In this article I have explained a couple of inverter circuits featuring an automatic feedback control for ensuring that the output does not exceed the normal specified AC output level, and also does not exceed the specified overload conditions.

What is Feedback Control in Inverters

A feedback control in inverter is generally incorporated to control the output voltage and output current and prevent it from exceeding beyond dangerous limits.

In this system, the output AC mains voltage is first dropped to a proportionately lower level, and fed to the shut down pin of the control IC. The stepped down feedback voltage now follows the output AC and varies up/down accordingly, in a proportionate manner.

The control ICs shut down circuitry comares and monitors this feedback signal with a fixed ference derived from the battery volatge of the inverter.

In an event that the output voltage tends to rise above the predetermined value, and increase beyond the reference level, it activates the error amplifier, which shuts down the inverter output PWM. Once this happens, the output voltage instantly dips, causing the feedback signal to decrease below the reference value. This situation prompts the shut down feature of the IC to get disabled, and the IC starts working normally again.

If the output yet again tries to rise beyond the unsafe level, the above process is repeated in the identical manner, and this goes on continuously and rapidly, ensuring that the output voltage is never allowed to surpass the specified unsafe level.

Feedback Control in SG2524/SG3524/SG3525 Inverters

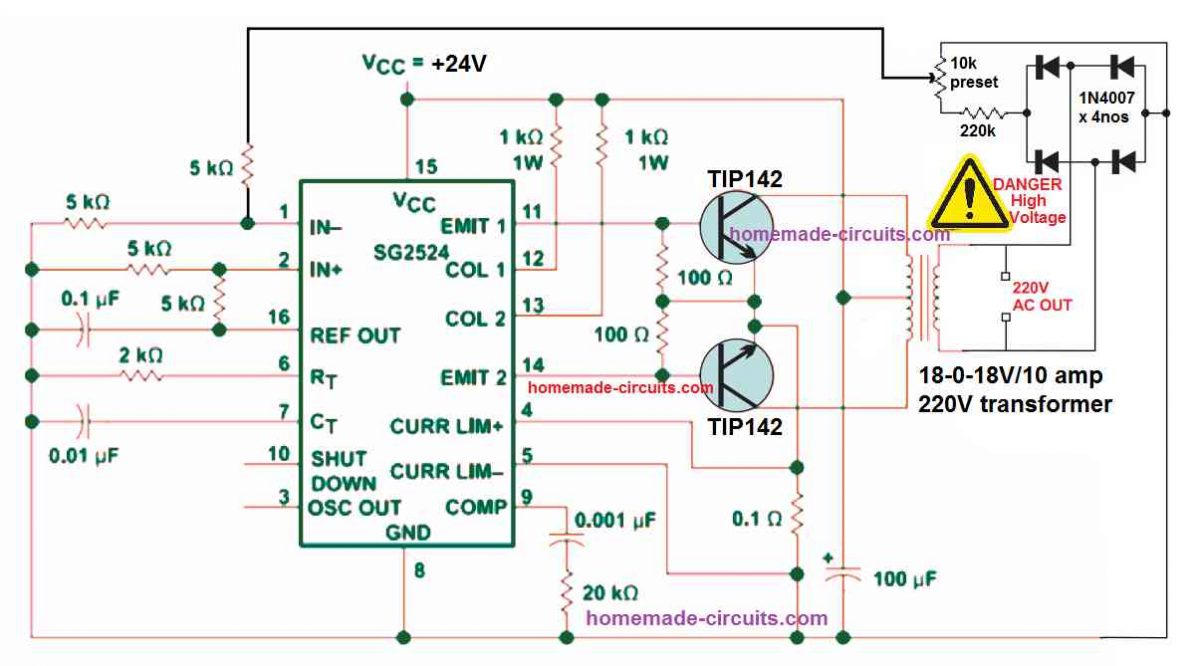

The first example circuit belw shows how an automatic feedback control can be added to a SG2524 inverter circuit. The same concept can be also applied to all the other inverter versions, using the IC SG3524, and SG3525.

You can refer to the following two datasheets for exactly knowing how the pinouts of the IC SG2524 IC are designed to function:

The feedback control loop is configured in the following can be understood with the following points:

The 220V AC output is first rectified using a 4 diode bridge rectifier circuit.

The rectified high voltage DC is dropped to a lower DC level, at around 5V to 10V through the voltage divider network built using the 220K resistors and the 10K preset.

The 10K preset is used to adjust the feedback voltage until the output voltage is controlled just at the right level.

The feedback is taken from the 10K preset's center arm and fed to the error amplifier's non-inverting input pin#1 of the IC 2524.

This error amplifier is nothing but an opamp set internal to the IC for controlling the PWM of the output pin#11 and Pin#14.

The inverting or the (+) input pin#2 of the op amp is clamped at a fixed reference level of +2.5V through the couple of voltage divider resistors configured around the pin#2 and pin#16 of the IC. The +5V reference potential is derived from pin#16 of the IC and then dropped to 2.5V using the two voltage divider resisters.

Since the pin#2 of the error amplifier is fixed at 2.5V reference, means that if the pin#1 of the opamp rises above the 2.5V level would instantly trigger the PWM feature of the IC, causing narrowing of the output PWM to the transistors.

The feedback 10k preset is adjusted in a such a way that feedback voltage at pin#1 reaches the 2.6 V mark as soon as the output voltage reaches the specified unsafe high voltage level.

In such situations, when the pin#1 receives a 2.6 V, it will cause the internal error amp to activate, narrowing the output PWMs to the transistors, which will in turn cause the output voltage to reduce to the safe lower levels, appropriately.

Adding Feedback in IC 555 Inverter

You might have already gone through the post which explains how to build simple 555 based inverters.

Although all these inverters are decently designed and will produce the intended 220 V or 120 V from an easy IC 555 set up, these do not have a built-in feedback system for ensuring a constant output voltage.

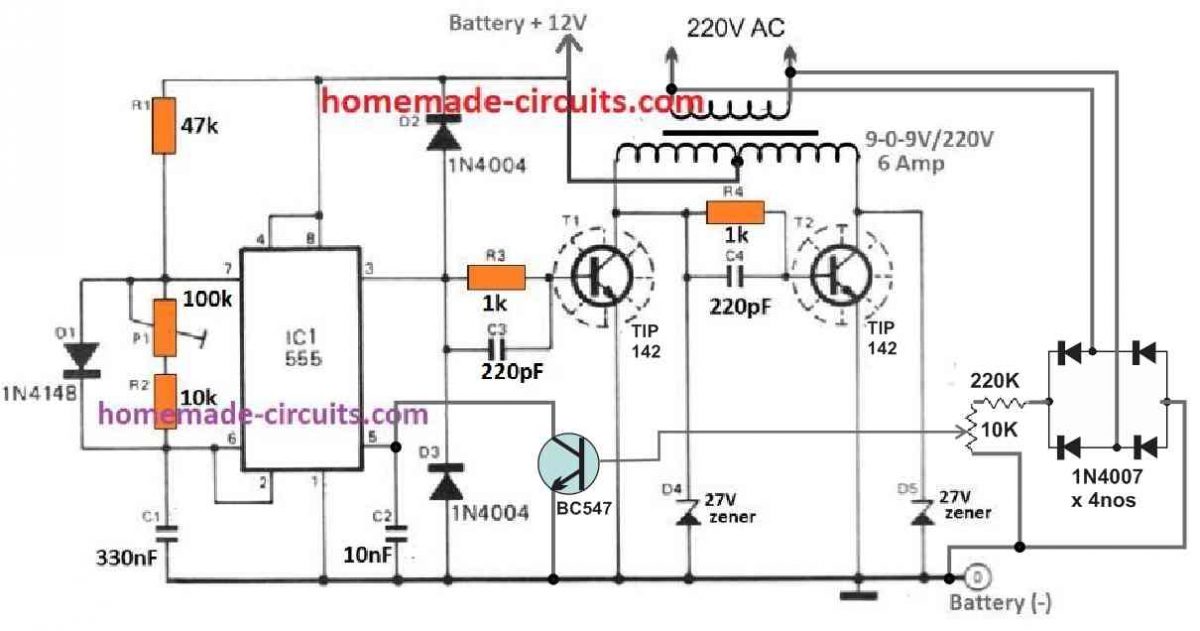

The following figure shows how an ordinary IC 555 inverter could be transformed into an enhanced inverter through an easy feedback loop control network.

In this circuit also, we find that the 220V output from the transformer is first rectified to a DC level, and then it is stepped down through a resistive network comprising of a 220K resistor and a 10k preset.

The 10k preset center lead is configured with the NPN transistor BC547, whose collector can be seen connected with the pin#5 of the IC which is control input of the IC.

We know that normally when pin#5 is open, the PWM at the output pin#3 of the IC has a maximum PWM, however, as the potential at pin#5 is reduced, the output PWM also gets reduced proportionately.

Grounding the pin#5 causes the output PWM at pin#3 to become very narrow, with almost zero average voltage at this pinout.

In the IC 555 feedback circuit, when the output voltage tends to rise above the unsafe high voltage threshold, as per the setting of the 10k preset, the base of the BC547 slowly starts getting biased. When this happens, the BC547 begins conducting and causes the pin#5 of the IC to get gradually grounded. The grounding of the pin#5 of the IC causes the output PWM at pin#3 to get narrower, which in turns causes the output voltage to drop to the normal levels.

Comments

is it possible to achieve overload and shortcircuit protection using current transformer and op-amp in an inverter? If yes please help with a circuit diagram

Sure….Please refer to the following article:

https://www.homemade-circuits.com/load-current-control-through-current-sensing-transformer/

Swatan.. I don’t know where to ask,,, I would like a circuit to make an inverted welder of at least 120 Amp to 250 Amp, I have type E ferrite cores from televisions, also the circular or round ones from vehicle audio amplifiers,,, but I need a diagram if possible checked

Hi, a TV ferrite core or an audio amplifier ferrite core will not be able to produce 200 amp current.

Unfortunately, I do not seem to have sufficient information about the details of this transformer at the moment..

Good sir. I have a problem with my sg3524 circuit.

I built this inverter with feedback voltage correction circuitry but when power it, its actually working is giving out 220v as i set it but while working the mosfet is extremely hot. I try everything i could but could not rectify the problem but when ever i remove the feedback topology and return it back to the normal switching circuitry, it doesn’t hot at all but am not ok with the output as soon i inserted a load to it. It will drop from 220 to 140v.

I actually use 7.2v center tap transformer.

Hello Abdul,

Please add a snubber network across the MOSFETs as discussed in the following article, and also add a reverse diode across the gate resistors of the MOSFETs, and add a 10k resistor between gate and source of the MOSFETs, and check the results:

https://www.homemade-circuits.com/explained-snubber-circuit-for-mosfet-h-bridge/

https://www.homemade-circuits.com/rc-snubber-calculator-for-mosfets-relay-contacts-and-triacs/

https://www.homemade-circuits.com/mosfet-protection-basics-explained-is/

swatan,,,, pregunto si tendrías algún circuito que pueda hacer para un soldador tipo invertir, para hacer si me das un esquema y detalles lo haré soy experto en electrónica..

Felix, I have answered to your question previously, but no problem I will answer it again.

Designing Inverter type welding circuit is possible, but 250 amps is huge, I have no idea which ferrite core would be required for such high current application.

https://drive.google.com/file/d/1HJ1BjVdX1m5d9tyioweUeXkwcNFR9wXL/view?usp=drivesdk

this is what i finally did,the feedback is working,but there is catch under capacitive load the output increases e.g phone charger, capacitor etc.,but if I put a 40w resistive load (incandescent bulb) and then plug any capacitive load it remains stable and don’t increase, pls what is the cause?,apart from this it is working fine my MosFets are not getting warm too quickly.i also want to add battery low circuit and fuse pls any idea?sport for so many resend I don’t know if you will see this one.

Capacitive loads like phone chargers or plain capacitors mostly pull reactive power, not real power. Because of this, the inverter thinks there is not much load so voltage can rise or go unstable, mostly if the feedback is not properly designed. Now when you connect a resistive load like a bulb, it pulls real power continuously so inverter starts regulating voltage properly. After that even if you add capacitive loads, still the voltage stays stable because real load keeps things balanced.

So you can try adding a 1k resistor at the output and check the results…

that is the issue if am going to use a resistor for the real load then I should be prepared for how to reduce the heat it is going to generate,pls what should I do about that?,also if am to use 1k pls what Watt should I use?and can even get it here cause it is not available.

Instead of a resistive method, please try connecting a 10uF capacitor across the output of the bridge rectifier and check the results.

By the way your MOSFET driver section looks bad…you must use the methods which I had suggested earlier.

can 30uf/450v Ac capacitor and AC circuit breaker be used to stabilize inverter output voltage?

Please show me the circuit diagram, I will try to figure it out….

https://drive.google.com/file/d/1sDAfqSz0v9xgZB20mmUiM3PCMeF3gXIt/view?usp=drivesdk

what will happen if you remove the 10k resistor from the oscillator pin ,with it affect the performance,cause when I want to add the totem pole driver I remove mine and my inverter was misbehave was it responsible for that?

Whether or not you connect a 10k between the oscillator output and ground does not make any difference, and will not have not any kind of effect on the inverter performance.

sir, when I implemented circuit 1 into my oscillator,it worked, but then my feedback was affected,my inverter started Misbehaving the output was no longer stable again.was could be the cause?also my inverter is sensitive to capacitor at it output or even at feedback so what could be the cause?

Jerry, please do not associate any capacitor with the feedback network, however connecting a capacitor at the output of the inverter should not affect the inverter performance. Make sure the capacitor is a non-polar PPC or MKT type such a 2.2uF/400V PPC etc. Moreover you need this capacitor mostly when you are using a modified PWM or SPWM sinewave inverters topologies, otherwise it is not required.

good evening, sir. happy new year. it been a while like a year since I work on my diy inverter, since am in school, but few day ago, while reading a course called power electronics, where I was drawing the waveform of bridge rectifier, I realized I never understood them cause I used ur circuit to design my feedback circuit for my diy inveter although the oscillator circuit is different, the issues was I always thought that the anode if a diode is the positive terminal and cathode for gnd, this was the idea I had while designing the feedback for my diy inverter, I mentioned earlier that when I implemented it at first it work even with capacitive load, after neating and coupling the inverter it misbehaved, this use due to me connecting my positive of my feedback voltage to gnd and negative or gnd through the voltage divider to pin 1, I never released this till after a year, I tried my best to find the issues, till I don’t even remember what I did that made the while system work with the feedback, but still misbehaves with capacitive load, although after my exam if I go home I would open everything and inspect what I did, cause hmmm, until after a year that I realized how bridge rectifier works, and the anode of the diode will be your ground, I pray I don’t just chastise myself when I see all my connection in the inverter. about the driver I will fix them using 4 npn transistor(the second method you show me), am also thinking of rebuild the whole osillator surcuit using your circuit entirely, that will be for maybe a second inverter and lastly thanks for all the help and advice it really helped, alot!!. the website update is nice also👌👌.

pardon me if you see this message more than once, I don’t even know if it is sent or not, that is the reason for the multiple resend

I would like to add that a thought came to me, that I can utilize your transistor driver which drine the primary winding directly, but instead used it to drive the gate of a mosfet instead, is this also ok?

Thank you Jerry for your kind and honest feedback…I appreciate it very much.

If you want to use a BJT driver for the MOSFET gates then make they are two of them connected in inverting mode, or in a totem pole mode.

what I was trying to say is that before I implemented the totem pole driver I already added feedback and it is working,when I power capacitive load with it it handles them also,but I noticed my mosfet got warm to quickly that is why I added the totem pole driver and on doing that the my inverter output stated misbehaving it was not stable going from 100v to 200v to and fro,but yesterday I added those 2 10k I mentioned to gnd and then I was able to finetune my feedback,but I added capacitive load and all of a sudden the voltage started fluctuating again,pls what is happening? thanks for your effort on me.

Then I think you should remove the totem pole and try the other driver configuration which I had suggested you using two NPN transistors. Make sure to connect each and every resistor correctly, otherwise it will not work:

https://www.homemade-circuits.com/wp-content/uploads/2017/04/arduino.jpg

when I return my circuit to old no (totem pole driver) ,I was able to retune my feedback again and capacitor no longer disturb it ouput,so pls what went wrong that if I add the totem pole is disturb my feedback?,cause I remove a 10k resistor from pin11 to gnd and another 10k from pin 14 to gnd.

Using totem pole for the MOSFETs should have no effect on the performance of the inverter, in fact it might only improve…

Since you have used the feedback with pin#10 of the IC so again no problems with that.

You can try connecting a 10k directly between the gate and source of the MOSFETs and check the response…

https://drive.google.com/file/d/1JLNH2vQWX9U98APID09i_wgj8zC9WCYZ/view?usp=drivesdk

pls sir is it ok to add a 10k resistor to the mosfet like this?

The resistor between the emitter and ground of the totem pole BJTs is not required, instead you can connect the 10k directly between the gate and source of the MOSFETs.

I have 4 MOSFETs in Parallel with each other and another 4 parallel MOSFETs for driving my transformer,the thing if I am to add the resistor from gate to source I will need to do that for all of my MOSFETs,and I already the mosfet,to add the resistor will the somehow stressful,the thing is the 10k resistor is already connected to MOSFET like this for each side of transformer and only one 10k was used for each side.

For connecting MOSFETs in parallel, just join their 3 relevant pins together, in parallel…

Good evening sir I actually implemented the feedback and it’s worked but lasted for like maybe 30 minutes this is the things sir the circuit I actually use was still my old oscillator circuit what I just did was use another external transformer and I try to use a voltage divider to implement the feedback but this is the thing when I tested it at first and it worked there was no voltage drop but when I realize that my battery was low ,I went to charge it but on retesting it again the inverter started to misbehave(output got to above 300v ,so I’ve been trying to figure out the issue that I was wrong with it,but my thought is maybe my voltage divider somehow is not right or my total feedback voltage(6v DC) was too low,I just want to ask that what could be the cause of this? I implemented the feedback it worked I captured the testing on camera and then on coupling the inverter and retesting after I recharge my battery,the inverter started misbehaving.

Hello Jerry,

Please provide me with the following details, I will try to figure out the issue.

1) Battery Ah value

2) Transformer voltages and wattage or current specifications.

3) Load wattage which is causing the voltage drop.

4) Battery voltage value at the time when the inverter output voltage is dropping.

For adjusting the feedback, you can simply do it by connecting an AC voltmeter to the output of the inverter transformer and then adjust the feedback preset until the output voltage settles down to the correct required output voltage level…

good morning,I have successfully implemented the feedback now and it is working,the issue before was the if I add capacitor for filtering either the output or feedback voltage the inverter misbehave so I remove all capacitor except from the oscillator circuit and it worked I added snubber circuit to the output though.now I have another question I noticed my MOSFETs warms up quickly when my feedback is now working,is it because I did not use a transistor at pin 11 and pin 14 like to function as a MOSFETs driver?,cause I have I seen two YouTuber did it but never explained why.

Hi, I am glad you could solve the problem so fast.

A driver transistor may be required for a MOSFET if the load is a high current load, otherwise not.

So for small inverters below 200 watt, driver transistor may not be required.

Just make sure to use gate resistors of small value, and put reverse diodes across these resistors.

good morning,pls do you have the schematic for the this so I can follow it?

Hi, you can try the arrangement as done in the following concept:

https://www.homemade-circuits.com/wp-content/uploads/2017/04/arduino.jpg

https://drive.google.com/file/d/1g1A6ua4Bw9Fxl_I96uJ_gGRwwCDPNap6/view?usp=drivesdk

what about this?

You can access it now,sir

but,sir I already bought component for circuit 1

No problem Jerry, You can use circuit 1 also, it will also work fine.

It is telling me to request access, please check your email ID.

my MOSFETs already has a 10k resistor from it source joined to another 10ohm resistor that goes to it gate and the junction where the two resistor joins together is where the Signal is sent to,so is the resistor connection not discharge?

https://www.homemade-circuits.com/wp-content/uploads/2025/04/mosfet-gate-discharge.jpg

The gate current from 10 ohm has to pass through the high resistances of 10k and the 1k to reach ground for discharging, which is not good. The 10ohm end must have direct access to ground during the off periods of the oscillator output.

Please use one of the two configurations which I showed you previously.

It is not opening…please get the link in the “shared” mode..

https://drive.google.com/file/d/1y_k110TcAp0FD7MXUTDEkyjjEcE14hvS/view?usp=drivesdk

which is more efficient among the two sir you gaver sir?,pls sir is there any component am missing out?

Both the designs are good, but the bottom one is better since it connects the MOSFETs gates directly to ground during the off switching periods. Your second design had a few mistakes, i have corrected them now:

https://www.homemade-circuits.com/wp-content/uploads/2025/04/mosfet-drivers.jpg

it is working now sir.

Yes, now I can see the diagram, but your concept is not very efficient, because discharging the MOSFET gate through the 1k can be slow and dangerous for the MOSFETs. Instead you can use a totem pole design, as given in the 2nd diagram below.

https://www.homemade-circuits.com/wp-content/uploads/2025/04/mosfet-driver.jpg

https://www.homemade-circuits.com/wp-content/uploads/2023/10/the-right-way-to-interface-SPWM-with-inverter-MOSFETs.jpg

I also want to ask what should be the maximum feedback voltage I mean when you rectify your AC I got sending it through your voltage divider what should be the maximum voltage is it that my maximum feedback voltage should be around 5 volts before it gets to the feedback I tried voltage divider

ok sir, thanks you sir.

It is correct and will work….

https://320volt.com/wp-content/uploads/2012/12/pwm-12vdc-220vac-150w-invertor-semalar-circuits.gif

will this work pls???