Triacs are one of the most important active electronic components which are exclusively used for power switching applications, these devices are especially suited to AC mains loads, and are able to switch large currents consistently.

Triacs are the solid state replacements to mechanical relays, and come configured as static relays.

The modern triacs today are highly sophisticated with their specifications and make, one such example is the BTA41, 600B, I have explained its technical specification and datasheet from the following points:

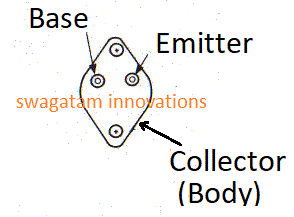

Identifying Print Value of BTA41/600B

- BT indicates series number,

- "A" represents that the device is insulated, while B would mean non-insulated. The insulation is provided on the Tab of the device upto 2500 volts.

- 41 = 4 and "one" zero, that equals 40 Amps

- 600 is the voltage handling capacity, therefore here it's 600 volts.

- B represents the triggering sensitivity that's 50mA in this case

- Absolute Maximum Rating (at around 25 to 40 degrees Celsius)

- RMS, continuous current handling capacity = 40 Amps

- Non repetitive peak current = 400 Amp, only for max 20ms.

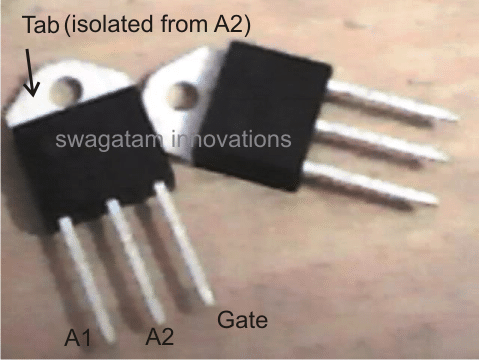

How to Connect

The pinouts are connected just as we connect other normal triacs. I have explained them yet again:

A1 should be always connected to ground. The ground doesn't have to be necessarily the neutral of the AC, it can be any one wire out of the two mains input.

The other wire will go to one of the load terminals, while the second wire of the load will go to A2 of the triac.

The gate should be connected with the desired trigger input which must be a DC, because the triac will conduct with every rising positive edge of the DC trigger.

Here the minimum triggering gate current is 50 mA.

A1 should be made common with one of the AC terminals as well as the ground of the DC trigger circuit, in case an external triggering circuit is incorporated.

Application Notes

As suggested in the above sections, the triac BTA41/600B is best suitable for applications concerning control of AC loads such heater coils, high power halogen lamps, AC motor pumps or simply motors such as in dryers, blowers and so forth.

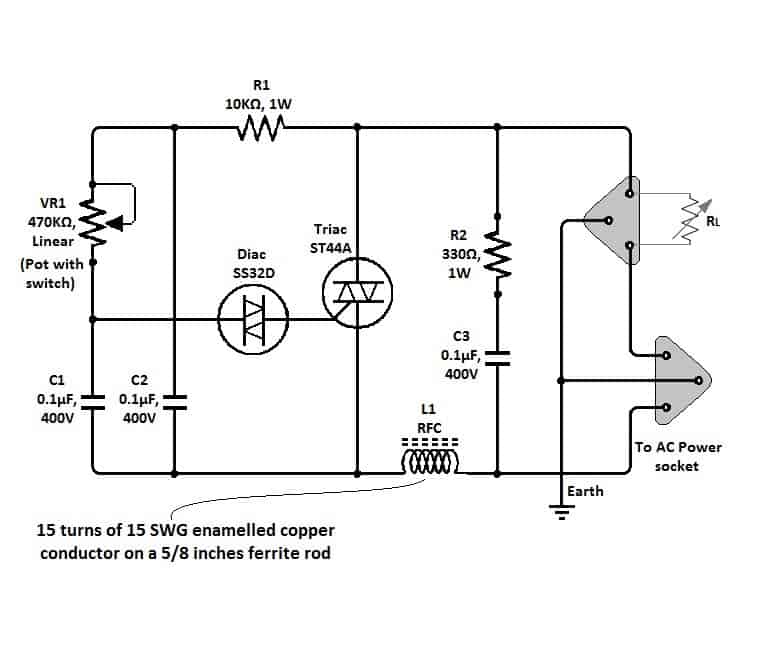

The following circuit illustrates how the device may be utilized for controlling heater coils such as in furnaces, induction cookers etc.

The above circuit can also be used for controlling AC motor speeds simply by replacing the heater coil with the motor wires.

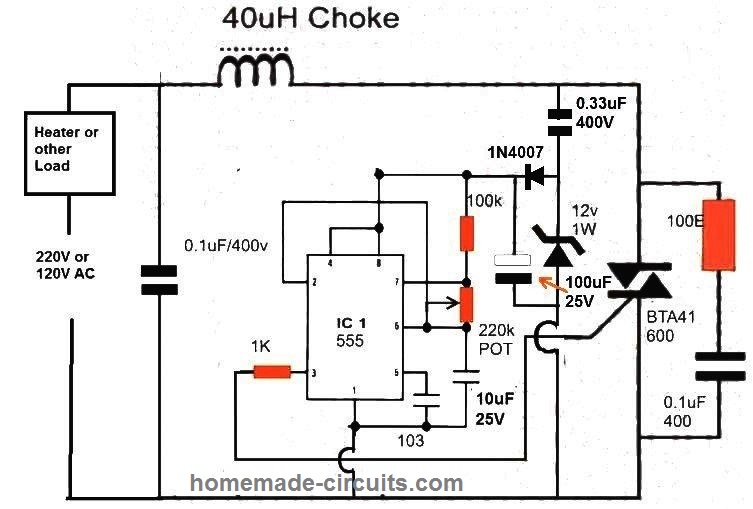

The adjoining diagram depicts another application of BTA41/600 where it has been configured as a PWM assisted AC motor controller or even heater coils.

WARNING: The above circuits are not isolated from mains AC, and therefore are extremely dangerous to touch in open and powered condition.

Comments

Hello sir. Can I make without inductor. I mean only triac, diac, capacitor, resistor. Potentiometer.

Hi Sakib,

yes you can skip the 40uH coil and the left side 0.1uF capacitor, and still get the intended results, however without the LC network, the circuit will generate a lot of RF noise and interference on nearby AM radios.

Hi Swagatam,

I would like to use the second with 555 timer for making a soft starter for my submersible pump (1.5 – 2 Kw) for a community farm. Is it possible. What I do want is using a MCB to switch on then the load will be fully started after 1-5 seconds longer or more to reach full speed or power.

Changing the value of the potentiometer will make the ramping up time longer? Also the Choke, do I have to use this choke?

Please advise

Best.

Hi Dang,

Yes that’s possible. But the controlling will need to be done manually.

Meaning, initially you will have to adjust the pot at narrow PWM level and then once the load is switch ON, you can increase the PWM to maximum.

However, if you want to have this soft start fully automated then you just have to connect a 100uF capacitor between pin#5 of the 555 IC and the ground.

Hi Swagatam,

Thanks for your response. My scenario is:

MCU control the MCB with an internal small relay (to supply AC power to the coil of the MCB for it to start)One the MCB starts, the board will automatic handle the soft starting for the pump in xx seconds.So with your advise, adding a capacitor to pin 5 of the 555 to GND, it will automate the soft starting in xx seconds using the set level in the POT? In your schematic, there is already a 103 Capacitor connecting ground. From your schematic, i understood that Live and Neutral are non interchangeable! Can you advise a value for the POT to make the 10 seconds ramping up to full power?

Many thanks for your advise

Best,

Hi Dang,

Here are answers to your questions.

You can replace the 103 capacitor at pin#5 with a 100uF or a 220uF as per the desired length of the slow start.

In this situation the pot can be used to set the maximum range of the pump speed. According to me the pot must be removed and replaced with a fixed resistor so that a maximum speed can be set using the two resistors.

The ramping length can be directly set through the capacitor at pin#5.

Make sure to test the results using an oscilloscope first.

Preferably, the phase or the LIVE should be connected to the LOAD side terminal, but this is not mandatory.

Even if you reverse the L/N connections the circuit will still keep functioning normally.

Hi – I would like to use the PWM assisted AC motor controller circuit to replace the triac driver in a large carpenters plane. The present triac driver circuit is not working. What frequency range and pulse width should I consider configuring the 555 for? The 10uf cap appears to be too large for a motor driver application, as the frequency is in the 1Hz range. What should the gate drive signal look like relative to the 60 Hz line frequency? Thanks in advance for your insight.

Hi, you can try reducing the capacitor value to 0.47uF and see how it responds.

The 60 HZ would be allowed for a few milliseconds by the PWM ON cycles and then interrupted by the PWM OFF cycles.

I would also suggest you to try the first circuit which is ideally suited for controlling AC motor speeds.

Hi Swagatam

I would like to make my own version of a solar proportional immersion heater controller to use surplus electricity from my solar PV array. I assume that an appropriate circuit will use this triac which will be triggered by a current transformer on the supply to the property to provide enough load to bring down the export of electricity to zero – tested during each cycle.

I would love to make a trial version but don’t have a circuit diagram – can i use this circuit and how do i integrate the current transformer?

Thanks

Gordon Webb

Hi Gordon,

I have current transformer circuit in this blog which can be perhaps modified to suit your application.

You can try the second schematic with a buzzer. If it works with a buzzer then a triac could be used at the output to switch ON a desired load.

https://www.homemade-circuits.com/load-current-control-through-current-sensing-transformer/

Hello, I have made this circuit with 555 pwm and trying to run infrared cooker coil with triac BTA41600B. But i am getting huge ac voltage on gate and gave 1k resistance to 555 pin3 to gate and resistance just burnt.none of triac pin is sorted.Is it okey to gate high voltage in gate?three of my 555 ic is already damaged.

Hi, How is it possible to get a huge voltage at the triac gate when the 12V zener is connected?

Did you connect the 0.33uF capacitor and the 12V zener diode?

You can try using 0.22uF instead of 0.33uF and check the results.

The voltage between pin8 and pin1 of the IC should be 12V, and the same should appear across the gate and the ground of the triac.

would you have a economical power supply circuit for a diy wire edm machine

Please provide more details for the power supply.

Hello Sir, I needed a Speed Controller for Industrial DC Motors.

Is it possible to use Your above circuit with combination of a MB3510 bridge rectifier for the

DC Motor? and also what modifications i can do to above circuits for using 2 phases as input of 440V AC to feed the bridge rectifier MB3510 and later the DC output to the motor?

I have posted the more detailed message on facebook with both the motor plates, Please Kindly Check, Waiting for Your Positive Reply

Thanks 🙂

Hello AK, for operating a DC motor you can try the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2022/05/DC-pwm-motor-control.jpg

More details are provided in the following article:

https://www.homemade-circuits.com/dc-motor-speed-controller-circuits/

Thank You very much for replying Sir, but Sir one of my DC Motor eats Four Hundred & Fourty DC Volts @ Ten point One Amperes of Current, and the another small one eats Two Hindred & Thirty DC Volts @ 8.1Amperes, how can such small circuit going to handle that much high load? and also can i by doing som adjustment i can control the speed while maintaning the torque with a external 0-10Volts DC supply?

I messaged on Facebook with much details earlier where You suggested me this circuit.

(https://www.homemade-circuits.com/wp-content/uploads/2011/12/MOTOR2BSPEED2BCONTROL.png)

Waiting for Your Positive Reply . . . .

Thanks

Hello AK, I actually suggested you the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2022/01/DC-motor-speed-controller-circuit-with-reverse-forward1-1200×474.jpg

You can see that the power transistors have a separate voltage connection for feeding the motor. You can feed the 440 V to the transistors separately for controlling the motor. For this you just have to replace the transistors with appropriately rated MOSFETs.

For further discussions please comment under the following article:

https://www.homemade-circuits.com/dc-motor-speed-controller-circuits/

Good!

Thanks for good job. Can the power booster you made with this triac be used for electronic appliances, such as ac television and radio, also?

Thank you, no, the booster circuit cannot be used for powering electronic devices.

Please, can you help me, then, with a power booster circuit that can power AC electronics. I will be very grateful if you do.

Thank you very much sir.

The only way to achieve this is to build an auto-transformer or buy one auto-transformer which will allow you to adjust the output voltage to the desired levels. By the way, power cannot be boosted…only voltage can be boosted.

Hello, I am looking for a circuit to control 120 A/C volts max 10 amps motor speed aiming to keep as much torque es possible.

The AC motor is to power a spindle of a home made flight cutter for metals such as on a milling machine.

Will that circuit above do?

I

Hi, yes, you can use the above circuits for controlling the specified load. However, decreasing the speed might also cause the torque to reduce proportionately.

Hi Swag, I am repairing this Samson SX3200 amp. It has two bridge rectifiers in each channel circuit. What is bothering me is the function of the negative and positive step driver circuits. Any idea? My email address is cgachuhi@yahoo.com.

Hi Gash, The two rectifiers could be for supplying the +/- dual voltages to the amplifier circuit, because most power amplifiers require a dual voltage to operate. This is my guess, not entirely sure though.

Sir,

My name is Dr.Chris Halgryn and I am a great fan of all your circuits however Sir, the circuit I want to build now looks good it is the speed controller using a BTA41 connected in series with a 0.1uF cap…. but, at the end of the schematic it shows a device marked “100E” what is this please????

Thank you

Chris

Thank you Dr. Chris,

I am glad to help you!

100E = 100 Ohms

the letter E stands for Ohms.

Thank you Sir my goodness I at first thought it was OHMS yet I feel such a fool but Thank you again for the prompt reply I keep on following your projects, built a few all in the past….. and YES!!! They all work fine thus, everybody should be thankful for ypour projects and schematics thank you again I HIGHLY Recommend you!!!!

Thank you

Dr.Chris

PS. I need a circuit in order to control the speed of my UNIVERSAL MOTOR without LOOSING TORQUE can you assist or will the present circuit help me… please thank you in advance~~

No problem Dr. Chris, I am always happy to help! I am also glad to know that you have tried my circuits and they worked for you, appreciate your kind response!

I have a high torque motor speed controller circuit published in this blog, but the circuit can control only low current motors up to 3 amps:

https://www.homemade-circuits.com/constant-torque-dc-motor-speed-controller-circuit/

Hi….I want to make a 3-phase voltage regulator to control the voltage input of a transformer’s primary winding, so that the output voltage of the secondary winding can be adjusted. The current requirements for the primary is max 20 A per phase. Can you help me with a suitable schematic ? I am planning to make use of 3 nos. of standard single phase SCR (BTA41 600B) voltage regulators connected in a star configuration (220V INPUT) and will take the outputs of these in a delta configuration (400V OUTPUT) to the transformer’s primary. Any suggestions will be a nice gesture…. thanks

Hi, sorry. I can’t figure out how a 3 phase AC regulator can be built. It seems difficult because there’s no neutral in a 3 phase system. If there was a neutral we could have simply used 3 AC light dimmers on each phase for controlling each of the phases.

Hi Swagatam….Of course there is a neutral in the three phase system, and that’s why in the absence of a single unit of 3-phase transformer, we can connect 3 units of single phase transformers for 3 phase use. The method is known as STAR-CONNECTION. The output can be made available as a no-neutral setup (called as a DELTA CONNECTION) or otherwise.

I actually wanted a good high power (standard single phase) dimmer circuit design with symmetrical wave-forms at the gate. And I will actually use three of them for the three phases, take each one’s phase output and use them as I wish, meaning STAR (with neutral) or DELTA (without neutral).

Thank you Aditya, for the information!

After some thinking I realized that for connecting a light dimmer on each phase a neural connection may not be required since light dimmers are designed to work in series with the load. So I think you can use 3 good quality high power light dimmers and fix them in series with a DELTA 3 phase wiring.

I have a light dimmer related article which you can find in the following link. The circuit shown under “Circuit Diagram of an Improved Light Dimmer” is a good circuit which was originally designed by the elektor-electronics engineers. However, to get a symmetrical control from the 3 dimmers you may have to use a ganged potentiometer for the 3 dimmers.

https://www.homemade-circuits.com/how-to-make-simplest-triac-flasher/

Hi, I’m intending to use a BTA 41-600B pot controlled regulator circuit (common on ebay etc advertised as a 220v 4000w regulator) to power an old valve radio main circuit (separate 6.3v tube heater supply) in place of a failed transformer. I will be connecting the output of the regulator to a silicon bridge rectifier which then feeds the radios circuits. As the regulator needs to be load connected to make it regulate will the rectifier alone be enough to trigger regulation. Otherwise I was going to build a small filament lamp into the case to fire up the regulator when switching the radio on. Not to sure what current draw will be needed to make the regulator start regulating.

Thanks in advance.

Hi, using a triac dimmer with mains AC can be risky for any low voltage project, therefore I would recommend you to go for a transformer and not with a triac based power supply.

What is the best testing method for a Triac p/n BTA41600B, outside of the circuit.

Thank you

Hi, the inductance should 40 uH. The 15 turns is probably incorrect, it must be around 50 turns

The core should be a ferrite core, If you use air core then the number of turns will increase significantly.

a 2mm diameter wire should be quite enough for handling 25 amp current.

Thanks for replying, can

the ferrite core (due to poor repelability) be smaller than 5/8 of an inch?

If so, would there be problems using this coil for 25A?

Thank you

You are welcome, It may be difficult to provide the exact size of the ferrite core. You may have to find it with some trial and error to figure which core and number of turns produce minimum RF disturbance on radio

Hello sir swagatam, thanks for your electronic guidiance.I’m nosa,I have a question,is it possible to use 3kva alternator generator ac output using BTA41/600b and to power 3hp ac electric motor or higher electric motor and can it runs the ac motor continuously without damages to the BTA41/600b circuits or what kind of circuit will you recommend sir.

Hello Nosa,

since the triac is rated to handle 40 amp continuous current, it should be able to handle the 3 hp load easily. So you can try it. Just make sure to mount the triac over a large heatsink

Thanks sir,I sent you an email of the picture of such design generator I want to use the triac circuit on.

I guess dis is your email address: hitman2008@live.in.

Here is my email address: nosaglee@yahoo.com. to send me usefull information sir.

You are welcome Nosa, however, I prefer discussing only through comments so that it can be read by all of us.

Yes you can use a BTA41 triac since it is rated to handle 40 amp current, meaning 220 x 40 = 8800 watts provided i mounted on a large heatsink

OK sir,from the above diagram of bta41/600b triac,so which side to connect the triggering DC to triac diagram or how can I connect the DC 5v or 12v triggering to the same circuit with the AC bta41/600b.please sir indicate to me the place in the diagram.

Nosa, you can refer to the first diagram from the following article, which suggests exactly how a triac needs to be configured with a DC switching circuit and an AC load:

https://www.homemade-circuits.com/simple-triac-triggering-circuits-explained/

After referring to your previous diagram I could not figure out how the opto coupler could be connected, so cannot go ahead with it. You can try using a 100uF in place of the 47uF and see whether it solves the problem or not. Try increasing the 47uF value and lowering the R2 value, until the right combination is found.

It seems along with R2, C2 is also responsible for delivering the required amount of current to the triac gate

Thanks for suggestion. Any Iink please for optocoupler driver?