In the following content I have explained two simple 12V, 1 Amp switch mode power supply (SMPS) circuit using the very reliable VIPerXX IC from ST microelectronics.

With the advent of modern ICs and circuits, the age old iron transformer type of power supply are surely becoming obsolete.

Today power supplies are much compact, smaller and efficient with their functioning. Here I will explain one outstanding switch mode power supply circuit which can be easily built at home for deriving clean, ripple free 12 V DC.

Thanks to ST Microelectronics IC, the VIPer22A, which has made the construction of truly efficient and compact SMPS power supply unit possible that too by using a very few number of electronic parts.

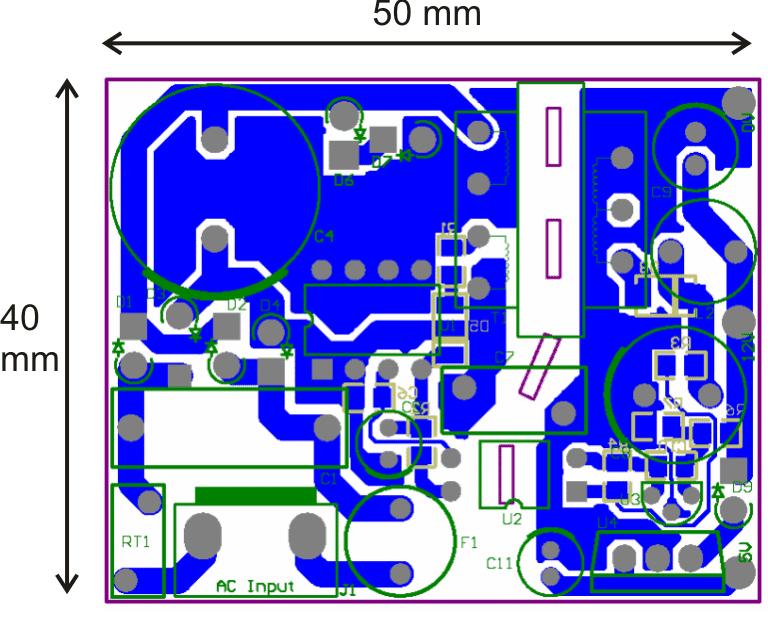

As can be seen in the picture, the circuit is indeed very small, compared to the power that is available from it. It's just 50 by 40 mm in its dimensions.

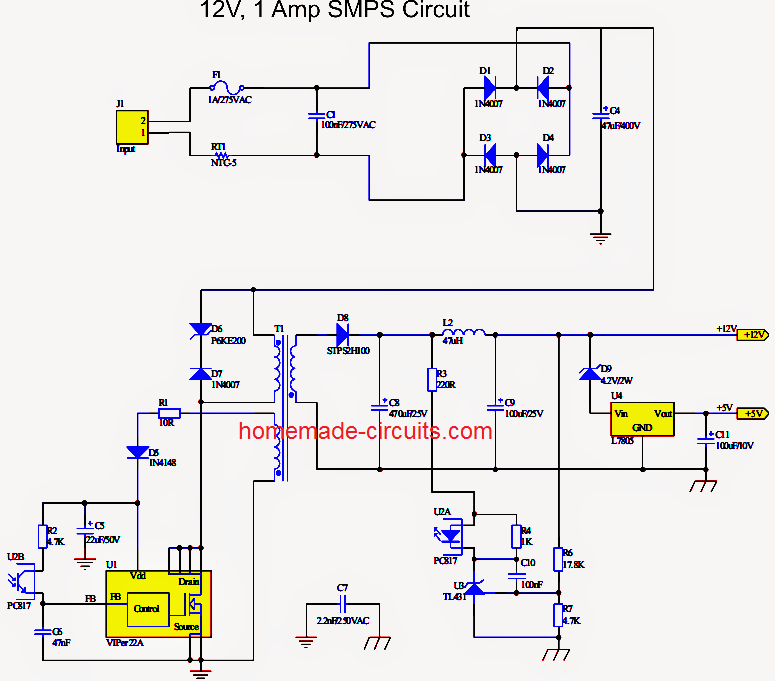

The circuit diagram is very easy to understand, let's study it with the following points:

1) SMPS using VIPer22A

Looking at the figure we can easily see that the configuration does not involve too many stages or parts.

The input mains AC, as usual is first rectified using ordinary 1N4007 diodes which is fixed in the bridge network mode.

The rectified high voltage DC is filtered using the high voltage capacitor.

The next stage is the crucial one which incorporates the outstanding chip VIPer22A manufactured by ST Microelectronics.

The IC alone functions as the oscillator and induces a frequency of around 100 KHz into the primary winding of the ferrite E core transformer.

The IC is absolutely rugged and is internally protected from sudden voltage in rush and other voltage related component hazards.

The IC also incorporates built in over heat protection which makes the IC virtually indestructible.

The voltage induced at the input is effectively stepped down at the output winding, due to low eddy current losses, about 1 amp current becomes available from a relatively tiny ferrite transformer.

With the coil specs shown the voltage is around 12 and the current is around 1amp.

A special feedback circuitry is also included in the circuit for maintaining high degree of protection and power saving features.

The feedback loop is implemented via an opto-coupler which becomes active during abnormal circuit conditions.

When the output voltage tends to rise beyond the set threshold the feed back loop becomes operative and feeds an error signal to the IC FB input.

The IC instantly comes into an corrective mode and switches off the input to the primary winding until the output returns to the normal range.

You may also want to read this: 24watt, 12V, 2 amp SMPS using a single IC Most recommended for you.

Circuit Diagram

PCB Layout

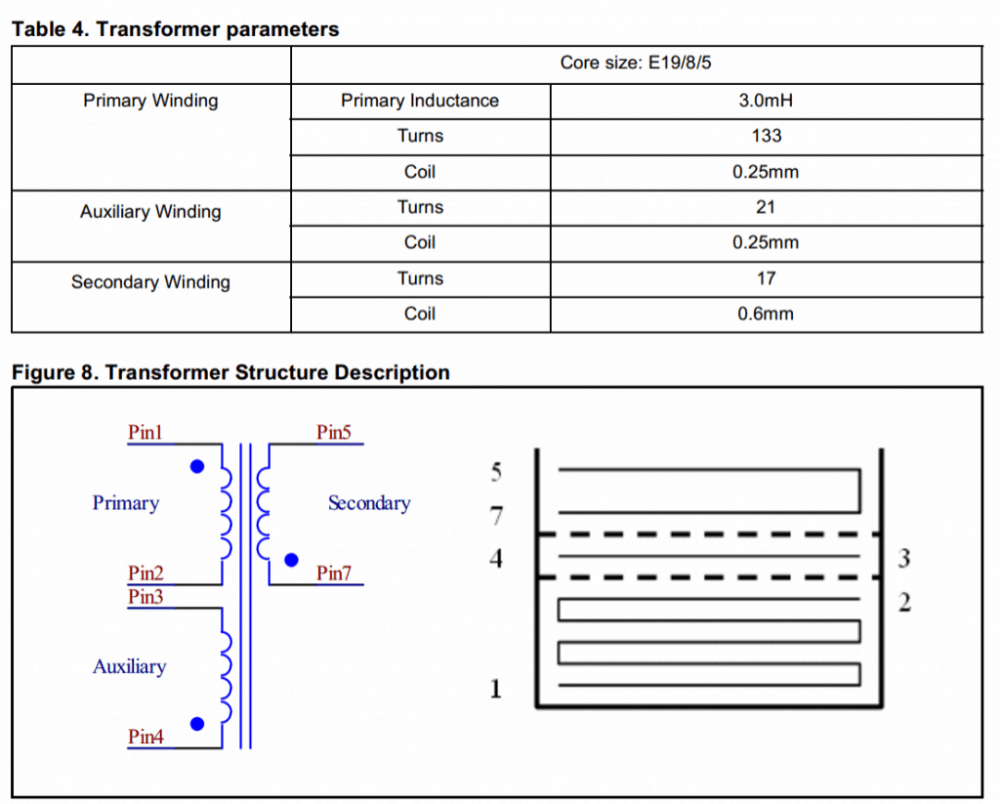

Transformer Winding Data

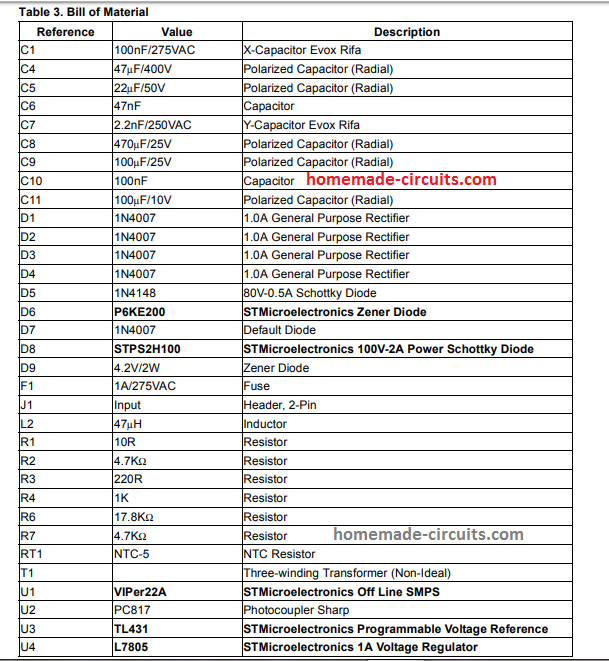

Parts List

For the original datasheet please refer to this article.

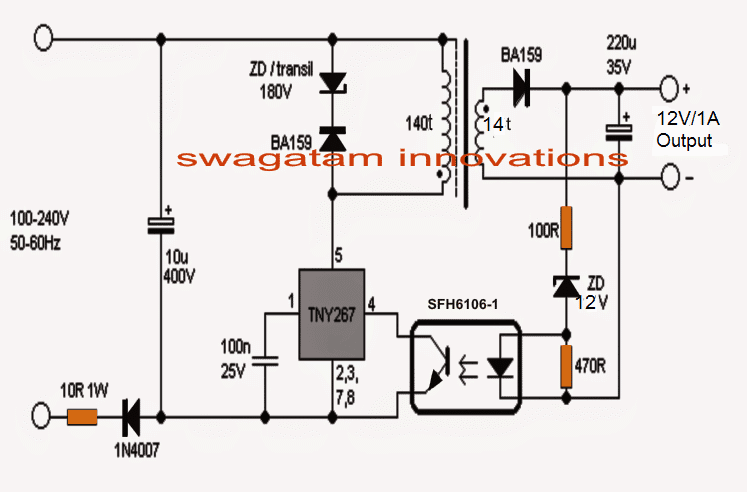

2) Another 12V 1 amp simple SMPS using IC TNY267

How it Works

The simple smps circuit shown above uses the popular tiny switch IC TNY267. It is a tiny mosfet based 120V to 220V switching oscillator IC which only requires configuring with a ferrite transformer and a stepped down Vdd operating voltage.

The design is so simple that a mere visualization of the schematic is enough to tell us the functioning details quickly.

The stepped down start voltage is acquired from stabilizing network using a 180V zener diodes and the fast recovery diode BA159 after rectifying the mains 220V through a 1N4007 diodes and the 10uF/400V filter capacitor.

As soon as this voltage is applied to the IC, it begins oscillating and its internal mosfet begins switching the ferrite transformer primary at the predetermined oscillating frequency.

Being a flyback design, the secondary also starts conducting during the OFF cycles of the primary through mutual induction and generates the required 12V voltage at the output side.

This voltage may not be stabilized, therefore an opto-coupler based feedback is used and the link is configured with the exclusive shut down pinout 4 of the IC.

This ensures that the output never exceeds, and remains fixed at 12V 1 amp proportion.

Transformer Winding Data

The transformer winding is actually quite straightforward, and may be done in the following manner. Keep in mind that the black dots indicate the start points of the winding which is very important, and must be strictly followed while winding the transformer.

The primary wound using 36 SWG super enameled copper wire upto 150 turns, while the secondary is wound using 26 SWG wire upto around 12 to 15 turns.

The core can be a standard E19 type ferrite core having a bobbin with central core cross section area of approximately 4.5mm by 4.5mm.

Hi Swagatam, what an excellent site you have, I was looking for information about pirs initially but came across your article about PSU.

I would like to ask you regarding this topic, I was thinking instead of building a PSU why not use a ready manufactured one as their are plenty of plug in PSU rated 5v or 12v with current capacity of 2amps or perhaps more?.

I want to drive my pir from such a supply and are these plug in devices give a good direct current or a way to improve if not.

Respectively

Thomas McGhee.

Thank you so much Thomas! I am Glad you found this site interesting!

Yes, you can buy any ready-made SMPS and use it to power your PIR circuit.

All these SMPS circuits will provide a decent DC output, nevertheless, you can further improve it by adding an external 1000uF/25V capacitor across the output +/- supply lines.

Let me know if you have any difficulties with the circuit.

For a PIR related question, please feel free to post your comments under any of the following articles:

https://www.homemade-circuits.com/?s=PIR

sir, what is the default diode 1N4007

Hello Thulaseedharan, there are 5nos of 1N4007 diodes, 4 in bridge rectifier and another one at D7

hi,

where do I get the detailed design on the smps ferrite transformer with flyback topology.I searched many on the design.

Hi, you can refer to the following post:

https://www.homemade-circuits.com/how-to-design-and-calculate-ferrite-core-transformers-for-inverters/

Hi,I designed the ferrite with 12v and 10 amp output and I used to install it in a working 12v 10 amp smps that I already made with a 120 watts ferrite core.but the problem is the switching mosfet getting hot when I connect the transformer (with no load output) that I designed.but I an getting 12v output and getting output side about 2 amp current.I tried increase the load but the mosfet getting too hot so I stopped it in 2 amp load

If the MOSFET is getting hot that means the transformer is not correctly wound and is not matching with the input frequency.

hi I successfully designed a smps with flyback topology.I need some help in making it a better one.need to use short circuit protection and also over current protection could you please help me with that.I am using uc3843 ic for smps.

It can be simply done by configuring the ISENSE terminal of the IC with the MOSFET source side current limiting resistor.

Please check out the following document. All the necessary details are provided in this document:

https://www.ti.com/lit/ds/symlink/uc3843.pdf

The actual purpose of use of PC 817 opto coupler along with fixed volts zener diode and resistor voltage regulator in the SMPS system of stepping down of emf voltsges……..

What is the meaning of the SWK WORD

There’s no SWK work in the article.

Please explain the 36SWK and 26SWK Wörds

They are SWG super enameled copper wires.

What is the diameter of the wire for trasformer

You can use any online software for converting SWG to mm

Dear sir,

I want to design

please share me 12v 1A schematic for non isolated without optocoupler

Arkesh, optocoupler is a must otherwise the output will float with dangerous mains AC voltage.

Hello Swagatam!

Good evening from Nigeria.

Please I have a serious issue with this design; I have built this circuit up to 4 times and in all, they work very well without load. But anytime I connect load such as relay, the voltage drops to almost 2.5volts. and when this happens, the opto-coupler will begin to make clicking sounds; but when I removed the load, the voltage goes back to normal and the clicking sound stops.

I made another one to serve as a charger for my cordless drill machine 21volts; the smps voltage is about 24volts on no load but when the batteries are connected, the voltage drops to about 18volts and the clicking sound begins to produce again. I have tried series of options but none could solve the problem. I used EE25 and tny268P tiny switching IC.

Hello Kingsley,

If your SMPS is dropping voltage when loaded then definitely it is due to a wrongly constructed transformer. The transformer is the crucial element of these SMPS circuits, and if it is not built optimally then the performance might suffer.

Also, Try using a bifilar type of wire for the transformer. Bifilar means using a bunch of thin wires together and winding them in parallel.

I think EE25 is quite big for the above SMPS designs. As mentioned in the winding details the E core size must be E19/8/5

Thank you sir for your response. Please I want to clarify something about the transformer and I wish to ask: do I have to make the primary turns half, then the secondary before completing the second half of the primary?

If not, then I think the transformer was wound very tight and the wires are padded tightly parallel to each other. I used single strand of 36AWG wire to make the primary turns and 3 strands of the same 36AWG wire to make the secondary.

I want to note that I made the primary turns in full before making the secondary turns.

I don’t think sandwiching the secondary between the primary is absolutely necessary. Normally the primary is wound over the secondary winding with a isolating tapes in between and on top.

The secondary winding which has higher number of turns must be wound first, after winding the secondary then the primary must be wound over the secondary.

Also the EE size must be as specified in the table.

Good evening Sir,

Finally the circuit is working. There was a problem with the core Ee 19. The core was not working above 35khz . I have bought ee25 core from Amazon and the core worked well with the prescribed winding direction. The ic is getting bit heated . I have used a aluminium heat sink Sir . Thank you very much Sir .

That’s great Shantanu, I am glad you could build the circuit successfully. I hope the other readers will find it inspiring!

Thank you Sir . Sir kindly let me know the direction of the windings of primary,secondary and auxiliary coils of the transformer.

Sir can you please provide me a low-cost circuit diagram which can generate square wave frequency between 25khz to 35 khz.

Thank you Sir . Subho Navami Sir.

Hi Shantanu, the direction of the winding is shown in the transformer winding layout diagram. The black dots indicate the start of the winding, the direction of the winding are identical for all the winding.

For a square wave generator you can refer to the following article:

Square Wave Oscillator Circuits

Wish you a Subho Navami to you also

Good evening Sir. Please provide me some more details information regarding the inductor to be used for Viper22a ic . I have Ee 19 core, but the core is not gapped . What is the air gap required . Also please tell me the direction of the turns of primary, secondary and auxiliary coil of the inductor. Sir please let me know. Happy Durga Puja Sir . Also Sir please let me know your email address so that I can send you the photos related to the subject in case of difficulty. Thank you Sir.

Hi Shantanu,

You can get all the required information under the table 4 and figure8. While fixing the E cores, make sure to insert a single layer of paper or insulation tape between the E core surfaces that touch each other. This will allow the necessary gap between the cores.

Pictures actually might not help to troubleshoot an SMPS, because SMPS is a complex circuit and will need a good prior knowledge to finish it successfully by the user…

Wish you too a Happy Durga Pooja.

Bom dia irmão, posso usar este circuito para uma carga com variação rápida da corrente? Entre 450 a 900mA

Hello Marlon, current cannot be varied in this SMPS design, but you can use any load rated at 12 V and below 1 amp

Hi sir, the second proposed circuit diagram, the diode employed, was to block the ac input, but to rectify the other hand ac input, can I give it a 1n4007 diode to retify it effectually? Thanks sir, looking forward to your quick response

.

Hi Eniola, Are you referring to the BA159 diode. Since the output is a high frequency AC, only fast diodes like BA159 is recommended, however you can also try 1N4007 and check if it works.

Hi sir,the ac input line, the one with 10R1W and 1n4007, but as you can see the diode latch off the AC line input, but the other hand no retify diode,so as to power the transformer efficaciously.can I place a 1n4007 diode?

Hi John, sorry I didn’t understand what you meant by latching of AC line. The diode will not latch anything, it will only rectify the half wave cycles of the AC, which ensures a reduced surge current on the circuit, compared to full wave rectification.

Fine

Thank you for the good work. I have always admired your posts.

My question is, how do I modify this power supply to charge a 12v 7AH lead acid battery?

Hi, you can adjust R6 value to increase the output to 14.1v for charging your 12 V battery

Thank so much for your reply.

mary xmass, pls sir is there a way u can provide me a circuit that can chase away squaerr from eating up my coconut . this is the way i want it to function each time the circuit sence the present of the squerrer it will emitt sound that will chase the farm animal away. waiting for your responds.

Merry Christmas youngking, you can try the last design presented in the following article:

https://www.homemade-circuits.com/dog-barking-preventer-circuit/

Components list plzz give me

Updated….

can i use e20 core

E19 is the recommended one.

Hi bro , can i use second circuit(TNY) for driving my 775 dc motor at 12v for nearly 8hrs with pwm speed controller ,will heating be a problem & also will 1 amp be sufficient for that motor?

Is there any IC for 12V, 2A smps range?

Sorry bro, 775 are 80 watt motors you can’t run a 80 W motor on this circuit…even a 2 amp cannot be used.

If you want 2 amp smps, you can try this:

https://www.homemade-circuits.com/12v-2-amp-smps-circuit/

Thanks for the quick reply,

In the link u mentioned can i use UC3842 instead & also i believe the circuit has a short circuit protection ?

Sorry, I don’t know about it. You can compare their datasheet if their pinout specs match then you can interchange them.

Ok. One more thing is that what might happen to the circuit (TNY) under short circuit at output (12V side) & how long it might handle?

The IC is short circuit protected according to its datasheet.

Circuit is nice

Can you share pcb file in whatever software you used so that we can use toner transfer method to prepare pcb.

If you share 1:1 scaled pdf in black and white that is also fine

Request to share it for all projects ehere uou have shown pcb layout.

This will be highly appreciable.

Thanks

Ulhas rane

Thank you,

The PCB is not designed by me, it was presented by ST microelectronics datasheet for “10 watt air-conditioner power supply”, so I do not have any further details except what is furnished in the above article.

Hi Swagatam,

Firstly, I must thank you for having this knowledge published in here.

I need bit more knowledge in making the 2nd circuit.

In there, I only see two black dots for the transformer. Could you please explain me why?

Are you able to show a sample picture of a transformer?

Secondly, by using 7805 regulator, can I get 5V up to 1A?

Appreciate your advises on above.

Thanks & regards

Lakshan Fernando

Thank you Lakshan, the black dots indicate the starting point of the winding, and the pins where the respective diode circuits needs to be connected. But since only two ends are present on the two sides you can do the winding without taking this into account. However while testing if you don’t get the required output you can just swap the secondary pins with the diode/filter circuit for rectifying the problem.

The transformer should like this: https://www.homemade-circuits.com/ee-core-trafo/

7805 will give you a maximum 1 amp but you may have to mount it on a large ehatsink.

Thanks for the prompt response.

So basically this transformer doesn’t require any auxiliary winding, am I correct?

Secondly, is there any way i can reduce the heat of 7805?

Thanks

Lakshan

Yes, The IC has an in built oscillator and mosfet so it can work without an auxiliary winding.

You can get 5V by using a 5V zener instead of 12V, in this way you can totally eliminate the 7805. At full 1 amp the 7805 IC will be hot and there’s no way control it except adding a heatsink.

Here’s a 5V version of the above:

https://www.homemade-circuits.com/220v-smps-cell-phone-charger-circuit/

You read my mind as I was to ask for a 5v version. 🙂

Many thanks Swagatam!

Let me try to get this working.

Cheers

Lakshan

It’s my pleasure Lakshan, please keep up the good work!

Good day Sir, it is possible to get a 12vdc from a commercially-available SMPS 18-36vdc power supply?

i thought of adding a 7812 IC, i just don’t know how and what other components needed! thanks!

Hi Amor, yes you can use a 7812 with 18V DC to get the required 12V from it. But don’t use with 36V because it will make the IC too hot! A single 7812 on heatsink would be just enough, and if possible add a 100uF/25V at the output

Hello,

Can I use the viper12a instead of viper22 in the circuit?

yes you can but the output current will be reduced to 350mA

25 years back if you had asked me to repair any transistor radio, even the ones that came tied in a gunny sack with thousands of pieces – I WOULD HAVE GUARANTEED ITS REPAIR to its near original state. NOW i AM ONLY WATCHING my younger brethren making things work, and believe me I enjoy a lot because they modt certainly stir up whatever grey cells are left up in my brain. Recently a similar smps circuit repaired by some one on you tube employed 8022 (either AP 8022 or AD 8022, i cant say) and repaired a 12V 1A smps supply. I have seen the application circuit on the manufacturers’ site and wish someone could make and tell me in such details as the instant example. Is anybody watching?

Hello please I am trying to build a battery charger with this smps.

I want to obtain 12V, 3A for the output.

Input would be about 220V, 50Hz.

How can I manipulate your design and also select the right material, that will give this requirement?.

Thank you

Hello,

sorry higher current than 1 amp may not be possible from this design unless voltage output is reduced below 12V, because the IC is rated to handle a maximum of 1 amp

Is the specific transformer available in market? Or have i to design it myself?

as far as I know it is not available in the market, you will have to build it according to the specified details

Hi sir.

This blog make my problem easy. but i have a question. if i increase the winding turn in parallel for achieving high current at output i-e (7A-10A), while keeping remaining circuit unchanged. Is this is possible.?

Thanks Adrees, sorry that may not be possible because the mosfet inside the IC itself is not designed to deliver that much current, the maximum rating being just 1 amp

can you please understands me the feedback with voltage refrance how it works to regulate the voltage? also tell this topology is DCM or CCM .one more thing how this ic can use tfor both modes interchangeabily

Plaese refer to the datasheet of the IC for a detailed information about the design

application-notes.digchip.com/005/5-10593.pdf

Hi, please tell me how to modify this circuit & transformer to make 24V DC/500mA output?

1. Will it work if I double the secondary winding and primary & auxiliary remain the same as in above circuit?

2. I'm planning to replace 7805 with 78L05 that will lower the output current to 5V/100mA, this will increase maximum current of 24V output. will this work?

2. Should I need to change value of L2, R3 or any other discrete component?

Hi, yes that's possible, you can try increasing the secondary turns to around 30 turns and also tweak the R6/R7 values to get 24V…a 780L5 can be used for restricting current, but a better way would be to make sure that the load connected with 78L05 is itself not rated to consume more than 100mA…

Hi. can I still use LNK623 instead of using viper22a??

It cannot be used in the above design, LINK switches have their own specific circuit which you can follow

chassis is supposed to be the metallic cabinet inside which the circuit is housed.

the negative line of the circuit is supposed to be connected with this metallic cabinet, and the metallic cabinet in turn is supposed to be connected to the mains earth pin via the mains cord.

Hi Swag!

What is that symbol that seems to be an “E” facing down? Is that the chassis ground symbol?

Hi Madubuze, yes that’s the symbol for the chassis connection

What is chassis ground?

How is it different from the normal ground? N how should I connect the chassis ground terminals in practical connection?

Sir. What does chassis ground mean and how is it different from ground symbol?

N how should i connect the chassis ground terminals in practice connection?

Hi, can I buy that transformer at any electronics store or I have to build it myself???

Hi, you will need to build it yourself or get it made-to-order, ….it's not available ready-made.

yes it is designed to work with 220V mans, I think you might have done something wrong in the design…get a professional help from any nearby source

Aoa how r u? Brother i have made it but problem is that it show 12 v on DMM but when i connect with led light it drop to 8 volts .where is problem?

Hi Faiq, what is the voltage and current specs of the LED??

Please note that the transformer is the cubical element in this design and in fact that's true in all SMPS designs….so make sure you have built the transformer with utmost accuracy….if possible please get it build from a professional winder…

sorry there's a typo in the above comment….I meant to say crucial and not cubical…

Ok.tnx for advice.ill try that one.

Hi Mark, I am not sure exactly what you are intending to make, I guess the following circuit might be more suitable to your need

https://www.homemade-circuits.com/2011/12/simple-led-automatic-daynight-lamp.html

I gave up on modifing the already made smps and returned it to my friend.instead ill copy your design.

https://www.homemade-circuits.com/2011/12/cheap-yet-useful-transformerless-power.html

with 12v(load)led in series and ldr in the middle. I have some question.

Do i need to adjust or raise the voltage so that the led would make its highest performance? My parts are

Ldr

Transistor npn

100k variable resistor

1k resistor

Is it ok to add regulator ic.lm7812.i got some spare.just for added protection.

Gani, yes you can try it…if the winding comfortably accommodate in the trafo then surely you might succeed in making it work.

Dear sir Swagatam. Using ferrite core of cfl is Ok, by removing out all copper wire and then change to the new one as the data showed here as freq nearly same and hole loc Ok.

Good day to you sir..

Can you pls help me design an smps for 12volts for an led with label dw-5630-6led-2b3c. With an LDR switch.

Im a newbie on electronics and wanted to learn more.cheaper parts would be much appreciated.

Good day Mark, please tell me the voltage and current specifications of the LEd, you can get it from the datasheet of the part, that will help me to understand your requirement in detail

Quantity: 3; Emitter Type: 5630 SMD; Total Emitters: 6; Power: 3 W; Color BIN: White; Rate Voltage: 10 V

The current is 1amp.i have many question and problems.hope you could help me learn more..

dividing 3 by 10 gives 0.3 amps

multiplying it by 3nos gives around 1 amp.

It means you can use the SMPS circuit that's explained in the above article for your need…

R6 or R7 can be suitably adjusted for reducing the 12V to 10V

Tnx for your help… can i ask what is the voltage needed for the ldr?

you can connect the LDR in parallel with R6, during daytime this combination will hopefully keep the opto switched ON and the SMPS output switched OFF

Tnx for your help sir.. your ideas are great.

you are welcome!

Good day to you sir swagatam..

A new problem came up.

When my ldr is lighted and decreases risistance the smps increases its voltage.thats the reason why my led wont go totally off.does putting a regulator would help(lm7810) solve the issue?

Hoping to learn more from you sir..

Tnx

Mark, manually experiment by changing the R6 or R7 values and identify which adjustment causes the most effective disabling of the output…you can then put the LDR in parallel with that resistor for the required response

Sorry to cause you so much trouble.but actually the smps i was refering to was an already made one.with some smd type of parts.

Is there a way i can modify it outside the already made smps??

in that case you can use an external light activated switch such as this one:

https://www.homemade-circuits.com/2012/01/how-to-make-light-activated-day-night.html

modifying the smps circuit could be difficult without studying the stages carefully

Sir how to make power supply 12v. With switch

Sir, how to make a pcb layout of dual porarity variable output power supply i want to see a diagram

hello sir,

thank for the great sharing.

from the circuit i see the out is 12V and another voltage regulator at 5V.

what is the current for 5V?

i want to build a PSU, for 12v 1amp and 5v 2amp. if i can combine the circuit. it will be superb.

thank you in advance for guide.

thank you kakipancingMUAR

the shown 5V would be also producing a max current of 1 amp.

5V 2 amp could probably be achieved by extracting a calculated tap from secondary and terminated out without a 7805.

how to calculate Transformer parameter to increase current?

Hello Sir,

I am new in SMPS design. I am facing a problem in this SMPS. SMPS remain ON for 15 second, after that it going to OFF for 7 second, again ON for 15 second and again OFF for 7 second. Such cycle continue. In ON condition, it giving 13.8V and in OFF condition it giving 0.8V. I apply 12V/100mA DC motor as a load. Kindly help me in this problem.

Thank You,

Hello Sujit, It would be difficult to understand the issue precisely, but normally this would happen if the IC is going in the shutdown mode due to overheating or over current.

This would most probably happen due to a wrongly configured transformer….check the inductance of the primary it should match the given specification.

also add a small heatsink with the IC.

hello sir,

how are you sir…after a long time i am here again with my another quarry …dear sir I have a inverter and it is giving me some problems…the problem is regarding to its charging function…earlier it starts trickle charging to the battery..when voltage reaches to 14 volt..but now it does not cuts the power after full charging of the battery…when the battery fully charged …then inverter makes humming sound and burnt the ac fuse..

So kindly help me about the problem..

Thanks a lot

Pankaj pandey

Hello Pankaj,

it would be difficult to judge without a practical diagnosing. most probably the relay associated with the full charge cut off circuit is responsible for this….it could be correctly tripping at the full charge level but in the process shorting something through its other pair or contacts.

check the response of the relay by supplying a varying voltage through a variable power supply across the battery points (without any batt connected)

Hi Swagatam,

Thanks for great tutorial.

I am trying this circuit and getting the result.

Now I am drawing 80mA of current at 12V through this circuit and it works perfectly. But when I increase the load to 150mA, the ST Viper22A gets too hot and cuts the supply for some time so the output voltage falls from 12V to 2V. After sometime it again starts supplying 12V.

The IC is getting overheated and it trips. Could you please suggest something.

Thanks in anticipation.

Hi Krunal, this circuit is rated to handle upto 1 amp, so 150mA shoudn't be a problem at all, not sure what might be causing this, most probably if the transformer is not built correctly could cause the circuit to malfunction, so it could be your trafo that's not correctly wound, please check it again and if possible take the help of a professional winder.

the above design is by STmicroelectronics so it should be perfectly correct with its data, for more info you can visit the original website from the given link in the article.

Hello,

Thanks for the reply.

I had given this transformer winding data to a professional manufacturer from Delhi and he has built it using the same data. Moreover the transformer is not at all heating up but its only the IC to heat up. I checked the voltage at Vdd of IC which I found to be -2V which seems to be wrong(still the output vtg is 12V), also the output of the rectifier is just 5V. All the components are cool while the IC is heated up.

Any suggestions.

Can you please tell me what are the expected voltages at few test points so that I can debug the circuit.

Sorry for wrong readings. I was taking wrong reference ground.

The voltage at Vdd pin of Viper22A is 12 VDC and

voltage across rectifier capacitor (47uF/400V) = 318 VDC

The transformer will not heat up, it is the fet inside the IC which will heat up if the winding are not correctly wound….especially theprimary winding is the one which will can make the IC hot if not wound correctly. According to the data the inductance of primary winding must be 3mH, please confirm this first…moreover all the winding has polarity which can also create an issue.

I am not sure about the voltages at different points, and is basically not required to be checked, because if the winding is correct and the IC is genuine then the circuit should work at the first go….considering the connections are all OK.

Hi, Thanks for all your suggestions.

Can I just reverse the primary winding and check? Will it cause any problem?

Also I do not have any LCR meter to check inductance.

I have ordered my components from element14 so IC should be genuine.

Also I am getting 12V at the output upto 80mA, so I think the connections are also OK.

Please suggest.

Hi, I think it can be tried, you can reverse the primary ends with the circuit and see the effect…however checking the inductance is more important as that would quickly help to solve the issue.

Hello, Good Morning.

I checked by reversing the primary ends, but this time I was not getting any output voltage at the output.

I have asked my friend to measure the inductance of it, and will update here after I get result.

Also, I would like to know if the IC is only used for switching, can I replace it with another MOSFET or optocoupler and driving it with 60KHz using LM555.

Also, I am not able to understand how the auxiliary winding is able to supply 12V to this IC.

I would like to know your experienced suggestions.

Thanks in advance.

Good morning, The above circuit cannot be modified in anyway and is not recommended, if you want to use discrete parts for the making the same design then you can try the following circuit:

https://www.homemade-circuits.com/2013/10/12v-24v-1-amp-mosfet-smps-circuit.html

the internal circuitry of the IC is initially switched ON through the drain connection, which internally applies a triggering voltage to the Vdd (@1mA), this action switches ON the mosfet which in turn causes the auxiliary winding to kick and apply a rising unregulated voltage to Vdd…when this voltage exceeds the internal limit, the internal regulator switches OFF, causing the mosfet and the IC to switch Off….the cycle now keeps repeating the sequence at around 60kHz

Hello, So I got the measured inductance and is only 0.046 mH.

I don't understand why my manufacturer did not paid attention to this.

What should I do now? Will it work just by adding an inductor in series?

Hi, you should get it done afresh and this time from a qualified winder who knows how to measure and assign the inductance values to the coils, because it seems this trandfrmer could have many winding errors .

adding a series coil will not do.

If you are in Mumbai get it done from Lamington road.

or if you have the access to a hand winding machine you can try it yourself at home.

Ohh, I am overwhelmed with your detail description, Thanks.

Yes, I think I have to look for another winder.

I am working in very rural area of Rajasthan without any access to advanced things except internet (Thank GOD). Also I have never been to Mumbai before. Still I would try to do something.

I am doing this as for my hobby. It would be really nice if you can suggest some winder.

Thank You very much for all your help.

Regards,

Krunal

You are welcome Krunal, I hope you get the issue resolved as soon as possible.

winders can be difficult to find online, alternatively you can try it winding by hand… with a lot of care and patience you could possibly succeed with it.

Hello sir plzz plzz do update same sort of post on FB.. Instead of here..

in Fb we can comment and have ur reply notification here really feeling hectic to find reply or comments back..

even for typing..

since this method is not much user friendly and transparent. it my suggestion

on behalf of everyone I am requesting u since some of my (electronic hobbyist) friends are having same opinion.. as most of us don't use Email and this website much compared to Fb and WhatsApp in there phone..

I respect ur knowledge and patience so I wish its being utilised to everyone in proper way..

i hope my msg convinced…

seeking for your valuable reply. .

Thank you regards your Fan Lokeshelectronic

Hello Sir. Would you mind sharing your PCB in PDF file? Thank you Sir 🙂

Soooooory… its TRUE !

3 pin triac is not IC . Any chip with 4 or more pins is called IC, this is what I learned. No intention of insult pl. But I like Ur up-frontness, pl never hesitate for what ever comes to ur mind, Love U !

sorry I am not sure to which comment you are addressing to?? but answering to your suggestion I must say that a 3-pin device can also be an IC….take for example 7805, 7812, TL431 these are all ICs.

I'll get back 2marow.What do u feel about the bleeder resist after the MOSFET !

mosfet is inside the IC

Thanks Bud, let me check up. Other thing which came to my mind to check the bridge diodes indevudaly . I,ll get back on the outcome.

yes buddy that's right, if the diodes are faulty it might send AC instead of DC to the caps and blow them of

I am Office Automation Techi, I have a problem with one power supply SMPS, there is a 470 mfd 400v capacitor after bridge rectification on A/C side getting blown even after changing the MOSFET along with it. Its blown thrice even after checking the rest of circut. It is further found that MOSFET is not burning.

check the voltage across the capacitor points, if it's exceeding 400V then that might be causing the explosion….if voltage is not the issue then probably you can try a non-polar capacitor and see if it works…a bad quality capacitor can also be the culprit

Hello Sir

currently we are using original ST L7805, the issue with it is, we converting 12v DC to 5v DC for consumption of up to 50mA. After putting it on testing we come to know that L7805 is heating too much, temp is not being measured yet, but it is enough to burn up your finger, will it make any kind of damage to further circuitry or L7805 will burn out within small life time?

Hello Bharat, if it's getting hot at 50mA then either the IC is not original (faulty) or there's some mistake in the connections.

Please measure the current using an DC ammeter in series with the load.

78XX can never get burning hot since they all have an internal thermal protection facility which don't allow their case temp to go beyond 100 C

when hot the IC will simply cut of the supply to the load and shut down itself until the heat reaches within the tolerable limits

Yes sir, I have both kind of 7805, the original one and fake identified by it's heat sink thickness. Both are getting warm up, where in the connection, I have 12V at pin1, Gnd at pin2 and 5V output at Pin3. I'm using 12v 1A ready made power adapter as source and converting it to 5V for controller. Is there any corrections needed?

Bharat, please check the output current consumption, I am sure it cannot be just 50mA..please confirm this.

Sir, I'm double sure about the consumption, I have also studied the datasheet of components used. It is not exceeding 50mA.

at 50mA any 78XX will not become burning hot according to me. Not sure what could the fault in your case.

Sir, is there any other connections needed? around 78xx.

left pin is input, center is ground, and the right side pin is the output for the load, that's all is required for getting the results from this chip….no further connections are required.

Ok thank you sir for reply. One last que. is there any specified life time of ST L7805?

thanks bharat, if the IC is operated within its specified tolerable limits then it can go on almost forever.

Thanks a lot for suggestions sir.

Ok. If possible please suggest any other IC for range 80-300 Volt AC.

Also do you have any tutorials related to Photodiode Interfacing. I am facing a lot of fluctuations while designing Signal Conditioning Circuits for BPW34

sorry, I do not know about any SMPS IC with that input range.

You can try LM567 IC for signal conditioning of the photo diode.

Thanks for your reply.

How can we achieve 80 to 300 Volt Range. What changes to be done in above circuit for desired Range

that might not be possible because the IC is rated for 85V to 285V operation, which cannot be changed.

…actually it's 265V and not 285V, so it's even less than what I mentioned

Hello

Can we use the above circuit with an Input AC Voltage range of 80 Volt AC to 300 Volt AC with Output Voltage Constant 12 Volt, 1 Ampere.

the operating range is from 100V to 285V

Hey Swagatam,

Really good Job, I really appreciate it.

I am an electronics designer and was looking for such design. I really liked it.

But can you please suggest me which transformer you had used for this. Is it ferrite transformer. Can you please tell me where can I buy this transformer or at least its part number.

Thanks in advance.

Thanks Krunal,

The circuit is by STmicroelectronics and indeed it looks superb.

the transformer is built over ferrite cores since it's an SMPS design, however the transformer cannot be procured readymade, you will have to build it as per the shown data.

The wire, bobbin and the cores can be easily procured from your local electronic spare part retailer….or if you are in Mumbai you can get these from Lamington Road.

Hello Swagatam,

Thanks for the reply.

Actually I am from Nagpur and now working at Rajasthan in rural area, Here I could not get them.

Still I have asked my friend from Mumbai & expect to get them soon.

Once again Thanks for your help.

Regards.

You are welcome Krunal!

Sir, can you please tell me how to design PCB for this circuit. I tried designing the same circuit using Proteus but can't find transformer package in it.

A professional PCB designer will be able to do it for you….

Hi, can this be used 24×7 the whole year

yes, it can be used continuously…and infinitely

but sir pic 817 has 4 terminal

check the datasheet:

http://www.farnell.com/datasheets/73758.pdf

Sir have y any circuis 12 v 2 amp and 4amp and not much part in the circuit?

bhavesh, you can try the following design:

https://www.homemade-circuits.com/2014/03/12v-5-amp-transformerless-battery.html

sir can i chang amp??

No current cannot be more than than 1 amp

Sir how may tuns includ in secandry need 2 amp??

2 amp cannot be achieved with this IC, because 1 amp is the maximum limit from this IC, still you try winding two strands of wire together in parallel for the secondary turns and check the response.

hai,

I am new, I designed this above circuit. I got some issues VDD Voltage is 4.1 v some viper is not switching,

can any one guide me.

thanx

hi sir,

i m facing problems in calculating primary , secondary and auxiliary winding's.please help me to calculation of exact winding's for 5 V,1 A smps.

Kindly reply as soon as possible.

thank you

Shaikh, you just have to vary R6 for getting any desired voltage in the range…the winding can be as suggested in the article.

Hello Sir

I got the current value by changing transformer winding's SWG, but one more problem has taken place, that SMPS is getting too hot, and after that it is restarting it self.

What can be the problem?

Hello Bharat,

I think the transformer is not wound correctly, please see the black dots those indicate the "start" of the winding….. did you follow those correctly?

the IC will reset if it detects overload…. which could be either at the output in the form of an actual overload or a wrongly wound primary….

OK got it….alternatively you can attach a small aluminum heatsink over the IC…this will stop the circuit from resetting….

it is around 50 mA per relay and I have only used 7 relays.

that's equal to 350 mA which is perfectly within the range of the design…it would be difficult for me to troubleshoot it from here…

the winding has polarity (start/finish) and that can be crucial, please check it and also try rewinding the secondary by using two strands of wire in parallel instead of one.

Hello Sir

I have implemented same design on PCB. I'm facing some problem. Like 5 V are coming perfectly on controller board, but when I connect relay board with it, and switch any two relay even, power supply is getting restart. Why this is happening so, i did't got any reason, can you pl help us?

Kindly reply as soon as possible.

Hello Bharat,

check the current consumption of the relay coil, by connecting a DC ammeter in series with the relay coil.

or may be you have not made the circuit correctly as per the given instructions.

hi sir,

i m facing problems in calculating primary , secondary and auxiliary winding's.please help me to calculation of exact winding's.

Kindly reply as soon as possible.

thank you

Hi Shaikh,

all the details regarding the trafo winding are furnished at the bottom of the article, please click on the last diagram, you'll find all the required data and the related layout diagram.

hello sir,

i have design same circuit 12v,1 Amp SMPS. But the problem is when i connect the load and it will consume more then 100mA current then voltage get drop to 11 volt.so could i maintain constant voltage 12 volt along with the load. or if voltage drop does it effect on stability.

hello shaikh,

that should not happen, if you have made it exactly as explained above then the smps should be able to withstand full 1 amp current… at 100mA the voltage should not drop…

the wire gauge determines the amp capacity of the smps, are you sure you used the specified wire dimensions?

Can I got for SR2100?

yes it will do.

well in that case 1N4007 will also be fine… rihgt?

1N4007 is not a fast switching diode, BA159 is a fast switching diode.

But I have seen many SMPS use ordinary diodes such as 1N5408 etc at the output so you can try a 1N5408 which is same as a1N4007 but much higher in amps.

and about, BA159 is of 1A only. Will it be fine with replacement of 2A schottky diode?

you can test it, if it heats up then we can look for some other option.

Is there any other option for increasing current?

the IC is specified to produce not more than 1amp, so it's not possible

is there any replacement of D8-STPS2H100? As it is not available in market.

Kindly reply as soon as possible.

Google for "700v mosfet", you will find many options to choose from….any mosfet with 700V and 5 amp would be ok

sorry… please ignore above comment

you can try a BA159 diode

1amp is the max current which cannot be increased with this IC

Hello Sir

How can I increase current rating?

Hello Sir

Can I have gerber data and BOM of the same as I'm not able to identify the component out here.

Kindly reply as soon as possible.

Thank you.

Regards,

Bharat Surani

+91787998867

suranibharat4@gmail.com

Hello Bharat,

Please click on the diagram to enlarge, you'll able to see the part specs in detail.

I am sorry a gerber file would be difficult from my side.

for more info and BOM you can refer to this original pdf source:

http://www.google.co.in/url?sa=t&rct=j&q=&esrc=s&source=web&cd=5&ved=0CDYQFjAE&url=http%3A%2F%2Fapplication-notes.digchip.com%2F005%2F5-10593.pdf&ei=UTaaVYWdF4uZuQTyvYOwBQ&usg=AFQjCNETxUPxGfwhkqnl61rOFrs0PtJXRw&sig2=t-GcqS0gHIw0fPxqKNz4NA

Dear Mr. Arya, it's not so critical, you can make it by winding a reasonably thick magnet wire over any type of ferrite core. Through some trial and error make the number match the shown value approximately….I think about 50 turns using 25SWG wire on any ferrite core would be good enough

Mr. Swagatam this thing is looking great for starter's scenario, can you give the detail about each components you have used in this circuit?

Thanks Mr. Akuu, I'll try to update the required explanation soon….

sir i have an ic cd6283cs audio amplifier circuit. i give 12v to use this circuit it gets heated up if input is more. and in datasheet it is given that it can handle upto 171v and utput 1500watts. it will be like that? on 12v only it gets heated then how come it will survive on 171v?

Rushi, the datasheet which you have referred to is of a TAZ (transient absorption zener) not your amplifier IC…..

the datasheet for your IC is probably not available on the net, so can't suggest much about it.

I want to make 5 to 12 volt smps work on 60 volt a/c input. may anyone tell me how to make it ?

you can try the following circuit

https://www.homemade-circuits.com/2014/03/12v-5-amp-transformerless-battery.html

What should be the changes to make it 12V, 2amp

make the secondary winding using two wires wound simultaneously…it's also called bifilar winding.

Circuit diagram isn't completely visible, it got clipped from top.

please check it now.

Hi Sir

i want a temperature control circuit for incubator.do u have any circuit diagram.

Hi Yasir, you can refer to this article:

https://www.homemade-circuits.com/2011/12/how-to-build-simple-electronic.html

Hello Pankaj,

555 is an evergreen versatile IC and will be there for at least another 50 years…may be its not available in your area.

Anyway, in your transistor circuit you can add a 100k pot in series with one of the transistor base resistors, this will give you an option for the required adjustments.

hello sir,

From where can i get this type of transformer.

hello hiren,

you won't get it readymade, you will have to make it with the help of the given date.

Dear Sir,

I am student of B.tech ECE.. I was trying to make SMPS of 150W (of voltage range 60 – 210 Volts DC & about 1 Amp. current). You are kindly requested to guide me for the same & oblige. My main problem is which transformer is to be used & the feedback circuit. I shall really appreciate if you could give me entire circuit.

Thanks & Regards,

Aseem Mittal (09417753155)

aseem.mittal19@gmail.com

Dear Aseem,

I don't have much idea about the transformer winding details, so I am sorry I won't be able to help with the project.

By the way what is the output voltage of the design?

Can I use any TNY series IC and opto coupler in simple 12V 1A SMPS circuit?

yes you can, according to me.

Hi P Pandey,

You can either connect three 1N5402 diodes in series with the battery and directly connect it with your phone, it will hopefully start charging it.

Alternatively you can just include a 4 ohm, 2 watt resistor in series with the battery positive and connect it directly with the cell phone for initiating charging of the phone.

yes you can achieve it by adding additional winding layers connected parallel to the existing secondary layer inside the transformer