In this post I have explained how to build a battery deep discharge protection circuit which can be used for protecting any type of battery from over discharge through a connected load.

Normally, we are mostly worried about battery getting over charged, and forget about a situation where the battery can get over discharged by the load. Although, overcharging a battery may be detrimental to a battery health and appropriate measures must be incorporated, an over discharge or a deep discharge can be also equally dangerous for a battery's health.

In the following paragraphs I will elucidate a very simple design for shutting off the battery to the load, as soon as the battery voltage has reached the critical deep discharge state.

The circuit is fully solid-state and uses only transistors for the switching, thus eliminating the need of bulky relays.

Circuit Specifications

The idea was actually requested by one of the dedicated readers of this blog, Mr. Saurav, as I have explained below:

Looking for some ideas/help/suggestions. I have installed a 2.2 kw off grid solar system, using loom solar panels, excide battery and excide solar inverter. The inverter has this pre-setup priority, first solar, then grid, last battery. I have disconnected the mains supply to the inverter, so for me it is solar then battery. To this overall setup, I have added an ACCL with grid as secondary.

So in the evening, whenever there is no solar and the battery is out of charge, it falls back to grid power.

This setup has one problem. ACCL switches to mains power at night, when the battery is completely drained out or deeply discharged and that's what I don't want.

I want to turn off the battery power, when the battery has 20% remaining power or the battery is at a certain voltage. That way battery life can be better.

Is this something doable? Do we have something readily available for this? Or do we need to build something for this?

The Design

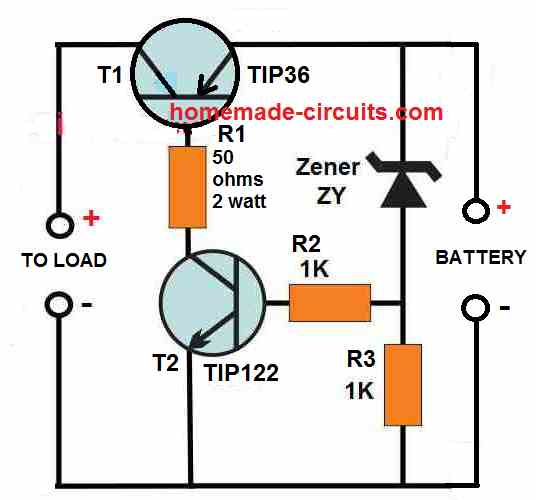

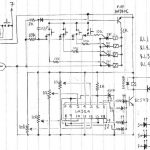

The circuit design for the proposed battery deep discharge protection circuit can be witnessed in the following diagram:

As can be seen, the circuit has a very components, and its working can be understood through the following points:

There are a couple of power transistors coupled with each other where, the base of the TIP36 transistor forms the collector load of the TIP122 transistors.

The base of TIP122 is biased through a resistor/zener diode network, where the zener diode ZY determines the cut off voltage for the TIP122.

The zener diode voltage is selected such that it matches the critical low voltage value of the battery, or any value at which the draining of the battery by the load is required to be stopped.

As long as the battery voltage stays above the zener voltage, or the voltage at which the cut-off needs to happen, the zener diode keeps conducting which in turn keeps the TIP122 in the conducting mode.

With TIP122 conducting the TIP36 gets the required base current, and it also conducts and allows the battery current to pass to the load.

However, the moment the battery voltages reaches or drops below the zener voltage which is also the deep discharge voltage level, causes the zener diode to stop conducting.

When the zener diode stops conducting, the TIP122 base voltage is cut off and it switches OFF.

With TIP122 now switched OFF, the TIP36 is unable to get its base bias current, and it also switches OFF turning off the battery current to the load.

The procedure effectively prevents the battery from further draining and depleting below its deep discharge level.

The indicated load can be any specified load, such as an inverter, a motor, an LED lamp etc.

How to Select the Zener Diode

The zener diode decides at what voltage the battery needs to cut off from the load. Therefore, the zener voltage must be approximately equal to the battery voltage at which the cut off needs to happen.

For example, if for a 12 V battery, the deep discharge cut off value is 10 V, then the zener diode ZY value can be also selected to be 10 V / 1/2 watt.

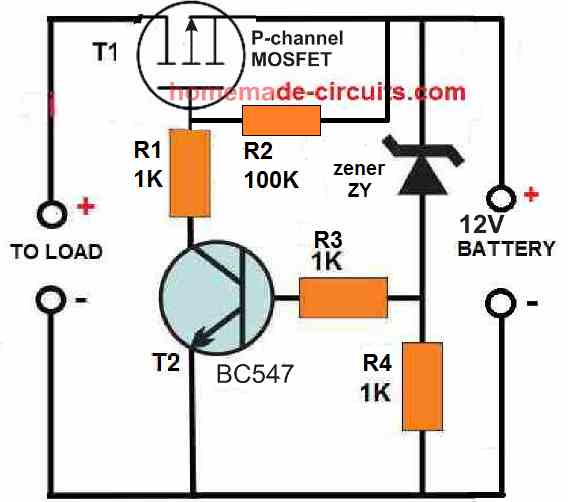

Using a MOSFET

The indicated TIP36 can supply a maximum current of 10 amps to the load. For higher current, the TIP36 could be replaced with a P-Channel MOSFET such as the MTP50P03HDL, which is rated to handle at least 30 amp current.

When a MOSFET is used in place of the BJT TIP36, the 50 ohms resistor can be replaced with a 1K resistor or a 10K resistor, and the TIP122 can be replaced with a BC547.

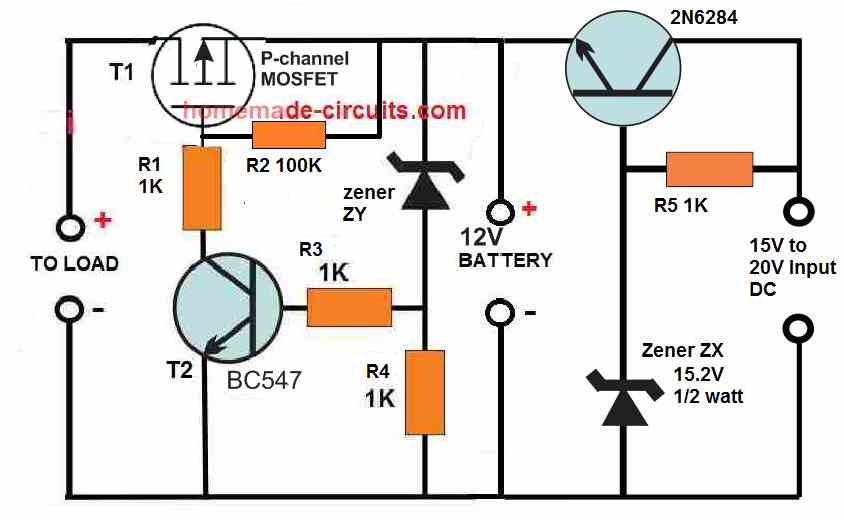

Adding a Battery Charger with a Single Transistor

The above discussed concepts are used to handle the over discharge situation of a connected battery. However, if you want the above circuit to also have its own battery charger, then the following circuit can be used for the process effectively.

Here we can see a transistor stage on the right side of the design, which is configured as an emitter follower. The transistor is a 2N6284, which is rated to provide at least 10 amp current to the battery, which means it is able to charge even a 100 Ah battery efficiently.

Since the transistor is a Darlington transistor and configured as an emitter follower, the voltage at its emitter will always lag behind its base voltage by 1 V or 1.2 V.

The zener diode must be cautiously selected so that it compensates the emitter drop of 1.2 V by providing a potential at the base which may be 1.2 V higher than the required emitter voltage.

Since the circuit is designed to charge a 12 V battery, the full charge voltage at the emitter of this transistor must be around 14.1 V. This implies that the base voltage of the transistor must be 1.2 V higher than the emitter, which amounts to a value of around 15.2 V to 15.3 V.

This is exactly why the zener must be rated at the above specified voltage for generating a constant 14. 1 V at the emitter side and across the connected 12 V battery.

While charging the battery when the battery terminal voltage reaches the 14.1 V value, it reverse biases the emitter of the 2N6284, which shuts down the conduction of the transistor, thereby stopping any further charging of the battery, and the battery is safeguarded from over charging.

The above shown circuit thus implements a 2 in 1 procedure of preventing battery over deep discharge and also over charging through the use a just a few transistors, and still is able to control a battery that may be as big as a 12 V 100 Ah battery.

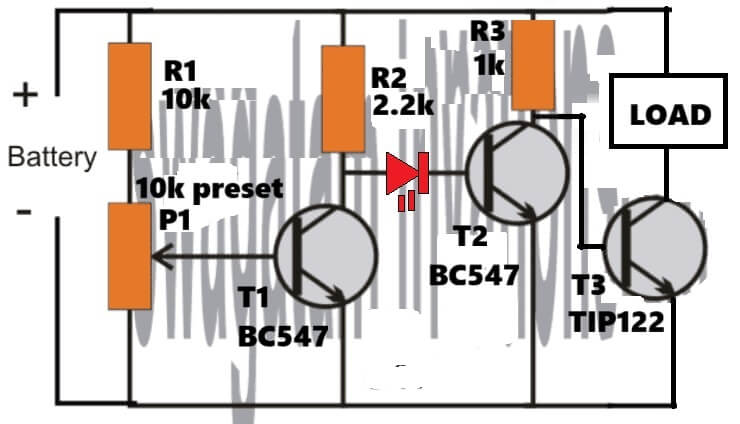

Deep Discharge Protection with more Accuracy

In the above 2 BJT concepts, cutoff drifts with load, so when load changes then behavior also shifts. Different transistor gives different cutoff point, since no two devices behave exactly same. Temperature sensitive too, so heat comes then things move. Due to this cutoff feels soft, kind of mushy, not clean break.

However in the following 3 BJT version, cut-off point stays stable, even when conditions change. Behavior is repeatable, so you build again and it works same. Disconnect of load is sharp, clear on and off. Works same with small load or large load, no deviations...

How it Works

This circuit keeps monitoring the battery voltage all the time. If the battery voltage is healthy then the LOAD stays ON and keeps working.

But when battery voltage drops below a preset level then the circuit disconnects the LOAD.

This helps prevent deep discharge, which otherwise damages batteries, especially lead-acid and Li-ion packs without BMS, so that damage part is avoided.

Blocks In The Circuit

The whole circuit can be seen as four simple functional blocks working together.

- First is the voltage sensing network using R1 and P1.

- Then comes the comparator transistor T1 (BC547).

- After that there is the switching or driver stage using T2 (BC547).

- Finally the power switching is handled by T3 (TIP122), which actually controls the LOAD.

Voltage Sensing (R1 + P1)

R1 (10k) and P1 (10k preset) form a voltage divider connected to the battery. The wiper of P1 feeds the base of T1 directly.

So as battery voltage rises or falls, the voltage at T1 base also changes along with it. P1 sets the cutoff voltage, so here you decide when the LOAD should disconnect, like at 10.8 V or 11.0 V and similar values. This part is basically the adjustment control of the whole circuit.

T1 – The Voltage Detector (BC547)

T1 works like a simple comparator here. When battery voltage is HIGH, the voltage at T1 base becomes greater than about 0.6 V, then T1 turns ON and its collector voltage drops toward ground.

When battery voltage becomes LOW, then base voltage of T1 falls below about 0.6 V, then T1 turns OFF and its collector voltage rises through R2.

So T1 converts the battery condition into logic levels, giving a LOW signal when battery is OK and a HIGH signal when battery voltage is low.

T2 – Logic Inverter + Buffer (BC547)

R2 (2.2k) pulls the base of T2 HIGH when T1 is OFF.

When the battery is OK, T1 stays ON, its collector is LOW, so T2 base is LOW and T2 remains OFF. But when battery voltage drops, T1 turns OFF, its collector goes HIGH via R2, then T2 base becomes HIGH and T2 turns ON.

In this way T2 flips the logic and also provides stronger drive for the power transistor.

LED Indicator Role

That LED is doing two jobs at the same time, it gives visual indication because when the battery voltage falls below the preset level, then the LED lights up, and because of that it acts as a LOW BATTERY indicator.

When the battery is OK the LED stays OFF, but when the battery goes LOW then the LED turns ON, simple and very useful in real-world use.

At the same time the LED also works as a reference voltage and level shift. A red LED drops about 1.6 V – 1.8 V, which is much higher and more stable than a normal diode, so because of this T2 does not turn ON immediately. It turns ON only when T1 fully releases the node, and that helps improve cutoff accuracy and noise immunity. In short, the LED creates a clean threshold for T2 switching.

Now looking at how the LED works inside this circuit, when the battery voltage is OK then T1 is ON and the node feeding the LED is pulled LOW, so the LED stays reverse biased and OFF. Because of that T2 remains OFF and TIP122 stays ON, therefore the LOAD remains powered.

But when the battery voltage drops below the preset level, then T1 turns OFF and the node rises via R2. At that point the LED becomes forward biased and lights up, so now the base of T2 gets proper bias and T2 turns ON. Once T2 turns ON, the TIP122 base is pulled LOW and therefore the LOAD disconnects.

T3 – Power Switch (TIP122)

TIP122 is a Darlington transistor, so it has very high gain and can handle high current loads easily. When battery voltage is OK, T2 stays OFF, so the base of TIP122 gets drive and TIP122 turns ON, allowing the LOAD to remain powered.

When battery voltage becomes LOW, T2 turns ON and pulls the base of TIP122 LOW, so TIP122 turns OFF and the LOAD gets disconnected. This is the stage where the actual battery protection happens.

Comments

Hi Swagatam,

I use a 2500W inverter with a 120Ah battery to supply me with 220VAC when we have a power outage.

I want to protect the battery from discharging below 11.9V. When the power is restored I then have a smart charger which will charge the battery and prevent over charging.

Can you suggest which one of your circuit’s will be sufficient to perform this task.

Regards

Jan

Hi Jan,

Since your battery is a high current battery, it will require a relay based cut off.

You can use the following circuit for implementing the battery over-discharge cut off:

https://www.homemade-circuits.com/wp-content/uploads/2024/05/battery-over-discharge-cut-off-circuit-using-741.jpg

Thank you Swagatam I appreciate your help.

Dear Swagatam!

I would like to use your circuit idea but I ‘m afraid that’s not suitable for my application.

So, I have to ask you about.

I need to use a battery over discharged protection, to an alarm panel were the battery is standing by.

The battery is all the time is under charge and when there is no AC, starts supplying 12V the system.

What do you suggest?

Hi George,

The deep discharge protector circuit explained above is created exactly for the kind of application that you have mentioned, so definitely you can use it and it will fulfill the purpose.

Is there any pcb design to print for the first circuit?

Sorry, I have not designed the PCB for this circuit, you may have to contact a professional PCB manufacturer for this.

In the battery discharge article can I use 2N3055 transistor in place of the stated 2N6284 because I cannot get here

Yes, you can use 2N3055, but make sure to calculate and adjust the R5 (1K) base resistor to the correct value so the transistors is able to deliver the required amount of current to the battery.

Thanks very much sir for the knowledge you pass to everyone

Thanks so much Kefson, Glad you found this site useful…

Hi Mr ingenious engineer. Straight forward post. Really you make complicated things so simple, which is a sign of mastery of your knowledge. Thanks.

My question: Can I use this circuit with a 3,7 battery diy Bank? If yes, what is the value of the zener diodes for the Charging Section (5,1v ?) and the Discharge Protection section ?

Thank you Abega,

You can use the above circuits for charging 3.7V battery but then a MOSFET cannot be used in the circuit, you will have use only BJTs.

In the last circuit you can replace the mosfet with a TIP127 transistor. The 2N6284 can be replaced with TIP122.

Zener ZY can be a 3.3 V zener diode, and ZX can be a 5.1V zener. However check and confirm the output at the emitter of the charger transistor, it should be around 4.1V

hello and thank you again

please tell me what is the R4 used for ? can we just omit it ?

R4 is required, it creates a voltage divider with R3.

Hello sir,

Thank you for such a simple circuit for deep discharge protection as well as charging with auto-cutoff. I want to use this circuit as a UPS system connected to my raspberry pi (I will step down 12v to 5v at the pi’s input). I have a question regarding the charging part of this circuit. I will set the charging voltage to 13.5v and charging current to about 650mA. Can I keep the charger connected to the 12v battery continuously, as a float charger? If I understand correctly, as the battery voltage will reach 13.5v, no current will flow from the emittor to the battery and this will act like an auto-cutoff mechanism, protecting the battery from overcharging. Is my understanding wrong in any manner?

Thanks again

Thank you Sandeep!

Yes, you can keep the charger permanently connected with the battery if you set the maximum charging voltage to 13.5V or even 14 V for a 12V battery.

That’s correct, once the battery terminal voltage reaches 13.5V it will automatically stop consuming the charging current any further.

However, please note that since the above circuit designs use only one transistor for the cut off, the process of cut off will be quite slow and gradual, meaning the cut off will not be sharp at a specific point, rather will happen within a span of around 1.5 V.

Thank you for the quick reply sir. Understood about the gradual cutoff. Also, can I add 2 or 3 diodes like 1N4007 so that the charging voltage drops from 14.5v to around 13.5v ? If this is not the correct way or a very efficient way to drop the voltage in the above charger circuit, can you please suggest any alternative method?

You are welcome Sandeep! yes, you can add 2 or 3 diodes to adjust the output voltage to the desired level. Just make sure the diodes are adequately rated according to the charging current. I think 1N5402 diodes will be quite enough for handling 650 ma current. 1N4007 may start getting hot at 650 mA.

Hello and many thanks again, I got here from https://www.homemade-circuits.com/gel-cell-battery-charger-circuit-constant-current-constant-voltage/ and I like this circuit, based on a transistor logic instead of one based on an opamp comparator, and since here the main value is obtained with a zener diode, now about replace it with a TL431 reference?

Many thanks and best regards

That’s great Andrea, all the best to you, hope it works for you.

Good day,I’m very interested in what you doing,and I’m able to learn more. When I got questions wil you be able to help me?

I’m a electronic technician and I love my work.

Best Regards

Friedell

Thank you, you can ask your questions, if it possible for me I will try to solve them for you.

Hi Swagatam,

Thanks for the swift reply, I’m making a mess of this.

What I should have said:

I would like to protect a 12V 14Ah lead acid battery from being overcharged or deep discharged.

The battery supplies LED garden lighting and is charge by an 18V 6W solar panel

Having looked at the components I have available, I wondered if the following would work?

From Circuit 1 ‘over discharge’ duel transistor arrangement

Replacing TI (TIP36) with TIP46C

Replacing T2 (TIP122) with NPN 2N2222

Zener ZY = 10V ½ watt, R1 =50 ohm

Adding the ‘overcharge protection’ from Circuit 3

Replacing T3 (2N6284) with NPN 2N6388G

No problem Peter,

Now it looks much better, and you can go ahead with it, except a few things.

I am not so sure about TIP46C since I could not find any data regarding it online. If it is a PNP and equivalent to TIP36 then it may be fine.

Also using a 10V zener would mean the battery draining down to 10V which may not be a good thing for the battery. Better to use a 11V zener instead.

The remaining aspects look OK to me.

Hi Swagatam,

Sorry, I missed a line from my previous post.

I would like to protect a 12V 14Ah lead acid battery from being overcharged or deep discharged.

The battery supplies LED garden lighting and is charge by an 18V 6W solar panel

Having looked at the components I have available, I wondered if the following would work?

From Circuit 1 ‘over discharge’

Replacing TI (TIP36) with DARLINGTON 2N6388G

Replacing T2 (BC547) with NPN 2N2222

Zener ZY = 12V ½ watt

Adding the ‘overcharge protection’ from Circuit 3

Replacing T3 (2N6284) with NPN 2N6388G

Thanks for the help,

Peter

Hi Peter,

2N6388 is an NPN so it cannot be replaced with TIP36 which is a PNP transistor.

The remaining selections are OK.

Hi, Greetings…!!!

Dear Swagatham,

Regarding the first circuit with tip122 and tip36…its workas fine.but when after the deep discharge terminal voltage rise immediately so it starts the chattering of output load.How can us make a little time delay to start the output again after once detected deep discharge.please help.

Hi Sison, I having difficulty understanding how and when the battery terminals will go high after the deep discharge? Do you mean when the battery is cut off from load?

Anyway you can try adding a 100uF capacitor across the base emitter of TIP122 and check the response.

On this last diagram where can I connect my PV if am using solar as I can see it has two inputs help me understand the circuit

On the last diagram you can connect the PV across the points indicated as “15V to 20V input DC”

Hello Swagatam, I have 15amps transformer which I want to use to charge a 200ah battery. Now i want to use this deep discharge circuit to help save the battery. I tried the second circuit auto cut off using lm358 in your article but I do find it difficult to set the two preset coz it’s not working for me. Can this deep discharge circuit help as an alternative to switch off the the circuit whn battery full and does it connect again automatically to recharge again? Pliz help.

Hello Morris, the above deep discharge does not have an auto cut off but in the last circuit, the transistor 2N6284 will automatically stop charging the battery once it reaches the full charge level as set by the zener diode value. Because when the battery voltage reaches the same value as the emitter voltage of the transistor then no current can flow from the transistor emitter to the battery.

Yes Swagatam, so once the the last circuit cut off upon reaching the charging level. Whn the battery starts draining to a lower level then it will reconnect to initiate charging again? Thanks

Yes definitely, as soon as the battery terminal voltage drops below the existing emitter voltage of the transistor, the current will start flowing from the emitter towards the battery positive, and the battery will start getting charged again.

But how do you see, if 2n6284 is a darlington transistor which is rated 100v 20amps. Can I use it to deliver the right charging current for 200ah battery? Secondly, if not do I go for another darlington transistor with at least 30amps or I use pieces and connect in parallel? Am using a rectified transformer with 15amps’ please guide.

You can replace the transistor with 2N5683. Or you can use two TIP35 in parallel. But make sure to convert each of these transistors into a Darlington by configuring a 2N2222 with their bases. After constructing the circuit you must adjust the zener value such that the emitter of the transistor produces a 14.3V output. You can further confirm the output by connecting a 1K load across the BJT emitter and ground. Also make sure to mount both the power transistors close to each other over a single common heatsink.

Greetings

Sir,

Regarding yor first circuit .For my low power of about 1ampere only can i replace tip36 with which transistor can substitute?(easly available in market)Morover need to change the value and watts of50 ohm resistor?

Expecting your valuable reply

Regards,

Sison

From Kerala…INDIA With❤❤❤❤

Hi Sison, for 1 amp load you can replace the TIP36 with TIP32 transistor or a TIP127 transistor. The 50 ohm can be replaced with a 1K 1 watt transistor

Hi mr swagatam..

Great circuit for deep discharge & cut it off.. In your last circuit, what should to modify for 18650?. Is it just modify both diodes?

Thanks for advise.please keep up the great works..thanks

Thank you MP3, glad you liked the circuit.

Yes it is only the zener diodes whose values will need to be modified as per your battery specs. Rest everything can be as is.

Swagatam,

I need to make a discharge circuit, that when pressing a switch is discharged to a limit, what calculations should I take into account and can I do it by means of resistors that absorb the current?

Hello Mariana, I think you can try the following concept. It will discharge your battery at constant current until reaches a particular voltage value.

https://www.homemade-circuits.com/precise-battery-capacity-tester-circuit-backup-time-tester/

Thanks, Swagatam.

I recently found another of your articles, which used an LM358 , and that seems to work very well; I can fine tune the cutoff point.

Thanks and I love your stuff.

It’s very informative.

That’s great Chris, Glad the circuit fulfilled your requirement. Please keep up the good work!

How can alter the charging current of the charger please

It will need to be controlled from the power supply side only.

Swagatam,

I am having trouble getting this circuit to work. I am using the p-channel mosfet (IRF4905) and the BC547 with the values you have shown. I am trying to get a 9v battery to be cut off when the value drops below 5 volts.

Actually, I am using a 1N4732A, or a 4.7V zener. When the voltage drops below the 4.7, the output just follows the declining voltage and doesn’t shut off as expected. Please advise.

Chris, The cut off will not be sharp since it is being controlled by a single BC547 transistor, rather this will be a gradual choking. You can try adding a 1N4148 diode in series with the emitter of the BC547 and check if that improves the condition.

Sir I mean from the first circuit diagram ( To Load), will it be connected to the inverter output A.c positive and negative?

Godspower, yes the load can be an inverter also, to the inverter battery points.

Hello Swagatam, which charger circuit do I use to charge solar battery in my shop? Which one is the best

Hello Morris, please provide the specifications of your battery, I will try to help!

Am using 100ah solar battery. Advise me which one to use with the modified sine wave inverter

You can use the last circuit from the above article, it will work for 100Ah battery also. Make sure to use a 10 amp charger as the supply source

Refer me to your best charger I can use to with my free maintenance battery 100ah sir. Am creating a backup in my shop, therefore I seek your guidance.

Please sir does it mean, that the output (to load) can be connected to output of an inverter? (I.e A.c )

Godspower, I did not understand your question?

You can refer to the following two articles, and select any one of them, all are good ideas:

Lead Acid Battery Charger Circuits

Op amp Battery Charger Circuit with Auto Cut Off

Thanks sir. But do have any best 10amp charger?

The 10 amp will depend on the transformer or the SMPS power supply used as the input…which you can buy and connect externally.

My lecturer, Swagatam, can I use ths deep discharge and over charging circuit in the modified sine wave inverter u referred to me as the the best in my workshop as auto cut off in my battery charger?

Thanks Morris, yes you can definitely use the last circuit with the modified sine wave inverter circuit

Hello, I consider your site a valuable source of consultations especially in power electronics with the topics of three-phase inverters, I have long searched for a three-phase signal generator out of phase at 120 degrees and here you have explained it, I would like to see a generator 180 degree phase shifted 3 phase square wave with operational amplifiers to control the speed of a 12 volt 3 phase motor using a full wave bridge with mosfet.

Thank you in advance for your cooperation

Respectful regards

Hello thank you, I am glad you liked this site, however you have asked your question under unrelated article. The above article is about battery deep discharge…for further doubts plese ask your questions in the following article:

https://www.homemade-circuits.com/three-phase-signal-generator-circuit/