In this post I have explained a four simple yet a safe way of charging a Li-ion battery using ordinary ICs like LM317 and NE555 which can be easily constructed at home by any new hobbyist.

Although Li-Ion batteries are vulnerable devices, these can be charged through simpler circuits if the charging rate does not cause significant warming of the battery., and if the user does not mind a slight delay in the charging period of the cell.

For users who want rapid charging of the battery, must not use the below explained concepts, instead they can employ one of these professional smart designs.

Basic Facts about Li-Ion Charging

Before learning the construction procedures of a li-Ion Charger, it would be important for us to know the basic parameters concerned with the charging Li-Ion battery.

Unlike, lead acid battery, a Li-Ion battery can be charged at significantly high initial currents which can as high as the Ah rating of the battery itself. This is termed as charging at 1C rate, where C is the Ah value of the battery.

Having said this, it is never advisable to use this extreme rate, as this would mean charging the battery at highly stressful conditions due to increase in its temperature. A 0.5C rate is therefore considered as a standard recommended value.

0.5C signifies a charging current rate that's 50% of the Ah value of the battery. In tropical summer conditions, even this rate can turn into an unfavorable rate for the battery due to the existing high ambient temperature.

Does Charging a Li-Ion Battery Require Complex Considerations?

Absolutely not. It's actually an extremely friendly form of battery, and will get charged with minimal considerations, although these minimal considerations are essential and must be followed without fail.

A few critical but easy to implement considerations are: auto cut-off at the full charge level, constant voltage, and constant current input supply.

The following explanation will help to understand this better.

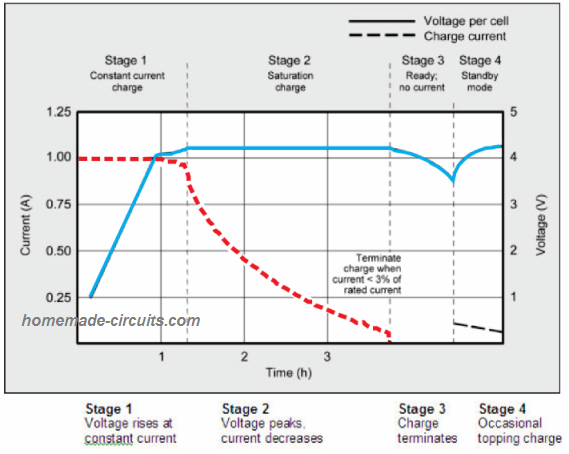

The following graph suggests the ideal charging procedure of a standard 3.7 V Li-Ion Cell, rated with 4.2 V as the full charge level.

Stage#1: At the initial stage#1 we see that the battery voltage rises from 0.25 V to 4.0 V level in around one hour at 1 amp constant current charging rate. This is indicated by the BLUE line. The 0.25 V is only for indicative purpose, an actual 3.7 V cell should never be discharged below 3 V.

Stage#2: In stage#2, the charging enters the saturation charge state, where the voltage peaks to the full charge level of 4.2 V, and the current consumption begins dropping. This drop in the current rate continues for the next couple of hours. The charging current is indicated by the RED dotted line.

Stage#3: As the current drops, it reaches its lowest level which is lower than 3% of the cell's Ah rating.

Once this happens, the input supply is switched OFF and the cell is allowed to settle down for another 1 hour.

After one hour the cell voltage indicates the real State-Of-Charge or the SoC of the cell. The SoC of a cell or battery is the optimal charge level which it has attained after a course of full charging, and this level shows the actual level which can be used for a given application.

At this state we can say the cell condition is ready to use.

Stage#4: In situations where the cell is not used for long periods, a topping up charging is applied from time to time, wherein the current consumed by the cell is below 3% of its Ah value.

Remember, although the graph shows the cell being charged even after it has reached 4.2 V, that's strictly not recommended during practical charging of a Li-Ion cell. The supply must be automatically cut off as soon as the cell reaches 4.2 V level.

So What does the Graph Basically Suggest?

- Use an input supply which has a fixed current and fixed voltage output, as discussed above. (Typically this can be = Voltage 14% higher than printed value, Current 50% of the Ah value, lower current than this will also work nicely, although charging time will increase proportionately)

- The charger should have an auto-cut off at the recommended full charge level.

- Temperature management or control for the battery may not be required if the input current is restricted to a value which does not cause warming of the battery

If you don't have an auto cut-off, simply restrict the constant voltage input to 4.1 V.

1) Simplest Li-Ion Charger using a single MOSFET

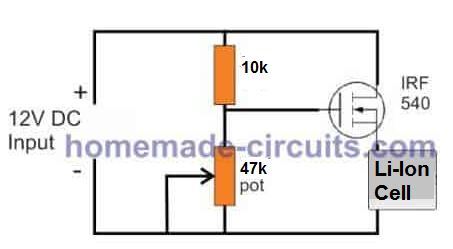

If you are looking for a cheapest and the simplest Li-Ion charger circuit, then there cannot be a better option than this one.

A single MOSFET, a preset or trimmer and a 10k ohm 1/4 watt resistor is all that you would need to make a simple and safe charger circuit.

Before connecting the output to a Li-Ion cell make sure of a couple of things.

1) Since the above design does not incorporate temperature regulation, the input current must be restricted to a level which does not cause significant heating of the cell.

2) Adjust the preset to generate exactly a 4.1V across the charging terminals, where the cell is supposed to be connected. A great way to fix this voltage is to connect a precise zener diode in place of the preset, and replace the 10 k ohm with a 1 k ohm resistor.

For the current, typically a constant current input of around 0.5C would be just right, that is 50% of the mAh value of the cell. So, the input supply should have a fixed 12V DC and a current that is 50% of the Li-Ion cells mAH rating.

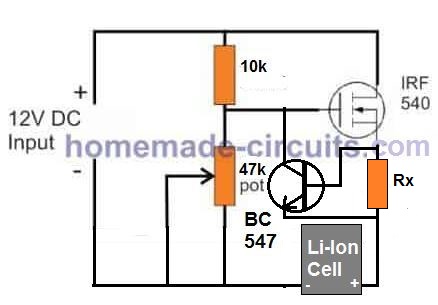

Adding a Current Controller

If the input DC supply source is not current controlled, in that case we can quickly upgrade the above circuit with a simple BJT current control stage as shown below:

Advantage of Li-Ion Battery

The main advantage with Li-Ion cells is their ability to accept charge at a quick, and an efficient rate. However Li-Ion cells have the bad reputation of being too sensitive to unfavorable inputs such as high voltage, high current, and most importantly over charging conditions.

When charged under any of the above conditions, the cell may get too warm, and if the conditions persist, may result in leaking of the cell fluid or even an explosion, ultimately damaging the cell permanently.

Under any unfavorable charging conditions the first thing that happens to the cell is rise in its temperature, and in the proposed circuit concept we utilize this characteristic of the device for implementing the required safety operations, where the cell is never allowed to reach high temperatures keeping the parameters well under the required specs of the cell.

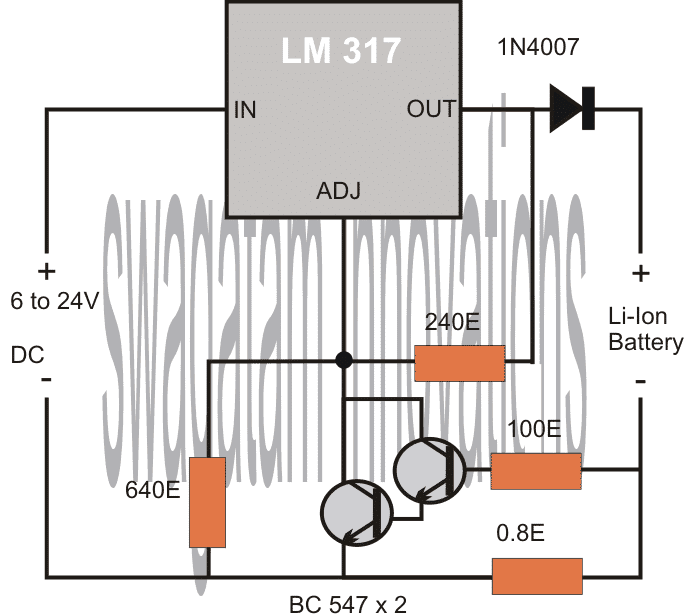

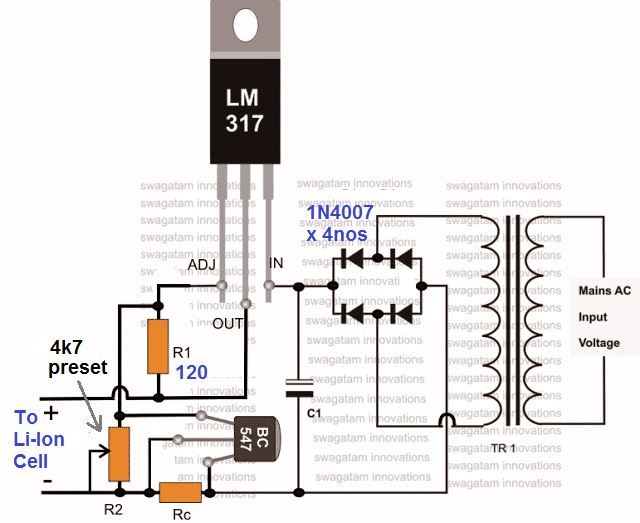

2) Using LM317 as the Controller IC

In this blog we have come across many battery charger circuits using the IC LM317 and LM338 which are the most versatile, and the most suitable devices for the discussed operations.

Here too we employ the IC LM317, although this device is used only to generate the required regulated voltage, and current for the connected Li-Ion cell.

The actual sensing function is done by the couple of NPN transistors which are positioned such that they come in physical contact with the cell under charge.

Looking at the given circuit diagram, we get three types of protections simultaneously:

When power is applied to the set up, the IC 317 restricts, and generates an output equal to 3.9V to the connected Li-ion battery.

- The 640 ohm resistor makes sure this voltage never exceeds the full charge limit.

- Two NPN transistors connected in a standard Darlington mode to the ADJ pin of the IC controls the cell temperature.

- These transistors also work like current limiter, preventing an over current situation for the Li-Ion cell.

We know that if the ADJ pin of the IC 317 is grounded, the situation completely shuts off the output voltage from it.

It means if the transistors conduct would cause a short circuit of the ADJ pin to ground causing the output to the battery shut off.

With the above feature in hand, here the Darlingtom pair does a couple of interesting safety functions.

The 0.8 resistor connected across its base and ground restricts the max current to around 500 mA, if the current tends to exceed this limit, the voltage across the 0.8 ohm resistor becomes sufficient to activate the transistors which "chokes" up the output of the IC, and inhibits any further rise in the current. This in turn helps keep the battery from getting undesired amounts of current.

Using Temperature Detection as the Parameter

However, the main safety function that's conducted by the transistors is detecting the rise in temperature of the Li-Ion battery.

Transistors like all semiconductor devices tend to conduct current more proportionately with increase in the ambient or their body temperatures.

As discussed, these transistor must be positioned in close physical contact with the battery.

Now suppose in case the cell temperature begins rising, the transistors would respond to this and start conducting, the conduction would instantly cause the ADJ pin of the IC to be subjected more to the ground potential, resulting in decrease in the output voltage.

With a decrease in the charging voltage the temperature rise of the connected Li-Ion battery would also decrease. The result being a controlled charging of the cell, making sure the cell never goes into a run away situations, and maintains a safe charging profile.

The above circuit works with temperature compensation principle, but it does not incorporate an automatic over charge cut off feature, and therefore the maximum charging voltage is being fixed at 4.1 V.

Without Temperature Compensation

If you want to avoid the temperature controlling hassles, you can simply ignore the Darlington pair of BC547, and use a single BC547 instead.

Now, this will work only as a current/voltage controlled supply for the Li-Ion cell. Here's the required modified design.

Since, here temperature control is not employed, make sure that Rc value is correctly dimensioned for a 0.5 C rate. For this you can use the following formula:

Rc = 0.7 / 50% of Ah value

Suppose the Ah value is printed as 2800 mAh. Then the above formula could be solved as:

Rc = 0.7 / 1400 mA = 0.7 / 1.4 = 0.5 Ohms

Wattage will be 0.7 x 1.4 = 0.98, or simply 1 watt.

Likewise, make sure the 4k7 preset is adjusted to an exact 4.1 V across the output terminals.

Once the above adjustments are made, you can charge the intended Li-Ion battery safely, without worrying about any untoward situation.

Since, at 4.1 V we cannot assume the battery to be fully charged.

To counter the above drawback, an automatic cut off facility becomes more favorable than the above concept.

I have discussed many op amp automatic charger circuits in this blog, any one of them can be applied for the proposed design, but since we are interested to keep the design cheap and easy, an alternative idea which is shown below can be tried.

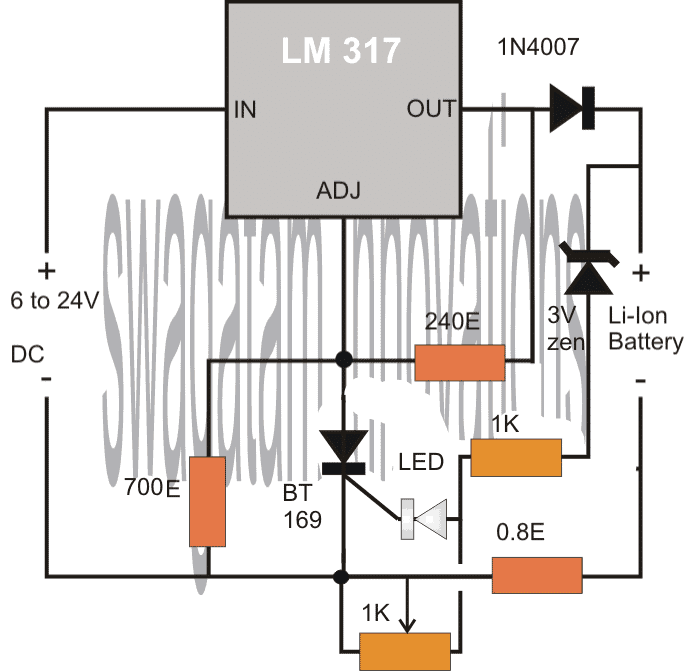

Employing an SCR for the Cut-Off

If you are interested to have an auto cut off only, without temperature monitoring, you can try the below explained SCR based design. The SCR is used across the ADJ and ground of the IC for a latching operation. The gate is rigged with the output such that when the potential reaches at about 4.2V, the SCR fires and latches ON, cutting of power to the battery permanently.

The threshold may be adjusted in the following manner:

Initially keep the 1K preset adjusted to ground level (extreme right), apply a 4.3V external voltage source at the output terminals.

Now slowly adjust the preset until the SCR just fires (LED illuminated).

This sets the circuit for the auto shut off action.

How to Set-Up the Above Circuit

Initially keep the central slider arm of the preset touching the ground rail of the circuit.

Now, without connecting the battery switch ON power, check the output voltage which would naturally show the full charge level as set by the 700 ohm resistor.

Next, very skilfully and gently adjust the preset until the SCR just fires shutting off the output voltage to zero.

That's it, now you can assume the circuit to be all set.

Connect a discharged battery, switch ON power and check the response, presumably the SCR will not fire until the set threshold is reached, and cut off as soon as the battery reaches the set full charge threshold.

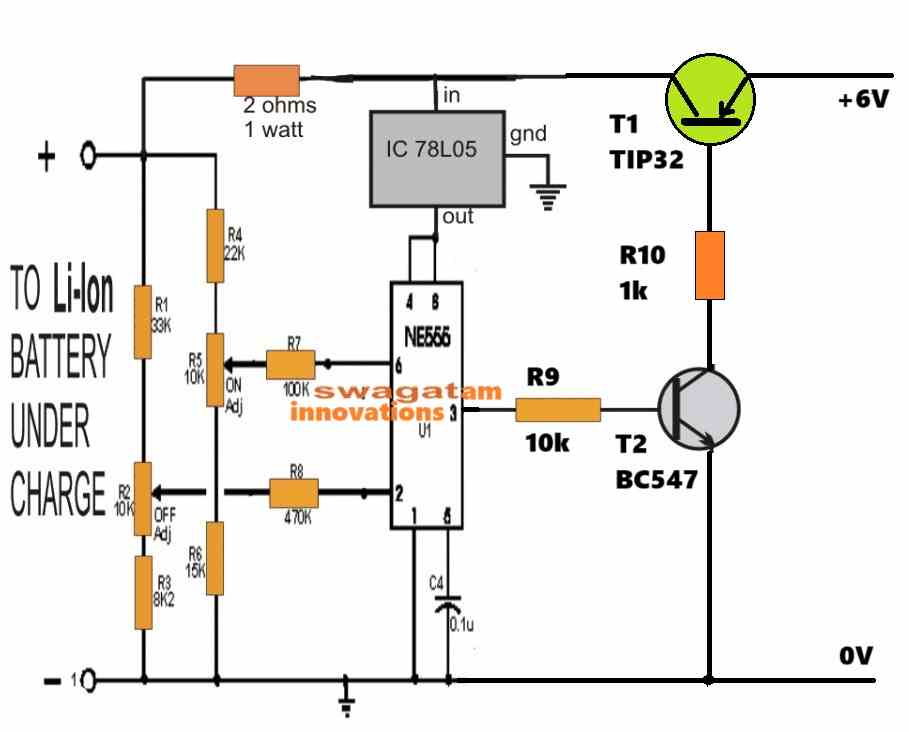

3) Li-Ion Battery Charger Circuit Using IC 555

The second simple design explains a straightforward yet precise automatic Li-Ion battery charger circuit using the ubiquitous IC 555.

Charging Li-ion Battery Can be Critical

A Li-ion battery as we all know needs to be charged under controlled conditions, if it's charged with ordinary means could lead to damage or even explosion of the battery.

Basically Li-ion batteries don't like over charging their cells. Once the cells reach the upper threshold, the charging voltage should be cut off.

The following Li-Ion battery charger circuit very efficiently follows the above conditions such that the connected battery is never allowed to exceed its over charge limit.

When the IC 555 is used as a comparator, its pin#2 and pin#6 become effective sensing inputs for detecting the lower and the upper voltage threshold limits depending upon the setting of the relevant presets.

Pin#2 monitors the low voltage threshold level, and triggers the output to a high logic in case the level drops below the set limit.

Conversely, pin#6 monitors the upper voltage threshold and reverts the output to low on detecting a voltage level higher than the set high detection limit.

Basically the upper cut off and lower switch ON actions must be set with the help of the relevant presets satisfying the standard specs of the IC as well as the connected battery.

The preset concerning pin#2 must be set such that the lower limit corresponds to 1/3rd of the Vcc, and similarly preset associated with pin#6 must be set such that the upper cut off limit corresponds to 2/3rd of Vcc, as per the standard rules of the IC 555.

How it Works

The entire functioning of the proposed Li-Ion charger circuit using IC 555 takes place as explained in the following discussion:

Let's Assume a fully discharged li-ion battery (at around 3.4V) is connected at the output of the below shown circuit.

Assuming the lower threshold to be set somewhere above the 3.4V level, pin#2 immediately senses the low voltage situation and pulls the output high at pin#3.

The high at pin#3 activates the transistor which switches ON the input power to the connected battery.

The battery now gradually begins charging.

As soon as the battery reaches full charge (@4.2V), assuming the upper cut off threshold at pin#6 to be set at around 4.2v, the level is sensed at pin#6 which immediately reverts the output to low.

The low output instantly switches off the transistor which means the charging input is now inhibited or cut off to the battery.

The inclusion of a transistor T1 stage provides the facility of charging higher current Li-Ion cells also.

The power supply must be selected with voltage not exceeding 6V, and current rating 1/2th of battery Ah rating.

Circuit Diagram

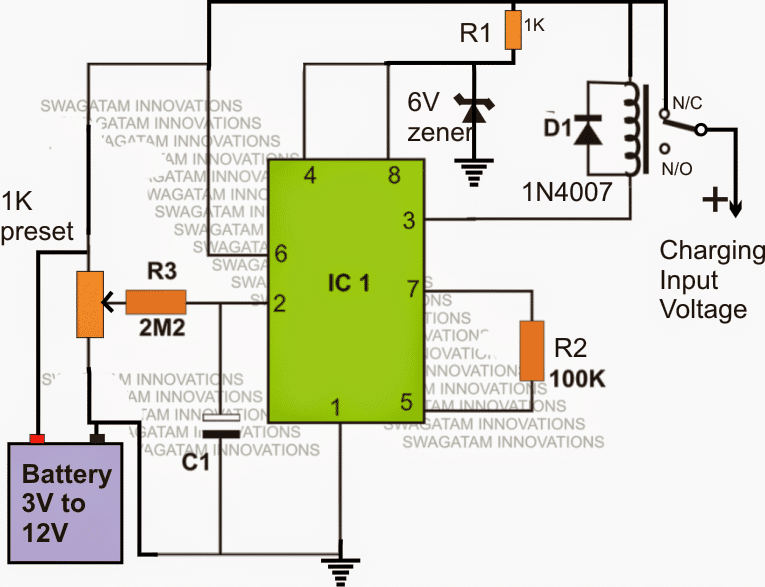

If you feel that the above design is much complex you could try the following design which looks much simpler:

How to Set up the Circuit

Connect a fully charged battery across the shown points and adjust the preset such that the relay just deactivates from N/C to N/O position....do this without connecting any charging DC input to the circuit.

Once this is done you can assume the circuit to be set and usable for an automatic battery supply cut off when fully charged.

During actual charging, make sure the charging input current is always lower than the battery AH rating, meaning if suppose the battery AH is 900mAH, the input should not be more than 500mA.

The battery should be removed as soon as the relay switches OFF to prevent self discharging of the battery via the 1K preset.

IC1 = IC555

All resistors are 1/4 watt CFR

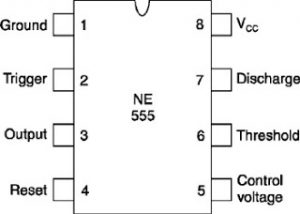

IC 555 Pinout

Conclusion

Although the designs presented above are all technically correct and will perform the tasks as per the proposed specifications, they actually appear as an overkill.

A simple yet effective and safe way to charge a Li-Ion Cell is explained in this post, and this circuit may be applicable to all forms of batteries since it perfectly takes care of two crucial parameters: Constant-Current and full charge auto cut-off. A constant voltage is assumed to be available from the charging source.

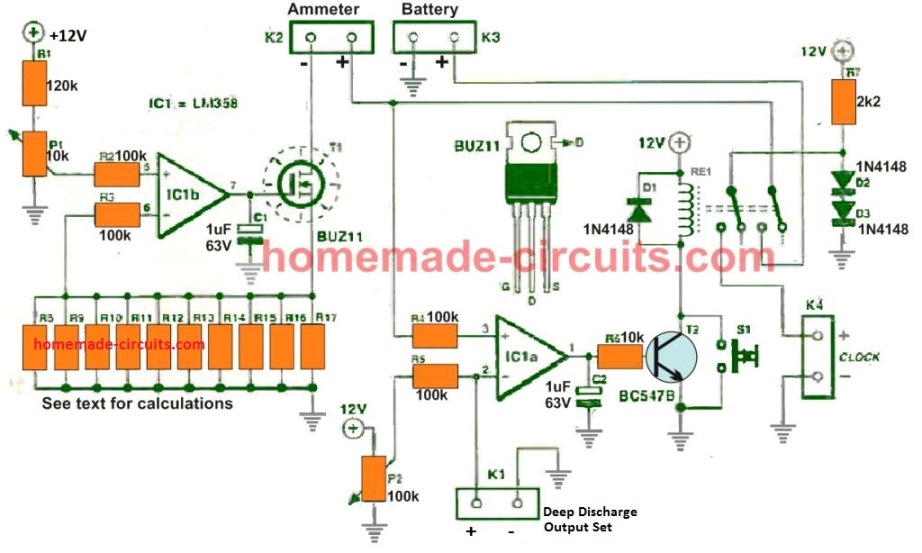

4) Charging Many Li-Ion Batteries

The article explains a simple circuit which can be used for charging at least 25 nos of Li-Ion cells in parallel together quickly, from a single voltage source such as a 12V battery or a 12V solar panel.

The idea was requested by one the keen followers of this blog, let's hear it :

Charging many Li-ion Battery Together

Can you help me design a circuit to charge 25 li-on cell battery (3.7v- 800mA each) at the same time. My power source is from 12v- 50AH battery. Also let me know how many amps of the 12v battery would be drawn with this setup per hour...thanks in advance.

The Design

When it comes to charging, Li-ion cells require more stringent parameters compared to lead acid batteries.

This becomes especially crucial because Li-ion cells tend to generate considerable amount of heat in the course of the charging process, and if this heat generation goes beyond control may lead serious damage to the cell or even a possible explosion.

However one good thing about Li-ion cells is that they can be charged at full 1C rate initially, contrary to lead acid batteries which doesn't allow more than C/5 charging rate.

The above advantage permits Li-ion cells to get charged at 10 times faster rate than the lead acid counter part.

As discussed above, since heat management becomes the crucial issue, if this parameter is appropriately controlled, the rest of the things become pretty simple.

It means we can charge the Li-ion cells at full 1C rate without being bothered about anything as long as we have something which monitors the heat generation from these cells and initiates the necessary corrective measures.

I have tried to implement this by attaching a separate heat sensing circuit which monitors the heat from the cells and regulates the charging current in case the heat starts deviating from safe levels.

Controlling Temperature at 1C Rate is Crucial

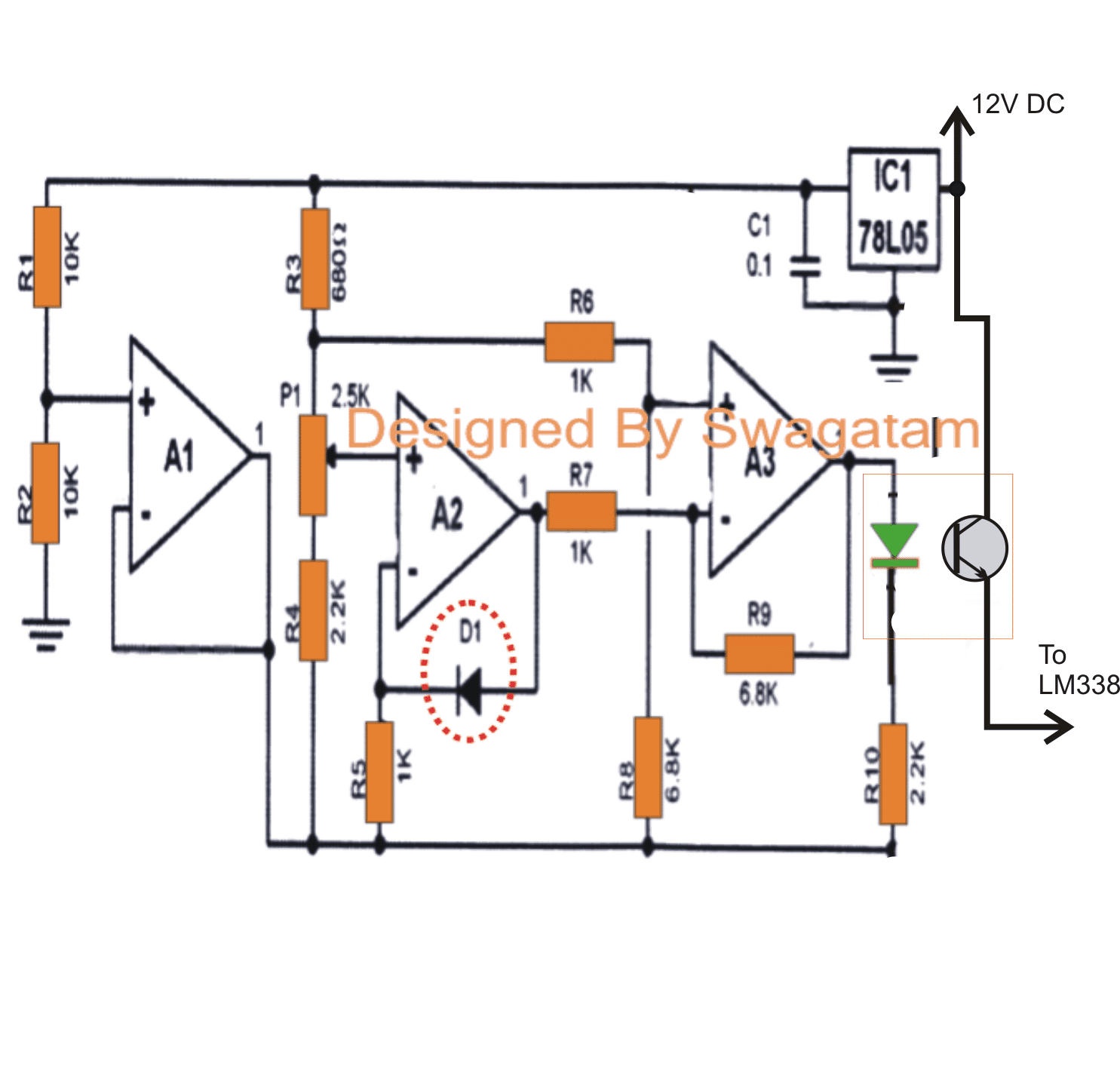

The first circuit diagram below shows a precise temperature sensor circuit using the IC LM324. Three of its opamps have been employed here.

The diode D1 is a 1N4148 which effectively acts as the temperature sensor here. The voltage across this diode drops by 2mV with every degree rise in temperature.

This change in the voltage across D1 prompts A2 to change its output logic, which in turn initiates A3 to gradually increase its output voltage correspondingly.

The output of A3 is connected to an opto coupler LED. As per the setting of P1, A4 output tends to increase in response to the heat from the cell, until eventually the connected LED lights up and the internal transistor of the opto conducts.

When this happens the opto transistor supplies the 12V to the LM338 circuit for initiating the necessary corrective actions.

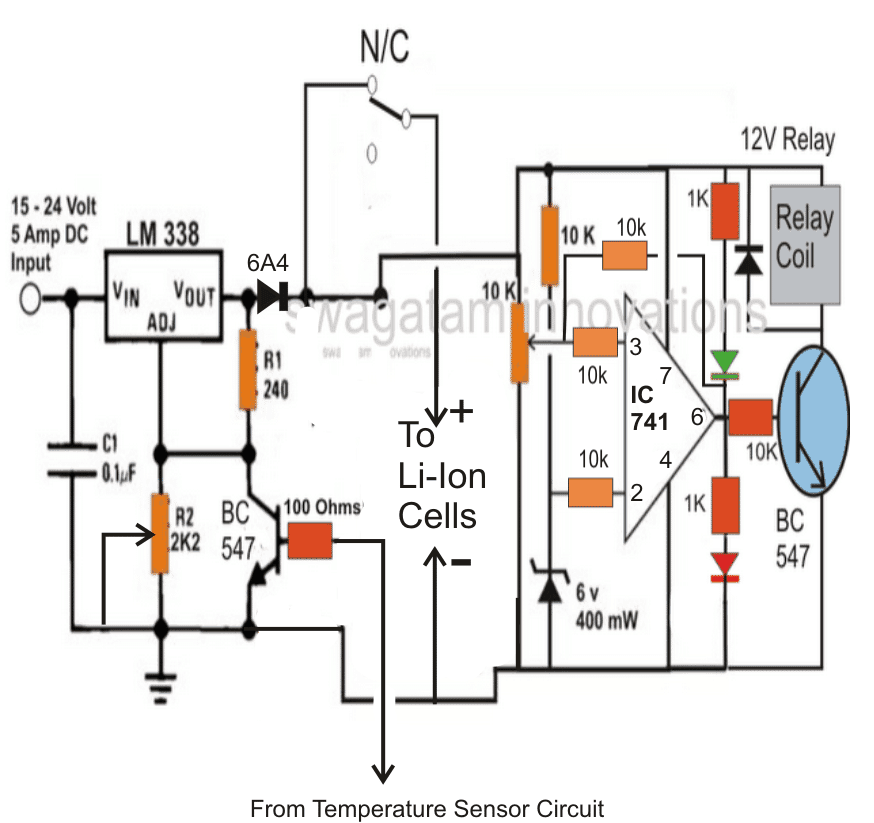

The second circuit shows a simple regulated power supply using the IC LM338. The 2k2 pot is adjusted to produce exactly 4.5V across the connected Li-ion cells.

The preceding IC741 circuit is an over charge cut off circuit which monitors the charge over the cells and disconnects the supply when it reaches above 4.2V.

The BC547 at the left near the ICLM338 is introduced for applying the appropriate corrective actions when the cells begin getting hot.

In case the cells begin getting too hot, the supply from the temperature sensor opto coupler hits the LM338 transistor (BC547), the transistor conducts, and instantly shuts off the LM338 output until the temperature comes down to normal levels, this process continues until the cells get fully charged when the IC 741 activates and disconnects the cells permanently from the source.

In all 25 cells may be connected to this circuit in parallel, each positive line must incorporate a separate diode and a 5 Ohm 1 watt resistor for equal distribution of charge.

The entire cell package should be fixed over a common aluminum platform so that the heat is dissipated over the aluminum plate uniformly.

D1 should be glued appropriately over this aluminum plate so that the dissipated heat is optimally sensed by the sensor D1.

Automatic Li-Ion Cell Charger and Controller Circuit.

Conclusion

- The basic criteria that needs to be maintained for any battery are: charging under convenient temperatures, and cutting off the supply as soon as it reaches the full charge. That's the basic thing you need to follow regardless of the battery type. You can monitor this manually or make it automatic, under both cases your battery will charge safely and have a longer life.

- The charging/discharging current is responsible for the temperature of the battery, if these are too high compared to the ambient temperature then your battery will suffer heavily in the long run.

- Second important factor is never allowing the battery to discharge heavily. Keep restoring the full charge level or keep topping it up whenever possible. This will ensure that the battery never reaches its lower discharge levels.

- If you find it difficult to monitor this manually then you can go for an automatic circuit as described on this page.

Have further doubts? Please let them come through the comment box below 🙂

Comments

HOW CAN I CHARGE A THREE 3.7V BATTERIES IN SERIES(11.1V IN TOTAL) AT 2AMPS

Use a voltage regulator to generate a 10.9V output at 2 amps and use it it to charge your battery…

Hello Swagatam!

It has been a few years since contact Sir. I had been in contact regarding a charging circuit for Li-Ion battery packs some time ago, and you gave me some great information and suggestions. I, however, lost the contact with you prior to coming close to a working circuit. I am so happy to have found you again!

To refresh, I had salvaged a transformer from a microwave oven, removed the secondary winding and was about to rewind the secondary. My original idea was to charge at 20 amp because the capacity of my 5, 4s packs were at 20 amps. You had suggested to charge at 0.5C to avoid heating the cells, and that makes a lot of sense. Well since then, there have been several cells that are no longer charging/holding a charge. Found that my system of use and charging was far from optimal. Have added BCM to each pack and replaced most of the cells with new cells. I was unable to get the same 4000 mAH cells that I originaly started with and opted for 3500 mAH cells. So my 0.5C has gone from 10 Amp to around 8 Amp.

I have rewound the secondary of my transformer with a copper strip 10 mm wide and approximately 0.25 mm thick. The original winding produced around 19 VAC. After my rectification circuit (with 2 Caps and an Inductor coil) the DC outptut was around 25 VDC. So, proceeding, I removed windings of the secondary to get around 17 VDC after rectification. My crude rectifier circuit utilized Schottkey diodes 15SQ045 rated at 45V 675W. Well I have already had 1 pop. So I will replace the 4 Schottkeys with 4 10A10 rectifier diodes that rated at 1000V 10 Amp.

I am still not sure of the Amp output of my transformer. Have done some research, and decided to try to build a load tester (it did not function) that I found online.

I attempted to make a circuit to regulate voltage and amperage… it also did not function. I have read that CVCC is ideal for charging Li-Ion cells. Do you agree with that theory?

I know you are great with helping in these areas, and I would be very grateful for any help you feel to lend.

Thank you,

Bill

Thank you Bill,

Yes, I remember the previous conversation we had about a similar topic, and also about our animal rescue stories :).

The CVCC method is indeed the recommended method for charging all types lithium batteries. Also, if the full charge level is chosen to be the maximum 4.2V per cell threshold, then an auto cut-off also becomes mandatory for these lithium batteries. However if you have a BMS installed with each of the batteries in the battery bank, then there’s no need of any external auto cut offs. But still I would recommend keeping the full charge threshold slightly below the maximum 4.2V per cell threshold, maybe at 4.1V… which ensures that even if a cut-off is not included with the input supply, still the battery would be perfectly safe along with the BMS circuits, and yet be charged optimally. Below given is a simple regulator design which you can try for your charging your Lithium battery pack safely. You can replace the main transistor TIP35 with a MJ11030 to ensure minimum heat dissipation from the transistor. In that case please also replace the 100 ohms base resistor with a 1k/2 watt resistor. The current controller BC547 can be also replaced with a 2N2222. The 3V zener is not necessary, and can be replaced with a direct short. Let me know if you have any further doubts…

https://www.homemade-circuits.com/wp-content/uploads/2022/04/simplest-bench-power-supply.jpg

Hi Swagatam,

Thank you for the circuit! In reviewing it (my understanding of circuits is somewhat limited, as I am still learning) please help me to understand what is happening.

I see it that the AC is rectified by the diode bridge. As mentioned prior, I am not aware of the Amperage output of my transformer. I also understand that the capacitor C1 is for smoothing ripple in the DC output of the rectifier bridge. C1 is at 1000uF 25V. In my rectifier I have set up 2 – 470uF 50V capacitors and an inductor (not sure of the Henry rating). Would the capacitors/inductor I have be sufficient, or should I step up to the recommendation?

From there I see the path direct to T1 (which it seems would be in conjunction with T3, Now would T1 limit voltage, and T3 limit Amperage? I see R1 is high capacity (2 watt) and is in series with T3, which would indicate Amperage control to me.

Then T2 has VR1 10K potentiometer on the gate, which would indicate voltage adjustment to me. Is my perception correct?

Also I would like to aim at 8 A 16.4 V output (0.5C and 4.1V per cell in my 4S packs) I see the voltage indicated to be variable. I there a way to make Amperage variable also, such as another potentiometer added in the circuit?

I know I have a lot of questions, and I thank you for your generosity in answering questions.

Just pondering, I have a 50 Amp battery tester for automotive batteries and a 600 amp meter for automotive. I could use that to test the output of my transformer, yes?

Bill

P.S. Yes, we have conversed about rescue animals. Your efforts are admired here!

Thank you Bill,

Your assumptions are almost correct. Let me explain the revised updated diagram as shown in the following image for the CC/CV Li-ion battery charger circuit. Here VR1 is used to set the output voltage. R3 decides the maximum current range at the output of the circuit. R2 can be used to tweak this maximum current range, to some other lower values, as desired. R1 is the base resistor for biasing the main pass transistor T1, which controls the output voltage as well as the current, with the help of T3 current sensor BJT, and the T2 which is the output feedback voltage controller.

Your 600 amp meter could be too big to sense the current of your transformer, but you can try connecting its terminals directly with the transformer secondary winding wires for a couple of seconds, which will show you the instantaneous max output current capacity of the transformer. Please do this only if the meter is an AC ammeter. Please let me know if you have any further doubts regarding eh circuit….

https://www.homemade-circuits.com/wp-content/uploads/2025/06/regulated-CC-CV-li-ion-battery-charger-circuit-diagram.jpg

Hi Swagatam,

I understand R3 determining the max amp output. The R2 appears to be a variable pot, yet states 1k preset (a little confusing), and that adds resistance in a parallel, yet the variable controls the gate of T3, which feeds more to the output?

And VR1/T2 would be the adjuster for voltage.

My ammeter mentioned is a DC automotive multi meter (designed to measure DC). I do have a multi meter that is suitable for AC amperage, yet the highest range is 10A. I guess the worst that would happen there would be blowing the fuse. What should I use for a load?

Thank you Bill,

R3 should be a preset or a trimpot so that the setting remains fixed and stable. A pot here could be prone to vibrations and its settings may get affected by mechanical disturbances.

R2 lets the base of T3 to adjust the amount of voltage it gets from the total voltage drop across R3, thereby fixing the turn ON threshold of T3, and the max output current cut-off range.

Yes, VR1 adjusts the output voltage.

You can try the 10 amp ammeter with a fuse, and also with a known load such as a bulb, or motor in series with the transformer:

https://www.homemade-circuits.com/shunt-resistor-calculator-for-ammeters/

Hello dear Swagatam,

First of all, thank you for your hard work. Every time I had a question, you guided me, and I truly appreciate it.

I have a few questions, and I’d be really grateful if you could explain them.

I have a 14.4V Makita cordless drill (American model) with a 2.2Ah nickel-metal hydride (NiMH) battery, which has now become very weak. I want to replace the internal cells and convert them to lithium-ion.

My questions are:

1. If I convert it to lithium-ion, can I still use the original charger for charging? If not, why? Is there any way to modify or hack it to work?

2. How many lithium-ion batteries do I need, and what type would be best for improving its performance?

I haven’t been able to find the original battery anywhere, and all available ones are 2Ah nickel-cadmium (NiCd), while my current one is nickel-metal hydride (NiMH) and has lasted over ten years.

Would it be better to buy a 2Ah NiCd battery, or should I convert it to lithium-ion?

And finally, if I convert it to lithium-ion and need a new charger, which circuit would be suitable for me?

Thank you very much. I wish you continued s

uccess and happiness!

Thank you John, for your detailed question.

You can replace the NiMH batteries with Li-Ion battery and use your existing NiMH charger with some external modifications.

You can add a constant current, constant voltage regulator at the output of the charger.

The current could be controlled at 1 ampere and the voltage can be restricted at 16V, fixed.

You can use 18650 Li-ion batteries, 4 in series.

Since we are restricting the maximum charging voltage of each Li-ion cell to around 4V, instead of applying the full charge level of 4.2V, so an automatic cut-off feature may not be required.

It might take around 4 to 5 hours for the battery to reach 16V level, with 1 amp charging current.

NiCd battery will not work because its charging/discharging rate is very low compared to NiMH or Li-in batteries.

Sir, I am thinking about to make a led string light which I want to operate on 3.7volt li-ion battery led are arranged in parallel and a fairy light and battery that I want to pack in a small plastic case then please suggest me a circuit which is so compact and tiny that I pack it to charge battery in little case. I’ll obliged to you

Ashu, you can try the first circuit from the following article:

https://www.homemade-circuits.com/make-yourself-simple-led-flasher-at/

Please comment under the above article for any further questions.

Hello: In plan number 1 🙁 Simplest Li-Ion Charger using a single MOSFET), the explanation given does not match the diagram shown!Thank you.

Thank you, please check it now!!

Hello, for the circuit with the LM317, can you please explain how did you calculate the resistance of each resistor and also why did you choose a 3V zener diode. thank you.

Hi, you can use the following software to calculate the Lm317 output voltage:

https://www.homemade-circuits.com/lm317-lm338-lm396-calculator-software/

3V zener was selected so that the SCR can never be triggered for any voltage below 3V.

0.8 ohm resistor decides the max charging current for the battery, using Ohms law.

so with R1 as 240ohms and R2 as 700ohms, the calculator shows an output voltage of 4.9V. How did you come to the conclusion that the battery required this voltage to charge? also what is the charging current in this case?

The maximum voltage is set at 4.9V, but the cut off must be set at 4.1V using the preset.

Charging current is

I = V/R = 4.1 / 0.8 = 5 amps approx.

5 amp is the max range, you can reduce it by increasing the 0.8 ohm resistor vaalue.

Thank you for your reply. Now if i want to calculate the exact resistance of the 1k resistor without having to manually adjust it until i the SCR turns on, how can i do the calculation? what is the exact value of the resistance required? Thank you

The SCR circuit can be difficult to setup and I won’t recommend this circuit, because there are much easier and effective alternatives.

You can try the second circuit instead, with current control.

You can replace the MOSFET with a TIP122 transistor, and set the preset to an exact 4.1V output.

It will charge your 3.7V li-ion battery safely and effectively upto 4.1V, providing an 85% to 90% charging.

Got it, however i am trying to understand the SCR circuit properly, and i am confused as to why do you have two 1K resistors, why can’t you have just one variable resistor and remove the other 1K, does that work?

If you have only the variable resistor, and if you accidentally move it to the extreme positive end, then your LED and SCR both can get damaged, that is why the other 1k is positioned, to safeguard against this situation.

Thank you very much for your replies. very helpful. just one last question. why is the 1K resistor being used as a COM? if this entire circuit is connected to a full bridge rectifier that converts AC to DC for power supply of this circuit, and the full bridge rectifier is already grounded, do i need the COM in the battery charging circuit or should it also be grounded?

You are welcome!

Can you please specify which 1k you are referring to?

I did not understand what you meant by “1K resistor being used as a COM?”

Please elaborate on this..

There’s no grounding needed in any DC circuit, the negative line from the bridge-rectifier itself refers to the ground line.

so in the circuit that has the BT169 SCR, at the very bottom there is a 1K resistor, and there is an arrow pointing downwards at it, i assumed this arrow is a COM. Can you explain what is meant by that arrow if it is not a COM?

The arrow refers to the middle wiper arm of the preset or the trimpot.

oh okay i got confused by this, thank you for clarifying. so the other 1k resistor that is closer to the LED, is that also a variable resistor or a regular 1k resistor? in short, how many variable resistors does this circuit have?

There’s only one variable resistor, the other 1k is a regular resistor.

I have simplified the design, you can check it in the following link. I have put the 0.8 ohm resistor on the positive line, which makes more sense:

https://www.homemade-circuits.com/wp-content/uploads/2024/05/li-ion-charger-with-scr.jpg

Good Evening swagatam & Thankyou for Ur circuit diagrams but I have doubt in 4th number can u help me, I want to build CCCV charger for Lithium-ion battery 4S3P So what modification needed in 4th number circuit for it. I want to build online UPS using lithium ion battery of200w so can u help me for this. I hope u reply me & give solution for it, Thanks in advance

Hi Pankaj,

The 4rth circuit will not be able to implement a balanced charging, since it is not a balance charger. However a balance charger is mostly not needed if the series/parallel batteries are rated with precisely identical specifications.

Also, if you charge the li-ion battery at 0.5C rate the temperature monitor circuit will not be required.

Also, if you keep the full charge level of the charger at 1V lower than the actual full charge level of the battery, then an auto-cut off will not be needed.

So basically, the 4rth circuit is unnecessarily complex, you can actually charge your batteries effectively and safely using any simple CC CV voltage regulator circuit.

Please let me know if you want to try one such regulator circuit for charging your battery

Yes I want to try this circuit for my project can u help me for building CC CV charger I need this type of charger, Thank you in advance ??

OK, here’s the regulator circuit which you can use to charge your Li-ion battery:

https://www.homemade-circuits.com/wp-content/uploads/2024/02/CC-CV-li-ion-charger-circuit.jpg

For 4S Li-ion battery the optimal safe maximum voltage range should be around 16.2V (4.1 x 4), so before connecting the battery make sure to adjust the VR1 to precisely 16.2V across the output terminals of the circuit. This takes care of the constant voltage adjustment.

Please tell me the mAh rating of the battery so that I can tell you how to calculate the R2 value for implementing the constant current output.

3.7V/ 2000mah or 2600mah lithium ion cell each cell I am using 4Series 3 parallel/4 parallel plz help me to design CC CV charger for my project

In the previous diagram the value of R2 can be 1.3 / 0.6 = 2 ohms 1 watt. The input supply can be from any 20V DC adapter with a minimum current of 2 amps.

Can this diagram work with CC CV mode? I have some doubts on the above circuit why there 3v Zener diode used?

It is a CV CC circuit, 3V decides the minimum output voltage, if you don’t want it you can replace it with a short.

Sir I want to design 3.7×4=14.8v nominal voltage lithium ion battery charger & sir how 3V decides minimum output voltage. Plz help regarding this, I am finding solution from 2 months

3V is the minimum setting, you can use VR1 to set the maximum voltage to 4.1 x 4 = 16.4V or 16.2V, please read the instructions which I provided with the previous link.

Li-Ion Battery Charger Circuit Using IC 555 will not work as the BD139 will never turn on!The earth to the 5v regulator and the 555 IC are both on the collector side of transistor!

The power supply earth is on the emitter of the transistor, so never the two will meet unless the transistor is turned on from the 555 IC which is without power!

Thank you for pointing out the mistake! I will try to correct the circuit soon using a PNP approach instead of the NPN.

OK, I have replaced the diagram with a new one using PNP transistor.

Hi Swagatam,

In the circuit using the SCR can I charge 2 3.7V Batteries of 1000mAH each connected in parallel (to achieve 2000mAH)?

Hi Nelio,

the SCR circuit is not confirmed practically so i cannot suggest much about that circuit.

Frankly speaking you can charge a Li-Ion battery most efficiently using a an LM317 or LM338 circuit, there’s no need of an auto cut off. You simply have to set the maximum output voltage to 4.1V and use a constant current control in it. That’s all is needed.

If you need an auto cut off then I would recommend using an op amp circuit for that.

Hi Swagatam,

Won’t there be any danger of the batteries be constantly under charge without the auto cut off?

To use a circuit with op amp, will require more space than there is available.

Hi Nelio,

A Li-Ion battery can overcharge once it reaches the 4.2V mark. But since we are keeping the LM338 output fixed at 4.1V only, it can never reach an overcharging situation. Keeping the max charging voltage 0.1V less will also help to enhance battery life.

At 4.1V the Li-ion battery can remain connected to the charger without any fear of over charging.

Hi Swagatam, a resistor of 700 Ohm will be dificult, eaven in 1%. Does it has to be that value?

Hi Nelio, You can adjust the values of the 240 ohm and 700 ohm resistors using the following software, and find the appropriate values which may be available in the market.

https://www.homemade-circuits.com/lm317-lm338-lm396-calculator-software/

Hi Swagatam, in the circuit with SCR, I assume the LED will light during charging, and after completion will turn off, since there will be no current at the gate of the SCR, correct?

Hi Nelio,

The LED will remain shut off until the battery voltage reaches the full charge threshold, when the current through the LED will trigger ON the SCR. you are right the LED cannot get current once the SCR is switched ON. That means the LED will remain shut off all the time. It is merely used as a voltage dropper for the SCR gate.

I am looking for a discharge, then charge circuit for Lithium-Ion 24-28vdc pack. So, each pack consists of 6 cells. Our float voltage is around 28vdc. Presently we discharge, disconnect and connect to a charging system. We charge at about 1 amp.

I would recommend you following circuit, just make sure to replace the LM317 with an LM338 IC.

https://www.homemade-circuits.com/wp-content/uploads/2019/07/Li-ion-charger-LM317.jpg

You can set the output voltage to the battery at 27.5 V using the 4k7 pot and current to 1 amp using the RC resistor.

For enhanced safety you can add individual over charge battery protection circuitry to each of the cells