In this post I will explain an innovative automatic dual battery charger with isolator circuit for alternators and engines, which allows monitoring of the charge levels of two individual batteries, and switching them across the loads appropriately.

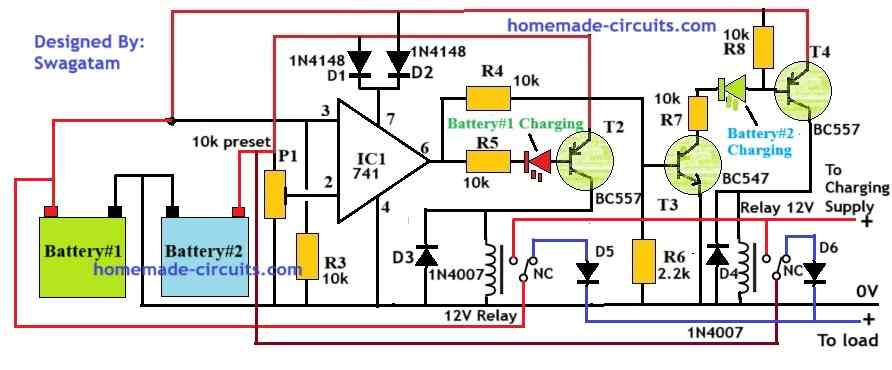

[New Entry] Single Op amp Dual Battery Charger Circuit

The circuit working for the above single op amp automatic dual battery charger circuit can be understood with the following points:

P1 preset is used to set the low battery changeover reference point.

Let's say it is set to 11V reference.

So, when the battery#1 voltage drops below 11V, pin#3 of the 741 becomes lower than pin#2 reference, causing the op amp output to go low.

The low output turns ON T2, which in turn activates the left relay. The left relay contacts now shifts to the N/O point allowing the charging supply to reach the batteryy#1. Battery#1 now starts charging.

In this situation, battery#2 is connected to the load via the N/C contacts of the right side relay.

When battery#1 is optimally charged above battery#2, or conversely, if Battery#2 voltage drops below battery#1 voltage, it causes the op amp output to flip and go high.

The high output turns OFF T2 and turns ON T4 via T3.

This causes the left side relay to turn OFF, and the right side relay to turn ON.

In this situation, the left side relay now begins supplying the load, and the right side relay starts charging the Battery#2.

In this way both the batteries are alternately charged and kept in a topped-up condition, through automatic sensing and relay changeover actions.

The next idea shown below was requested by Mr. Daz.

Technical Specifications

Very promising circuits you've always shared, actually I always visit your blog coz im also electronics hobbyist from Philippines ..

i have read many of your posted electronics design especially on battery charging circuits 🙂 its very simple and yet reliable and efficient circuits, building those circuits using your designs works great and thank you so much swagatam!

but until, i was thinking an solid-state automatic dual battery charger isolator for deep cycle agm 100ah batteries, i am using some of your design charging circuits and delay and relay techniques, but unfortunately, always got me an error...

what should I do sir?. can you guide me with my issues? thanks so much.

here is the step of how the circuit may do...

1. before starting, the two agm batteries 1&2 will combine in parallel connections to be used for starting the engine in order to provide smoother and more power to the start.

2.Then, once the engine is started, the battery 1 will automatically disconnect via a relay for automatic fast charging until float mode is reached.

3.while the battery 2 is connected, a voltage low level cut-off circuit will be monitoring its condition until its voltage reaches 11.5v,4.

When the low volt reaches 11.5v, the circuit will automatically trigger the relay connecting the fully charged battery 1 parallel with battery2.5.

after battery 1 is connected in parallel, a delay relay cut-off will disconnect of battery 2 and engage it for automatic fast charging and to float mode.6.a continuation cycle of relays, monitor, charging. that's it.

I hope you understand of what i mean.

hoping to hear from your sir. i hope you can help me with this circuits to make.

Thank you so much and more power to you sir!

The Design

Instead of addressing the two batteries as battery#1 and battery#2, I thought it was better identifying them as "charged battery", and "partially charged battery".

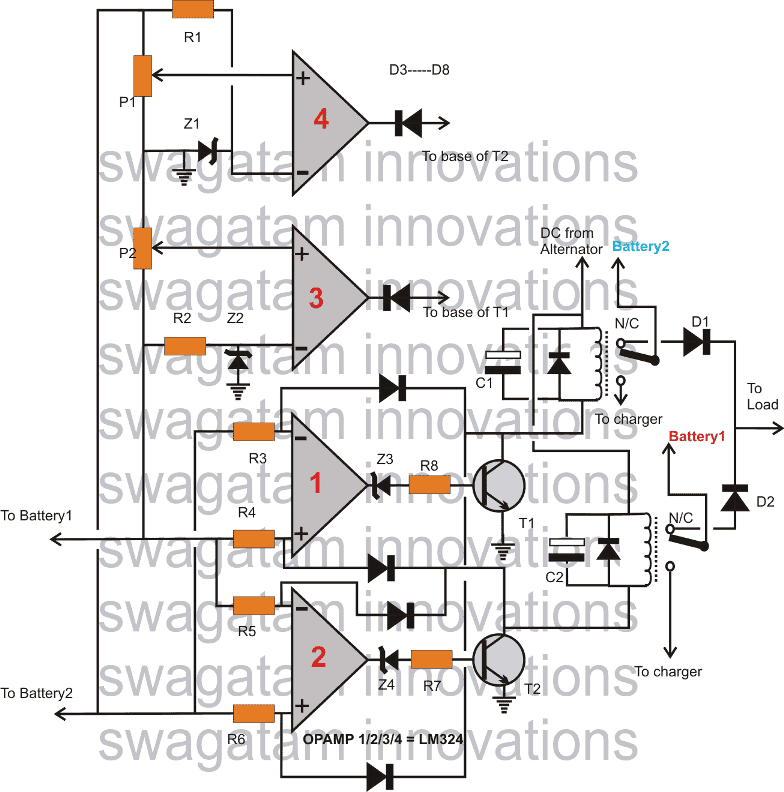

The proposed design of an automatic dual battery charger with isolator circuit for alternators may be understood with the following given points:

Initially due to absence of power, the two relays are held at their respective N/C positions which allow the two batteries to get connected in parallel with the load.

How the Batteries are Charged

Let's assume battery#1 as the charged battery, now when the engine is switched ON, both batteries provide their combined power to the alternator via the relevant N/C contacts.

As soon as the alternator starts, it powers the opamp circuit so that the opamps 1 and 2 which are configured as voltage comparators are able to sense the connected battery voltages at their relevant inputs.

As assumed above, since batt#1 has the higher voltage level, triggers opamp1 output high.

This in turn activates T1 and it's relay, which instantly disconnects battery#2 from the load.

Battery#2 now gets connected with the charger via the N/O contacts and starts getting charged at the relevant current.

At this point T1 executes two actions: It clamps the inverting input of opamp1 and non-inverting input of opamp2 to ground, latching their positions. It means the relays now hold their positions without any further interventions from opamp1 and 2.

In course of time, battery#1 starts getting discharged via the connected loads, and this condition is monitored by opamp3. The moment battery#1 charge reaches around 11.5V set by P2, opamp3 output goes low.

Since opamp3 output is connected to the base of T1, the above triggering instantly breaks T1 conduction resetting opamp1 and 2 into its original situation allowing them to yet again track the battery voltages.

This time battery2 being the one having higher potential activates opamp2/T2 and the lower relay.

The actions quickly disconnects battery1 from the load and connects battery#2 with the load.

Opamp4 now monitors battery#2 condition until its voltage also falls below the 11.5V mark when the situations yet again reverts.

The cycle continues as long as the engine and the load remain in the discussed chain.

The capacitors C1, C2 ensure a smooth transition between the relay switching.

Circuit Diagram

Note: Connect the emitters of T1/T2 to ground through 1N4148 diodes, this is important otherwise the opamp3/4 outputs won't be able to switch OFF the BJTs correctly.

As we can see in the above automatic double battery charger with isolator circuit, the relay N/O contacts are responsible for the required charging of the connected relevant batteries.

Since these batteries need to be charged with an "intelligent" charger, the system should be a step-charger kind of unit.

One such circuit has been discussed in this 3 step battery charger circuit, which may effectively employed here for the proposed method of charging both the batteries.

Parts List

All resistors are 1/4 watt CFR

- R1, R2, R7, R8 = 10k

- R3, R4, R5, R6 = 1M

- P1, P2 = 10k presets.

- D1, D2 = asper load current.

- D3---D8 = 1N4007

- All zener diodes = 4.7V, 1/2 watt

- T1, T2 = 8050

- C1, C2 = 220uF/50V

- Relays = SPDT, 12V, 30 amps contacts

- Opamps = LM324 (see datasheet)

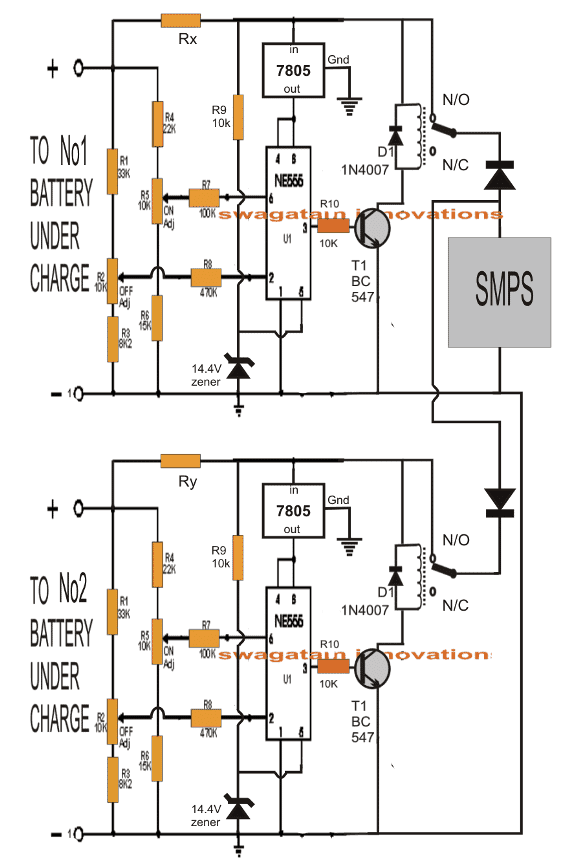

Dual or Double Battery Charger using IC 555

The following paragraphs explain a simple automatic double battery charger circuit from a single power supply. The idea was suggested by "Superbender" I will explain the details.

Technical Specs

Thanks for the great circuits. I am looking forward to start putting one together for hibernating my RVs battery over the winter.

However, can I exchange the transformer + diode bridge with the +15V DC power output from an old PC power supply, i.e a switched power supply?

I don't see any reasons why not, but don't know too much about the charging restrictions for 12V Lead Acid Batteries.

I think I'll be moving down the path with a switching power supply that is rated for 5A max current. However, I am wondering if I can charge 2 batteries at the same time.

I have an older VW camper that has an auxiliary battery as well as a starter battery.

Over the winter I'd like to keep both batteries happy and your schematic seems to be promising to achieve that. The batteries are not connected to each other when the car is off.

Do you think it is possible to use only one power supply, but two NE555 schematics to achieve this? I am thinking that I could use one NE555 schematic per battery, probing for voltage levels and controlling individually when each battery is charged.

I am also thinking to put a diode into the current path to the battery so that, when both batteries are charging, the current can never flow from one battery to the other.

According to the spec sheet, the 44 Ah auxiliary battery that I am going to buy has a max charging current of 12A.

The other battery should have about 75Ah capacity. My interpretation of those values is that both batteries can handle the full 5A current when only one is charged.

If both are charged simultaneously, they'd simply take longer and current will distribute itself according to the voltage levels of the battery.

Obviously I am trying to prevent buying two switching supplies (the PC power supply actually didn't offer 15V when I checked), which would keep the cost to a very interesting level => ~$30 vs. ~$55 for a system with two PS or vs. about $90 for buying two chargers.

Looking forward to your thoughts on this.

Thanks again

Superbender

The Design

The proposed automatic double battery charger circuit from a single power supply shows two identical stages made by using the IC555. These stages are basically responsible for controlling the lower and upper charging thresholds of the connected batteries.

The SMPS which is the common power source for both the 555 stages supplies power to the batteries via the individual diodes and the relay contacts of the respective 555 stages.

The diodes make sure that the power stay well isolated from the two stages.

However the crucial part of the circuits are the two resistors Rx and Ry which are the current limiting resistors for the two stages.

These resistors ensure the correct specified amounts of current to the respective batteries This further ensures that the SMPS is loaded uniformly across the connected batteries.

Rx and Ry should be calculated as per the AH ratings of the batteries with the help of Ohm's law.

Schematic

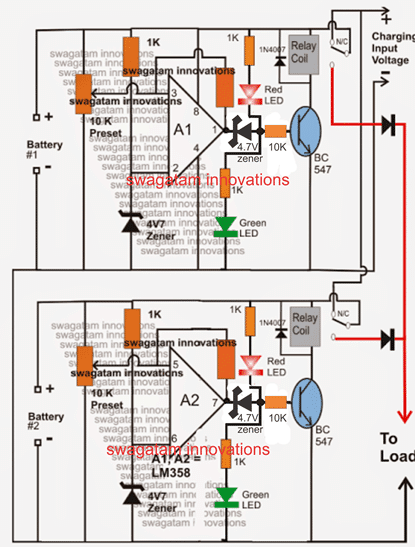

Another Simple Split Battery Charger

In the following paragraphs we investigate another interesting twin or split battery charger circuit with auto-changeover illustrates a method through which two 12V lead acid batteries can be charged and discharged in tandem by switching them appropriately across the charging voltages and load alternately.

This ensures that the load receives a continuous supply of power irrespective of the actual source conditions such as a solar panel, wind generator etc. The idea was requested by Mr. Mohammad Zain.

Design Objective

I am looking for a automatic 12 volt lead acid battery charging circuit, Which indicates when the battery is full and when it is out of charge.

Or if you can help me design a charging circuit that will use two batteries that is it will charge one battery at a time so when it gets full it will switch to the other battery

Your help will be really appreciated .

Working Details

The discussed split battery charger can be studied through the following detailed explanation:

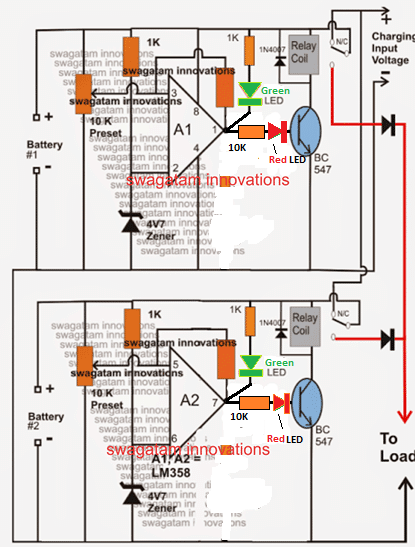

Referring to the circuit diagram, two identical opamp stages A1/A2 can be seen incorporating the IC LM358. Both the opamps are rigged as voltage comparators.

A1/A2 are basically configured to detect the over voltage and low voltage thresholds of the respective batteries and to switch the corresponding relays for initiating the required cut-offs when the relevant conditions are detected. This is sensed with reference to their inverting input voltage levels fixed at the corresponding zener voltages.

The over charge cut-off threshold is set by appropriately adjusting the 10k preset associated with the non-inverting inputs of the battery.

The feedback resistor across the outputs and non-inverting inputs of the opamps determine the hysteresis levels which in turn decide the low battery restoration so that the relevant batteries begin charging once the corresponding lower thresholds are crossed.

Suppose battery#2 is initially fully charged, and battery#1 is being charged through the N/C of the A1 relay stage.

The connected load at this situation receives the voltage through the N/O of A2 relay since it's already in a disconnected state due to full charge condition of battery#2.

Now let's assume after a period of time battery#1 gets fully charged, A1 output goes high triggering the connected relay driver stage which disconnects the charging voltage to battery#1 by shifting from N/C to the N/O contact.

At this instant both the batteries get connected with the load reinforcing the supply to the load.

However, sooner or later battery#2 reaches its lower discharge threshold, forcing A2 to restore the charging process by flipping its relay from N/O back to N/C.

Battery#2 now gets into the charging phase leaving battery#1 to handle the load, the operations keeps repeating as long as the system stays switched ON.

For ensuring a balanced switching responses from the two stages one battery must be completely discharged while the other fully charged at the beginning when the proposed twin battery charger circuit is first initiated.

Circuit Diagram

Simplified LED Connections

For ease of testing and optimization please modify the positions of the LEDs as per the following diagram. The zener diodes at the transistor bases can be eliminated in this case.

How to Test

We will refer to the above modified diagram for the set up procedure.

As we can see, the A1 and A2 stages are exactly identical, therefore these two stage should be set up separately.

Let's begin with A1 stage adjustment.

- Initially keep the feedback resistor across the op amp output and preset disconnected.

- Rotate down the slider arm of the preset to ground level (0V).

- Connect an external DC of around 14.3V from the "battery side". You will see the green LED light up.

- Now, carefully rotate the perset towards the positive side until the green LED just shuts off and the RED LED lights up, this will also switch ON the relay.

- THAT'S ALL! Your circuit is set now. Reconnect the feedback resistor, which could be any arbritary selected value between 100K and 470K.

- Repeat the procedure for the A2 circuit stage and integrate the two stages with the relevant batteries for a practical test.

The FEEDBACK resistor decides at what lower threshold the battery will start charging again, and will need to be fixed with some trial and error. 100K would be a good value to start with.

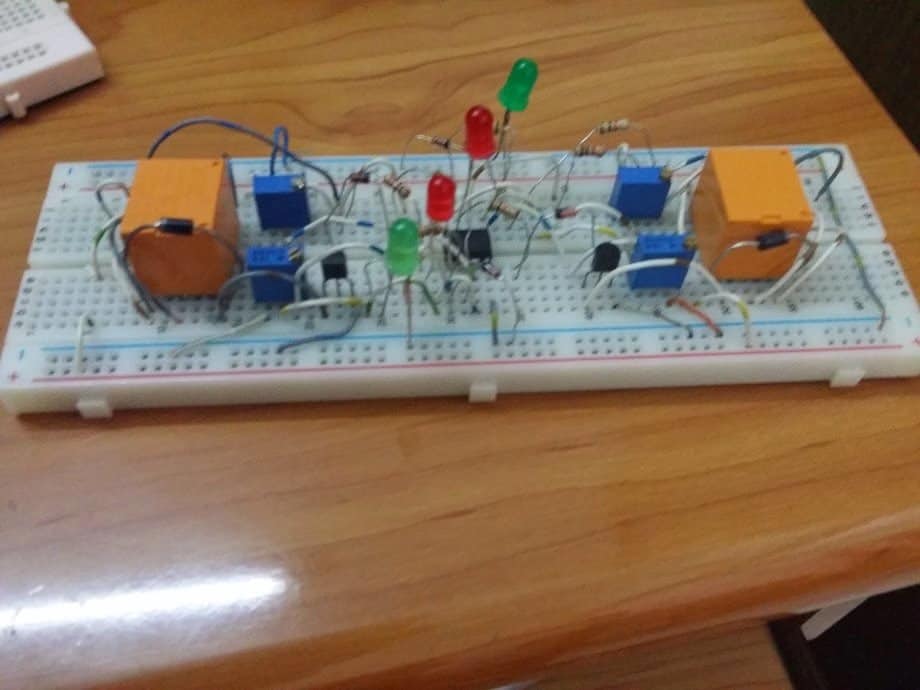

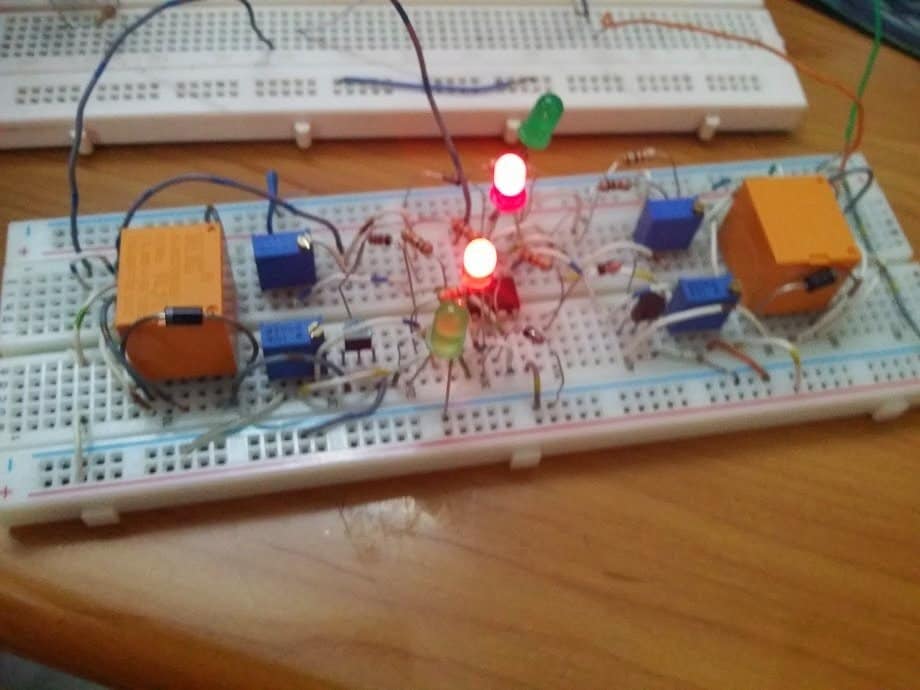

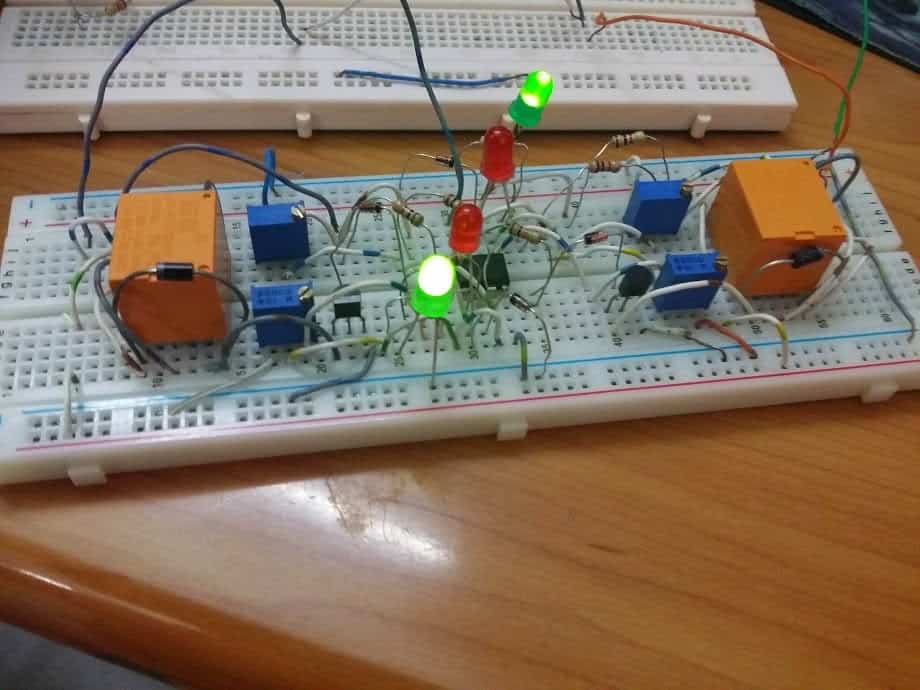

The above explained selectable 12V battery charger circuit was built and tested successfully by Mr. Dipto a dedicated member of this blog.

The implementation details may be witnessed in the following images of the prototype, sent by Mr. Dipto.

I am surprised that a manufactured unit for this circuit hasn’t been produced for retail purchase. For an off grid solar set-up with 2 or more deep cycle lead acid batteries this is the best circuit for ensuring that power will always be available, (at least if the sun shines a little bit every few days), maximizing the lifespan or condition of the deep cycle batteries while also allowing them to be of different sizes, ages, health, etc. If there is such a unit available i would like to know because i have not learned how to read the design schematics for this stuff.

Thank you! I appreciate your valuable feedback! These units are available in online stores like amazon.

I have not seen any as a single unit. I’ve seen voltage sensitive relays, isolators, etc. I did find one mppt controller featuring inputs for connection to a start battery and ignition switch so a running vehicle could also contribute charge, which is really cool but i already have a nice mppt controller. Maybe you can share a link? Thanks

Yes, it seems you are correct. When I tried searching for “Buy Dual lead acid battery charger”, I could not get any proper results to support my search query….

Very nice site

Dear swagatam,

Thanks for helping but i want to knw this circuit will be work in all voltages lik 60v and 72v als na, as i discuss previously comments my lithium battery is 62v 24h batter and othr is 72v 24ah is this circuit will works on 60v 10ah input and same as 72v10ah als will works na. Or any components can i change pls tel me.

Hello Suman, you can use the following modified diagram for your application:

Make sure to connect the 12V negative with the circuit negative.

The full charge voltage for 72V battery should be 81 V and not 87 V. I got the data from amazon but after calculating, it seems 87 V is not the correct value.

Hi swagatam,

In LM358 IC Pin 3to1&5to7 what is the resistor u used and where can i connect when charging battery level indicator on this circuit.

the relay that used int the ckt 12v 10 spdt. Can u pls tel me tht diode used to load wht type of diode and diode no.

The output diode current rating will depend on the load current…the diode should 2X than the load current requirement.

Suman, that resistor decides the low voltage battery charging restart. But here we are using it only to ensure that the relay does not rapidly switch ON OFf (chatter) at the full charge level, so this resistor can be any high value around 100K.

For your earlier email I have already provided the solution through a diagram in one of my previous replies…..

Hi swagatam,

Today again i send u a mail with attachment , getting error output is 62v

Hi Suman, did not reach me yet, can you please tell what you had in the attachment, and also regarding the 62 V error?

Hi swagatam,

The givn modified circuit output is 62v but b4 keeping charging battery inwas check the voltage is 62v after 30min als same voltage and auto cut off not working nd whn not connect to batter green light is on same constant. Pls help to recheck the circuit

Hi Suman, it is 100% tested design, and should work perfectly if the presets are adjusted correctly, did you adjust the presets as per the given instructions and LED indications? Did you confirm the auto cut-off through a variable supply input, you must confirm it with a variable supply first, if you don’t then your circuit will not work? By the way please write in proper English, it is difficult to understand what you are trying to say.

Hi swagatam,

Pls find the mail i share the video link,

Hi Suman, I cannot find any email sent by you.

Hi swagatam,

I share the video link from my mail.

sorry, I did not get any email from you, except one which was sent long back by you.

Yes just now I got it, but I could not understand anything what you are trying to show in it, I can only see the preset being turned by you and the 69 V appearing on the meter.

Hi swagatam,

In this video showing tht from starting voltage is 4.3v after preset adjusting o/p voltage is 69v but still auto cutoff not happn evn red light not on , and same if i connected in 83v in 2nd circuit o/p is 0 evn i adjust preset als .

Hi Suman, you must use a 0-69V variable power supply to check the auto cut off, did you use a variable power supply?

And did you use 12V separately for the op amp and the relay stage?

Unless you do exactly as suggested you cannot get the results.

Hi swagatam,

Yes i used two variable power 68v and 12v for relay i used seperately, in video i shown u both types of adjusting whn cut off low volt is 4v o/p and again adjustment O/p is 69v . But auto cutoff not workng whn battery if full and again whn battery is 63v not connecting automatic charing .

Hi Suman, I cannot see any variable power supply in the video, you are only adjusting the presets. I have explained you the procedure many times, this is the last time I am explaining….. please do it accordingly.

1) YOU WILL NEED A VARIABLE POWER SUPPLY WHICH CAN BE ADJUSTED FROM 0 TO 69 V CONTINUOUSLY.

2) THE 12V FOR POWERING THE OP AMP SHOULD BE FIXED.

3) Put the op amp preset to ground level initially.

4) Remove the feedback resistor which is connected across the output of the op amp and the preset center pin.

5) Connect +12V to op amp and relay as shown in the diagram

6) Connect the 0-69V variable supply connection to the indicated points.

7) Connect the ground of the both 12V and the 0-69V supply together in common.

8) WITHOUT CONNECTING ANY BATTERY, Switch ON both the power.

9) Green LED must come ON.

10) Adjust the 0-69V variable supply input to 69 V or 67 V whatever may be the full charge level of your battery.

11) Now very very slowly adjust the op amp preset until the green LED shuts off, and RED LED lights up.

12) Once this happens, adjust the input variable 0-69V supply to check whether the re;lay automatically clicks at 67V or 69V or not, this will confirm the set up.

13) Don’t use battery until the above procedure is confirmed.

is it possible to install LEd to see the percentage of batteries, separately ?

It is possible, you can use the schematic explained in the following article, replace the speaker with your battery

https://www.homemade-circuits.com/subwoofer-music-level-indicator-circuit/

Sir I make the above circuit (using LM324). I am facing problem to set preset and confused in alternator, for that reason my circuit is not working. Please guide me ????????

Nitin, as you can see the circuit is quite complex and has many operations, so it will be difficult for me to troubleshoot your circuit without practically seeing it.

Instead of the first circuit can you try the last circuit which is much easier, and I can guide you with that circuit.

Okay and what about diodes’ specification that are connected in parallel to C1 and C2?

Those are 1N4007..

Dear Sir,

I have another query about circuit 1. I already have bought capacitors and every other component, but the diodes that are connected in parallel with the 2 capacitors and relay switch have not been mentioned anywhere. How can I know the specifications of those 2 diodes and how to connect with relay IC and capacitors on the bread broad.

Dear Hajira, the output diode current rating must two times more than the maximum current rating of the load.

You should test the circuit by soldering on a strip board, bread-board can have many problems.

I need the circuit with the Isolator. Where can I order the circuit?

Really sorry, due to lack of time we won’t be able to do it for you!

Oh!! Can you at least suggest me any website where I can order these components at least?

Google “buy electronic components” and you will be able to many options.

Hey! I want to make the dual charger circuit with isolator but the problem is that the opamps’ specification is only for 1.5 to 15 V and current is in nano and micro range. While my voltage is 24v or above and current is 5V. How can I change the specifications of each component in your circuit for my voltage and output current?

Hi, you can use a 7812 IC for regulating the supply to the Vcc terminal of the ICs, rest all can be the same. You can try the last concept in the article.

I want to implement the ist circuit named ” Dual Battery Charger circuit with Isolator”. So, the idea that you just gave in the previous comment can be implemented to that one? I am not sure which of the three circuits you’re talking about and saying me to use 7812 ICs? Can you please clarify?

For a 24V input 7812 will be required for all the ICs across all the designs.

I am recommending the last circuit since it’s easier to configure, set, and test.

Which circuit you’re talking about? I actually have to use the first circuit (Dual battery charger circuit with Isolator) and I was asking about the current and voltage limitations of the opamps of that circuit. So please clarify your suggestion was for which circuit?

Sorry, yes for the first circuit you won’t require a 7812, because IC LM324 is rated to work with up to 32V. Current is not relevant as long as the voltage is below 30V

Thanks alot Mr. Swagatam.

Hello.

Mr. Swagatam, the issue on the above circuit diagram. How will the

transistor stage be used to replace the diodes at 3/4 of the op-amp i.e

if you can please give an update on the circuit diagram.thank you.

Hello mawuli

use BC557 transistors…….bases to opamp outputs…emitters to the bases of T1, T2, collectors to ground

Mr Swagatam:

I have been a fan of your site for awhile and have found uses for some of your circuits, one such circuit is the one that Mr Dipto posted. I am a ham and have two batteries that I would like to use this circuit for (dual charger that charges one battery then the other) charging my batteries however I would like to use Mosfets instead of normal relays. Can you help me with this please? Thank you for whatever help you can give.

Joel

Thanks Joel, I’ll try to update the article with a mosfet version soon…

Sir, i need an automatic charger with selector switch individually to charge, if one battery to charge by clicking the selector switch to 1 for just one battery, for two batteries selector to 2, so on and so forth.. are individual batteries having a different charging amperage? please help me with these sir thank you….

Vinn, to make this happen you will need to first disconnect the batteries from its direct parallel connections and connect them back through schotkey diodes, only then these could be charged through a selector switch separately.

sir kindly send me a diagram for this charger and how to set it up. ideas from your circuitry inspires a newbie like me… thanks.. this is my email: vinnfernandez@yahoo.com

Vinn, I'll try to do it if possible.

Hi sir! do you have a charger circuit for 10 car battery connected in parallel?

Hi Vinn, do you want it to be an automatic type or manual switch off type?? please specify

sir i need an automatic charger, capable to select from one battery to 10 batteries, with LED indicator for power and battery full. (optional: with analog amp meter).. kindly help me with these… thank you sir!

Good evening Swagatam,

Great Blog, very interesting and worthwhile. Very impressed.

I have a question in regards to this automatic dual battery charger circuit. I am an avid camper and enjoy getting out and about for long periods camping. I would like to be able to charge by dual batteries in my 4WD by either alternator with engine running, as per this circuit, but also from wind turbine and solar panels. The wind turbine is a DC one with built in charge controller and solar panels also have charge controller. Would this circuit work correctly, if I simply built it 3 times, one connected to alternator charge current, one to solar charge current, and one to wind turbine charge current, but all connected to batteries? I wonder if the battery voltages being sent to the circuit for sensing purposes, would be al stuffed up if the batteries were being charged by another charging source?

All help is much appreciated.

Regards

Dave

Thanks so much Aussie,

Yes the above design could be used for your requirement by adding a third identical stage, but there's even a simpler option of implementing the same through a method shown in the following circuit:

https://www.homemade-circuits.com/2014/05/twin-or-split-battery-charger-circuit.html

The idea is less complex and the stages are easily distinguishable.

Here too you may want to add an additional identical stage for integrating the third battery through the third energy source.

The circuit employs separate relays and diodes for the individual connected batteries, so there's no chance of the voltage lines getting mixed up with each other, and therefore the isolation can be considered extremely safe:)

…the diagram in the link shows a common supply fed to the relays N/C contacts which are rigged up together as a common terminal, for your application the N/C contacts of each relay would need to be separately terminated to the available energy.

But it seems too late. At least one or two days appeared per a comment. I don't know why sir?

Hi! Sir. Can you tell of how to post a comment on your post? I try to comment a question on your blog 1.5v to 12v converter, but my comment didn't appear. what is the problem sir?

Your comments are getting rightly posted in this bog…no issues.

Thanks!

That's ok. Thank for your reply. Would you mind if i ask you for help about electronic circuit when i have some problems with it?

Everybody here are welcome to ask questions, you too can feel free.

Hi Swagatam

I look to all these circuits, but I need a balancer for 2 deep cycle batteries connected in series. These circuits is more for 2 parallel batteries. 2 series batteries is connected with 24v charger and not with 12v charger.

Many thanks

Hi Pierre, I have not yet figured out how to design a balance charger perfectly without using a complex circuit, If I happen to find the design, will update you regarding the same…

GURU JEE, REALLY TUSSI GREAT HO!

Theoretically, the circuit is very nicely planned.

Thanks Abu-Hafss!

But there may be one glitch in the design, the diode at the outputs of opamp3/4 will not allow complete switch off of the transistors since the diodes will hold 0.6V at the transistor bases…the issue can be easily corrected by replacing diodes with transistor stages at opamp 3/4 outputs.

hi.sir. i have a problem with FPGA coding. can you help me?

hi! sir. i have a problem with fpga coding.can you help me sir?

I am sorry Seok, I don't have much idea about the subject, so can't provide you any help.

Thanks very much Tushar,

Sorry, never heard of antonio circuit, no ideas…..

hello sir,

awesome!

what is Antonio circuit(some thing like this). my teacher asked today. don't know about it.Google doesn't help much

also sir,how many post where there before you apply for ad-sense

thank you

alwals enjoyed your post

keep it up!

regards

tushar

hi swagatam,

whoaa what a quick respose! thank you so much my friend.. will do now then the construction, ill be back to you once this made and im not forget what i promised. thanks you so much! more power!

kind regards,

daz

Thanks Daz,

I appreciate your kind gesture, if it works successfully for you that would be more than enough for me….I am not expecting any sort of compensation for this, feel free to ask me if you have any doubts while you make it, we'll solve it together.