output from a 5V input to a -12V output.

As soon as the circuit is powered, the T2 switches ON via R3. This allows T1 to also switch ON through the negative base bias received via R1 and T2.

This causes the full +5V to be applied across the inductor L1 via the collector of T1.

The inductor, due to it reluctance opposes the instant rise in current across it and in the process begins storing energy inside its winding.

Now, slowly the inductor reluctance drops and it starts passing more and more current through. Due to this the base current of T2 is pulled to ground through the inductor and via R2 and C2.

This causes T2 to shut off momentarily.

Now, the stored energy inside the inductor is released back to the output across C1.

C1 now charges fully and simultaneously the output is also supplied with a negatively boosted voltage.

The 12 V diode makes sure that the inverted output boosted voltage does not rise above -12V.

Subsequently C2 begins charging until it is fully charged, which allows T2 to switch ON again, and the process repeats. This repetition process continues at a high frequency.

The frequency of the converter is determined basically by the values of R2 and C2.

By appropriately tweaking the values of R2 and C2, this two transistor circuit could be optimized either to work like a buck converter or a boost converter.

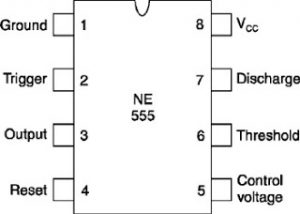

Using IC 555 for the Buck-Boost

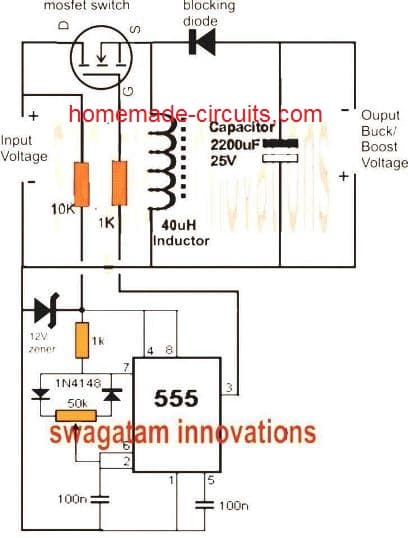

This highly efficient and effective buck-boost circuit using the work horse IC 555 would allow you to convert an input source voltage to any required degree, either bucked or boosted, as desired.

We have already learned the concept comprehensively through one of my previous articles where I have explained the versatility of this buck-boost type of topology.

As shown in the circuit diagram below (click to enlarge) the configuration is basically a combination of two distinct stages, viz the upper buck-boost converter stage and the lower IC 555 PWM controller stage.

The buck-boost stage consists of a mosfet which acts like a switch, the inductor which is the main power converting component, the diode which just like the mosfet forms a complementary switch, and the capacitor quite like the inductor forms a complementary power converter device.

The mosfet needs to operate through pulsed triggering so that it alternately switches the input voltage ON and OFF across the inductor in response to its gate voltage.

Therefore the gate voltage should also be in a pulsed form which is accomplished through a IC555 PWM generator stage.

Circuit Operation

The associated IC555 PWM generator is integrated to the mosfet for accomplishing the above discussed operation.

During the ON time of the mosfet, the input voltage is allowed to pass through the mosfet and is applied right across the inductor.

The inductor owing to its inherent property tries to counter this sudden infliction of current by absorbing and storing the power in it.

During the subsequent OFF period of the mosfet, the input voltage is shut off by the mosfet, the inductor now experiences a sudden change in current from peak to zero. In response, the inductor counters this by reversing its stored power across the output terminals via the diode which now acts in the forward biased condition.

The above power from the inductor appears with opposite polarity across the output where the intended load is connected.

The capacitor is positioned to store a portion of the power in it, so that it can be used by the load during the ON time of the mosfet when the diode is reverse biased and power cut off across the load.

This heps to maintain a steady and stable voltage across the load during both ON and OFF cycles of the mosfet.

Using PWM as the Controller

The level of voltage, whether it's a boosted voltage or bucked voltage depends upon how the mosfet is controlled by the PWM generator.

If the mosfet is optimized with higher ON time than the OFF time then the output would generate boosted voltage and vice versa.

However there may be a limit to this, care must be taken not to exceed the ON time beyond the full saturation time of the inductor, and the OFF time must not be below the minimum saturation time of the inductor.

For instance suppose it takes 3ms for the inductor to become fully saturated, the ON time in this case can be set within 0 - 3ms, and not beyond that, This will result in a boost from minimum to maximum depending upon the value of the chosen inductor.

The associated pot wit the IC555 PWM generator can be effectively tweaked for acquiring any desired buck-boost voltage at the output.

The inductor value is a matter of trial and error, try to incorporate as many winding as possible for acquiring better and efficient results and diverse range.

Circuit Diagram

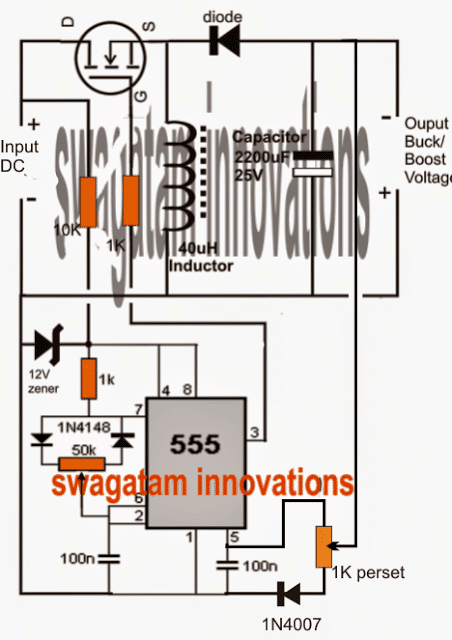

The above design can be suitably upgraded for implementing an automatic output voltage correction with the help of the following modifications:

The 1K preset may be appropriately set initially for determining the desired control point.

IC 555 Pinouts

Comments

hello,

Question on the simple two transistor boost converter

1st it shows the output as a 12v negative voltage and 0v, so where does the positive output come from ?

diagram shows 5v+ input and ground,

and output shows the 0v from the 5v ground and 12- from the positive side.

2nd it says for the output is in the mA range, how can i make it around 2a ?

3rd that do i need to change to make it work for a 12v input(car battery) to 18v 2a output (powering a speaker bar) and for one that output is 42v 5a for charging a 36v ebike battery ?

thank you.

Hi, In the 2 transistor buck-boost circuit, you get a negative voltage from the back EMF discharge of the inductor L1.

During this process the -12V becomes the negative terminal, while the common “ground” line becomes the +12V.

If you want a positive voltage regardless of the output polarity, you can connect a bridge rectifier across the output terminals of the circuit and get around 11V positive output. Just make sure to attach the C1 capacitor after the bridge rectifier.

And for the existing circuit, this C1 polarity is actually shown the wrong way, it must be turned upside down.

To get 2A current, you can try replacing the 2N2907 with a TIP127 BJT.

i want to make a buck boost converter using 555 timer ic the one you gave its not working for me i get 0v at output i followed everything i am implementing it on proteus can you help me please

Please try as per this concept:

https://www.homemade-circuits.com/buck-boost-converter-calculator/

Configure the PWM input circuit using a 555 PWM circuit, with part values as calculated by the calculator.

Hello engineer, please can you help Me solve a problem I am facing with 555 buck converter, I extrapolated from your 555 parameters, 24v to charge 12v 18ah battery. The voltage reduces but no corresponding current increase. Thank you sir.

Hello Atinuke,

Did you calculate according to the following article:

https://www.homemade-circuits.com/calculating-inductor-value-in-smps/

First you must check whether your 555 is oscillating or not, and also the 555 supply must be restricted to 12V.

If possible please provide all your circuit details through your comment under the above linked article

You said in this article:

“The 1K preset may be appropriately set initially for determining the desired control point.”

Please how will I set this?

It means you have adjust the preset with some trial and error to find the expected working output voltage.

Thanks, the preset is not respond to any change. The 50k preset was changing the duty cycle, but the feedback preset for the 555 timer does not respond any change in the wiper.

Are you getting the buck boost output from the circuit, and is the output output voltage varying in response the duty cycle changes?

Yes, with the duty cycle but not the feedback, I don’t know how the feedback back will work?

I hope you have connected the output filter capacitor which should keep the output stable (if your input supply is stable).

Anyway, you can try this modification in the feedback section. Connect the wiper arm of the preset with the pin#5, and connect one outer end of the preset to the buck-boost output and the other outer end of the preset with the ground, and check the response.

Nice to look at some of your designs as always. It’s me again and this time, I’m needing to build a boost circuit to work with the LED lights in my RV. So here’s the deal. Sometimes my Bvoltage goes a little low to power the lights I have been building. So what I want to do is construct some really simple boosters to power with around 9.5 to 13.8 v input, I need to output to stay at a constant give or take a volt. I’m looking at the simple 2 transistor setup which shows an inverted output. Going to put this together on a bread board, add a bridge rect. to the output to invert again? Everything would be isolated this way as I see it with the boost circuit running between the single push tactile switches in the lights and the push on push off circuits, this way the nothing is powered on until I do so. So I would according to this circuit need a 7805 in there to regulate the incoming V to run the Q’s and that 12v Z could be replaced with something like a 14v Z. This would keep the Lumens up no matter how low the Bat V goes. Space is limited in the Poly cases I’m using but I think I could squeeze this in there. I have some SMD 555’s on the way also but the rest of the pieces, I have in hand now. Not the FR107 but another FR part that should be fine, was also thinking maybe a 4001 would be fitting as these lights only draw +/- 0.05A? Multiple strings of SMD high intensity white LEDs in series/par. Beyond that, I have a couple of Mains LED fixtures that are supposed to be dimable but not able to track down the controllers for those as yet. Looking for a way to get a 120VAC input for these with a way to dim them, the circuits in these fixtures indicates as far as I can recall, 36 to 57v drive. I’ll have to get back to you on this later if you have any ideas.? For now lets work on the drivers for the DC powered fixtures I’m working on now. Cool beans my friend.

On my first build on the proto board the 2 Q circuit failed to deliver. The output was less then the 9v battery I was using to power the circuit. I ohmed out the circuit and scratched my head and pondered what went wrong but found nothing and moved on after an hr or so. I never did figure out why the circuit didn’t work. I’m waiting on some SMD 555’s and when those come in, I’m going to try a different approach. I really need to get a boost circuit up and working to install in those LED arrays that I can switch on with the functioning momentary push switches and want to build a few more fixtures to put outside in water tight poly cases with clear lens for lighting outside, under my hoods of vehicles and where ever.

In the first circuit I think the 100uF polarity must be reversed.

By the way the circuit was designed by the elektor electronics engineers so it cannot be wrong.

Thank you Bret, for the detailed explanation.

Yes, the first circuit looks good and may be suitable for your application. I have another article on boost converters specifically, which also includes a few good designs. You can find the article under the following link:

https://www.homemade-circuits.com/how-to-make-simple-boost-converter-circuits/

Do let me know if you have any further questions.

What is the motivation in designing dc-dc convertor/please add something that motivates.the study of dc-dc convertor !

Designing DC Dc converters require complex calculations, so unfortunately motivation might not work for this type of projects.

Hello noob here, can i ask what specifications am I going to use for my device. Im trying to create a wind turbine using a three phase permanent magnet ac generator, from the generator, it will be connected to a rectifier to convert it from ac to dc, then connected to a buck booster, but the question is what type of buck booster would i use?

Hello sir. I enjoy following your work. But for some reason you always work with low voltage. For example, I could not find a voltage regulator whose input voltage is max 100v, output voltage can be adjusted 12, 24, 48 v. Do you have any such work?

Thank you Ibrahim, you can try a bench power supply as explained in the following article, you can get a 100V max adjustment feature from this design:

How to Design a Bench Power Supply Circuit

Hi sir

Please what is the formula used in determining the frequency of the PWM generator used in this circuit thanks for your time

Hello Emmanuel, the formula can be found at the bottom section of this article:

https://www.homemade-circuits.com/timer-ic-555-explained/

Bonjour monsieur. C’est aussi possible de contrôler les grandes tensions telles que 400V?

Hello Daoud, yes high voltages upto 400V can be also controlled, provided the inductor is calculated correctly.

D’accord monsieur. Merci

You are welcome!

Noob here! Trying to build a very high current variable voltage power supply, 50 amps at 2-10v dc. Could I use this circuit as is by just changing the MOSFET to a 100 amp capable MOSFET?

Yes that may be possible, but the circuit will need to be confirmed on a smaller scale first, and then probably upgraded for higher power outputs!

Many thanks for replying Swagatam! Much appreciated. I will definitely try this next week. Am currently working on a PWM solution by using an Arduino Nano with a STP80NF55 80NF55 MOSFET. Dont know if its a better approach. But am comfortable coding more than soldering so trying out the Arduino way first. If you could spare 2 more minutes for me, what components will need upgrading along with the change to a 100Amp MOSFET or can I use the circuit as-is after changing only the MOSFET.

Thanks Again!

You are welcome Prabeer, in today’s electronics nothing can be better than knowing how to code Arduino circuits. So definitely Arduino is the best way to go since it can be controlled digitally and more accurately simply by adjusting the codes.

For the above 555 buck boost circuit, as long as the input voltage is withing 40 V, the current will not matter for the other components except the MOSFET. So it is only the MOSFET that will need to be upgraded, remaining components can be as is.

what the range of input voltage of this buck boost converter??

up to 50 V

Hi, can you explain briefly regardig inductor selection I want to know easy mathematical calculation for find out inductor value. you have mentioned 40uH but not mentioned its input voltage & current. If I use for heavy load power control then dv/dt & di/dt complusory needed or not, if it is please explain the application process.

Hi, Actually there’s no easy mathematical procedure to find out the mentioned details. You can go through the following articles to get an idea regarding the various formulas:

How Buck-Boost Circuits Work

How to Design a Flyback Converter – Comprehensive Tutorial

I’m also trying to build a Buck converter.

I have a 48 V voltage source, with which I want to charge a 36 V battery (42 V, full).

I would be interested in a converter that can withstand a current of 5 A.

A 12V zener can be used at the input, for 555.

And the Mosfet transistor is powered from 48 V.

Thanks for the explanations.

Thank you for your circuit. I have made it by doing some modification such as putting the feed back with 12v zener, 100k resistor and bc547 from the output to the pin 5 of the ic555 in order to have 12v stable.

can i use it to power my LED TV from the solar battery?

You can confirm the results by using any other type of load like a car lamp and once the results are verified you can use it for your TV

hi dear Swagatam, how can i make this work with coil from plus + to drain of transistor, and then use the diode to the positive of the output?

Hi Nelson, I don’t think that would work, the configuration has to be exactly as given in the diagram.

Greetings and thank you for your work, Mr Swagatam.

I’ve been trying for a few days to get this circuit to work, but all I accomplish is burning up mosfets. Also it does not seem to oscillate at the frequency you above suggest is good for such an application, and the 10k resistor in series feeding the 555 seems to be too large, I’m only getting 1 volt out of it to power the 555, from a 16 volt supply. Lack of a part list with part numbers for the mosfet, blocking diode, and lack of description of how the input voltage is related to the inductor winding and affects operation of the circuit, are probably contributing to my difficulties. I really appreciate the effort you put into your work and your website, but if there’s any chance you might improve this project page, giving a bit more description of the operation of this circuit, and some details such as recommended oscillation frequency, that would be really great. Cheers!

Thanks Sasha, the diagram is only for understanding the basic working of a buck boost design. Modifying the parts according to a specific need is not difficult at all. I used 10K considering the input voltage could be as high as 60 V. For lower voltages you can simply reduce to 1K or 2K2.

And there’s nothing critical about the parts, all the resistors are 1/4 watt….MOSFet Vds and ID can be as per the output V and I requirement. You can try a IRF540.

You must test it with a low current input, may be 100mA, and adjust the frequency by monitoring the output waveform with a scope. The frequency that gives the optimum amplitude response can be considered as the right frequency. Next, you can try different input voltages and check if the output produces the required buck boost effect or not.

Thank you so much for your fast and detailed reply! In fact I have been using IRF540 because that’s what I have a bunch of right now (had, actually). Also tried the circuit with a transistor in place of the mosfet for testing, and it basically worked, but it seems I’m not getting the voltage differential required to operate the mosfet which I think is why I’m burning them up. Perhaps I need to consider using low-voltage mosfets for easier switching with my power gate voltage. My inductor is homemade and definitely needs a rewind, but I have some on mail order which should work better. As for input voltage range, I expect to usually supply the circuit using a 12VDC adapter, however I want the circuit to be able to accept maybe 12 to 18 volts, yet output the same voltage consistently (like a linear regulator supply) but using a linear regulator on the input is not sensible nor practical so I must come up with some other approach for getting a constant voltage out when the input voltage varies.

Thank you again for everything; I will take your suggestions into account as I make another attempt at this cool circuit.

Thank you Sasha, the voltage at the IC 555 side could be dropping due to low current from the resistor zener network. You can replacing the resistor/zener network with a 7812 IC and see the result, this will allow full 12 V to appear at the MOSFeT gate.

blocking diode is high current rectifier diode or fast recovery?

Both, current will depend on the load

Dear swaggertam, i am a newbie to this. Which one of your circuits would you recoment for the problem with having 18v solar chargers about 20w to 100w depending how far wallet goes buying ingredients for circuit. Small 12v warped car battery only. Old laptop with 19v 3.42 to 18.5 v 3.5 A 65w max ????.not that much sun. No 220v in my hut only this battery and i have a few salvaged items and can order online. Gas soldering the lot so might overheat things a little. Would like to be able to charge laptop so can use for half an hour or so.

Dear Mindy, if your car battery is damaged then it might be of no real use. Still assuming it’s a 50 Ah battery you can connect an 18V 100 watt panel directly to the battery and keep a voltmeter connected across the battery. When the voltmeter reaches 14.2V, simply disconnect the battery from the panel.

I am suggesting a direct connection because the sunshine will probably keep receding and soon might reach 15V, so no problem if the initial voltage is slightly higher.

Hi bro, i want to use this circuit for making a small power bench power supply but is it possible to add a variable current feature for this circuit ? Do you have any such circuit( variable voltage & current) presented in your website?

Hi Charan, it may be possible but will require some additional circuitry to be added….however the first challenge would be to build this converter successfully because optimizing the inductor in buck boost circuit is never easy.