The circuits presented in the following article could be used for generating strobed lighting effect over 4 Xenon tubes in a sequential manner.

The proposed sequential xenon lighting effect could be applied in discotheques, in DJ parties, in cars or vehicles, as warning indicators, or as decorating ornamental lights during festivals.

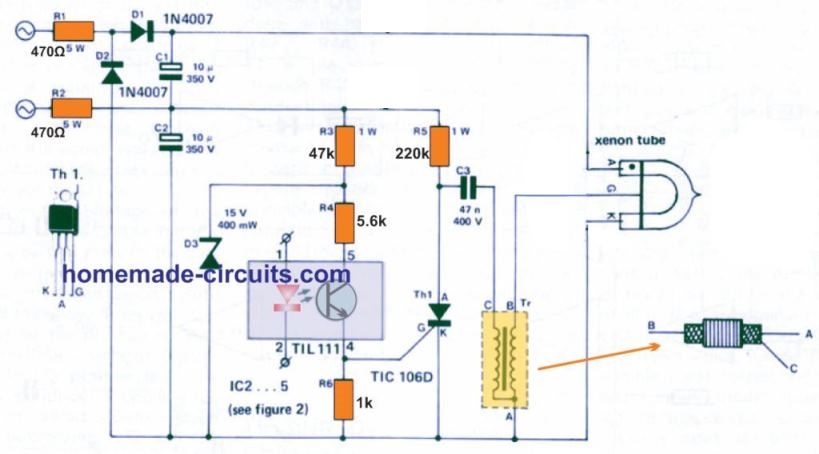

A wide range of xenon tubes are available in the market with a matching ignition transformer set (that we are going to talk about afterwards). In theory, just about any xenon tube works extremely well in the strobe control circuit presented in figure below.

How Xenon Tube Rating is Calculated

The circuit is designed for a '60 Watts per second' xenon tube and this is all it is going to accommodate. Sadly, the power ratings of xenon tubes are typically mentioned as "x" watts per second, which often signifies an issue!

The reason behind the particular capacitor values in the diagram and DC voltage level may be comprehended through the following simple equation:

E = 1/2 C.U2

The quantity of electrical power utilized by the xenon tube may be determined simply by multiplying energy and the xenon repetition pulse frequency.

With a frequency of 20 Hz and a power of 60 Ws, the tube might 'consume' around 1.2 kW! But that looks huge, and can't be justified. Actually, the mathematics in the above is using an incorrect formula.

As an alternative, this should be depending on the optimum acceptable tube dissipation and the resulting energy with respect to the frequency.

Considering that the xenon tube specifications which we are enthusiastic about should be capable of handling a highest possible dissipation up to 10 W, or an optimum level of 0.5 Ws energy should be discharged at 20 Hz.

Calculating the Discharge Capacitors

The above explained criteria calls for a discharge capacitance with a value 11uF and having an anode voltage of 300 V. As could be witnessed, this value matches relatively well with the values of C1 and C2 as indicated in the diagram.

Now the question is, just how do we select the correct capacitor values, in a situation where we have no rating printed on the xenon tube? Currently since we have with us the relationship between 'Ws' and W', the below shown rule-of -thumb equation could be tested out:

C1 = C2 = X . Ws / 6 [uF]

This is actually just a relevant clue. In case the xenon tube is specified with an optimal working range of under 250 continuous hours, it is best to apply the equation over a reduced allowable dissipation. A useful recommendation you may want to follow with regards to all types of xenon tubes.

Ensure that their connection polarity is proper, this means that, attach the cathodes to ground. In many instances, the anode is marked with a red-colored spot. The grid network is either available as like a wire at the cathode terminal side or simply as a third 'lead' between the anode and the cathode.

How Xenon Tube is Ignited

Alright, so inert gases have the ability to generate illumination when electrified. But this fails to clarify just how the xenon tube is actually ignited. The electrical power storage capacitor described previously is indicated in figure 1 above, through a couple of capacitors C1 and C2.

Given that the xenon tube needs a voltage of 600 V across the anode and the cathode, diodes D1 and D2 constitute a voltage doubler network in conjunction with the electrolytic capacitors C1 and C2.

How the Circuit Works

The a pair of capacitors are consistently charged to the maximum AC voltage value and as a result R1 and R2 are incorporated to restrict the current during the xenon tube's ignition period. If R1, R2 were not included the xenon tube would at some point degrade and stop working.

The resistor R1 and R2 values are selected to ensure C1 and C2 are charged up to the peak voltage level (2 x 220 V RMS) with the maximum xenon repetition frequency.

The elements R5, Th1 , C3 and Tr represent the ignition circuit for the xenon tube. Capacitor C3 discharges through the ignition coil's primary winding which generates a grid voltage of many kilovolts across the secondary winding, for igniting the xenon tube.

This is how the xenon tube fires and illuminates brightly, which also implies that now it instantly draws the entire electrical power held inside C1 and C2, and dissipates the same by means of a dazzling flash of light.

Capacitors C1, C2 and C3 subsequently recharges so that the charge allows the tube to go for a new pulse of flash.

The ignition circuit obtains the switching signal through an opto-coupler, an built-in LED and a photo transistor enclosed collectively inside a single plastic DIL package.

This guarantees excellent electrical isolation across the strobe lights and the electronic control circuit. As soon as the photo transistor is lit up by the LED, it becomes conductive and actuates the SCR.

The input supply for the opto-coupler is taken from the 300V ignition voltage from across C2. It is nonetheless lowered to 15V by diode R3 and D3 for apparent factors.

Control Circuit

Since the working theory of the driver circuit is understood, we can now learn how the xenon tube could be designed to produce a sequential strobing effect.

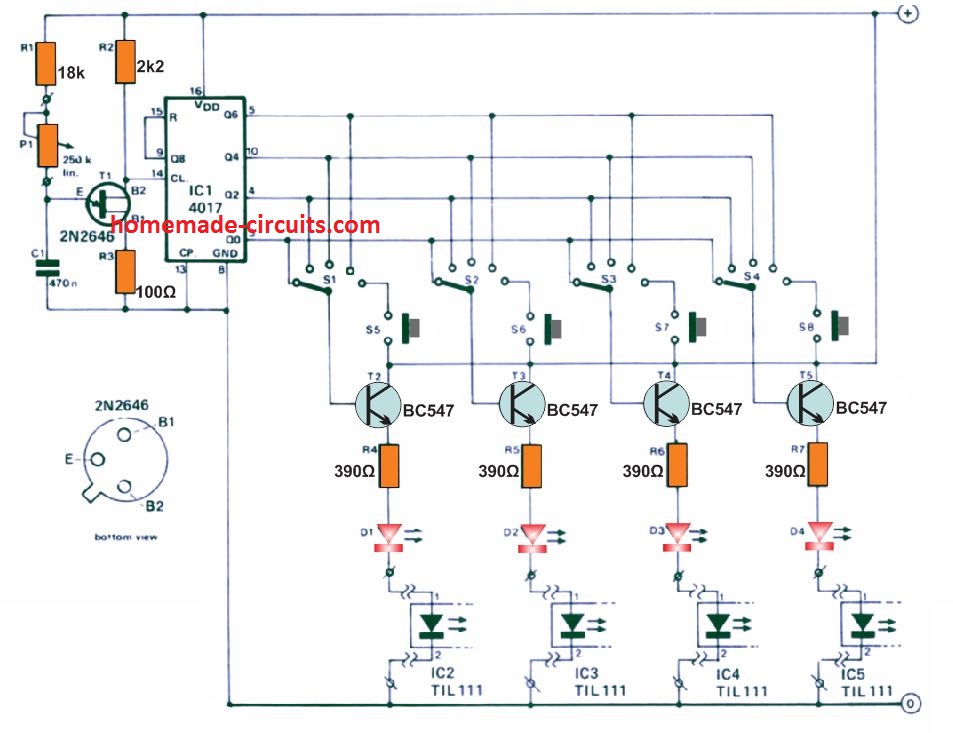

A control circuit for producing this effect is demonstrated in figure 2 below.

The highest repeat strobe rate is limited to 20 Hz. The circuit has the capacity to handle 4 strobe devices at the same time and essentially is made up of range of switching devices and a clock generator.

The 2N2646 unijunction transistor UJT works like a pulse generator. The network associated with this is intended to enable the frequency of the output signal to be tweaked around the 8 … 180 Hz rate using P1. The oscillator signal is fed to the clock signal input of the decimal counter IC1.

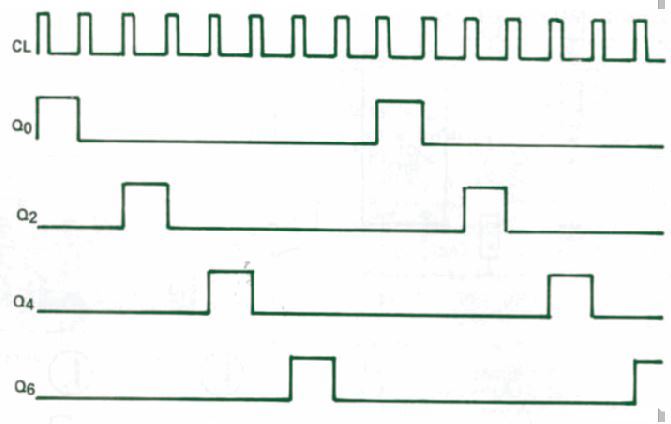

Figure 3 below shows a picture of the signal waveforms at the IC1 output with regards to the clock signal.

The signals coming from the IC 4017 switch at a frequency of 1 … 20 Hz are applied to the switches S1 … S4. The positioning of the switches decides the sequential pattern of the strobe. It allows the lighting sequence to be adjusted from right to left, or the opposite, etc.

When S1 to S4 are set at totally clockwise, the push-buttons become in the operational mode, enabling one of the 4 xenon tubes to be activated manually.

The control signals activate the LED driver stages through transistors T2 . . . T5. The LEDs D1 … D4 work like functional indicators for the strobe lights. The control circuit could be tested by just grounding the cathodes of D1 … D4. These will show immediately whether or not the circuit is working correctly.

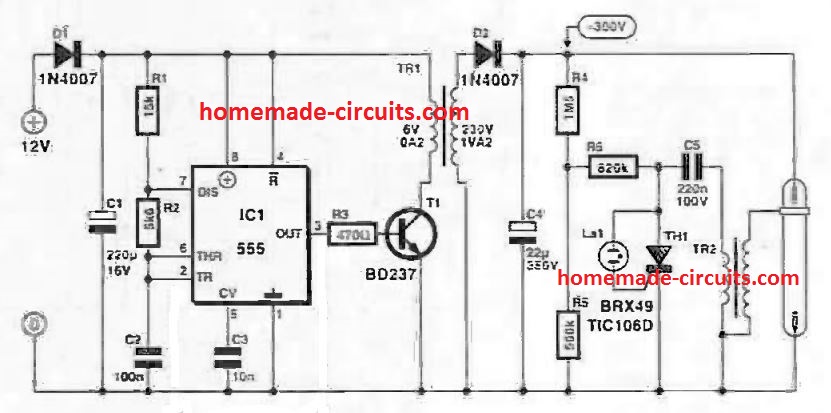

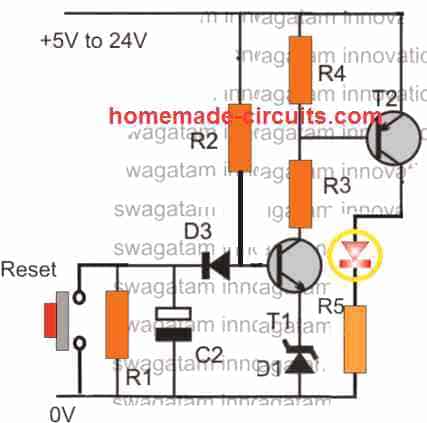

A Simple Stroboscope using IC 555

In this simple stroboscope circuit the IC 555 works like an astable oscillator driving a transistor and an attached transformer.

The transformer converts 6V DC into 220 V low current AC for the stroboscope stage.

The 220 V is further converted to a high voltage peak 300 V with the help of the diode capacitor rectifier.

When the capacitor C4 charges up to the triggering threshold of the SCR gate neon bulb, through the resistive network, the SCR fires and triggers the driver grid coil of the stroboscope lamp.

This action dumps the entire 300 V into the stroboscope bulb illuminating it brightly, until the C4 is fully discharged for the next cycle to repeat.

Another Xenon Strobe Light Circuit

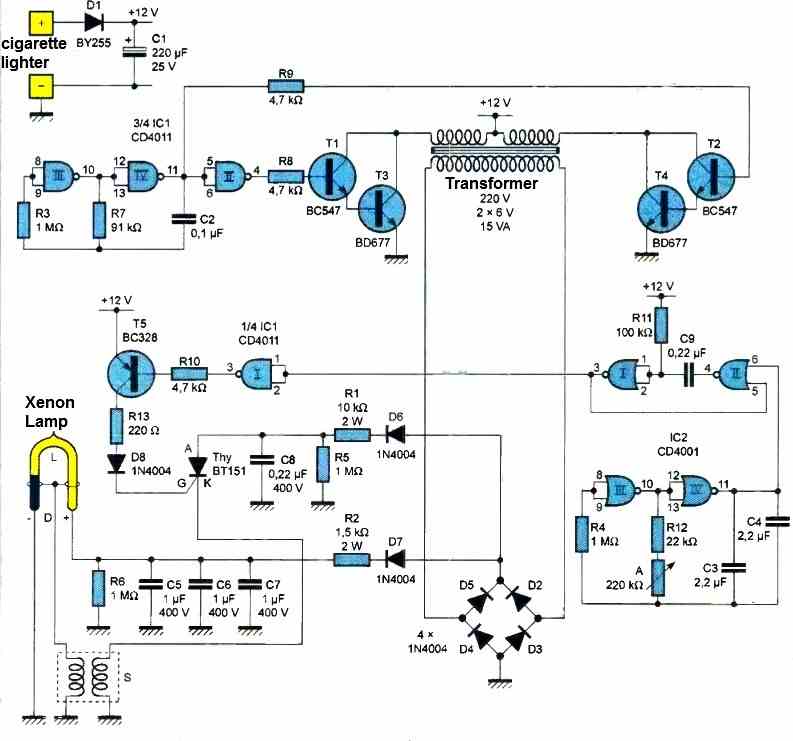

The next setup we propose is a warning strobe light circuit which, in case of a breakdown that immobilizes your vehicle on the side of the road, should be placed to attract the attention of other road users and therefore protect you.

It should be placed on the ground or, even better, on the roof of the vehicle, and will emit regular flashes of light visible from a relatively long distance. It will be directly powered by the vehicle battery by simply plugging it into the cigarette lighter socket, for example.

Power supply

The energy is taken from the vehicle battery through diode D1, which also serves as a polarity detector (Figure 4). Capacitor C1 provides some filtering due to the pulsed operation mode of the circuit. The current consumed can reach several amperes, so it is important to use a suitable power supply wire to limit the voltage drop along the line.

High voltage production

NAND gates III and IV of IC1 constitute an astable oscillator that generates square-shaped pulses on its output with a period of about 20 milliseconds, which corresponds to a frequency of 50 Hz. The output of NAND gate IV (pin #11) drives a pair of NPN transistors, T2 and T4, forming a Darlington pair.

It should be remembered that such a configuration produces very high current gain. Another Darlington pair is formed by T1 and T3. The latter is controlled by the output of NAND gate II, which performs a phase inversion compared to the control of the first pair.

The collectors of T1/13 are connected to one of the two secondary windings of a transformer, while the collectors of T2/T4 are connected to the other secondary winding. The common point of the two windings is directly connected to the positive pole of the 12-volt power supply.

The resulting magnetic field is alternately oriented in one direction and then in the other, which produces an alternating potential at the primary winding of the transformer, albeit not sinusoidal. This potential has relatively high peaks because the transformer operates as a voltage booster in this application.

The four diodes D2 to D5 constitute a bridge rectifier for the two alternations. Through D6 and R1, this bridge charges capacitor C8. Similarly, through D7 and R2, it charges the set of three capacitors C5, C6, and C7.

The resulting DC potential on the positive plate of these capacitors is about 350 volts. The high-value resistors R5 and R6 serve to discharge the capacitors once the circuit is disconnected from the power supply. This precaution avoids unpleasant shocks to anyone inadvertently touching the plates of these capacitors.

Command Triggering

The NOR gates III and IV of 102 form a second astable oscillator whose generated pulse width is variable from 0.2 to 2.3 seconds, depending on the angular position of the adjustable A cursor.

The rising edges ensure the start of a monostable flip-flop formed by NOR gates I and II of 102. The latter then periodically delivers brief positive pulses lasting about 15 milliseconds that the NAND gate I of IC1 inverses to low states.

Flashes triggering

During the low states presented by the output of the NAND gate we have just mentioned, the PNP transistor/T5 saturates. This results in the establishment of a very brief current in the gate/cathode junction of the Thyristor Thy, through R13 and D8.

The consequence is the conduction of the thyristor. In particular, an intense current whose potential comes from the high voltage available on the positive armature of 08, flows through the anode/cathode junction to supply one of the two trigger windings of the trigger transformer. Capacitor C8 discharges on this occasion.

As for the trigger transformer, the winding concerned is the one with the smaller number of turns. This results in a strong rise in potential across the other winding.

The latter is in connection with the triggering electrode of the flashing lamp. This then causes the lamp to ignite. The potential accumulated in capacitors C5, C6 and C7 discharges suddenly, and a bright flash appears between the positive and negative electrodes of the lamp.

Comments

Hi mr Swagatam

I am looking for a practical, buildable circuit to drive a xenon flash tube. The tube’s operating charge voltage should be in the range of about 200–300 V DC. Could you please share a working schematic, PCB layout (if available), a complete parts list with component ratings (especially capacitor and transformer/charger specs), and brief instructions for safe testing and triggering? Thank you very much for your help.”

Hi Ramin,

You can refer to the following article, it might be suitable for your requirement:

https://www.homemade-circuits.com/mains-ac-xenon-tube-flasher-circuit/

If you have any doubts please let me know…

Can you kindly share your e mail. I have a project on Xenon Lamp. This is high power Xenon Lamp : 1500 W. We need to control On and Off time of the lamp. I can send the specifications for your help and guidance.

Hello Ramachandra, I will try my best to help you, however, I prefer discussing through this comment platform since it allows the other users also to learn from our discussions.

Nevertheless, if you want to send your schematic for reference, you can send it to my email, I will check it out:

homemadecircuits

@ gmail.com

I have an important need to fire a xenon strobe at a spinning disk with an image on it. The speed will vary from 2 to 5 rotations per second. The image must appear to be still and the strobe must fire once per rotation at the same point. I’m told that a Hall effect sensor is the best solution but I need to integrate it with the strobe. PLEASE HELP ME. I am willing to pay a fee for design of the circuit.

Thanks,

Sven BAidenmann

503-473-7356

Hi,

yes, a hall effect sensor can be used to detect the rotation and trigger the xenon at a specified fixed point. You can buy a readymade hall effect sensor module such as the “A3144 Hall Effect Sensor Module” and quickly use it for the application.

Let me know if you have any further doubts or questions.

Thank you but my dilemma is I need a strobe circuit that is so bare bones it doesn’t have a.trigger or timer system already built in. and that it is easy to accept the hall sensor. I have looked high and low and I find nothing, so look I assume that I will have to build it but again….. I find no schematic. I don’t need high power. the person viewing the image will be in total darkness and sitting two to three feet away.

I have been trying to solve this issue for three years and I just don’t know where else to look. Help me please

You can try the following design, it is the most base bone you can get:

https://www.homemade-circuits.com/wp-content/uploads/2020/08/simple-stroboscope.jpg

In this design you can replace the 555 astable with a 555 monostable and trigger the monostable with your hall effect sensor signals.

Alternatively, you can simply remove the 555 stage entirely, and directly configure your hall effect trigger with the base of the driver transistor T1.

Let me know if that helps!

Hello there,

What would be the considerations for designing a higher power Xenon control circuit?

Have been thinking of scaling up the circuit for a lamp up to 500W (200W minimum).

Any ideas on the correct approach?

Hi,

a motorcycle CDI circuit could be tried to fire a high watt stroboscope tube. Here’s an example concept which may be considered:

https://www.homemade-circuits.com/make-this-enhanced-capacitive-discharge/

I have similar strobe like this but its not working and im trying to fix it, but im lost. Its a 24vdc supply industrial grade strobe, what could be the most common issue with this type of circuits?

The problem can be with the SCR, the strobe tube wire connection, the transistor (if any), the diac (if any) or the pulse transformer.

It is important to find whether the high voltage before the triac triggering stage is available or not. If the high voltage is available that means the problem is in the triggering circuit.

I am desperate! I need to trigger a strobe light using a hall effect sensor. Basically, a turntable with a image on it that must be frozen to the eye as it spins. The speed changes but the image must appear still. I have been looking for over two years for a solution. Every circuit I look at has unnecessary triggering components. I want a pure circuit able to accept a mechanical close via a magnet glued to the rotating turntable passing a reed switch. RPMs are well within the ability of any strobe. Minimum is zero, maximum would be around 5 rotations per second. Average is about 2 per second. Please direct me to a resource that might be a solution. I realize that an electrical engineer could solve this in a heartbeat. I have very limited funds but I am willing to give from what I have. My name is Sven Baidenmann. THANK YOU for anything that might bring me closer to solving this problem. It is the last piece to a much bigger project. I am willing to share more details if you are interested.

Hello Sven,

you can try implementing the first circuit from the above article. You can feed the opto coupler input with your hall effect signal through a transistor driver.

Let me know if you have any further doubts or queries.