In this article I will try to explain the making of a 1500 watt simple heater controller circuit at 25 amp current rate using an ordinary triac based dimmer switch circuit

Using Advanced Snubber less Triacs

Controlling heaters rated as high as 1500 watt requires stringent specifications with the controlling unit for safe and effective implementation of the intended operations.

With the advent of advanced snubber-less Triacs and Diacs making heater controllers at massive watt levels has become relatively easier today.

Here we study a simple yet entirely suitable configuration which may be utilized for making a 1500 watts heater controller circuit.

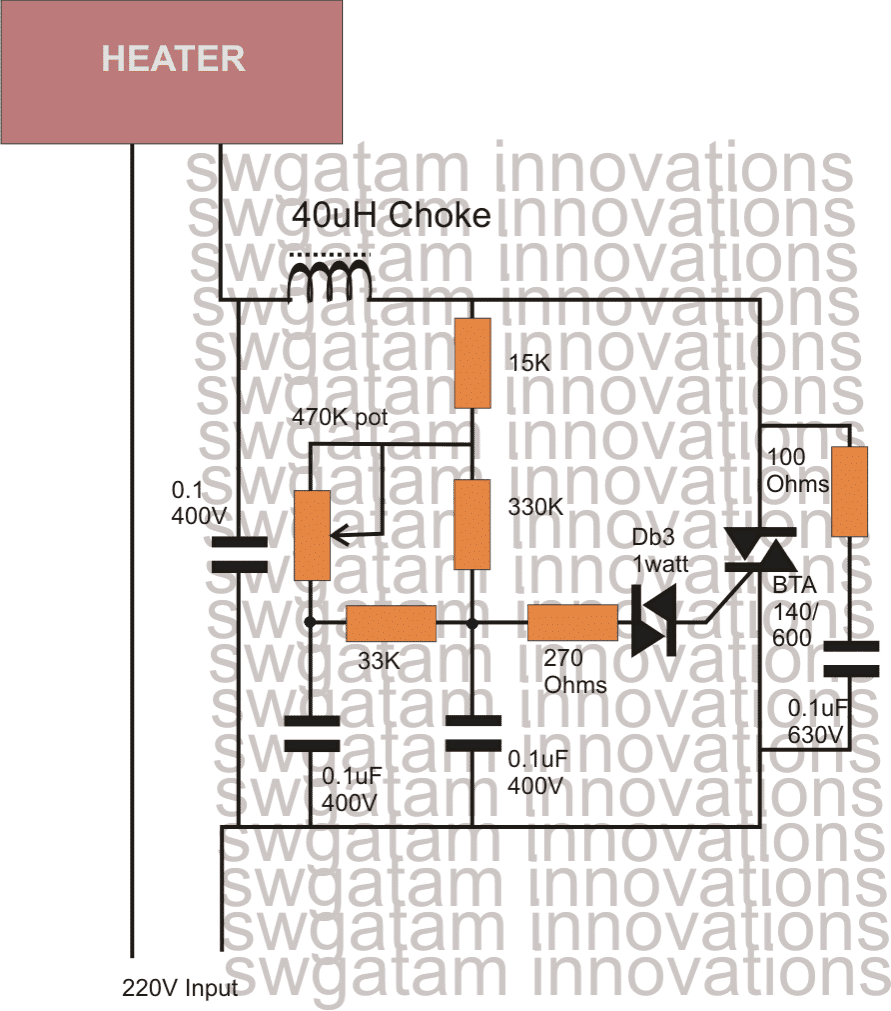

So I have explained the given circuit diagram with the following points:

How the Triac/Diac AC Controller Works

The set up of the circuit is pretty standard as the the wiring is very similar to the ones which are normally employed in ordinary light dimmer switch circuits.

The standard triac and diac set up can be seen for implementing the basic switching of the triac.

The diac is a device which switches current across itself only after a certain specified potential difference is reached across it.

The following network resistors and capacitors associated with the diac are chosen such that they allow the diac to fire only as long as the sine curve remains below a certain voltage level.

As soon as the sine curve crosses the above specified voltage level, the diac stops conducting and the triac is switched OFF.

Since the load or the heater in this case is connected in series with the triac, the load also switches OFF and ON in accordance with the triac.

The above conduction of the triac only for a specified section of the input sine voltage curve, results in an output across the triac which has the AC chopped into smaller sections, making the overall RMS of the resultant drop to a lower value, depending upon the values of the relevant resistors and capacitors around the diac.

The pot which is shown in the figure is used for controlling the heater element which initiates the above explained procedure.

The greater the resistance, the longer it takes or the capacitor to charge and discharge whih in turn prolongs the firing of the diac/triac pair.

This prolongation keeps the triac and the load switched OFF for a longer section of the AC sine curve which results correspondingly lower average voltage to the heater, and the heater temperature remains at the cooler side.

Conversely when the pot is adjusted toward to produce a lower resistance, the capacitor charge and discharge at a faster rate making the above cycle rapid which in turn keeps the average switching period of the triac at the higher side, resulting a higher average voltage to the heater.

The heater now generates more heat due to the increased average voltage developed across it via the triac.

Circuit Diagram

Parts List

Resistors 1/4 watt 5% CFR

- 15k = 1

- 330k = 1

- 33k = 1

- 270 ohms = 1

- 100 Ohms = 1

- Potentiometer 470k linear or 220k linear

Capacitors

- 0.1uF/250V = 2

- 0.1uF/630V = 2

Semiconductors

- DB-3 = 1

- Triac = BTA41/600

Inductor 40uH 30 amp (optional)

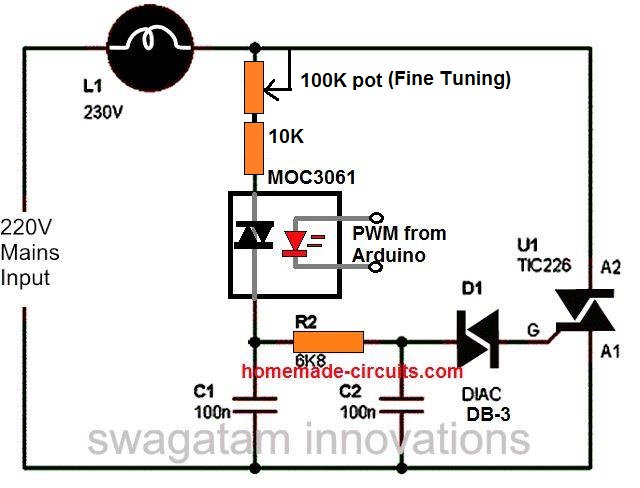

Controlling through Arduino Pwm

The above simple 220V dimmer switch control can be also effectively implemented using an external Arduino PWM feed through the simple method shown below:

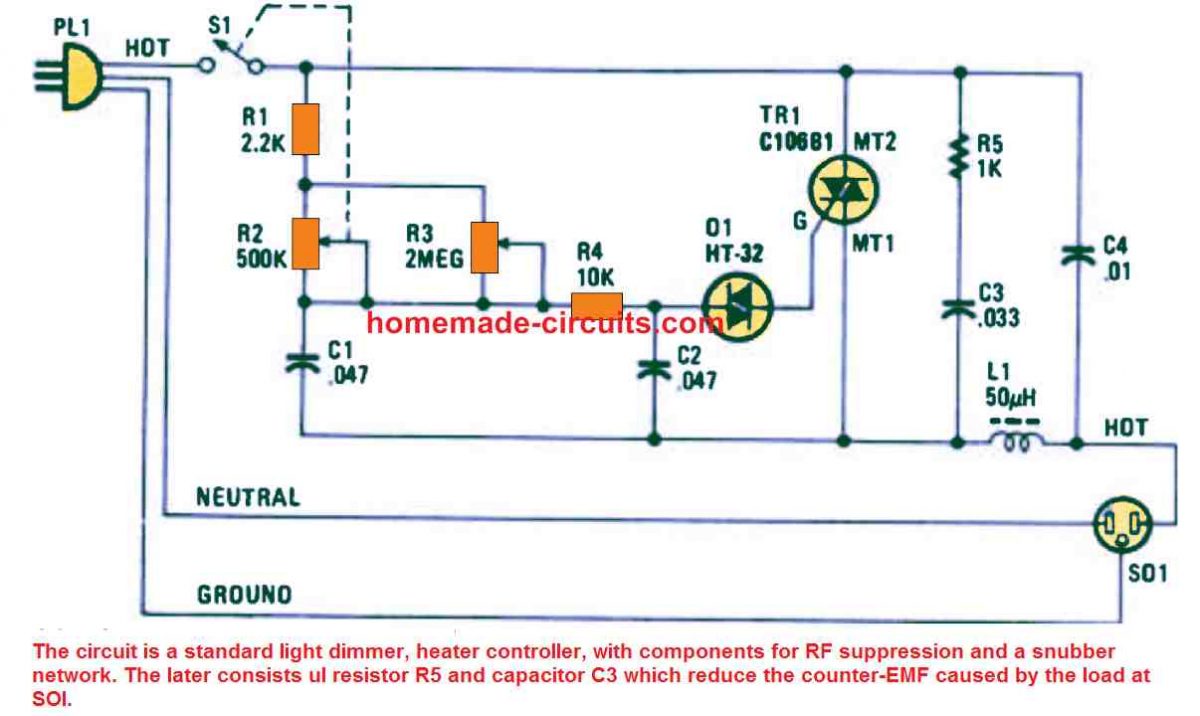

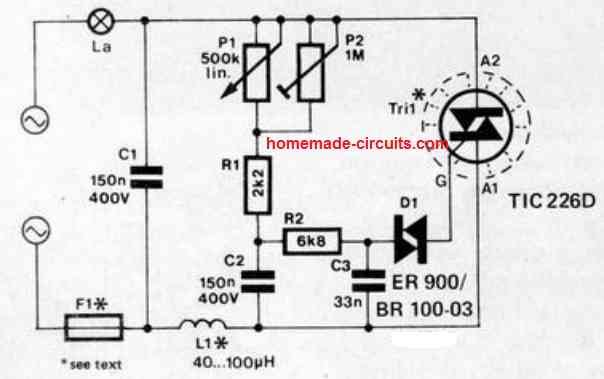

Advanced Heater Controller with Snubber and RFI Elimination

As soon as the voltage around C2 increases over approximately 30 volts (during any phase cycle), the Diac (D1) breaks over and produces a trigger pulse for the gate of the Triac (TR1).

This leads to the Triac switching ON and it applies the entire AC line voltage to the load hooked up to SO1.

Adjusting the potentiometer R2 varies the phase (timing) of the trigger pulses applied to the Triac and therefore modifies the average power level going to the heater load.

Resistor R5 along with the capacitor C3 works like a a snubber network over the Triac to safeguard it from the reverse EMF voltages spikes created by inductive loads every time the Triac is switched OFF.

Inductor L1, which is a 50 µH choke, and capacitor C4 are configured like an interference suppression filter, that enables the elimination of the RF noise commonly generated by this type of light dimmers or heater controllers.

The preset R3 adjusts the minimum starting range of the heater temperature, and helps the user to ensure that the power to the heater always starts from the minimum power when R2 is moved to the minimum position, and the heater gets maximum power when the R2 is moved to the maximum adjustment point.

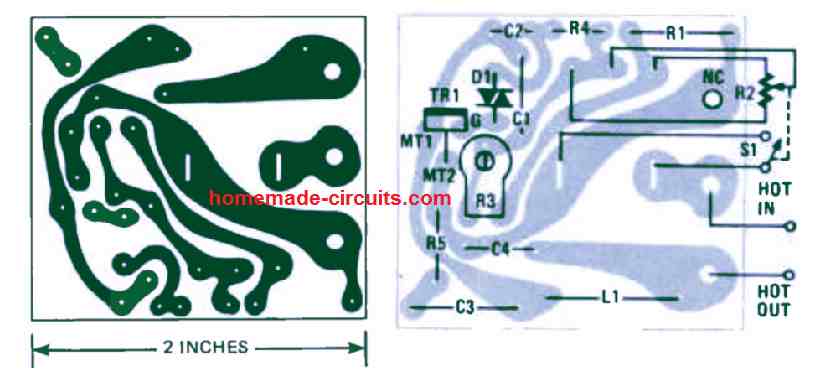

PCB Design

1000 watt Light Dimmer

Nearly all light dimmers that you can get from the common electrical products stores can simply manage pretty small electric power.

A few hundred watts is normally the handling capacity. The straightforward dimmer circuit demonstrated below is designed to control a power as high as 1 kW.

There is nothing much to be explained regarding the details of the circuit.

This high power light dimmer includes one triac, a single diac and an RC network where the period of the charging and discharging of capacitor C2 could be fixed using potentiometer P1.

Noise disturbances and transients are kept under control through capacitor C1 and the inductor L1.

How to Set up

Setting up of the circuit requires adjusting the pot P1 so that it reaches its maximum resistance, and then preset P2 must be tweaked until the attached lamp is just at the verge of shutting down.

In case a lamp higher than 100 W is utilized the triac should be attached to a heatsink having a heat transfer specification rate of about 6 °C/W.

When the circuit is used like a 1000 W dimmer, suppressor coil L1 should be rated to handle a current of 5 A with an inductance value that may be up to 40uH, while fuse F1 must be rated at 6.3 amps.

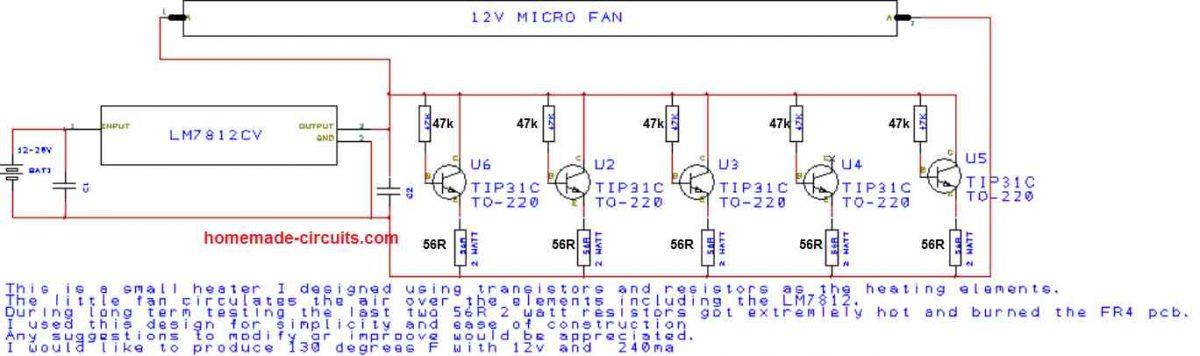

Heater using Transistors and Resistors

This unique heater circuit which involves transistors and resistors for the heat dissipation instead of a heater coil was designed by Mr. Norman, but he faced an issue with the circuit.

The problem and solution for the design can be understood from the following discussion:

Problem:

I designed a small heater using LM7812 voltage regulator and Tip31c transistors and resistors.

I tested it over several hours and found a problem. The last two 56R resistors got extremely hot and burned and scorched the pcb. I am attaching a schematic.

I couldn't find a similar project on your website, so I am trying to contact you through this contact point. Thanks!

The Solution:

That looks very strange because the 56 ohm resistors at the emitter of the transistors should force the transistor to dissipate the heat equally among the resistors and the transistors.

The last two 56 ohm resistors getting hotter means that the last two BJTs are conducting more freely than the remaining transistors.

The easiest way to tackle this problem is to mount all the transistors over a common aluminum strip, so that the transistor exchange their body dissipation uniformly with each other and thus all the transistors conduct and dissipate equally.

Comments

Hello, I am a laboratory science expert with 20 years of experience, but I am very interested in laboratory equipment repair. I’m new to electronics. Help me understand electronic circuits better. Building simple and practical circuits allows me to understand many things, such as a heating control circuit. Please provide me with a description of each item used in the circuit.

Hi, thanks for your question, and I appreciate your interest very much.

However, the explanation about the first heater controller is already given in the above article, please let me know if you could not understand any section of the explanation…

Hi, i found your great post, that for sharing.

My purpose for using this is for controlling a water boiler of 1200w that heats up too fast. Its water heating block from an old automatic espresso machine. Its a boiler that heats the water as it passes trough the block. As it is its heating the water faster than the pump passes it trough.

My idea is to use the first sketch and adjust the pot to heat enough for the water to have a specific temperature when it exits. Just to see if it works.

My if that works as intended my next step is to move it in to a arduino and have a temp sensor at the exit adjust the effect to the heater to keep the exit temp fairly consistent regardless of the water pumps pressure.

Do you have any suggestions how to implement that. My idea is to use a Waterproof DS18B20 to measure the temp.

Thanks, and Glad you liked the post.

You can definitely try the first schematic.

However my Arduino knowledge is not good, so helping with Arduino code may not be possible for me.

Nevertheless, I can suggest a simple op amp based heater controller with a sensor, no need of Arduino.

That would be great. Many thanks.

You can try the last circuit from the following article:

https://www.homemade-circuits.com/lm35-circuit/

When the LM35 is heated by the heater temperature, it reaches a certain point (as per the adjustment of the 4k7 preset) the op amp triggers ON the relay which switches OFF the heater and the process repeats.

In the first circuit why is some parts in parts list has different values?

Also is it possible to use the first circuit for a heating coil which was 1500w but is cut to half it’s length somehow? Or can you design a simple circuit like the first one for the above heating coil I mentioned. Please do respond.

The parts list shows 0.1uF/250V and triac BTA41 which are also correct and can be used in the circuit without any problems.

If you cut 1500 watt wire into half, then its wattage becomes 3000 watts. Assuming the voltage is 220V then the current will be 3000/220 = 13 amps. So the first circuit will still work and can be used for your requirement.

I wish to make a polyfoam cutter. I tried using a length of nichrome 26 guage (400mm length) 4.2 ohms in series with a 600w light dimmer wired to ac voltage of 20 volts. It did the job, but the nichrome wire drew 5.6 amps, making the dimmer hot.

Please tell me how to wire this up.

The dimmer was connected to the secondary side of the 230volt stepdown transformer.

Thank you,

Nanshir

Kuala Lumpur,

Malaysia

Using high wattage load at high voltage can keep a triac cooler, due to lower current. In your case you are doing the opposite, you are using low voltage and high current, that is why the triac is getting hotter. The only way to solve the issue is by using a higher rated triac, and then mount it over a large heatsink.

Another great idea is to connect the dimmer on the primary side of the transformer, and connect the nichrome wire on the secondary side of the transformer. So your dimmer controls the primary winding at 220V, and the load is controlled via a correspondingly varying secondary voltage of the transformer.

Yes, Swagatam, thank you. I tried as you suggested. Works perfectly.

Thank you again.

Victor nanshir

My pleasure Victor, glad it worked!

Hi Swagatam,

On heater controller circuit above with 470K potensio, at highest resistor adjusted, does it reach 0V, by meant it cut off Triac current?

Thanks

Hi Awak, yes it will reach 0V but 0V is not recommended. Therefore use 220k instead of 470k so that it doesn’t go below 10% heat at the lower limit.

Thank for respond. I have built a dimmer with other circuit where use 500K potensio, the lowest voltage is 95V, actually I need 0V or at least close to 0V. My purpose with that circuit is to control my step down transformer for battery charging, use BTA41 triac. Please advise, what is proper potensio to get this purpose? Is 1M enough?

Thanks for help.

You can try a 1M pot, or increase the two 0.1uF capacitors around 33k to 0.22uF….but this will not allow proper starting of the load….the load will not start until 150V is reached.

Ok thanks. This mean just to start the circuit, don’t we? So, after that, we can adjust to the lowest voltage, right?

Yes, that’s correct.

Hi! Swagatam,

I made the change of adding the 1k preset from pin 5 to ground and it allowed me to reduce the output below 700ma. It was real touchy to adjust, so I took it off and replaced the 5k preset with a 10k preset and it works perfectly with a 12v supply.

I have a second circuit that uses a 20v-5Ah battery, so I have a 7812 reducing the 20v supply to power the 12v micro fan and to power the two 12v-25 watt pad heaters in parallel. The 20v supply also powers the 7809 for the control circuit. I have a 334 capacitor on the power in to both 78xx ic’s. I have a 104 and a 10uF capacitor on the power out of the 7809. I have a 104 and a 2200uF capacitor on the power out of the 7812. I can only get a max of 540ma out of the circuit. As I increase the milliamp draw above 540ma, then the 12 volts begins dropping dramatically. I am puzzled by this as it appears the 7812 is not passing enough power. I first had a 10uF cap on the 7812 output and changed to a 220uF which helped, so I tried a 1000uF and then increased to the 2200uF. Any suggestions as to what may be a solution of having more adjustment of the milliamp output of the circuit?

Hi Norman, the 7812 can deliver full 1 amp @12V only as long its case temperature is below 40 degree Celsius according to me. So make sure the 7812 temperature is below 40 degrees C. Otherwise you can try LM338 for the regulator, or the following fixed variant

https://www.homemade-circuits.com/12v-5-amp-fixed-voltage-regulator-ic/

Hi Swagatam! I built the heater circuit and it worked. I had to increase the milliamp draw to 1000ma to get the two 12v 25 watt heaters in parallel above 100oF. The transistor I used was a TIP33 because that is what I had on hand. The temperature of the TIP33 was over ranging even with a heat sink and a micro fan blowing on it, so it was thermal cycling. I noticed on one of your motor speed control circuits you used a mosfet. I had a FQP30N06L Mosfet, so I replaced the TIP33 with the mosfet and it worked great. The mosfet stays really cool. The problem is I had to adjust the 5K variable resistor to limit the amp draw and the least amount of milliamps I can get is 700ma. How can I change the circuit to be able to reduce the amp draw down to 500ma? Thanks!

Hi Norman, glad it is working, however the issue that you are facing looks strange because the circuit is supposed to provide a PWM control from 5% to 95%.

You can try adding a 1 K preset between pin5 and ground, and check if its adjustment provides you the required reduction in the PWM

Thanks! Swagatam you are the greatest! Fast complete response! I hope everything is going well for you and your loved ones.

Thank you Norman, we all are good here, appreciate your kind thoughts very much!

Hi Swagatam! I have a small silicone pad heater that is rated 12v @ 25 watts. If hooked up to 12v it draws 1.3 amps and gets to 200 oC. It is made up of nichrome wire between two sheets of silicone. I would like to have two of these heaters in parallel and control the temperature to about 130 oF at 240ma each. I am supplying 20v with a 5 Ah lithium ion battery and plan to reduce this voltage to 12v to control a 25mm fan for air distribution. I think maybe a PWM circuit might work as it will reduce the ma output. I want 240 ma to each of the two heaters to make my battery last 10hrs. these heaters are touching expanded polystyrene which will collapse at much over 150 oF. The battery circuit has a low voltage cutoff set at 15.3v to protect the battery for over draining. I may have to have separate circuit for each of the heaters. Safety is a real concern as these will be attached to my house. I cannot stand for the heater to run away with itself and burn something up. Your perusal and suggested modifications are required. Thanks!

Hi Norman, you can use the following simple IC 555 PWM circuit, for fixing the heater temperature to a constant level, through the pot adjustment. The 7809 IC is important which ensures that the PWM is always constant regardless of the input voltage variations:

Complimenti bravo continua cosi!!ottimo lavoro Grazie!!

Hi,

I want to build a coffee roaster, and I want to use a 2,000 watt heat gun heater (220 v). Will this circuit handle that element? If it won’t, what mods need to be made to handle that much electricity?

Thanks.

Hi, yes you can use the above circuit for controlling a 2000 watt heater element. Make sure to use the triac that’s shown in the first image, and put a large heatsink on the triac

Hi Swagatam!

I want to build a 1000watt water boiler by putting a heating element around a steal pot (not bottom). I want it to power it using 12v DC battery.

Which heating element do you recommend for it? And how can I make a circuit for it?

I was considering using PTC heating element but that might take a long time to heat the water.

Your suggestion will be very helpful!

Hi Shraddha, using a PTC sounds a good idea as these are self optimizing and do not depend on external systems for the temperature control. Yes the heating effect will be delayed a bit as they are not designed to heat beyond 300 degrees Celsius. Perhaps, using an aluminum or copper pot may help speed up the process even with this heat, considering that this heat will all around the pot..

But the actual problem will be the supply source which will need to be rated at 83 amps if a 12 V is used. This will call for a 12 V 800 Ah lead acid battery or a 12 V 100 Ah Li-ion battery

Thank you for the response. I see, do you recommend on any other heating element I could use ? That will probably boil the water faster than PTC element.

The other option could be the standard Nichrome type heater coil, which will need to be controlled through an external circuit to prevent overheating

You show in the parts list 2 capacitors 0.1 µF/630V but only one in the schematic.

Is the other 630V capacitor the one right at the heater?

Thanks.

Actually both can be 630V or 400V, but not less than 400V

I am interested in making this heater control circuit to power my electric samovar. 10 Ohm heater coil, 110 V Ac

Could you forward a parts list. Amazon seems to have most of the items, but I am not sure which ones to use.

I was an electronics tech in the Air Force 1972-75. Much has changed since then.

The first circuit above can be applied for your heater. I have added the parts list below the diagram. Please make sure to add a heatsink on the triac

What is the value of R2?

It is 6.8k

I am still trying to find out the purpose of 330k and the 33k resistors. My guess is they are used to bias the diac. Could you explain the purpose of those resistors.

The RC network is specially configured to ensure a gentle step-wise firing of the diac and to make sure the triac is never allowed to go through sudden and abrupt switching.

Good day Swagatam

Please give suggestions on how to convert the circuit so that I can use a 3 to 20 Ma loop to controll the heater element

Looking at 4 to 5 kw element

Thanking you in advance

Chris

Hi Chris, sorry I do not have much idea regarding how to create a 3 to 20 mA loop to control heater element.

I’m using a solar array (and someday, a wind generator) to recharge a 540 Ah lead-acid battery bank on an ocean-going sailboat. Due to the charging profile of the lead acid batteries, I often have excess power available in the afternoon and I’d like to use this to run the AC heating element in my hot water tank, via an inverter. However, that AC heating element is 1600 watts, which would be well in excess of the power my panels can produce and will drain my battery bank quickly. I need a way of manually adjusting the current going to the AC heating element so I can balance the power to the heating element with the power produced by the solar array. I’m not an engineer so building circuits is not really my thing, so is there an off-the-shelf current adjusting mechanism that would lower the power to the element from 1600 watts to 800? Or better yet, be widely variable so I can adjust it?

What is the voltage spec of the heater? Here’s one design which could be modified for your application:

https://www.homemade-circuits.com/solar-water-heater-with-battery-charger/

You will have to adjust RV1 so that the op amp A output goes high when the battery is fully charged and the solar panel voltage tends to exceed this level.

Conversely, RV2 must be adjusted to ensure that the op amp B output goes low whenever the battery gets fully charged

First, i thank you for your reply .

Hello to you again .

About the lionel train of my son, ( YES ) i know that is realy important to calculate the exact A C output

voltage so i done that .

So, a hobby shop telling me to install a 50 watts-30 ohms rheostat on the ZW big lionel transfo as 275 watts -60 cycle , i was doing this but the rheostat start to work only when i reach the half way on the wire wound ,so,

another person explaned to me that my rheostat have too much ohms ans suggest to me to reduce the

ohms to only 10 ohms that supposed to be enough ,so , do i have to reduce only the ohm or the wattage and ohm like an 25watts-10 ohms or keep same wattage and only change ohms like an 50 watts – 10 ohms ??

P.S: I think that the wattage is important too!

What is the big difference from a TRIAC and a RHEOSTAT ??

Thank’s again .

Dan.

Hi A rheostst is a high watt variable resistor, which will reduce current and voltage by converting the excess power into heat, whereas a triac is like an electronic switch that will control power without power as heat. You can try a dimmer switch between the power source and the railway tracks for efficient power control

OK thanks!

Ok. I’ll try that resistor. I think I’m going to test another pot with higher resistance too. Your schematic said 100k, but it would seem it’s a little too low. I’m gonna tinker some more with it.

About the timestamps, I was referring to these posts, not the publishing date of the articles.

I guess the flickering could due to diac firing issue, you can try adding a 100 ohm in series wit the diac, and check the results.

Or if you wish to have perrefct results then you may go for a PWM/MOSFET configuration, and by supplying a rectified 220 V to th MOSFET via the load.

to know the post publishing sequence, you can check the following link:

https://www.homemade-circuits.com/blog/