The 4 simple car voltage current regulator circuits I have explained below is created as a immediate alternative to any standard regulator and, although developed principally for a dynamo it will function equally effectively with an alternator.

If the functioning of a traditional car alternator voltage regulator is analyzed, we find it amazing that these kinds of regulators is often as trusted as they are.

While most contemporary cars are furnished with solid-state voltage regulators to regulate the voltage and current output from the alternator, you may still find countless earlier cars installed with electromechanical type of voltage regulators that happen to be potentially unreliable.

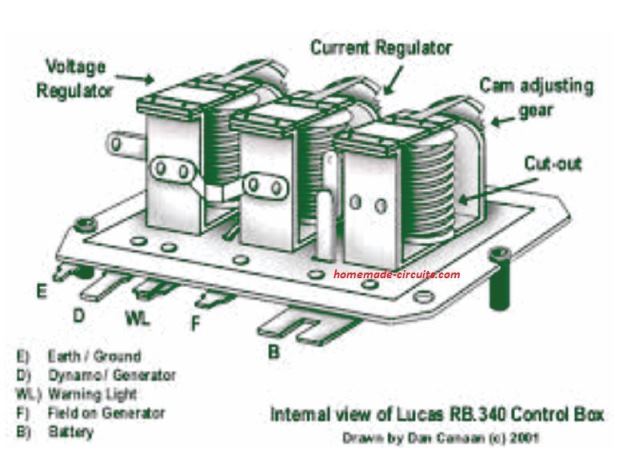

How Electro-Mechanical Car Regulator Work

The standard functioning of a electro-mechanical car alternator voltage regulator can be as I have explained below:

Once the engine is in the idling mode the dynamo starts getting a field current through the ignition warning lamp.

In this position the dynamo armature remains unattached with the battery since its output is smaller compared to battery voltage, and the battery starts discharging through it.

As the speed of the engine begins increasing, the output voltage of the dynamo also begins rising. As soon as it surpasses the battery voltage a relay is switched ON, connecting the dynamo armature with the battery.

This initiates the charging of the battery. In case the dynamo output goes up even more an additional relay is activated at around 14.5 volts which cuts off the dynamo field winding.

The field current decays while the output voltage begins dropping right up until this relay deactivates. The relay at this point consistently switches ON/OFF repeatedly, sustaining the dynamo output at 14.5 V.

This action safeguards the battery from overcharging.

There's also a 3rd relay containing its coil winding in series with the dynamo output, through which the entire dynamo output current passes.

Once the safe output current of the dynamo gets dangerously high, may be due to over discharged battery, this winding activates the relay. This relay now detaches the field winding of the dynamo.

The function ensures that just the fundamental theory, and the specific circuit of the proposed car voltage current regulator may have different specs depending on a specific car dimensions.

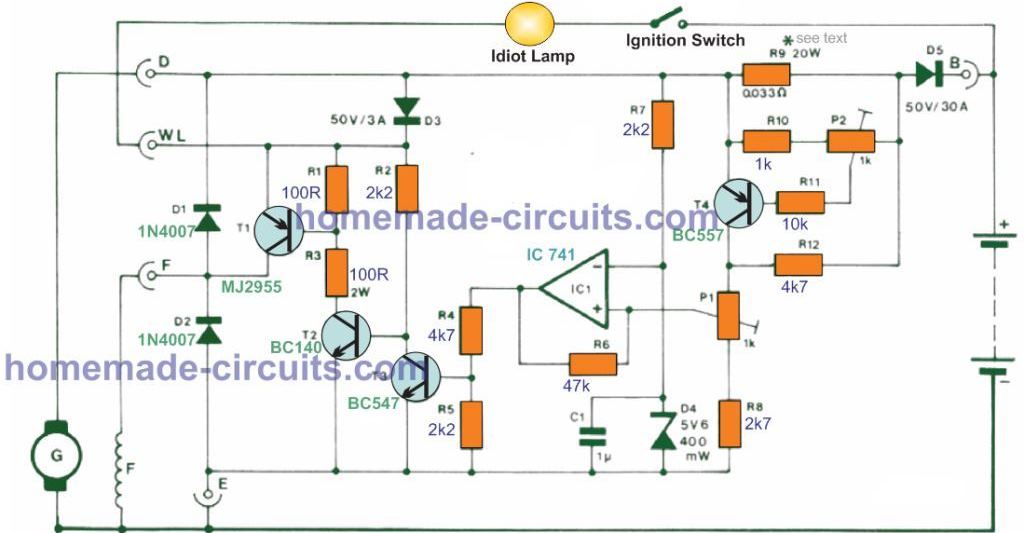

1) Using Power Transistors

In the indicated design the cut-out relay is substituted by D5, which gets reverse-biased as soon as the dynamo output drops below the battery voltage.

The battery as a result is unable to discharge into the dynamo. If the ignition is started up the dynamo field winding gets current through the tell-tale light and T1.

Diode D3 is incorporated to avoid current becoming drawn from the field coil due to the reduced armature resistance of the alternator. As the speed of the engine increases the output from the dynamo proportionately rises, and starts delivering its own field current by means of D3 and T1.

As the cathode side voltage of D3 goes up the warning light gradually dims until it fades off.

When the dynamo output reaches to around 13-14 V the battery begins charging again. IC1 works like a a voltage comparator which tracks the dynamo output voltage.

As the dynamo output voltage increases the voltage on the op amp inverting input is at first greater than at the non-inverting input, hence the IC output is held low and T3 remains switched off.

As soon as the output voltage goes higher than 5.6 V the inverting input voltage is regulated and controlled at this level by D4.

When the output voltage goes past the specified highest potential (set through P1), the non-inverting input of IC1 becomes higher than the inverting input, causing the IC1 output to change into positive. This activates T3. which switches OFF T2 and T1, inhibiting current to the dynamo field.

The dynamo field current now decays and the output voltage begins dropping until the comparator reverts back again. R6 supplies several hundred millivolts of hysteresis which helps the circuit to work like a switching regulator. T1 is either toggled harder ON or is cut off such that it dissipates fairly low power.

Current regulation is impacted through T4. Once the current by means of R9 is higher than the selected highest level, the voltage drop around it results in T4 to switch on. This raises the potential at the non-inverting input of IC1 and isolates the dynamo field current.

The value selected for R9 (0.033 Ohm/20 W, made up of 10nos of 0.33 Ohm/2 W resistors in parallel) is suitable to get a optimum output current as high as 20 A. If larger output currents is desired, R9 value could be reduced appropriately.

The output voltage and current of the device must be fixed by appropriately setting up P1 and P2 to meet the standards of the original regulator. T1 and D5 should be installed on heatsinks, and must be strictly isolated from the chassis.

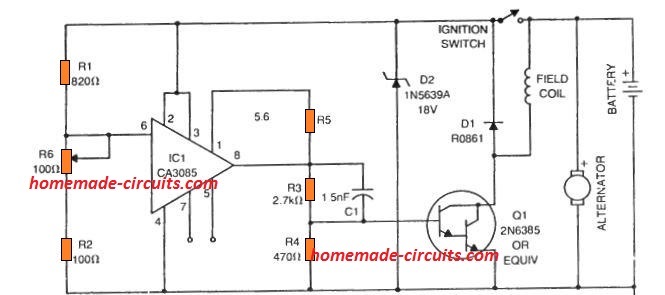

2) A Simpler Car Alternator Voltage Current Regulator

The following diagram shows another variant of a solid state car alternator voltage and current controller circuit using minimum number of components.

Normally while the battery voltage is below, the full charge level, the regulator IC CA 3085 output remains switch OFF, which allows the Darlington transistor to be in the conducting mode, which keeps the field coil energized, and the alternator operational.

Since the IC CA3085 is rigged as a basic comparator here, when the battery charges to its full charge level, may ba 14.2 V, the potential at pin#6 of the IC changes to 0V, switching OFF the supply to th field coil.

Due to this the current from the alternator decays, inhibiting any further charging of the battery. The battery is thus stopped from overcharging.

Now, as the battery voltage drops below the CA3085 pin6 threshold, the output becomes high once again, causing the transistor to conduct, and power the field coil.

The alternator begins supplying to the battery, so that it begins charging again.

Parts List

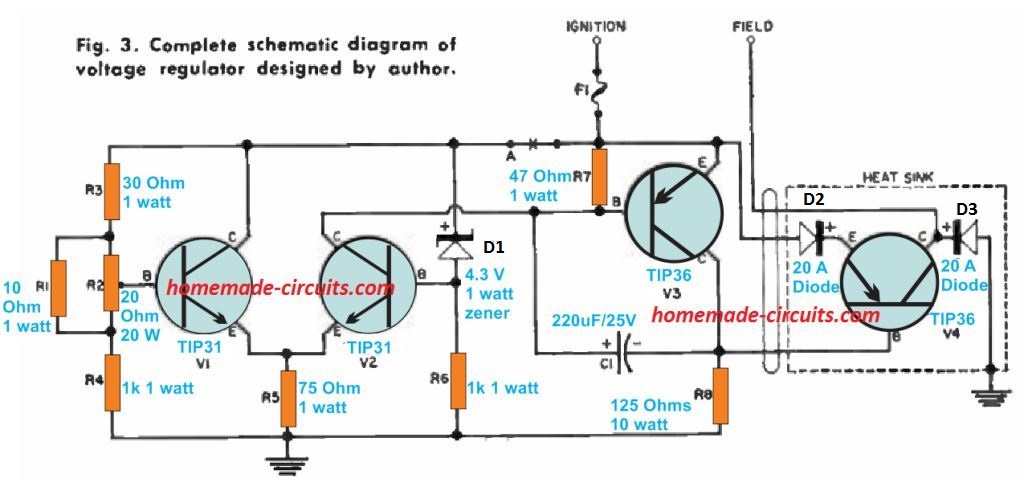

3) Transistorized Car Alternator Regulator Circuit

Referring lo the nest solid-state alternator voltage current regulator diagram below, V4 is configured like a series-pass transistor which regulates the current to the field of the alternator. This transistor along with the two 20 amp diodes are clamped on an external heatsink. It is intriguing to see that dissipation of V1 is not really very high even during the maximum field current, rather merely within 3 amps.

However, instead of the mid-range at which the voltage drop across the field is corresponding to that of transistor V1 causing a highest dissipation of not more than 10 watts.

Diode D1 provides protection to the pass transistor V4 from the inductive spikes generated within the field coil any time the ignition switch is switched off. Diode D2 which transfers the entire field current supplies extra working voltage for driver transistor V2 and guarantees that the pass transistor V4 could be cut-off at large background temperatures.

Transistor V3 works like a driver for V4 and a base-current swing of 3 ma to 5 ma upon this transistor allows total "on" to full "off" switching of V4.

Resistor R8 offers a route for the current during excessive temperatures. Capacitor C1 is essential to protect against oscillation of the regulator because of the high gain loop that is created around the the system. A Tantalum capacitor is recommended here for increased precision.

The primary element of the control-sensing circuit is enclosed within the balanced differential amplifier consisting of transistors V1 and V2. Special concern had been provided to the layout of this alternator regulator is to make sure there is no temperature drifting issues. To achieve this most linked resistors must be wire-wounds types.

The voltage control potentiometer R2 deserves specific consideration as it should never move away from its settings due to vibrations or temperature extreme conditions. The 20-ohm pot employed in this design worked ideally well for this program however nearly every good Wirewound pot in the rotary style might be just fine. The rectilinear trimpot varieties must be avoided in this car alternator voltage current regulator design.

The zener reference diode is important. Not just because it sets voltage reference but also because it controls system temperature coefficient. So the differential amplifier is made temperature-stable to stop drifting. It uses known diode coefficient about -0.04% per degree centigrade.

Now how it works is simple. When engine speed goes up then battery voltage also goes up. This makes charging current increase.

If field current stays same at start then higher battery voltage increases base current of transistor V₂. Then base current of V₁ also increases but less than V₂. This happens because of resistor network R₁ R₂ R₃ and R.

Ok… since collector current of V₁ goes down and V₂ collector current goes up, something interesting happens. Current in resistor R stays about same because it comes from V₂ collector current and V₁ base current. So when V₂ collector current increases, it must make V₁ base current smaller. This also reduces alternator field current.

Because of this alternator output voltage comes back to almost same as before. How close depends on regulator gain. In this case gain is very high.

Now about the setup. Transistors V₁ and V₂ are put on heat sinks. Not because they need cooling but to keep them strong.

Best if they stay close together so no temperature difference happens between them. The reference zener CR has its own place.

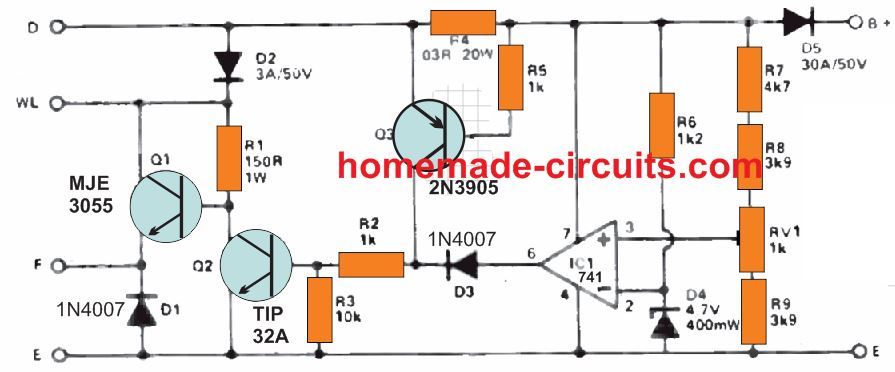

4) IC 741 Car Alternator Voltage Current Regulator Charger Circuit

This circuit offers solid-state management of battery charging. The alternator's field winding is in the beginning stimulated through the ignition light bulb just as in a traditional method.

Current moving across the WL terminal travels via Q1 to the F terminal then finally on the field coil. As soon as the engine is powered, current from car's dynamo moves through D2 to Q1. The ignition tell-tale lamp fades out since the WL terminal voltage exceeds than that of the battery. Current likewise moves through D5 towards the battery.

At this point, IC1 which is rigged as a comparator detects the battery voltage. When this voltage on the non-inverting input becomes higher than the inverting input (clamped at 4.6 volts via zener D4) causes the output of the op amp to go high.

Current subsequently passes via D3 and R2 towards the Q2 base and instantly switches it ON. This action as a result grounds the Q1 base switching it off and removing the current applied on the field winding. The alternator output now drops, causing battery voltage to also drop correspondingly.

This procedure ensures that the battery voltage is always held constant, and is never allowed to be over charged. The battery full charge voltage can be tweaked through RV1 to roughly 13.5 volts.

During cold weather conditions while starting the car, the battery voltage may drops significantly low. As soon as the engine has ignited the battery's internal resistance also become quite low, forcing it to pull too much current from the alternator and thus leading to a possible deterioration of the alternator. In order to restrict this high current consumption, resistor R4 is introduced within the primary power terminal from the alternator.

The R4 resistance is selected making sure that at highest possible current (Commonly 20 amps) 0.6 volts is generated across it which causes Q3 to turn ON. The moment Q3 activates current moves through the power line through R2 towards the Q2 base, switching it on, which then, shuts off Q1 and cutting off current flow to the field winding. Due to this the dynamo or the alternator output now drops.

No modifications need to be made to the original wiring of the alternator in the car. The circuit could be encased within an old regulator box, Q1, Q2 and D5 must be attached to an appropriately dimensioned heat sink.

Comments

Hello, I’m thinking about assembling the No.1 project, the regulator for generator using power transistors! Some of the parts have confusing part numbers like what is a 2K2 resister or a 2K7 resistor, 100R, 4K7, 5V6 Zener?

2k2 = 2.2k, 2k7 = 2.7k, 100R = 100 ohms, 4k7 = 4.7k, 5V6 = 5.6V

hi, do you have a 24 volt version about the number one project?

best regards,

Giovanni

Giovanni, did you find a 24v version? as I am still looking.

Sorry, I do not have the 24V version for the #1 project…

I had seen a circuit with a mosfet, for generators not car alternators, the designer says it is noty the same, but I have test it and it works, it goes in switching when on regulating mode. I see chopping voltage on the alternator coil.

The version you have post is one who use a floating rotor coil, because of that it is a npn power transistor.

I have redrawn the original rover P6 3500 dynamo regulator from motorola, this one use a rotor coil with one side grounded, and a npn version of transistor who I have replace for a P mosfet and some changes for drive it, this do chop a pwm signal when it is on regulation to act fast, years ago motorola did now this already, because of pwm also the dissipation of the transistor is very low making it more indestructible. I can share schematic but here I can not post this drawn.

Thank you very much, sounds great! please send the schematic to my email ID, I will update it in the above article:

homemadecircuits

@gmail.com

If you have a simulator (LTspice) I can send also the schematic for sim.

Then you need to email me.

Sorry, I do not use simulators softwares for my circuit, rather I use my knowledge and brain simulation. But no worries, it’s fine…

This kind of circuits do normally not need a simulator, I can drawn this by my self, but I do use it to fintune the parts, simulation these days are very accurate and real time calculations..

I do use sim for the class D amps and normal amps I do, for this it is very usable, class d is complicated signal path, so yes need it, but the circuit is not that complicated.

The schematic from ltspice is a redrawn schematic from bosch, and have use a fet in it and some modifications. Do work fine. you can place that here for the others.

remove the moderated awaited first post pleas, thanks.

Thanks for your response, if possible you can send the schematic to my email ID.

Thank you for the information! I appreciate it! If you have a schematic please provide it to us…

Regarding the first circuit: Is it possible to connect the charge control lamp to terminal F and not use a terminal WL? Would the lamp then go out, or would it always glow slightly? Would like to build the circuit into the housing of a mechanical regulator which only has terminals 30, 31, 67 and 51 (B+, E, F and D)

I don’t think that would work. The connections should be exactly as shown in the diagram.

could you help with my classic car dynamo? it is a 1952 Austin Champ, the old electro mechanical relay box has failed and I would like to build and fit an electronic unit like your designs however it is a 24v system at 12 amps and a nominal max output at 28v. regards John

The above circuits are all rated to work with a 12 V supply, so the above designs cannot be used for your application. If I happen to find a 24V system I may surely inform you about thee same.

Hi, any luck with a 24v dynamo design? Regards John

The last diagram in the above article, that is the one you can easily modify for a 24v system.

Let me know if you have any further doubts.

Hello, Can you please help me with the 2nd simpler Car AVR circuit diagram..? Can you please tell me the resistance of the R5 resistor? Thank You.

According to parts list it is 5.6. It should be 5.6K

Hi Swagatam

I thought this might be interesting but it actually goes a bit further than what I was looking for. On an old motorcycle I already have a separate regulator which supplies the 12v DC from the on-crank alternator. Unfortunately on this model there was no “idiot” light to warn when the system was NOT supplying the full voltage (it comes on when ignition is turned on and goes out when the system supplies above 12v – usually 13,5). So all I really need is a simple circuit to light an LED at 12v battery voltage and turn off when the output is high enough. Don’t know whether you can help but thanks in advance.

Hi Martyn,

As far as I have understood, the LED should be ON until the battery voltage reaches 13.5V, where the LED must turn OFF, right?

Correct. Thanks for the quick response

OK, you can try the first circuit from the following article. To setup the circuit simply adjust the 10K preset such that the LED just lights up at a voltage below 13.5 V

https://www.homemade-circuits.com/how-to-make-simple-low-battery-voltage/

Hi Swagatam,

Thanks for that, I’ll look into it. Not sure if I have a 741 op-amp in my box of bits ;-). I was looking at a possible design using an NPN tranny and an assortment of rectifier diodes, zeners and resistors – most of which I already have. It also had a branch at the 12v input with a TVS diode to gnd to intercept any spikes (Can’t see a way to upload an image to show what I mean). The spike intercept would be an interesting option as I recently had a serious spike incident which destroyed all the bulbs in the system, a controller for the indicators and a commercially available item to do exactly what I need to model – it’s no longer available, thus DIY. We believe the spike occurred because of an instable earth connection but is being looked into.

Thank you Martyn,

For a transistorized version you can try the circuit given in the following article. To control and eliminate spikes, I think the alternator regulator circuit must be good and well equipped to do this efficiently. A shunt regulator is the preferred form of regulators for alternators.

https://www.homemade-circuits.com/low-battery-indicator-circuit-using-two/

Hi Martyn an Swagatam, I came across this site by accident and it is interesting. Martyn, as for your query, all you need is an amp, and a reference. You can use a 723, or a 3085 also. Or any other amp like 710. And use external reference. Chose a 5.1 v, which has the best temp coeff. I am Nathan, and can be contacted at vmnath at hot mail dot com.

Swagatham, tell me this, without supplying batt voltage, the car alternator does not produce any voltage?? It need excitation, is it?

Contact me any time…it will be a pleasure.

Thank you Vish, for your valuable feedback.

Yes, I think a car alternator will require an external DC to initiate its field coil, without which it cannot start.

What is the maximum current of the field coil?

Is it possible to reconfigure circuit 2 to run a 48 volt alternator no current limiting is required the alternator in 200amp

It may be possible, but the IC will need protection from the high voltage, this could be probably done by placing a 1K 1 watt resistor between the ignition switch and D2

I found what i was looking for a simple Alternator voltage regulator. I may have new way to push pistons in an engine thus getting rid of the EMC. Which controls the voltage regulator in my alternator right now. I will replace the whole assembly for what you have presented. Thx so much, God bless

Glad you found the post useful. All the best to you!

Is this your design? Thx I have been looking for this solution for sometime. Do you have a design circuit for a tachometer to work from the pulses of a crank position sensor? Thx for everything. Have a great day!

No, these are not my designs. I have a few tachometer circuits in this blog, you can refer them here:

https://www.homemade-circuits.com/?s=tachometer

Hi Swagatam

Hopefully I’m in the right place now….

I’m hoping to build a (voltage) Adjustable Alternator Regulator for the engine in my sailboat.

The pic I sent had the PotMeter fitted to the circuit board. I was hoping to have the PotMeter remotely located around the chart table area where the Volt/Ammeters are located.

I’ve got three reasons for wanting to building my own regulator…

Reasons being:

-Fixable. Too much gear nowadays is so complicated it’s near impossible to repair.

-Adjustable. Not many regulator controllers do what I need as a liveaboard

-Cost. The ones that do everything I want are absolutely stupid money (£650+)

I was thinking of having a relay on the field output wires linked up to a voltmeter which has relay outputs in the event of the voltage going through the roof (for whatever reason), the relay would cut the power, hopefully reducing damage to other electronics onboard.

Unfortunately I’m a total electronics novice at the moment but will be learning what I need to complete it (Fingers crossed)

How do you think I/we should go about changing this dream into a reality ?

Brilliant website, by the way. I’m hoping it’ll teach me what I need….

Hi Neil, I checked your diagram, it seems quite OK to me:

However, I am not sure how accurately the PTC would respond?

Do you have a diagram that would do a better job, maybe with a little modification ?

Your diagram looks quite good, any other modifications could make the design more complex.

Hi Swagatam

The PTC would be bonded to the alternator to reduce the output in the event it get too hot, so I suppose it doesn’t have to be too accurate, compared to what It would have to be if it was controllng the battery temperature/voltage.

Do you think, by locating the potmeter 10 ft away it would cause any problems ?

OK, then it’s fine!

I don’t think the 10 feet distance of the pot location would cause any problems since the op amp inputs are high impedance and therefore slightly higher resistance of the wires will not make any difference.

HI Swagat ; I am thinking to make vertical axis wind turbine using car alternator. I could not find suitable PM low rpm alternator at suitable price. For alternator, here the case is different as compared to vehicle. The turbine will start/stop 1000 times in a day and secondly always RPM not sufficient. So if I give field excitation continuously then battery may get discharged. So I am thinking to detect rotor RPM by Hall sensor module and if it is sufficient then I will supply field current from battery for say 1 sec and then remove for self excitation. In this way I will avoid unnecessary drainage from battery by field coil. How do you like this idea? Pl comment.

Hi JK, the idea sounds perfectly OK to me.

if the battery is fully charged then regulator will reduce the field current to ZERO? If the field current is zero and bettery voltage falls below then how will alternator start without initial excitation from battery ( start switch and lamp) ; mean to say that it can not start from zero field voltage and current. I mean it may be never coming to fylly ZERO? Really what happens?

Current passes through indicating lamp again and also through parallel resistors( to indicating lamp). When the alternator stops supplying, battery starts to supply current in to field coil through indicating lamp

According to the diagrams, the power to the field coil will switch OFF completely, until the battery starts consuming the charge current again. However, the alternator will remain operational through the vehicle engine, and as soon as the battery discharges, the supply to the field coil will be instantly restored back….

The above circuits might require a lot of modifications to work with a 48V alternator, so I guess it may not be a feasible idea.

Hi can I use this to control the field circuit of a 48 volt alternator

Hello Yoan, the main purpose of the circuit is to safeguard the alternator from rising voltage and current. If the current control is removed, the alternator winding may be subjected to a rising high voltage and current due to the rising speed of the vehicle, causing burning of the alternator winding.