A water level indicator is an electronic circuit which indicates the various levels of water inside a tank. This happens when rising or dropping water levels come in contact with the respective water sensors arranged step wise inside the water tank at different depths.

In this post I have explained 2 interesting ways to make simple water level indicator circuits using transistors, CMOS NOT Gates and some LEDs, the later section of the articles also discusses how to upgrade the circuit with a relay.

Circuit Objective

There are many posts in this blog which essentially explain water level controller circuits, with the specific intentions of switching the involved motor pump when the tank fills up.

However there are folks who just require an indication of the different levels of water in the tank rather than have an automatic shut off facility.

The switching OFF of the motor is preferred to be carried out manually, which is considered more reliable and safe by them.

For a Wireless Water Level Indicator you can Refer to This Article

1) Using Transistors

We know that undistilled water conducts electricity, although with some resistance. The resistance may be anywhere from 100K to 500K, depending on the purity level of the water. This property can be effectively used for switching transistors ON/OFF.

We use this characteristic of water to switch the base of a series of BJTs sequentially as the water level goes up and down across the sensors attached with the respective transistor bases.

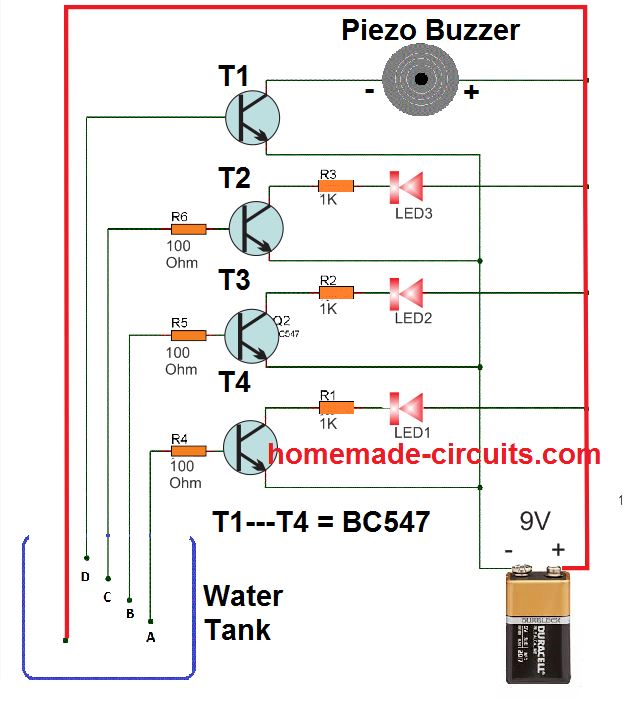

A simple circuit for this can be visualized below:

Video Illustration

The idea is as simple as it can be. The positive terminal of the supply can be seen immersed at the lowest level of the tank, so that water is in contact with this positive even at the lowest level. The bases of the respective transistors are arranged sequentially across the water tank depth, such that when the water fills the tank, it sequentially connects the positive supply with the relevant BJT bases through the rising water level.

When this happens the transistors begin getting biased one by one, illuminating the collector LEDs in the same sequence. When the water reaches the full level, the buzzer is immediately sounded by the topmost BC547.

This helps the user to get a clear idea of the water level, and also when the water has reached the overflowing level.

Parts List

All resistors are 1/4 watt 5%

- 1K = 3 nos

- 100 Ohm = 3 nos

- BC547 = 3 nos

- Piezo Buzzer = 1 no

- RED LEDs = 3 nos

2) Using CMOS NOT Gates

The proposed water level circuit idea is specifically suited for the above type of readers who are satisfied with the indications only and want to do the shutting part of the motor manually as per the readings of the indicator and as per the desired water levels in the tank.

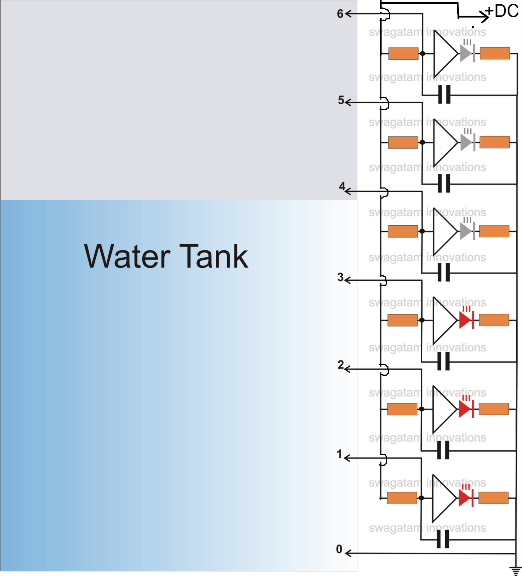

- The circuit presented here is again super simple to build, involving only a single IC 4049 for the intended applications.

- The IC as we all know have six NOT gates, these gates are simple inverters, meaning they will invert any voltage level at their input pins to exactly the opposite level at their output pin.

- So if a positive is applied to the input, the output would instantly produce a negative and vice versa.

- The high input impedance of CMOS gates makes sure that potential even with very low currents are suitably sensed and interpreted by them.

- The idea is simple, the ground or the negative voltage (point 0 in the figure) is held at the bottom most part of the tank, such that the water reaches this point first up when it starts filling.

- As the water level goes higher, it subsequently comes in contact with the inputs of the NOT gates arranged serially upwards.

- The negative voltage stationed at the bottom of the tank leaks through the water and comes in contact with the relevant inputs of the gates.

- This negative potential applied at the subsequent inputs of the gates means a production of an opposite voltage, that is a positive potential at their outputs, that's what exactly happens.

- The positive voltage thus generated lights up the concerned LEDs, indicating which input of the gate at what level has come in contact with the rising water level.

- The sensor wire terminals from the circuit in the form of the points 0 to 6 may be arranged over a non conducting stick made up of plastic with brass screw heads fitted as the sensor termination.

- The LED illuminations give a direct indication of the water levels, as these are stationed with calibrated positions in the tank (see circuit diagram)

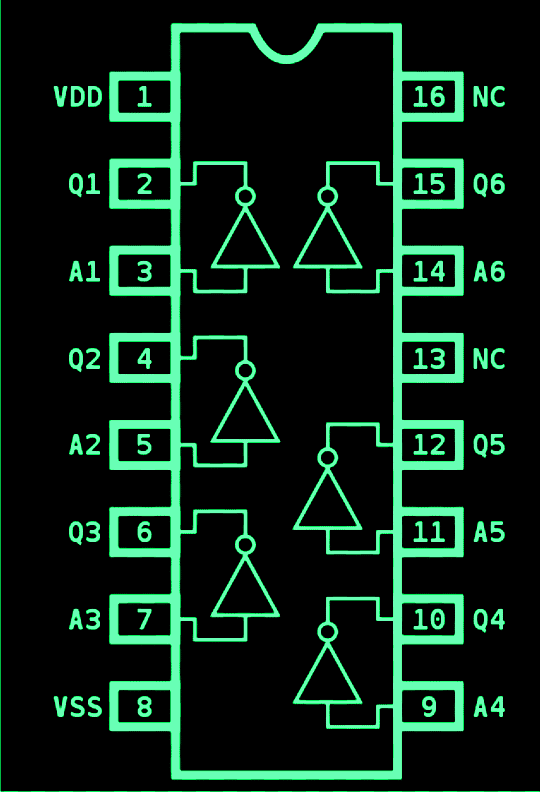

The pin out diagram of the IC

Simulation: A rough simulation of the discussed water level indicator circuit is shown below. We can see how the LEDs light up sequentially in response to the increasing water level coming in contact with the respective sensor points inside the water tank

Part List.

- All LED resistors are 470 Ohms,

- All gate input resistors are 2M2

- All capacitors are 0.1 disc ceramic.

- All the gates are CMOS NOT Gates

- All LEDs are red 5mm, or as preferred by the maker.

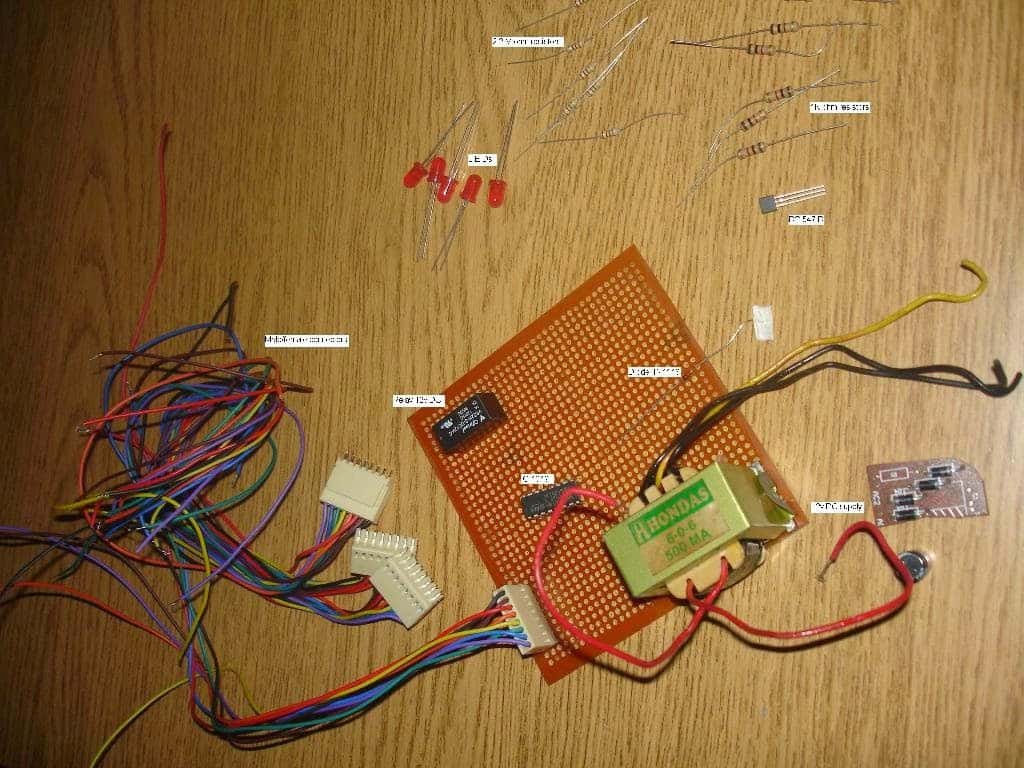

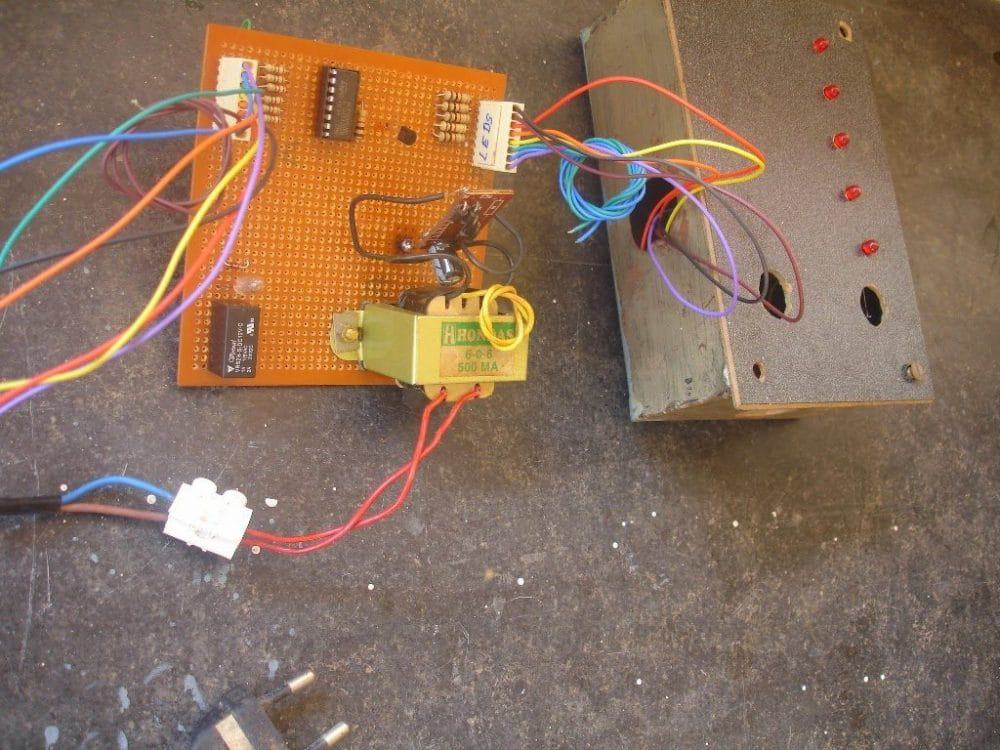

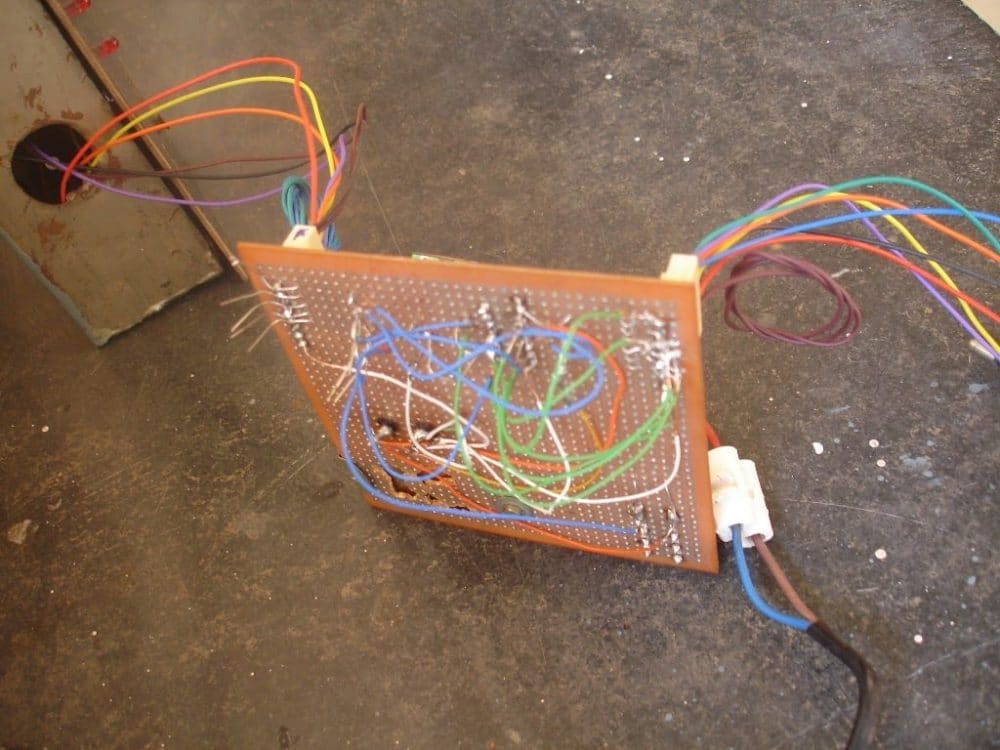

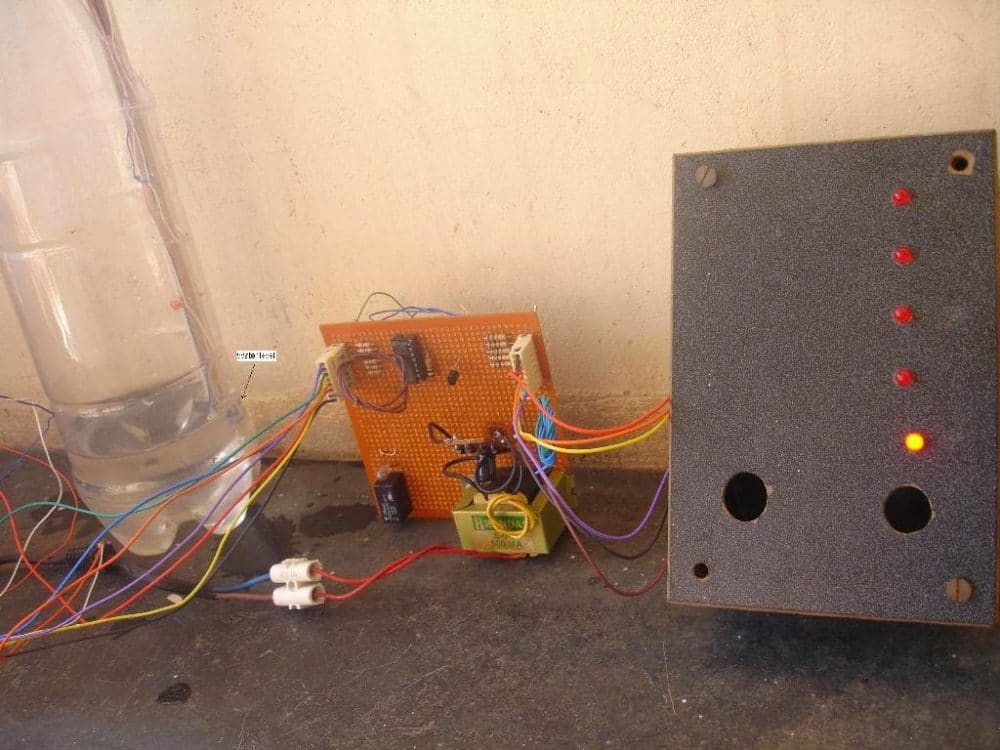

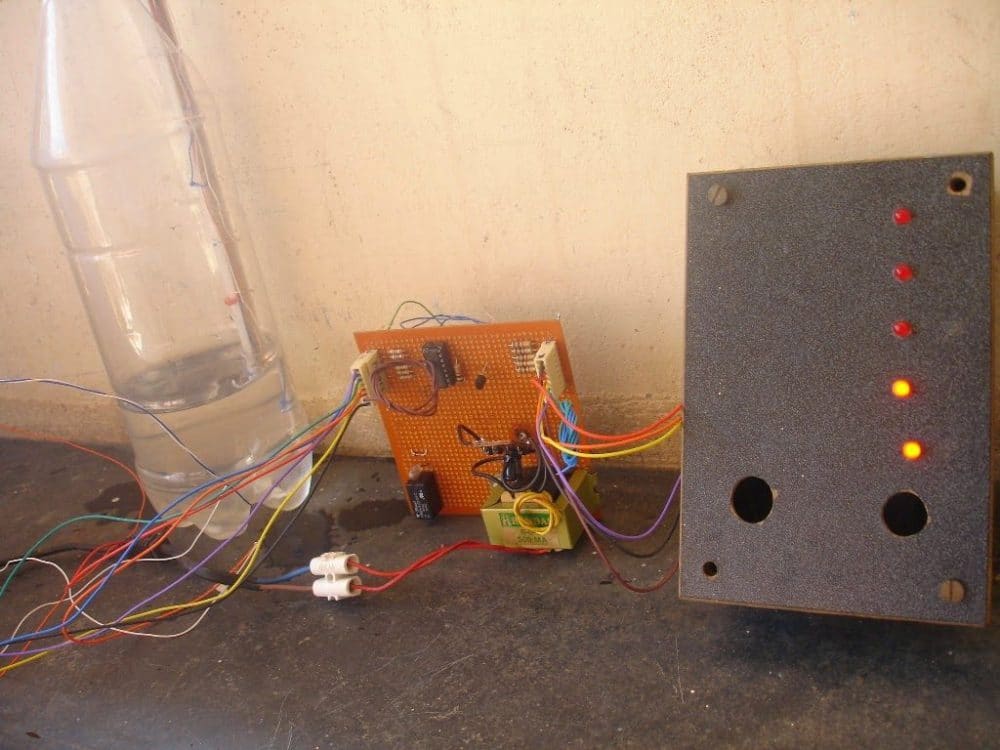

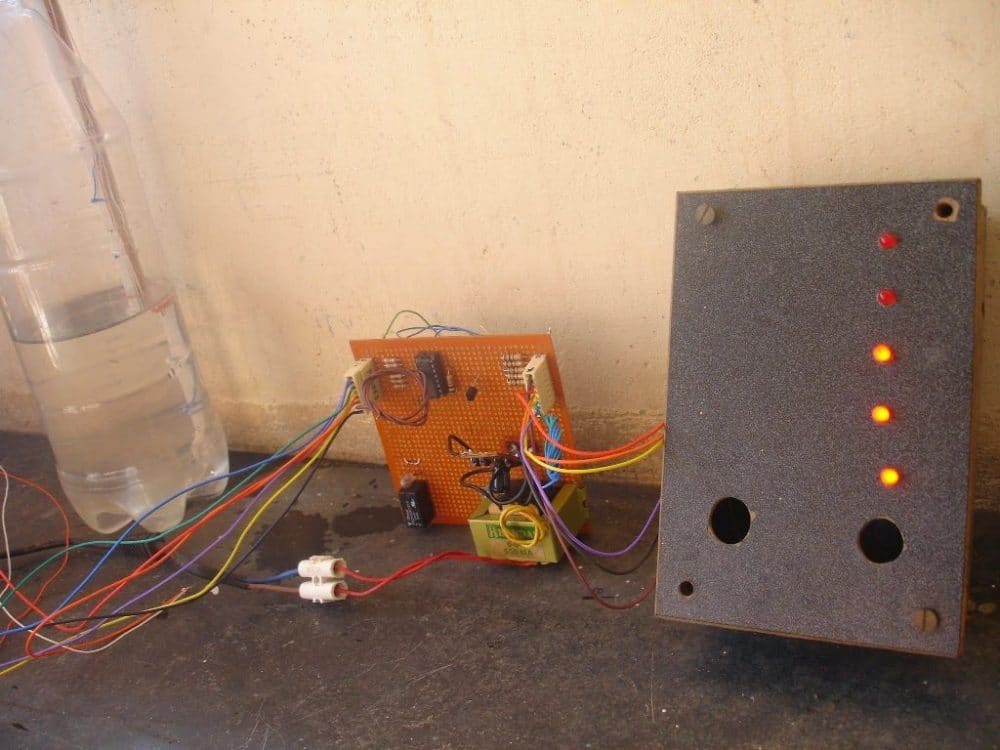

Practical Tested Prototype

The above circuit was successfully built and tested by Mr. E.Rama Murthy who is one of the regular and dedicated readers of this blog. The following pictures of the built prototype were sent by him, let's investigate the results closely.

Hi Swagatham

This is Vee I want to make a water level switch which would switch on a relay and in turn switch on a solenoid to open a water line to fill a small tank when the level goes down, How many amps would a reed switch handle to activate a 5 volt relay

Please send me the circuit to my email also,

Thank you Swagatham and all the best & God bless you

Hi Val,

You can get the circuit diagram in the following video:

https://youtu.be/u9xWVH-NENo

A reed switch can easily handle upto 200 mA current, so no problem with the 5 V relay.

Hi sir, I’m using the simple water level indicator circuit with transistors (bc 547) as given in this post. I have added a buzzer as the last stage of sensing at which I will be able to stop the motor manually. But problem is that the sensing wires corrode after some days and buzzer sounds very feeble. I got a float switch but it is ‘Normally Closed’ one. Pls let me know how to use this ‘NC’ float switch using transistor(pnp or npn) for indicating the uppermost level giving a buzzer sound.

Hi Binoj, I guess you are referring to a normally closed (N/C) reed switch? For an N/C reed switch you can try implementing the following transistor configuration:

Ys it’s now perfectly working sir..Great deal with you and your invaluable articles…Thank you ????????

Thanks Binoj, Glad it worked!

Sir please can i have the literature review of the water level indicator?

Victor, I wish I could do it for you, however due to lack of time it is difficult for me to create a literature review at this moment of time.

Can I use 12v dc to this circuit instead of 9v dc shown

To have heigh beep sound what type of buzzer is to be used

yes 12V can be used. A normal piezo buzzer used in automobile flashers will be good enough

In our circuit we have used BC148 npn 220 ohms insted of 100ohm in your circuit. Kindly clarify 12v dc can be given in place of 9v dc as 12v readly available solar battery

Yes 12V can be used without any problems.

Can you tell me why did you put LEDS at collector terminal? And can i put buzzer instead of LED? I don”t understand why transistor is switching mode

Where else do you think LEDs can be put? Collector is the perfect place for the LEDs… Yes you can use buzzer in pace of the LEDs.

I have a question,,,

Can you explain why you put resistance to the base of the transistor and to the collector?

those are current limiting resistors. Base resistor is always required otherwise the transistor will burn due to base overcurrent. The collector resistor is also for the same reasons, for protecting the LED and the transistor both from overcurrent

Hi Swagatam,

may it be possible to replace the metal electrodes as sensing elements, by graphite electrodes, to avoid corrosion problems?

Thank you in advance, and best regards

Alfredo

Thank you Alfredo, that’s a good idea, and can be tried.

what is m2m and why is capacitors used??

Hello, i want to ask that how is the circuit of water level indicator sensor with alarm using LDR component.

Why do you want to use an LDR?

Sir I need another 2 indications to the same circuit

1) water filling to tank from municipal source

2) water from under water source.

We should know which source of water was filling to the water tank by “Led” indication this should be by same circuit was it possible

Manjunath, it can be very easily implemented. Suppose you want the 6th gate to inform you about this, then you can pick one link from the 6th gate input and another link from the ground line and position the end terminals 1 inch apart and place them at the mouth of the source. So when the water arrives it will connect these terminals and the respective IC gate will illuminate the LED providing the required indications.

Sir,

but sixth gate is already used for water level “full” indication.

Without interrupting, the above indicators, can I use sixth gate as another indicator for ground water inflow indicator to the water tank. By adding another component that would work as 6th gate as water level full indicator ( as shown in diagram) and also ground water inflow indicator

Hi Manjunath, I just gave an example of the 6th gate….if you actually use the 6th gate for indicating the water source then it will illuminate in advance if the water comes from that source and will become ineffective as the full level indicator.

Instead it’s better to employ a separate PNP BC557 Darlington based network, and use it for sensing water from the source through its base, and the ground line.

please advice value of R 13 in circuit diagram with pump control. in circuit diagram you show 13 resistors but in pictures only show 12 resistors. R1 TO R6 = 2M2 and R7 TO R12 = 1K. What is value of R13 ?

R13 can be a 10K 1/4 watt resistor, for the transistor base

Thank you sir.

Good day. I would like to know if i can make sensor f and o common, will that turn off the relay when water level drops below sensor fo? ( sensor f and o is one sensor.) and will the rest of the circuit function normal?

Hi Ian, that may not be possible without some elaborate modifications, I have updated the modified design for enabling this operation, you can find the upgraded design at the bottom section of the article. This will allow the motor to switch ON only when the water level reaches point “F” and switch OFF when it drops below point “D”

Good day.

Thank you sir for your quick response, time and effort to modify this circuit for my kneed, i rely appreciate it.

I have a 45 L reservoir filled by hand with water and a submersible pump and aquarium heater inside the reservoir. The heater stays on permanently and regulate the water temperature with a thermostat, the pump is controlled through a timer at regular intervals of two hours off and fifteen minutes on. The water that gets pumped out of my reservoir into a separate hydroponics system, finally flows back into my reservoir through gravity, but eventually the plants use some of the water and the water level in my reservoir drops and needs topping up. The hydroponics system cannot over fill because there is a extra drain pipe, placed at the correct level, draining back to reservoir. This hydroponics system is called flood and drain.

I want to use the water level circuit to indicate the water level in my reservoir without opening the reservoir and to protected my pump and heater from running dry or switch off power to pump and heater below sensor D for example. With your new circuit i can clearly see where to incorporate the two transistors to control the relay for switching power to pump and heater. The SCR, in my case, is not needed so i can use N1 gate to turn on an extra led placed at the correct place for a more accurate water level indicator and include a buzzer for audio warning when water level drops to low with the extra gate available now.

I hope my explanation of my requirements makes sense to you, but one thing is for sure, i know now how to switch what ever at what ever level with this circuit.

Please correct my if i am wrong with reading and understanding your new circuit. Circuit must indicate water level of reservoir and audio alarm at sensor D and turn of power to pump and heater at sensor E and now extra sensor F gained from not needed SCR.

Thank you Sir.

Thanks for the detailed explanation,

However I think the SCR is crucial here, otherwise it would be same as the earlier circuit and the relay would keep toggling ON/OFF in response to the upper water level.

The SCR ensures that once the motor is initiated with the top level water, it doesn’t stop until the water level has reached below the “D” point.

So the SCR along with the two transistors are crucial in the last modified design.

Dear sir,

I made a water level controller with your help but the problem arises with corrosion at probes. so I need your help and want to know about such a material that do not corode.

One thing I want to mention that I have used a water level controller device of skylet company, its sensor do not corode over long period of use so I want to know what type material they use?

Thanks.

Dear Rakesh, corrosion can be avoided by using brass terminals coated with good quality solder, however it is not the corrosion we are worried about, rather it is the formation of a non conductive layer over terminals which can create problems. That can be prevented by a applying a push-pull kind of supply to the terminals.

An alternative long term solution would be to use separate ground terminals for each of the sensing terminals, instead of a single ground at the bottom of the tank.

for enabling a corrosion operation you can probably try the last updated design as shown in the following article

https://www.homemade-circuits.com/anti-corrosion-probes-for-water-level/

Dear sir,

Please tell me why 0.1 disc capacitor is used in the above circuit. Will it work with out the capacitors ?

Thank you .

Nataraj, the 0.1uF are positioned to prevent stray disturbances affecting the gate input pins, and to prevent false LED illumination.

If the sensing wires are small then the capacitor can be avoided otherwise it is recommended to include those capacitors.

Ok thank you sir.

sir as the wire immersed in water . later on a thick white layer formed arround the cutted part of wire , and it stoped working , so what should i do to work that for long period.

thak you sir

manjunath, did you tin the terminals with ample solder metal?? make a ball of solder at the ends

make sure to use good quality 60/40 solder and then check the response

and what about during ligtning period, since it is connectd to mains through transformer, if it affects than suggest me the rating of fuse to connect to the primary of transformr

use an 300V MOV at the primary supply input for safeguarding the circuit from a possible distant lightning induction.

Sir where to connect the MOV at 220v ac side or 6v ac side

220V AC side

Sir whwen I connected the MOV at 220V side the voltage reduces to 30-40V, and thus circuit does not work………….???

and one more thing , I want to connect a pre-recorded voice buzzer that will sound like."your tank is full plz switch off your motor"

and i could not find this type of buzzer on the internet . …..so plz suggest me the name of this type of buzzer and also some online store …thanx

Shah, an MOV will never drop the AC mains even by 1V….and if its dropping by 30-40V then that indicates heavy current shorting and should blow the mains DP fuse….I am not sure what may be the problem?

the prerecorded system will need to be made to order from the market….or you may have to buy special audio clip reorder IC for enabling recording and playback

sir if i connect 12 ac in place of dc in the above, then will circuit work? If yes than will the tank water give any shok?

And i have one more question that i have made the same thing but the circuit is different in which 6V ac is used by a stepdown 220/6 v 500mAmp transformer. And the circuit is working quite good, so my Question is that is their any chances of shok in tank water if any person come in contact.

hussain, ac supply will damage the IC immediately, not sure how it's working for you.

you can put a diode in series with the positive for applying a pulsating DC, that might work but never use AC.

6V, or 12V pulsating DC or AC will not give any shock in the water.

and also sugest such materials as probe which will not get corroded very soon, amd also which wire should i use cu or aluminium

use tinned copper….apply thick coat of good quality solder on copper.

sir, i have made this project.. And it was working quite good but after two week the probe get corroded and due to this circuit is not working properly ie led light flactuation . Etc

Hussain, you can try using pure stainless-steel probes and see if that helps.

Hi, It is IC CD4049UB a good alternative to IC 4049 ?

it' one and the same

Im not an electronic guy. Is there any way you can do in and sell it to me?

sir i want connect an alarm so what modifications should i do if the alarm is high power alarm generally used as door alarm

thanx

sir your posted image has been included with detail. was it correct sir this would be more usefull to new commers

https://lh3.googleusercontent.com/-AJkM6aVBKnY/VTyUB774UvE/AAAAAAAAA_8/WnNsvn_jwUE/w163-h110-p/20150426

manjunath, sorry I could not properly understand what you are trying to say….

yes, the explanation in the above article is correct and is in detail

your image is too small to see.

Sir , In this circuit can I make only 4 indicator levels instead of 6 as shown in diagram.

was it works,

If it works, wheather should I connect input gate and output gates one by one order or any

gates like for level 1 input pin 3 of 4049 and output pin 2

For level 2 input pin 9 output pin 10

visa versa

Hi Manjunath, you can use 4 gates out of the six, but make sure that the input pins of the remaining two unused gates are connected either to ground or to the positive rail…the outputs can be left open.

you can arrange the gates as you want, all the gates are exactly similar and can be positioned randomly or as desired, a specific sequence is not necessary.

I have added the IC image just to make it clear about the inputs and the outputs and the supply pins to the newcomers.

Hey, i'm in software domain. Actually i need this circuit design to implement in my home.

Could you please send me detailed labeled circuit diagram with IC 4049 connected.

Thanks in advance..

Keep up the good work.

The "triangles" inside the 4049 and the corresponding pinouts are shown in the second pic, you just have to connect the involved pins as per the circuit diagram given in the first pic, it's quite simple actually.,

any "triangle" can be positioned anywhere all are identical with their characteristic

yes that's absolutely correct

Can we use it for long range?

yes you can, just make sure to connect 0.22uF capacitor across the base/emitter of all the transistors.

hello my name is amir'm from Buenos Aires Argentina.

I need your help designing a circuit.

I need a circuit to heat water in a tank and when it reaches a temperature has to cut the feeding 220vca..y … also it disconnects itself from already thank you very much.

Hello, I'll try to design it and let you know once it's completed.

how much output current on any pin of 4049. because i want to connect alarm bell with pin. so i want to know how much power of bell i can use.

and i want to use door bell like (ding dong) with this circuit then how can do this. i think i require one another circuit in which thyristor is used to connect with this circuit for connecting ac bell. Am i right?

10mA will be available at the gate outputs.

It's advisable to use a transistor/relay driver at the output of the gate for operating a high power bell, whether AC or DC

yes the diagram looks OK to me, the latching would work and stop the relay from reactivating, but the circuit will need to be reset each time the water level goes below the lower threshold.

the shown 2M2 is also a big value, but if you want to use even bigger values you can try, for example 10M could be tried instead of 2M2.

sir in your Water Level Indicator Circuit with Relay Controller in water tank A B C D is marked there these are sensor or not

Sharan, the A B C D points are sensors made by using tinned copper wires, you can also use tinned brass metal. Larger surface area will give better results.

Hi,

Yap it should be switched off manualy after filling.

I have one question it seems that logic gates have big resistance so I think about putting resistor of bigger value in parallel with logic gate so that final resistance is lower and then it could work in water with big resistance, is it possible in real world? It seems that it is working in simulation but I am not sure.

Hello Thanks!

Yes, that looks OK to me. but the relay will keep switching everytime the water level dips below the upper threshold.

Hello,

this is a bit tweaked circuit and it seems in simulation that it could be used to turn water pump off automaticly when water reaches some level…but I have no idea how it would act in real life xD

s21.postimg.org/bkntb9dpj/auto_off_water_pump_circuit.png

Best regards.

Hello Swagatam,

What would be the effect, if base of the transistor is connected at the same position of the LED of gate 6 which will energize a relay to open its normally open contact?.

If it can not work that way, what needs to be done to consider it and automatic control circuit?.

Regards

Hello Kevin,

Yes it can be wired in that way, the idea has been discussed in the following article:

https://www.homemade-circuits.com/2012/01/circuit-provided-in-this-article.html

hello sir

could u pls suggest a circuit for alarm which use input from one of the output of above circuit

coz i have three overhead tank n a underground tank . want to use single speaker (8 ohm )

hello aashish, do the following things:

make a 555 astable multivbrator circuit with a frequency that would generate the required alarm audio

connect pin1 of the IC to a 8050 transistors collector, connect its emitter to ground, base to 4049 ICs any one of the outputs via a 1k resistor.

connect the speakers one of the wires together and connect the common joint to pin3 of the 555, similarly connect the common wire joint of the speakers to ground.

that's it once activated all the speakers would start buzzing

Hi Sir,

Greetings..!!!

When im trying(4049 circuit #4)to connect (intermittant) pizo buzzer via 1k resister to bc548 and connect to buzźer the problom is before the led glows the alarm sounds.means when we hear the sound of buzzer still the bulb is not glowing the upper level to which we connect the 1k resistor to bc148 and buzzer. How we can solvr the problom for realtime buzzer?

Sison, use 10K for the base resistor instead of 1K, and also connect a 2k2 across base emitter

sir,

in my previous mail the circuit is 2 circuit.not#4.water level indicator circuit by 4049 not gate.

THANKS

but could u pls refer me its circuit diagram

as soon as I'm free I'll try to present it in the above article.

thank you

i will keep looking for it . can we use other sound library ic available in the market like IC HT2844P or pic16f887

yes any audio circuit as per preference can be tried

thank you

dear ashish,

yes the remaining pins are not used.

a piezo buzzer can be connect directly across one of the outputs of the gates and ground, just as the LEDs are connected.

dear swagatam,

refering to pin out diagram only 2,3,4,5,6,7,9,10,11,12,14,15, numbered pins are to be used and others left idle.

also pls suggest to how to add buzzer to the circuit

Please say that anyone who tested this experiment. Is all perfect circuit. for usage

I think at 12V electrolysis could be very negligible to affect much especially without any acidic agent in water, moreover natural electrolysis of this kind will only dissociate water ions not the electrode ions.

Lead may be tightly bonded in solder metal so it will not easily separate, and whatever may dissolve could be again too insignificant to cause any health issues.

yet for extreme safety two things can be done, use electroplated electrodes (tin or chromium plated) and connected 100k resistors in series with each sensing terminals for reducing current such that only the IC is able to sense it without initializing electrolysis.

with AC the circuit will not operate and moreover higher volt could force more electrolysis to occur.

You can tin the terminals with a thick layer of solder for reducing corrosion as tin is resistant to most passive chemical reactions.

The indicated ground is the 12V adapter supply ground (negative), it's not the earthing type of ground, so lightning will not get attracted to it in anyway.

You can connect and ground the tank body with the your home earthing wire for more safety if you feel it necessary.

Hi

One basic question.

What is the current being passed through the probes?

Is there any risk to human life when the current passes through water?

I dont want to have shock when I turn on tap in my kitchen.

Pallavi

Hi,

It would be 100 times less than your cell phone battery, so it's absolutely safe.

Refer to the IC pin out diagram given below the circuit diagram, you can easily compare and replace the pin numbers over the circuit and understand the inputs and the outputs appropriately.

refer to the diagram and count them, it's so simple.