In this article I have explained how to make a cheap yet effective mains operated AC overload and over-current protector circuit using very ordinary discrete components.

Introduction

I have published a few mains voltage stabilizer circuits in this blog, these units are designed and intended for safeguarding the connected appliances at their outputs.

However these equipment lack one protection which is the overload protection.

The Importance of an Overload Protection Circuit

A particular stabilizer unit may be rated for handling a maximum specified limit of power, beyond which it's effects may start diluting or might become inefficient.

Overloading a voltage stabilizer might also result in heating of the transformer and fire hazards.

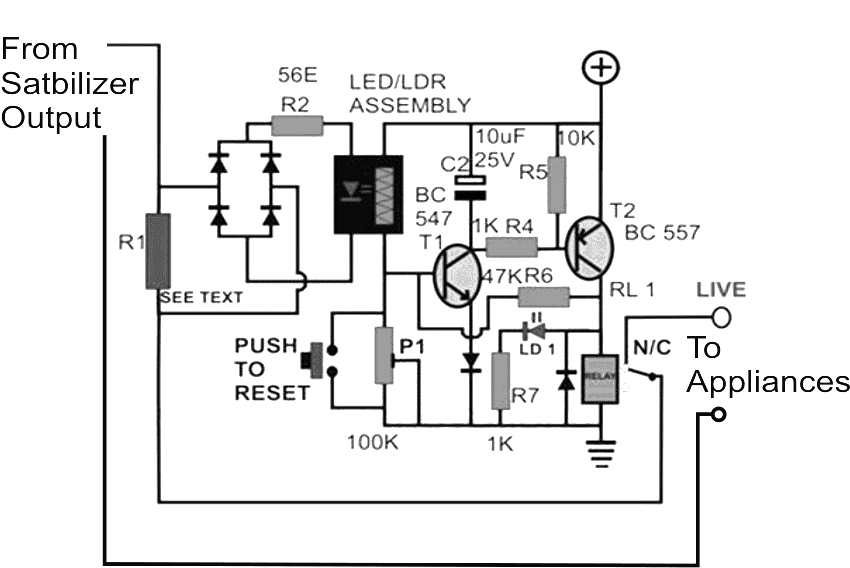

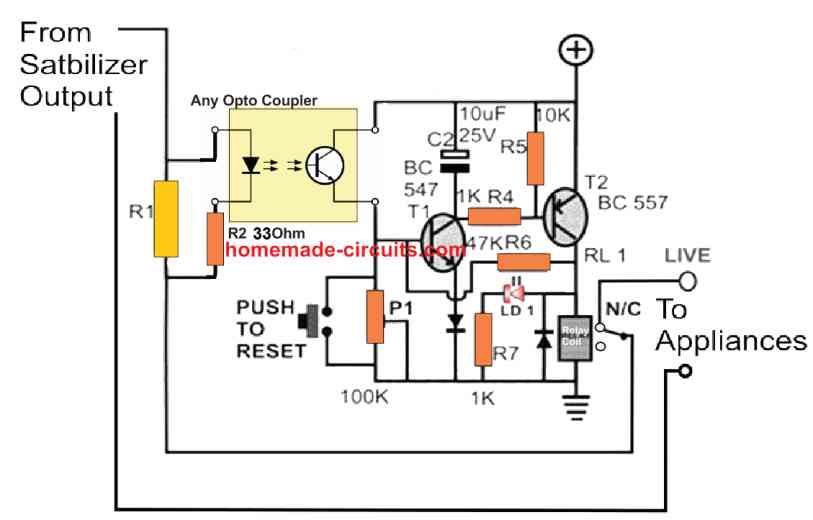

A simple circuit shown below may be incorporated with a stabilizer circuit or any such protection circuit for reinforcing the safeguarding capabilities of the units.

How it Works

The diagram shows a very simple and straightforward configuration where only a couple of transistors and few other passive parts are used for forming the intending design.

The mains stabilized AC is derived from the stabilizer outputs and allowed to switch through another RL1, via its N/C contacts.

One of the wires of the AC mains connections is added with a series resistor of a calculated value.

As the load across the mains output increases, a proportionate magnitude of voltage starts developing across this resistor.

The value of the resistor is so selected that the voltage across it becomes just enough to light up a connected LED in response to a load that might be considered as dangerous and over the maximum tolerable limit.

When this happens, the LED just lights up, an LDR positioned and enclosed in front of the LED instantly drops its resistance in response to the illumination generated by the LDR.

The sudden reduction in the resistance of the LDR, switches ON T1 which in turn switches ON T2 and the relay, initiating the latching effect of the circuit and the relay.

The load or the appliance at the output is thus immediately switched off when an overload situation is detected.

The whole action takes place within a fraction of a second, giving no chance for any untoward consequence and the whole system is safeguarded by the inclusion of this simple AC mains overload protection circuit.

Formula for Calculating Current limiting Resistor

R1 = 1.5 / I(intended current limit),

For example if I =15 amps, then R1 = 1.5/15 = 0.1 Ohms, and it's wattage will be 1.5 x 15 = 22.5 watts

Parts List

- All resistors are 1/4 watt 5% except R1 (see text)

- R4 = 56 ohms

- R4, R7 = 1K

- R5 = 10K

- R6 = 47K

- P1 = 100K preset

- Diodes = All are 1N4007

- T1 = BC547

- T2 = BC557

- C2 = 10uF/25V

- LD1 = red LED 20 mA

- Relay = 12 V/200mA 30 amps

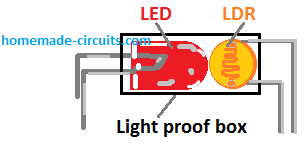

The LED/LDR device can be assembled manually as per the following example image

Comments

Hi,

Is it possible to build a mosfet based circuit with a gate driver ic, that cuts off the mains ac at 250V (between line and neutral) and doesn’t let it build to to the 350V peak and then again reconnect the circuit when the voltage falls below 250V and vice versa in the bottom half of the cycle?

This circuit will feed a diode bridge and capacitor and motor driven by pwm motor driver ic. The motor driver ic output igbt often fails short at 350V, so I want to reduce the peak voltage across the diode bridge and capacitor to 250V. A transformer might solve the problem, but if input mains voltage goes too low, then motor may burn out due to high currents.

Instead of unregulated mains ac, regulated ac at 180V or regulated dc at 250V would be very helpful. Total power required is around 500W. Inrush filter is already present in the circuit. Can only tinker with the input to the existing pcb. It will be too complex to redesign the pcb.

I am open to any other design as well. Thanks.

I think regulating the DC side would be less complicated than controlling the AC peaks.

So, yes that’s possible using a simple linear MOSFET regulator as explained in the following article.

https://www.homemade-circuits.com/0-300v-variable-voltage-current/

What can I do to reduce the electricity bill?

Use LED bulbs for all the lamps and reduce the fridge setting to minimum, don’t use geyser too often.

Dear sir,

Please sir, help me with an Ac circuit that can protect 220V Ac led bulbs, flat screen Tv etc from over voltage/current condition from the Mains supply.

Godfrey, for this you will have to install a voltage stabilizer unit which can regulate the voltage for the loads. Or you can also build an over voltage cut off circuit as explained in the following article:

https://www.homemade-circuits.com/highly-accurate-mains-high-and-low/

Okay sir

Thank you very much

Operating supply is 12v think, coz not define in schematic.

yes can be 12V or 6V depending on the relay coil voltage

Hello sir , have a nice day ,

Sir I need a circuit diagram for Overload , No load protection for 1 hp submercible Motor . used by current transformer .

thanking you .

with regards ,

Mohamed farook .

Hello Mohamed, if possible I will to design it and post it here:

R1 dissipates a lot of power. Could you suggest a way to reduce this?

Thank you!

Try the following modified diagram using a standard opto”

Calculate R1 in the following manner:

R1 (Ohms) = 1 / Max current limit (Amps)

Wattage = 1 x Max current limit

Thanks for all your replies. My current motor is of 50 watts , 220v specs so I calculated Amps as 60w /220v = 0.273 A so R1 resistance is 3.66 Ohm = 1 / 0.273. I calculated with an additional tolerance of 10w thus total as 60W however the resistance seems high and shall dissipate too much heat (around 50w). I may found it as an aluminum body power resistance but during 30 to 40 minutes operation of spinner motor it may get too hot. Is all calculations are right and I have to go through this route? Thanks and regards

Here, for the voltage we have to consider the voltage across the resistor which should be around 2V, for properly illuminating the optocoupler LED.

So, R = 2 / 0.273 = 7.32 Ohms

Power = 2 x 0.273 = 0.546 or maybe 1 watt.

The power rating looks weirdly small but I cannot see anything wrong with the calculations.

If you are not comfortable with 1 watt you can increase it to any other higher value.

Ok, I have found out that there are different types of AC motors and perhaps my motor is “Permanent Split Capacitor (PSC) Motor” which does not need a centrifugal switch. Am i right? regards

That’s correct Sak,

A permanent split capacitor (PSC) motor does not require a switch because it has a permanently connected capacitor that is always in the circuit.

Dear Swagatam,

I have observed that many AC motors have a centrifugal switch which is used to disconnect the capacitor + motor running coil after motor’s shaft have some momentum built however I have observed that Spinner/ Dryer 50W motor has no such switch? It is stated that in AC motors if this particular switch does not open the contact switch then continuous power to running coil burns it. What spinner motor has no such switch? Thanks and Regards

Thank you Sak, for the interesting information.

Yes, you may be correct. However I cannot confirm this, because I do not have sufficient knowledge of centrifugal switches.

Thank you so much for an example as it cleared out all ambiguity and I do remember Ohm’s law as well. Now I clearly understand I can use a germanium transistor for a V = 0.3, or a silicon transistor for V=0.7 etc. and subsequent lowering resistance as well. Moreover I got confused by resistance power rating. I think I can now use a carbon resistance to check this whole idea and in final design a wire wound resistor may suffice. Well let me experiment it on a bread board first. Moreover how do we suggest a fuse rating for a 50 watt 220v washing machine motor, is there any formula? Regards

Thank you Sak, Glad it helped.

let me know how it goes.

Fuse rating is actually quite easy to calculate, for 50 watt 220V, the fuse rating can be:

50 / 220 = 0.227 amps, if we provide slight more margin, it can be rated at 0.250 amps or 250 mA.

PS: After answering my earlier question, I have one more question. as per stated motor ampere facts, what should be the overloading ampere cut off i.e. 1.5, 1.6 or 2 ampere? Do some kind of theory exists for that as well?

It depends on the motor current specifications. The overload current can be around 20% more current than the normal current rating of the motor.

Dear Swagatam

I have tried to checked the above concept and put a resistance in series with motor and it smoked away (as per above discussion, it was being calculated with a 50 watt motor). I have then checked the spinner motor with Amp meter and my readings are as below:

1): Spinner Motor without any Load:

==========================

1.2 to 1.2 Ampere as startup and after 1 second keeps fluctuating and after 8 seconds settles down to 0.75 Amps

2): Spinner Motor with Load:

====================

Startup 1.3Amps and immediately settles down to 1.2 Ampere and stays there (measured for 8 seconds).

With above facts my new calculated resistance should be R=1.5Ohm with V=2 and Amp = 1.3. My problem is that there is very slight difference between 1.3 Amp to 1.2 Amp or 1.1 Amp.

Q.1)-The voltage drop remains enough to illuminate an LED whether its 1.2 or 1.3 Ampere? Circuit should turn off in either case, how to correct it?

Q.2)-Since resistance is fixed at 1.5 Ohm then as per calculation, if Ampere goes down then resistance value is changed as well in formula but in real world with a fixed resistance how does it behave?

Regards

Hi Sak,

Which type of resistor did you use. You must use a wire-wound resistor which will never smoke.

Also, if the motor starts with a high current initially and then drops to a lower value, then that is again a problem, because the circuit will trip at the start up. In that case we have to bypass the resistor for a few seconds during start up.

Since opto coupler sensor is not very accurate so the cut off cannot precisely be be at a fixed current, there may be some variations.

If you don’t want a fixed resistor as the sensor, you can add a rotary switch with multiple calculated resistors and then select the appropriate resistor as per the load current.

Q1.”The voltage drop remains enough to illuminate an LED whether its 1.2 or 1.3 Ampere?”

Ans. LED brightness will vary according to the varying current. At 1.2A the brightness might be dim which might increase at 1.3A. At what point the circuit trips that must be verified with experimentation.

“Circuit should turn off in either case, how to correct it?”

Ans: Circuit will trip only when the LED brightness is just sufficient to switch ON the circuit and this cut-off threshold would be approximately fixed.

Q.2)-“Since resistance is fixed at 1.5 Ohm then as per calculation, if Ampere goes down then resistance value is changed as well in formula but in real world with a fixed resistance how does it behave?”

Ans: With one fixed resistor you can have the cut off only for a particular current level. If you want the cut off at different current levels then you may have to use a selector switch to select different resistors.

Thanks Swagatam. Great explanation.

My pleasure, Sak.

Another important importation I was looking for was to suppress arching at relay contacts and I have found it also:

https://www.homemade-circuits.com/prevent-relay-arcing-using-rc-snubber-circuits/

Thanks for all these important building blocks.

Thanks! yes, one of those concepts can be used for suppressing relay arcing.

OK, since an inductive load was involved so the inrush current. For the sake of completeness and helping some other needy, a complete discussion regarding motor inrush current is available in this article. So suits the overall situation more :

https://www.homemade-circuits.com/mains-over-load-protector-circuit-for/

Regards

Thanks for the suggestion, it looks more appropriate for your application.

Thanks for your update, and here I am. In my last comments I raised my doubts and you directed me here. As comparing main article’s diagram, this one looks more promising. However after observing the relay contacts I have yet some more concerns:

1). I think In some other post, I read about HYSTERESIS, how it is handled in this circuit. In case the HYSTERESIS is still a problem then IC based circuit shall resolve it or just the transistor circuit as above.2). If for some reason i.e. the power to above circuit is not working etc. the circuit may turn on the load but Overload protection may remain absent. Is it possible to make it work the opposite way i.e. Appliance in Normally Open contacts of the relay so circuit Must Turn On to enable the load. In this case if something is wrong with circuit so default state for load is to be off.

3). Do you have something similar in solid state form. Powered directly from 220v and doing the above as well?

4). Am I right about the R1 being a steel wire resistor? Is it available ready made or I have to work it out myself?

5). Is it possible to keep the calculated resistor to a fixed load i.e. 100 watts and change circuit in a way so it can trip for 10, 50 or 100 watt without changing resistor.

Thanks for your patience and help.

Regards

Thank you for posting your questions here.

1) The HYSTERESIS aspect may not be relevant here, because when an over current situation is detected the relay and the circuit get latched, and remain in the latched position until the circuit is reset manually.

2) That’s a good point and can be solved easily with some minor modifications in the design. For this, the positions of the opto-coupler and the push-button/P1 need to be swapped with each other. The P1 actually can be entirely removed with only the push button staying in the new position for initiating the circuit manually. The push button will need to have a series 2.2M resistor for protecting the T1 base.

3) That might be possible by replacing the relay coil with the input of an SSR circuit. You can find a few good SSR circuits in the following post: https://www.homemade-circuits.com/efficient-electronic-relay-ssr-circuit/

4) R1 does not need to be a steel wire, it can any ready made wire wound resistor rated at 20 watt or above.

5) That may be possible by adding a preset control parallel with R1. This preset value can be adjusted to vary the load current threshold for the opto coupler.

Let me know if you have any further questions!

Dear,

I plan to connect it to 5kva stabilizer, and cutoff watts will 4700watts @240v,

please advise the value and watts for R1 resistor, please tell me what is the alternative option if specified R1 resistor is not available…

You can create R1 by adding many high watt resistors in series/parallel combination, until you reach the correct desired value….

Sir ,

please advise the value and watts for R1 resistor,i am planning to build 5kva stabilizer, and cutoff watts will 4700watts @240v

Arun, please see the formula and the example solution at the end of the post. In your case “I” will be 5000/240 = 21 amps, now please calculate the rest.

sir is can you explain what led/LDR means because i dont have enough knowledge about electronic parts or is it found in chargers.

can i get the part number for the LDR thanks

To make this, you have to pack an LED and LDR face to face inside a light proof box….or you can simply use a ready made opto coupler.

LDRs do not have any number.

Hello sir, is it possible to modify this circuit by adding a delay timer for automatic restarting? If yes, pls throw more light to that. Thanks.

Hello Solomon,

it is possible, you can integrate the 3rd circuit from the following link with the collector of the above circuit, and get the required results

https://www.homemade-circuits.com/simple-delay-timer-circuits-explained/

I hope you will know how to do it

Hello sir, can i use TRIAC instead of relay, if yes how can i connect the pin

yes it is possible, I will to update it soon…

Hi Swag,

Will this also help in short circuit?

also I have both MCT2E (6pins) and PC817 (4 pins). which one should I use for better detection?

I know PC817 is most used in many power supply circuits and MCT2E is absolute i think.

Thanks. Will update you with experiments.

OK thanks!

Hi Saqib, yes it will also safeguard against a short circuit.

any opto coupler can be used here, although in the diagram an LED/LDR hand built opto is shown, an LED/transistor opto will also work.

be sure to check and confirm the stages separately while setting up the design.

you are welcome!

Ok sir. Thank you very much.