In this post I have explained a simple car laptop charger circuit for charging laptops from a 12V car battery using a IC 555 based boost converter. The idea was requested by one of the avid readers of this blog.

Making a 12V to 19V Converter

May I request you for a circuit diagram for a transformerless small 100w inverter which can be used with a car 12V battery to power a laptop? I've found one circuit online but as I am a very new comer to electronics, I didn't understand that. Your help will be highly appreciated. Thanks

You may also like: 12 V to 19 V Converter Circuit

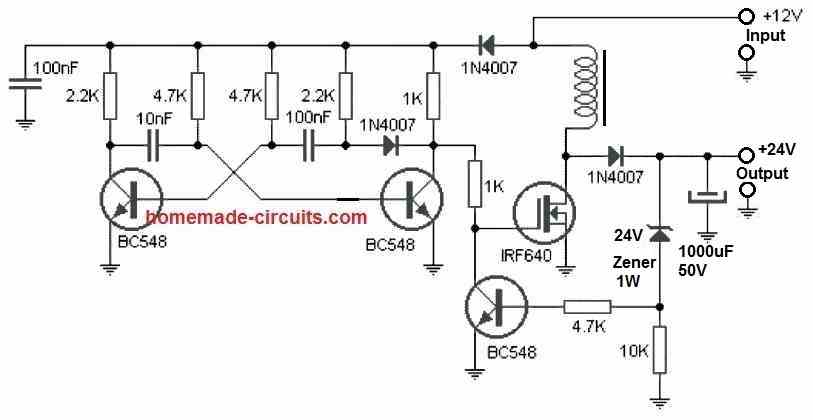

The Transistor Astable Design

A classic boost converter which will perfectly suit the proposed 12 V to 24 V car laptop charger application can be quickly built using a fully transistorized design as shown below:

All the shown parts are standard, or could be replaced with other suitable equivalents.

The inductor which is one of main parts of the circuit is built over a ferrite rod 1 cm in diameter, by winding 100 turns of super enameled copper wire having 1 mm thickness.

Actually, the inductor is dependent on the frequency of the transistor astable. For higher frequencies the number of turns will proportionately go down, and is a matter of some experimentation. The turn number will also depend on the ferrite core shape, and may significantly decrease if a ring type ferrite core is used.

Calculating the Part Values

Astable Multivibrator Section:

The astable multivibrator is designed to generate a square wave to drive the MOSFET. It uses two BC548 transistors with capacitors and resistors which forms the timing network.

Frequency Formula:

f = 1 / (1.44 * (R1 + 2R2) * C)

Here:

R1 = 2.2k ohms (astable feedback resistors)

R2 = 4.7k ohms (base resistors)

C = 10 nF

Calculations:

f = 1 / (1.44 * (2200 + (2 * 4700)) * 10 * 10-9)

f = 1 / (1.44 * 11600 * 10-8)

f ≈ 6.06 kHz

Thus the switching frequency of the square wave is approximately 6.06 kHz.

MOSFET Boost Converter Stage:

The IRF640 MOSFET switches the inductor to step up the voltage.

Inductor Value (L):

The inductor value depends on the peak current (Ipeak), duty cycle (D), and switching frequency (f).

The output voltage (Vout) is determined by:

Vout = Vin / (1 - D)

For Vin = 12 V and Vout = 24 V, the duty cycle is:

D = 1 - (Vin / Vout)

D = 1 - (12 / 24) = 0.5 (50 percent)

The inductor value is calculated using:

L = (Vin * D) / (f * ΔI)

Assume ΔI = 20 percent of Iload, where Iload = Pout / Vout.

For Pout = 20 W:

Iload = 20 / 24 ≈ 0.84 A

Peak-to-peak ripple current:

ΔI = 0.2 * 0.84 = 0.168 A

Now calculate L:

L = (12 * 0.5) / (6060 * 0.168) = 0.005893 Henry

L ≈ 5.893 mH

We will choose a standard inductor value of 6 mH.

Output Capacitor (Cout):

The output capacitor filters the ripple voltage.

Cout = (Iload * D) / (f * Vripple)

For general-purpose applications we can take output ripple voltage of 1-2% of the output voltage.

For Vout = 24 V

Vripple ≈ 0.02 * 24 = 0.48 V

However it is better to assume a smaller ripple such as 50 mV (much less than 2%) which can ensure much tighter output regulation.

So, assume Vripple = 50 mV:

Cout = (0.84 * 0.5) / (6060 * 0.05)

Cout ≈ 693 μF

Choose a standard capacitor value of 1000 μF, 50V.

Diodes (1N4007):

The diodes must handle the peak current and voltage. The current rating should exceed Ipeak = 0.42 A and the voltage rating should exceed Vout = 24 V.

The 1N4007 diodes (1A, 1000V) meet these requirements.

Feedback Network:

The 24V Zener diode ensures that the output voltage is regulated. It clamps the voltage at 24V to prevent overvoltage. The 4.7k resistor limits the current through the Zener diode.

Final Results:

- Frequency: 6.06 kHz

- Inductor: 6 mH

- Output Capacitor: 1000 μF, 50V

- Diodes: 1N4007

- Zener Diode: 24V, 1W

- Feedback Resistor: 4.7k ohms

The IC 555 Design

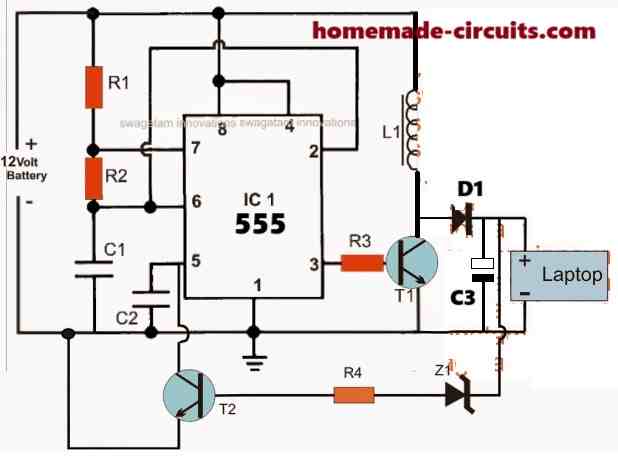

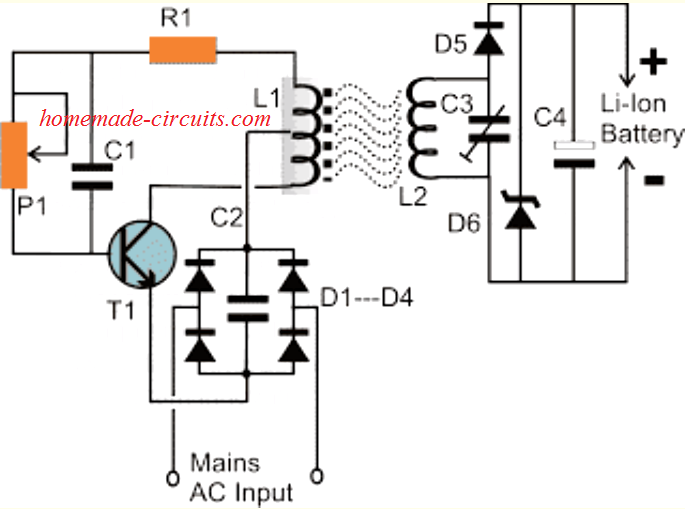

The proposed car laptop charger circuit is actually a simply boost converter unit designed for generating the required laptop charging voltage.

A simple boost converter can be made using the IC 555, I probably have discussed it through many other posts in this blog.

As may be witnessed in the following figure, a simple yet very efficient boost converter circuit can be constructed for using with laptops from any high current source having a lower voltage than the laptop charging level.

Circuit Diagram for the Boost Converter

The various stages included in the above 12 V laptop boost charger circuit may be understood as follows:

IC1 which is a 555 IC is configured as a standard astable for generating a stable predetermined frequency at the rate of 12 kHz which is acquired at pin3 of the IC.

The above high frequency output is fed to the base of a driver BJT T1 for inducing the above frequency with high current in L1.

Due to the inherent property of the inductor L1, during every OFF time of T1, an equivalent amount of boosted voltage is kicked back from the inductor L1 and supplied to the load connected at the output via the fast recovery diode BA159.

The load here is the laptop which accepts the boosted voltage for charging its internal battery.

Since the laptop may require a precise 19 to 20V for the operations, the output from L1 must be regulated and stabilized in order to make things safe for the connected laptop battery.

The above criterion is taken care of by introducing T2 and the associated R4 and Z1 components.

Z1 is selected to be exactly equal to the laptop charging voltage that is at 20 V (17V is wrongly shown in the diagram).

Whenever the output tends to drift away from this value, Z1 gets forward biased triggering T2, which in turn grounds pin5 of the IC.

The above situation immediately reduces the IC 555 pin3 voltage to minimal levels for that instant until Z1 stops conducting and the situation is restored to the safe zone....the switching is sustained at a rapid speed maintaining a constant voltage for the laptop.

This car laptop charger circuit can be used for charging a laptop in any car which uses a 12V battery.

Calculating the Part Values

The above 555 circuit is designed to convert 12V DC input to 19V DC output with a current of 2A for charging a laptop.

Output Voltage and Current:

- Input Voltage (Vin): 12V

- Output Voltage (Vout): 19V

- Output Current (Iout): 2A

Inductor Selection (L1):

The inductance is calculated using the formula:

L = (Vin * (1 - D)) / (f * ΔI)

Where:

- Vin = 12V (input voltage)

- D = (Vout - Vin) / Vout = Duty cycle

- Vout = 19V (output voltage)

- f = 50 kHz = 50,000 Hz (switching frequency of the 555 timer)

- ΔI = 20% of Iout = 0.2 * 2 = 0.4A (ripple current)

Step 1: Calculate Duty Cycle (D):

D = (19 - 12) / 19 = 7 / 19 ≈ 0.37

Step 2: Calculate Inductance (L):

L = (Vin * (1 - D)) / (f * ΔI)

L = (12 * (1 - 0.37)) / (50,000 * 0.4)

L = (12 * 0.63) / 20,000

L = 7.56 / 20,000 = 0.000378 H = 378 µH

Inductor Value: 378 µH

Output Capacitor (C3):

The output capacitor filters the ripple voltage. Use the formula:

Cout = (Iout * D) / (f * ΔVout)

Where:

- Iout = 2A

- D = 0.37

- f = 50,000 Hz

- ΔVout = 0.05V (assume 50mV ripple)

Cout = (2 * 0.37) / (50,000 * 0.05)

Cout = 0.74 / 2,500 = 0.000296 F = 296 µF

Capacitor Value: 296 µF (choose a standard value of 330 µF, rated at 25V or higher)

Feedback Zener Diode (Z1):

The Zener diode regulates the output voltage to 19V.

Zener Diode Value:

- Breakdown Voltage: 19V

- Power Rating: Pz = Ifeedback * Vz = 0.01A * 19V = 0.19W

Choose a Zener diode rated at 19V, 0.5W.

Base Resistor for Transistor T2 (R4):

The resistor R4 controls the base current of T2. Use the formula:

R4 = (Vout - VBE) / IB

Where:

- Vout = 19V

- VBE = 0.7V

- IB = Iout / hFE, assuming hFE = 100 (gain of T2)

Step 1: Calculate Base Current (IB):

Since IC555 pin#5 is a high impedance input, just a 10mA current would be enough to sink by T4 collector, so we can select Iout = 10 mA

IB = Iout / hFE = 0.01 / 100 = 0.02A

Step 2: Calculate R4 Value:

R3 = (19 - 0.7) / 0.0001

R3 = 183000 Ω or simply, 180 kΩ

Base Resistor for Transistor T1 (R3):

The resistor R3 controls the base current of T1. Use the formula:

R3 = (Vout - VBE) / IB

Where:

- Vout = 19V

- VBE = 0.7V

- IB = Iout / hFE, assuming hFE = 100 (gain of T1)

Step 1: Calculate Base Current (IB):

IB = Iout / hFE = 2 / 100 = 0.02A

Step 2: Calculate R3:

R3 = (19 - 0.7) / 0.02

R3 = 18.3 / 0.02 = 915 Ω

Resistor Value: 915 Ω (choose a standard value of 1 kΩ)

Final Component Values for the Boost Converter Stage:

- Inductor (L1): 378 µH

- Output Capacitor (C3): 330 µF, 25V

- Zener Diode (Z1): 19V, 0.5W

- Current-Sense Resistor (R4): 180 kΩ 1/4 watt

- Base Resistor (R3): 1 kΩ 1/4 watt

Calculating IC 555 Part Values

Now let use calculate the IC 555 astable circuit so that it becomes compatible with the above calculated boost converter parameters.

Main Calculations for R1, R2, and C1 in the 555 Timer Astable Circuit:

Our specific goal is to design the 555 astable circuit to operate at a frequency of 50 kHz with a duty cycle of 37% for the intended boost converter configuration.

Formulas:

- Frequency: f = 1.44 / ((R1 + 2R2) * C1)

- Duty Cycle: D = ((R1 + R2) / (R1 + 2R2)) * 100%

Data for satisfying the boost conversion:

- Desired Frequency (f): 50,000 Hz

- Duty Cycle (D): 37%

- Assume C1 is = 1 nF (0.000001 F)

Step-by-Step Calculations:

Step 1: Solve for R1 + 2R2 Rearranging the frequency formula: R1 + 2R2 = 1.44 / (f * C1)

Substituting the values: R1 + 2R2 = 1.44 / (50,000 * 0.000000001)

R1 + 2R2 = 1.44 / 0.00005 = 28,800 Ω

Step 2: Solve for R1 and R2 using the Duty Cycle formula

Rearranging the duty cycle formula: (R1 + R2) / (R1 + 2R2) = 0.37

Cross-multiply: R1 + R2 = 0.37 * (R1 + 2R2)

Expand and rearrange: R1 + R2 = 0.37R1 + 0.74R2

Rearrange further: R1 - 0.37R1 = 0.74R2 - R2

0.63R1 = 0.26R2

Solving for R1 in terms of R2:

R1 = (0.26 / 0.63) * R2 = 0.4127R

Step 3: Substitute R1 into R1 + 2R2 = 28,800

Substituting R1 = 0.4127R2: 0.4127R2 + 2R2 = 28,800

Simplifying: 2.4127R2 = 28,800

Solving for R2:

R2 = 28,800 / 2.4127 ≈ 11,940 Ω

Step 4: Calculate R1

R1 = 0.4127 * R2

R1 = 0.4127 * 11,940 ≈ 4,930 Ω

Final Component Values of the Astable 555 Stage:

- R1 = 4.93 kΩ (use standard value: 4.7 kΩ)

- R2 = 11.94 kΩ (use standard value: 12 kΩ)

- C1 = 1 nF

Verification:

Frequency: f = 1.44 / ((R1 + 2R2) * C1)

Substituting values: f = 1.44 / ((4,930 + 2 * 11,940) * 0.000000001)

f = 1.44 / (28,810 * 0.000000001)

f = 50,000 Hz

Duty Cycle = D = ((R1 + R2) / (R1 + 2R2)) * 100%

Substitute values: D = ((4,930 + 11,940) / (4,930 + 2 * 11,940)) * 100%

D = (16,870 / 28,810) * 100% ≈ 37%

So we have now verified the calculations and they are perfectly correct.

Full and Final Parts List

All resistors are 1/4 watt 5% CFR

- R1 = 4.93 kΩ (use standard value: 4.7 kΩ)

- R2 = 11.94 kΩ (use standard value: 12 kΩ)

- R3 = 1 kΩ 1/4 watt

- R4 = 180 kΩ 1/4 watt

- C1 = 1 nF

- C2 = 10nF

- C3 = 330 µF, 25V Electrolytic

- T1 = TIP122

- T2 = BC547

- Z1 = 19V, 1 W zener diode

- L1 = 378 µH, using 1 mm super enameled copper wire (magnet wire), over a 1cm diameter ferrite rod.

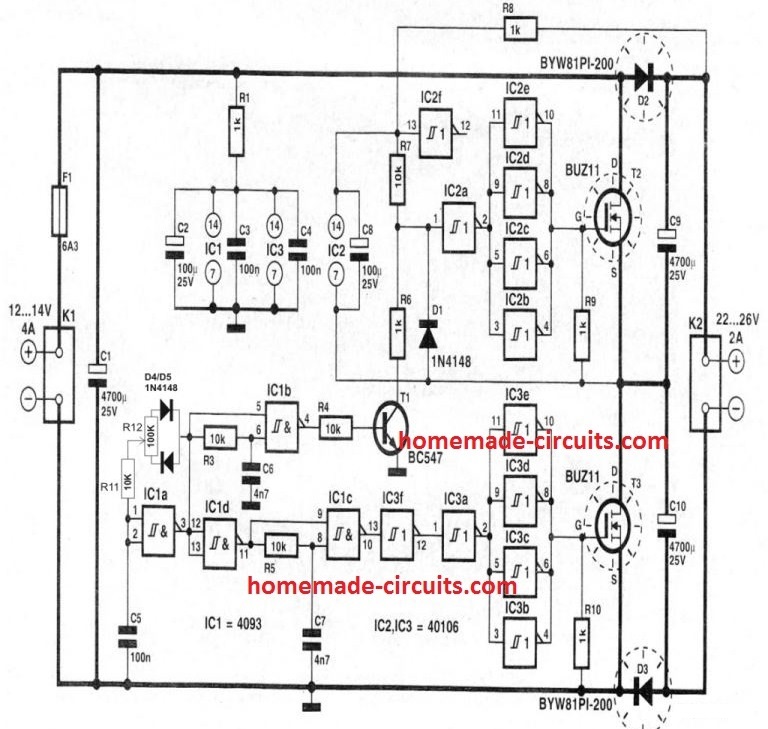

Using MOSFET Voltage Doubler Circuit

Nest, I have explained a simple circuit which may be incorporated for charging a laptop while driving in car or some other vehicle. The circuit runs without incorporating an inverter or inductors in its configuration Let's learn more.

Using Voltage Doubler without Inductor

The good thing about this circuit is that it does not rely on an inductor topology for the required actions, making the design simpler, and yet effective.

As we all know a laptop runs using a DC potential from an in built Li-Ion battery just as our cell phones do.

Normally we utilize a AC DC adapter for charging a laptop battery in homes and offices, these adapters are actually SMPS power supplies rated with the required and matching specs of the laptop battery.

However the above power supply units work only with AC supplies, and in places where an AC outlet may be available. These units will not work in places where an AC source is not present such as in cars and other similar vehicles.

A novel little circuit presented here will allow a laptop battery to be charged even from a DC source such as a car or truck batteries (12V). It's a very simple, cheap, versatile and universal circuit which may be dimensioned for charging all types of laptops by adjusting the relevant components provided in the circuit. It's a simple plug and play charger circuit.

Normally most of the laptop adapters are rated at 19V/3.5Amps, however some may be rated at higher currents for facilitating fast charging.

PWM Charging Control

The discussed circuit has a voltage adjustment features (via PWM) which may be suitably adjusted as per the required specs.

The current may be suitably safeguarded by adding a 3 ohm 5 watt resistor at the output positive terminal.

As can be seen in the circuit diagram, the design is basically a powerful DC to DC voltage doubler circuit which utilizes a push pull mosfet stage for the required boosting of the voltage.

The circuit requires an oscillator stage for initiating the proposed operations which is configured around IC1a.

The components R11, R12, C5 along with the two diodes becomes a neat little PWM controller which sets the duty cycle of the entire circuit and can be used for adjusting the output voltage of the circuit.

Typically the circuit would generate around 22V from a 12V source, by adjusting R12 the output may be tailored to an exact 19V, which is the required laptop charging voltage.

Comments

you listed only c1 and c3 what about c2 please check the parts list well

C2 = 0.01uF ceramic disc

please put items list because you just listed only the final ones only

I have updated the full parts list, you can check it out…

you have not said the number of the capacitor in the middle of the rectifier diodes ba159diode

I have updated all the required information in the article now, please check it now…

please sir, what is the effect of bridge rectifier ba 159 diode rather than single diode. can this diode handle 20Amps current.

please how can I use a single unit for double output, like 24v/36v just like mppt controller can have multiple output automatically.

Thanks sir

Thanks Daniel, you are right, the bridge rectifier is not required, just a single diode rectifier with a filter capacitor should be enough.

If assuming you have set the coil to generate 36V, then you may have to find another tap from the coil to get the 24V output and use a separate diode/capacitor filter stage for that output, in this way you can get two separate outputs of 36V and 24V with maximum efficiency.

Thanks sir, please won’t the feedback settings of one affects the voltage output.

Daniel, the feedback will control both the outputs together, meaning if you have 36V on one tap, and 24V on other tap without the feedback, then if you set a feedback to fix the 36V at 36V, then the 24V would also get fixed at 24V.

I didn’t find lm555 can I use ne555 instead?

And again I can’t find ferrite rod what should I do please ????

Any type of ferrite will work the one which are used in radio receivers are the best.

Or you can use a ferrite ring core also, select a bigger one so that it can accommodate at least 100 turns using 0.5mm thick magnet wire

Yes, any 555 ic will work…

can i use any of this circuit to increse the out put to 240v with a input of say 120v

It may be possible but for that you will have to upgrade all the transistors to 400V and calculated the resistors using an astable calculator.

Please how many amp is the output

Will depend on the coil and the transistor power

Hello Sir, my name is Precious Victoria from Nigeria. I really love what you are doing here. I wish I could be on your team.

Thank you Precious, I appreciate your thoughts very much!

Greetings Sir,

So sorry correction of the first comment

You are doing a great job. Please sir I need your help with a circuit that will help me switch automatically between two batteries connected to my inverter so I will not use a panel to charge the batteries. They work interchangeably

Hi Donald, you can try the last circuit from this article:

https://www.homemade-circuits.com/automatic-dual-battery-charger-with/

Hi Swagatam,

First I thank for your help. I made some projects. I want to supply power from 12V battery to My old laptop when there isn’t main power. My laptop(LG Xnote LW25) hasn’t battery and charger adapter is 18.5V/ 3.5A. Which one should I change. Can I use UF4007 instead of BA159? And any other alternatives for 17V Zener and TIP122.

Thank You.

Thank you PLAA, I think you can try the first circuit which looks more robust and reliable. The 555 circuit is also good but you may have to experiment with the coil a bit to find exactly what number of turns provides the best results. 1N4007 can be tried but BA159 will be better, you can also try FR107. Instead of 17V zener you can use two 9V zener in series. You can use TIP3055 instead of TIP122

Thanks. I’ll try to do it.

Hi Swagatam,

I have bought a cheap 12VDC source to 19VDC(selectable) power adaptor for my laptop that generates a lot of heat (almost too hot to touch) and so wastes a lot of my valuable off-grid amp-hours. It smells like something’s burning/melting too. If there are several circuit types that cater for this requirement then which of these, in your mind, is likely to be the least wasteful and the most efficient? I have skimmed over some of the comments here regarding heating and possible tuning so is my observed problem down to the fact that the circuit I have bought is an approximation of the ideal design to cater for the selectability rather than being optimised for the fixed output voltage that I need? Thank you.

Hi Tim, if the adapter is heating up without a load then it is a faulty design, if it is heating up with load then probably the parts are not appropriately rated. Even with the selectivity feature a switched power supply should not heat up.

The first design from the above article can be optimized for a fixed output or even a selectable output without much heating up, provided the coil is correctly wired

Is there any chance you or anyone has created digital version of these circuits on an application like EveryCircuit?

Hi Swagatam, I’m testing the circuit (IC555 with rectifier bridge – L1 20 turns) with a regulated power supply (12V 2amps). I’m getting 27V of output (testing with a 1k resistor connected). The TIP122 is quite hot. Should I reduce turns from the coil, and add a bigger heatsink? I’m using a 35mm * 25mm *15mm aluminum heatsink.

Hi Juan, I think you can try increasing the number of turns, and use a thinner wire, may be a 30 SWG. Heatsink may be also required, and you can also experiment with the PWM adjustment.

Hi Swagatam

What if I have the input of 30v DC and the desired output is 19v -3amp

Then what are the changes I need to make???

Thanks

Hi Shuvam, you will need a buck converter for that, not a boost converter

hi, what shall be max current for this circuit?

Hi, it is around 1 amp

hi dear sir i would require an circuit that convert input 220v to 5 v withe transformerless and fully to be protected from hi voltag withe output 5 volt to doing input voltag for chip atmega

Hi dear sedigh,

you can try the first circuit from the following article, you can adjust the pot to set the required 5 V:

https://www.homemade-circuits.com/how-to-make-led-bulb-circuit/

sir , i am doing a project on electric vehicle charger so i need some information regarding , AC-DC converter circuit for single phase 230v , can you help me with circuit design for an output to charge the electric car battery

Hi Varun, I will try to help, please provide the full specification of the battery.

Hi Swag,

I remember posting a while back about making a high speed shutter using a 35v solenoid on a 5-6v circuit. The issue was charging a capacitor to deliver that jolt to the solenoid on command. I already have an ATTINY85 to control the signal to activate the shutter.

I think the last post I made on the question vanished as I cannot find it anymore.

So which circuit would I use to do this? I think from memory it was a 555 circuit.

Thanks as always!

Hi Nathan, do you remember under which post it was posted? because I don’t remember deleting any comment so far.

As for the mentioned question, you could use an IC 555 based monostable for powering the solenoid for a fraction of a second in response to the shutter triggering. You can implement the concept shown in the following article

https://www.homemade-circuits.com/intruder-position-indicator-security/

remove the piezo connection and replace it with the trigger from the MCU. Use a higher value for C1, may be around 4.7uF for an optimal response. The output ON time can be adjusted by tweaking the R3, R4 C2 values.

i have query about my laptop charger project.

Using a step-down transformer (220V to 12V) with the polaroid capacitor (35V 1000microF), diode(N4007) and resistor(1K)….the voltage we are obtaining is 18 V instead of 12V.

how is this possible? kindly point out this issue and will be really thankful for that.

The 12V from the transformer is the RMS values of the AC. If you connect a rectifier and a filter capacitor, the output turns into DC having the peak value of the AC. The peak value can be calculated by multiplying the RMS voltage with 1.414.

12 x 1.414 = 16.96

I remember you said a few posts were lost in anti spam plugins. I searched for the original and couldn’t find it.

I have the sketch for triggering and sending the signal to the shutter for the desired amount of time already on the ATTINY85, so simply charging the capacitor and releasing the charge into the solenoid is the part of the circuit I need to do. Thanks, I’ll check the link.

Can you please post the question in the forum section, I will try to figure out the design and post the schematic there.

https://www.homemade-circuits.com/community/electronic-circuit-forum/

OK yes, I seem to have read the datasheet in a hurry and interpreted the diagram wrongly. in that case you surely can give it a try.

Sorry, but you seem to be misstaken about the LM2587-ADJ….

It’s more expensive, but appears to have good performances.

There’s even already-made circuits, which aren’T set for the voltage/intensity I’m looking for, as 12->24V/1A or 5V->12V/1.2A…

Hi again Swag,

That would be great.

In the meantime, I’ve found an interesting alternative circuit that seems to be simpler, based on the LM2587-ADJ and requires fewer components. It’s also providing an higher frequency, at 100KHz.

I’ll evaluate both options once I’ll have all the components specs.

In that case the above circuit can be used.

I do not have the exact data for the coil and the frequency, it will need to be identified with some trial and error, by building and experimenting the circuit practically.

If possible I may solve it myself with a video within a couple of days.

Hi Mpil23,

The mentioned IC seems to be a buck converter IC, not a boost converter. It is designed to reduce input voltage, your requirement is the opposite

Just to be sure you understood my first post correctly, I am considering this circuit to connect the laptop directly on 12V batteries by converting 12V->19.5V/5A, thus bypassing the 120V AC inverter and the AC OEM laptop charger.

I tried simulating your circuit, bus as I can’t get an exactly matching inductor value, I can’t get a relevant simulation…