In this post I have explained a small induction heater circuit for school project and exhibitions, using a very ordinary IC 555 astable PWM circuit. The idea was requested by Mr. Anthony

Technical Specifications

For a school project i need to construct an AC induction cooktop and was wondering if you could help me put together a part list for a much weaker induction cooktop than yours, it only has to warm up a few ML's of water.

Is this something that is possible?

The Design

An induction heater is considered as an amazing circuit which is capable of converting electricity into heat with utmost efficiency and without much losses.

However a little contemplation will make you realize that actually it's just the opposite. An induction heater circuit is an extremely inefficient circuit which converts all the electricity into heat.

This opinion is with regards to the general view about electrical and electronic circuits where the emission of heat is considered to be inefficient and undesirable.

But for an induction heater, this inefficiency attribute becomes its positive aspect, and the more inefficiently it is designed, the more beneficial it becomes for the user.

To be precise, an induction heater is an inefficient transformer which is purposely mismatched with its frequency and the core material specifications.

In this concept the core is normally a ferromagnetic material such as iron having a copper coil wound over it. The copper winding around this iron core is oscillated at a relatively higher frequency which may be not suited for the iron material.

The bad conductor nature of iron finds it difficult to resonate at the high winding frequency resulting in the generation of high back emf eddy currents which in turn causes high temperatures on the core material.

This feature is exploited in induction heaters for the intended purpose of achieving high temperatures

Although massive induction heater units can be built for generating extremely high temperatures using the same concept, a small induction heater circuit for school exhibition project can also be implemented easily using ordinary parts such as a IC 555 and some other inexpensive passive components.

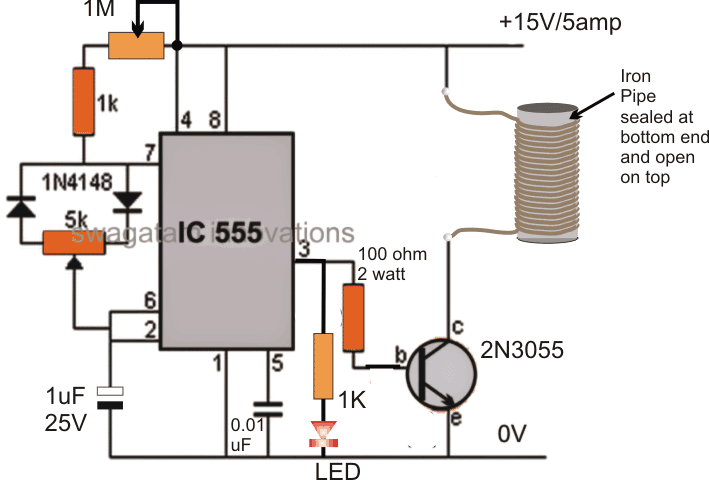

Circuit Diagram

Circuit Operation

A simple IC 555 induction heater circuit for school project is shown in the above figure.

Here the IC is configured as a PWM generator circuit, which is adjusted using the 5 K pot. The frequency is adjusted by tweaking the 1M pot or the 1uF capacitor specifically for achieving the optimized heating effect on the work coil.

The working coil here is made by winding around 50 turns (not critical) of 1mm super enameled copper wire over a fabricated iron pipe whose dimensions may be selected as per individual preference, and could be anywhere between 10 to 20 mm in diameter and 30 to 40 mm long.

Once the above set up is built and switched ON, the coil and the iron pipe could be seen developing heat gradually, and anything placed inside the pipe could be witnessed getting heated up.

If it's water inside the pipe, then it could begin warming up and even reach the boiling point if the coil is optimized correctly through the frequency and PWM adjustments.

The idea behind this small induction heater circuit is simple, it is to force the iron pipe atoms to electromagnetically oscillate at an incompatible frequency resulting in the production of huge amounts of opposing eddy currents and a proportionate amount of heat due to this opposing current in the metal.

If you have more questions regarding this induction heater circuit for school science project, do feel free to ask them through comments, below.

Comments

Hello gd morning my question is that how will it work without resonant tank

Hi, This circuit is intended for low heat, you can add a calculated capacitor across the coil if you want to achieve high heat on the coil through resonance.

across means capacitor in series or parallel to coil.

It means parallel to the coil…

Good Day, This is an interesting development project. Could you please advise on practical frequency range and waveform,

Kind Regards, Greg

Hi, thanks for your interest in this project,

any frequency above 1kHz should initiate a heat build-up on the coil.

Can I use this circuit as soldering iron ? many thanks

No, this circuit will not generate heat to the level of a soldering iron.

Exelente sitio, para mi es unos de los mejores de nuestro planeta sin haberlo visto a todos pero aquí he saciado mis deseos de ver artículos mun actuales y novedosos, felicidades para el administrador de este sitio tan especial.

Thank you so much, Glad you found the site helpful!

Sizi uzun zaman önce görmüştüm devre şemalarınızı teşekkürler hocam

You are most welcome, Harun.

hello sir make videon on this topici i want to make induction cooktop for uses

Im looking to make an induction heater using a bifilar work coil with tempature adjustment. After looking into zvs circuit for driving the coil I realised it was overkill for my application due to max temp is 195 degrees F. After combing through all of the induction circuits on web Found your wonderful bank of knowledge here and this circuit which seems it should work. Just need a calculator to figure out the proper work coil winding specs, the link you provided for one located here comes back with a 404 error. I was hoping you could provide me with working link or even the raw equation/formula to figure this out by hand.

Thank you, I appreciate your feedback, yes the above circuit should be OK for low temperature heating, as for your application.

Unfortunately I do not have the formula for calculating the number of turns that would produce this temperature, and you may have to figure it out through some practical experimentation.

You can start with 100 turns over an iron core and then tweak the frequency of the IC to modify the temperature.

Hope it works.

Hi, I like some of your design and schematic on induction heater I have seen. Please am contructing something similar for HND school project, in particular: design and construction of temperature control induction heater. Your advice and tutoring will be of great help me in getting the most inexpensive materials to use in design, schematic, construction etc. Hope to hear from you, thanks.

Hi, Glad you liked the circuits. If you have specific queries, feel free to ask them, I’ll try to help!

Do you have a circuit & coil design for soldering copper pipes with an induction heater

Hello Swagatam,

I have a 10kW induction heater circuit design project(only on paper not a real one). Is it possible to increase the input voltage of this project to reach 10kW power output or should i use more advanced circuit to reach that much power? and which are the other ways to achieve higher power outputs?

Regards.

Hello Yasin, you can try adding more MOSFETs in parallel to the existing ones and then check the output response. Also make sure the input is capable of providing the intended amount of current.

Hello Swagatam!

Awesome and informative read! I am trying to teach myself some EE skills through fun projects such as this. (My goal is to heat up a cup of coffee with this) I was wondering if you could possibly help answer some questions I had that were not previously asked.

1. Why would you not need a waveform generator for this circuit?

2. My power supply is 0-30V, 0-3A. How would I adjust the my circuit calculations, if possible?

3. How should I begin designing my coil design?

I cannot explain my appreciation for you knowledge and patience with my project. Thank you!

Madison

Thank you Madison, Glad you are enjoying my articles.

A frequency based design ensures higher heat with lower consumption.

The circuit and the coil can be best optimized with some step wise trial and error method.

For the coil you can start with a 50 turn coil over an iron core. Adjust the frequency to around 5 kHz, reduce the voltage to 3 V, then gradually increase the voltage step-wise, while also experimenting with the frequency until the highest possible heat is achieved….simultaneously also making sure the transistor never exceeds its maximum tolerable dissipation limit.

Wow amazing answer thank you!

This might be a question with an easy answer but how do I measure the adjusted frequencies when playing with the 1M pot ? Also what if I match that limit? I have never came across that issue yet, I am just starting with IC 555 and transistors but I great appreciate your advice!

Frequency can be measured by any frequency meter, once the resonance is struck you will find the current consumption decreased and the heating effect increased.

Hi Swagatan,

I am new to electronics and I want to make this school project induction heater then I want to make your more advanced ones. I have made a diagram showing the components as I understand them. Can I send it to you to see if I understand everything correctly? I don’t have a 2N3055 but I do have some Mosfets that I have shown on my drawing. Could you recommend one?

Kind regards,

Mike

Hi Swagatam,

I tried to send the link yesterday from my PC but it didn’t work so I am trying from my phone. Here is the link:

https://drive.google.com/file/d/1u2U9qiVGka6VbqhedRxsObi241M-39jl/view?usp=drivesdk

I forgot to show the ground on the PS.

Kind regards,

Mike

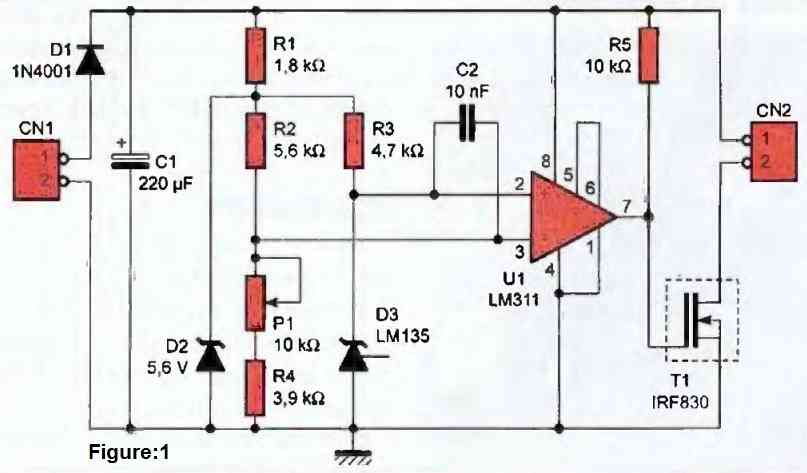

Hi Michael, I looked for your comment and found it in the spam folder, and have restored it to the main section. The diagram looks fine, just make sure to limit the input current to 5 amps initially using IC lm338 until the right right optimal frequency is determined. Also use a 0.1uF or any small value capacitor across the coil to create a resonance effect and improved efficiency.

Hi Swagatam,

Thanks for reviewing my drawing. I’m happy to know that it’s OK.

I’ll get started.

Kind regards,

Mike

No problem Michael, wish you all the best!

Hi Michael, yes you can use a MOSFET for example the IRF540, but make sure to add the current limiter stage in the same way as shown with the 2N3055 transistor. You can upload the diagram on any free image hosting site and provide the link here, I’ll check it out.

Hi Swagatam,

I have tried three times to post the link to my drawing, twice with my PC and once from my phone. This time I am leaving out the link to see if the message gets posted.

Kind regards,

Mike

Hi Michael, Yes it is posted now, seems the http was causing it to land in the spam folder. You can send the link without the http/https

Hi Swagatam

Did you specify the dimensions in cm? Not millimeters?

With respect Alexey

Thank you Alexey, yes it is actually in mm, I have corrected it now….

Hi Swagatam,

Nice useful circuits. By the way, is there any optimum frequency? I see cooktop set 30kHz 50kHz or more than 100kHz. Or it depends on what?

Hi Cesar, If you connect a capacitor parallel to the coil then you may be able to adjust the frequency to some optimal level for getting maximum heat at minimum dissipation. It depends on the resonance frequency which is determined by the inductance value of the coil and the switching frequency

first thank you for this circuit , i have been looking alot to find, but can i use 5v

you are welcome! 5V may work, but the current will need to be more than 5 amp or 7 amps.

Hi Swagatam

i used to have doubt with most induction heating circuit, the doubt is in the collector of the transistor i m thinking that the heat generated by the ferromagnetic material and the copper wire will greatly affect the transistor collector. is this the case? if yes what are the majors need to be taken.

thanks alot.

Hi Abba, the transistor is normally kept some distance away from the coil, therefore the coil temperature won’t affect the transistor pins, although the transistor would get hot due to high current oscillations.

Can i use astable multibrator vibrator circuit instead of ic 555

you mean BJT astable? yes that’s possible…

I made the circuit with 32khz frequency but it is not heating the iron core i used the d882 transistor for astable multibrator and 2n3055 as driver for coil.

And it barely light up a led when i put a secondary coil near it connected with led but when i bring the same coil to zvs induction heater it immediately blown up.

Do the 2n3055 transistor require extra driver for astable multibrator circuit?

show me the schematic, I’ll try to help, upload it in some free image hosting site and provide me the link….

Deepak, please provide all the details regarding the solar panel and the induction heater, so that I can understand the operations correctly.

Deepak, buy a readymade induction heater kit or PCB module. Remove its main work coil, measure its inductance, make another work coil which will be flat as per the cook top specifications, connect it with the circuit. Test the response!

Sir

Power supply is from solar panel, inverter and battery setup which produce 550 watt power.

When I connect induction cooker, inverter goes trip, can we do some change in circuit of induction to overcome the problem of inverter trip

Sir,

I want to build a induction cooktop which can work on 400 watt power, please tell me how to design circuit for it

Dear Fery, yes it should work, but you will have to adjust the frequency correctly since it is not a ZVS circuit…

Dear Swagatan,

Is the circuit work with coil winding 100-120mm?

Thanks for your attention,

Regard,