A Negative Temperature Coefficient (NTC) thermistor is a device which is able to suppress switch ON current surge due to its initial higher resistance at room temperature.

However, as the NTC suppresses the initial surge current, it warms up causing its resistance to drop to nominal levels and this in turns allows the current to flow through it at an acceptable rate, and the connected load is able to work normally.

In this post I have explained how to use an NTC thermistors in circuits for suppressing surge current during power switch ON. We also learn the datasheet and the electrical specifications of an NTC.

Today electronics is getting more and more compact and light weight, it's basically due to the involvement of compact converters which have completely eliminated the age old iron cored transformers.

However, this had to come at a cost, these units became too vulnerable to switch ON power surges.

But electronics always has appropriate answers, whatever may be the issues. NTC thermistors were created exactly for tacking this, that is in-rush surge currents during power switch ON.

What's an NTC

NTC (Negative temperature coefficient) thermistor is a semiconductor that contains metallic oxides.

It displays an electrical resistance which has an extremely foreseeable alteration with warmth.

The resistance differs substantially with heat, much more in comparison to

normal resistors.

These are incredibly perceptive to heat change, very precise and interchangeable.

They possess a broad temperature envelope which enable it to be hermetically packed to be used in damp conditions also.

Main Features:

* Durability of service, superior stability

* Compactness, robustness, sturdy surge current resistance

* Quick reaction time to surge current

* Extensive operating spectrum

* Significant element constant (B value), minimal stay resistance.

How does an NTC Functions

An NTC is attributed with a special property through which it is able to raise its resistance significantly during power switch ON.

When used in electronic circuits this property helps blocking the initial surge currents in to the connected circuit.

However in the process, the NTC becomes relatively warmer, which brings down its resistance to lower levels such that the normalized safe power subsequently is allowed to pass over to the adjacent circuits.

Practical application:

Thermistors are commonly used as

* Inrush current limiters

* As Temperature sensors

* In the form of self-resetting over current protectors

* In self regulating heating elements

* Power Converters, switch mode power supply SMPS, UPS power protection

* Energy efficient lights, electronic ballasts and chokes,

* Many vulnerable electronic circuits, power supply circuits etc.

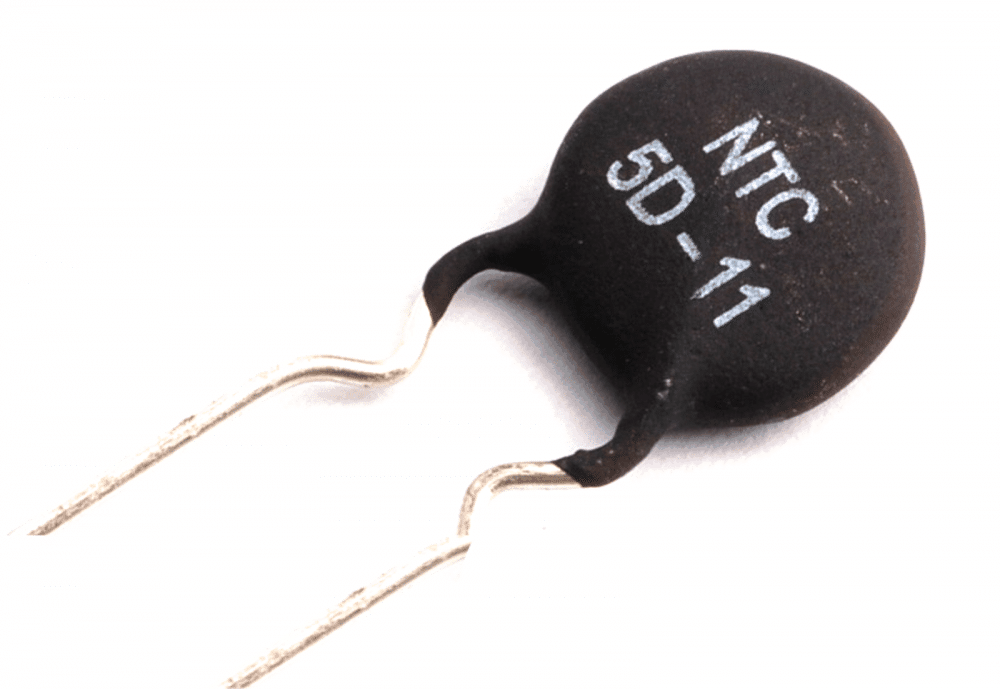

The following image shows an example NTC component:

Identifying the NTC Thermistor from its Print Mark:

Before learning how to use an NTC thermistor, the users must first know to read the label and the rating of the device. The first digit "5" indicates the resistance of the part at normal conditions. Here it indicates 5 Ohms.

The subsequent alphabet and the digit indicate the diameter of the particular part, here it's 11mm.

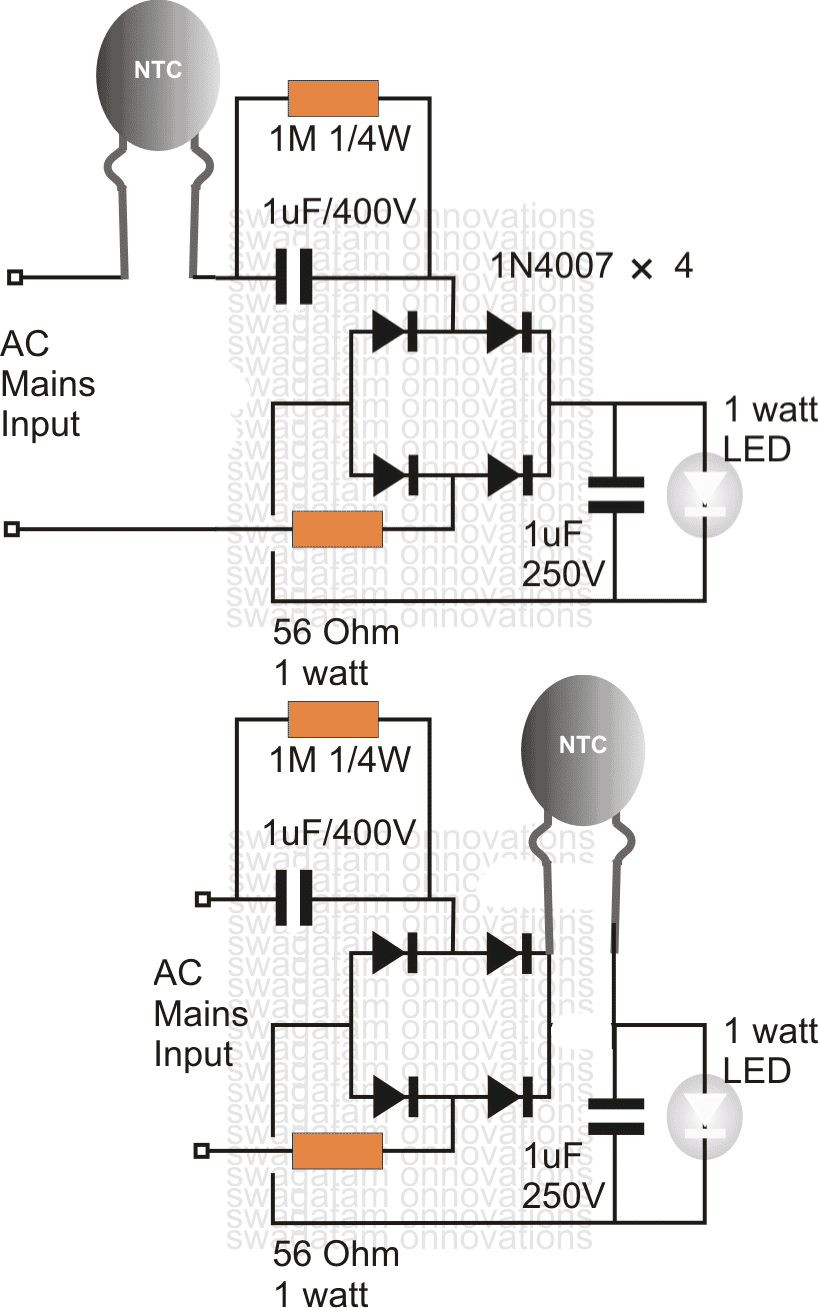

How to Connect an NTC Thermistor in Practical Electronic Circuits

Normally in an electronic circuit an NTC is connected at one of the mains inputs, in series.

Alternatively, an NTC may be also used by connecting the device after the bridge rectifier, as shown in the following examples of surge controlled compact transformerless 1 watt LED driver circuits.

Filter Capacitors and NTC

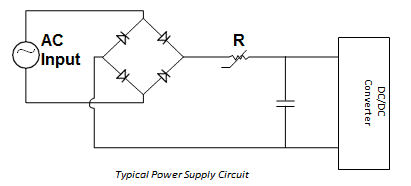

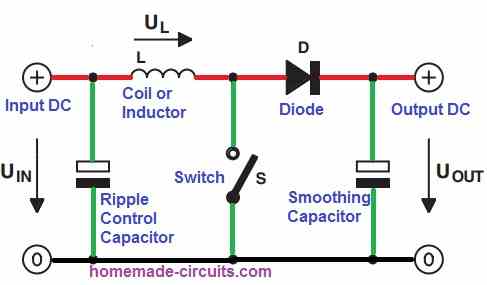

The main issue related to current surges in switch-mode power supplies is a result of the large filter capacitors employed to filter the ripple in the rectified 60 Hz current before getting chopped at the high frequency.

The picture below shows a circuit generally found in switching power supplies.

In this schematic the highest current during power switch on is the peak line voltage divided by the value of the resistor R.

For mains supply of 120 V AC, this can be roughly 120 x √2/R.

In the best possible scenario, just when Power is switched ON, the value of the resistor R needs to be much bigger, and quickly after once the mains supply is in its normal state, the R value must drop to zero.

An NTC thermistor is designed to work quite in this way, and therefore is best suited for most power supply application.

The job of an NTC is to limit the initial switch ON surge current by working like a power resistor that drops from a high value cool resistor to a low value warm resistor, the warmth being created by the normal current flowing through it.

NTC Considerations

A few of the aspects that needs to be considered while using NTC thermistor as an inrush current limiter are:

- Highest allowable surge current during Power switch-on

- Finding the equivalent thermistor size with respect to the the filter capacitors

- Maximum value of the current during it staeady state and normal continuous operation

- Highest possible ambient temperature around the thermistor

- Maximum expected life of the power supply

Maximum Surge Current

The major intent behind restricting inrush current is always to protect the electronic components that are connected in series with the input line of the DC/DC converter.

Generally, inrush protection inhibits annoying blowing of fuses or tripping of circuit breakers and sometimes burning or fusing of the of switch contacts.

Since the majority of thermistor elements are extremely ohmic at any assigned temperature, the lowest no-load resistance of the thermistor is computed by dividing the peak input voltage by the maximum permissible surge current in the power supply

Normal NTC Resistance = Vpeak / Imax surge

Turn-ON Current Surge

As soon as the input AC of an SMPS is switch-ON, all the associated filter capacitors inside the SMPS act like temporary instantaneous short circuit points, which store a charge equivalent to 1/2CV2 .

This sudden and instantaneous large inrush of current due to the the capacitors storing the charge has to make its way through the NTC.

Due to this the NTC temperature rises rapidly during this period, and as a result its resistance drops which ensures that subsequently when the capacitors are charged the NTC will stop restricting any further current and allow the current to reach the load normally.

The total time taken by the capacitors to charge optimally is dependent on the voltage.

The amount of current surge or power surge the NTC will be able to tolerate, fundamentally depends on the "mass" of the NTC.

The above logical view can be justified with the following expression and formula:

Input Energy = Energy Stored + Energy Dissipated

Pdt = HdT + (T – TA)dt

where:

- P = Amount of power developed inside the NTC, t = Time

- H = Capacity of the thermistor to heat up

- T = Thermistor body Temperature or the Dissipation constant

- TA = Ambient temperature

During the brief moment while the capacitors are charging (normally lower than 0.1 second), hardly any power is dissipated by the NTC.

Almost all of the input energy is adjusted as heat within the thermistor body.

In standard charts for inrush current limiters you can find outlined an advisable value of maximum capacitance at 120 V and 240 V.

This rating is not really meant to specify the overall capacities of the thermistors; rather, this indicates a practical value over and above which there can be some decrease in the life span of the limiter device.

Maximum Steady-State Current

The maximum steady-state current rating of a thermistor is mainly decided by the practical life of the power supply unit, for which the thermistor is being used and selected for protection.

In the steady-state situation, the balance of power in the differential equation explained earlier boils down to the below given heat balance formula:

Power = I2R = (T – TA)

As higher and higher current passes through the limiter device, its steady-state working temperature increases and its resistance decreases.

The highest current rating corresponds to the maximum permitted temperature.

In the standard inrush current limiters tables you will find a list of resistance values with respect to the load for each device, and also a recommended optimum steady-state current.

These ratings are dependent on standard PCB heat sinking, without considering the air ventilation, within a ambient temperature of 77° (25°C).

Having said that, the majority of power supplies include a reasonable air flow, which means a further increase in the the safety margin in addition to what is actually included in the maximum current rating.

In order to derate the maximum working steady state current with an increased ambient temperatures, you may make use of the below shown equation:

Iderated = √(1.1425–0.0057 x TA) x Imax @ 77°F (25°C)

Comments

Hi Mr Swagatam,

I would like to share my test result with the 170uF capacitor. I see the opening screen and when pushing the the choice “start” I can see the menu screen / session. But as soon as I choose the option “temperature” the screen collapses and the result is black screen. However as the next try I measured the voltage over the 170uF capacitor then I saw the continuously increasing voltage from 60 to 190V then I cut off the circuit. I think all the 220 voltage is being accumulated on the capacitor.

Hi Suat,

You must measure the voltage across the load, not across the capacitor.

As we discussed previously, the electronic system is shutting down because it is detecting an initial high voltage.

Please check the voltage across the load wires, it should be 120V.

Also check whether the capacitor is heating up or not….if not then it is fine…

Swagatam, as you advised, I measure the voltage of the load (air fryer) and it is about 220V AC. The capacitors are not heating up. I see the opening signals (a few beeps) and and the “start/stop” option on the display. But after the about 10 seconds the air fryer shuts itself off and the AC voltage increases.

Hi Suat,

If the voltage across the air fryer is not dropping to 120V, that simply means the device is not switching ON and accepting the AC 220V input.

As I suggested previously, the electronic circuit inside is quickly detecting the 220V and shutting off the system, so it is not possible to use this concept for your device, mainly because of the electronic shut-down feature of the equipment.

If suppose you connect only the heater coil of the equipment with our circuit then the voltage will quickly drop to 120V and the device will work as intended…

Thank you Swagatam, at least I have been learning something new. I dismantled the device and tested the the heating resistance and the voltage was about 140 AC.

(I am not sure this is normal or higher than the necessary) As the result, That is not too much important and I would like not to keep your time too much but is it possible to exclude the shut-down feature or increase the its resistance value? (For instant it may be the TL431 or similiar topology controlling the input voltage.) So, thank you very much one more time and please do not waste time if it would be the issue for you since I know the difficulty of the remote controlling / repair as the master of the such circuits.

Thank you Suat,

Yes, that looks better, with 140V drop the heater coil would be working good. You can try using a 150uF capacitor to drop the voltage further down to the required 120V.

Yes, there might be some voltage sensing stage in the shut down circuit which could be tripping the system, which could be eliminated for the heater to work normally with the 220V input AC.

Hi Swagatam I am not sure on how to express my gratefulness for your kind support for this and also about in the past and so far. The followings are limited due to over 10 messages. So I opened new header. I have used the lower capacity (474K 400V) capacitor and double parallel 100 ohm resistor before the relay upon your advice. It seems that the problem is solved and I think this is the minor problem. Now is it possible to increase the capacitor rate from 135 to 170uF and test the result?

No problem Suat,

Can you confirm if the relay is operating after a little delay, maybe a fraction of a second late after power switch ON?

If yes, then you can use the 170uF capacitor now….

I hear the click sound of the relay at the beginning and I hear the another click sound when the power is off. But as if there is no little delay but simultaneously runs with the start. Or I am not able to catch that activity at the first start. However if the switch is off then I am able to hear little delay of the relay.

There should be some delay happening when power is switched ON, because of the 220uF capacitor. The 220uF has to charge first, and only then the relay can activate…but the delay could be in milliseconds, that is why it appears undistinguishable…

No problem you can still try using the 170uF capacitor now…

Or if you have a 1000uF/50V capacitor, you can try that in place of the 220uF check the response…

Hi Swagatam;

You had advised me to use 5 Ohm 10A NTC (or double 10 ohm 5A) for the serial connected 170uF capacitor and 110V air fryer under the 220AC, so today I went to capital city center market of my country and no one has the NTC with the 5A capacitiy. And also I checked the local internet market but they all are used to giving diameter and resistance value not current capacity of the NTCS. In the case you would advise to stop the activity or suggest a new solution?

Hi Suat,

In that case you may have to build a small soft-start circuit, which will require a relay, a 1uF/400V capacitor, bridge rectifier and the 170uF/400V capacitor. Let me know if you would like to include it in your circuit.

Thank you very much Swagatam, I appreciate. I would like to complete my work indeed and learn something new(soft start). Could you please give me the detail or the page of your site?

P.S.: We had tested the 110AC air fryer with the 150uF and it was successful.

No problem Suat,

You can use the following soft-start circuit for your load to suppress the initial surge without depending on an NTC:

https://www.homemade-circuits.com/wp-content/uploads/2024/11/220V-to-120V-converter-with-soft-stat-circuit-diagram.jpg

I would recommend trying first with the 150uF capacitor in the above circuit instead of the 170uF, and confirm the results.

Thanks Swagatam for your kind support. I have 24V relay but about 1K5 and also I have 0.39uF and 0.47uF capacitors. Is it possible to use 2 of them as the parallel connected instead of the 1uF capacitor. And I have 2X50uF + 2X35uF (totally 170uF) capacitors. Is it possible to use first time 135uF for the test since the heating element(1000W) is not active while the initial start.

Hi Suat,

Yes, you can do all that you have mentioned, to adjust the capacitor values…no problems at all, just make sure the capacitor voltage ratings are as described in the diagram. 1.5k is also OK…for the resistor…

I am sorry Swagatam but the 1K5 resistor value in my previous message was for the relay resitance(not 400 ohm). However Is it possible to use 2K 5W resistor instead of the 1K 5W resistor at the load side?

No problem Suat, understood! a 1.5 k relay will also work. And for the 1k 5W resistor, you can easily replace it with a 2K 5W, no issues…

Swagatam here is the test result; I use 2A main fuse before the circuit and the capacitor value is 135uF, then I see the some beeps and the warning “start/stop” message on the display. All seem good so far but when I shut down and reopen the circuit, the 22 ohm (I used 33 ohm) protector resistor is always blown up.(I hope that was the expected result) Now please I remain for your latest instruction / advice?

Thank you Suat, for the detailed update!

Please try replacing the 33 ohm resistor with a wire wound 33 ohm resistor maybe 1 watt or 2 watt.

Or you can replace it with any 1 amp NTC, which you may have with you.

https://www.homemade-circuits.com/wp-content/uploads/2024/12/220V-to-120V-surge-suppressor.jpg

….also the 1uF/400V can be replaced with a 0.47uF/400V since the relay coil resistance is high (1.5k)

Hi Mr. Swagatam;

I have 220AC 1600W analog oven. I also have some NTCs at home. Is it possible to test the current of the NTCs by using them with the oven?

Hi Suat,

You can test your NTC with that load, if your NTC starts getting hot, that would mean your NTC is not 5 amp or 10 amp rated.

Hi Mr. Swagatam;

I need a 10 Ohm 5A NTC. Is the item NTG05-010 at the farnell datasheet list proper for the purpose?

https://www.farnell.com/datasheets/3217126.pdf

You are correct Suat, it is NTG05-010…

Hi Mr. Swagatam;

How can we know / understand the current rate of the NTC? Or Is it possible to connecte them in serial or parallel?

Hi Suat,

It will printed on it as code. You can get all the information from the datasheet: You will have to connect it in series with the 150uF capacitor.

https://www.farnell.com/datasheets/3217126.pdf

Thanks Swagatam. I had meant by saying “connecting in serial / paralel”: If we have double NTC, is it possible to connect them like the resistors? (serial and parallel connection of the double or more NTCs)

Hi Suat,

You can connect NTCs in series and parallel, but make sure that the thermistors have similar characteristics (e.g., resistance vs. temperature curve).

Dear author

Hello author, I sincerely thank the author for the article I just read, I am a mechanical repair technician, so I also have a passion for learning about electricity and electronics, through this article I hope the author will share with me some basic, rudimentary knowledge about electronics in general and electronic circuits in particular so that I can read and understand the basic circuit diagram,

Sincerely thank the author

Thank you PT,

I appreciate your interest.

This blog has many circuit designs and concepts dedicated to newcomers like you, which you can try.

If you face any problems understanding the concepts, you can always feel free to comment under the post to get quick solutions from me.

Hi Swagatam, I am looking into a circuit simulator to the one above. Filter Capacitors and NTC. Would you or have you ever made a circuit that will allow me to input a 120v Ac voltage to a 2 volt dc, 20 milliamp led Optic coupler? Your circuit looks very close to what I would like to accomplish. So, I have saw this done, but no values shown. The circuit is setup, Ac in to a 3 watt resistor and then what looks like a MOV to neutral. Then after the resistor something that looks like a capacitor and then into a Bridge rectifier. The positive output of the bridge rectifier goes to the optic coupler LED. Then returns to the bridge rectifier. The other end of the bridge rectifier goes back to a LED indicator then to neutral. There is also a diode facing backwards with a resistor in parallel with the indicator LED. Sorry for the long explanation. Could you give me any information that may help? Thank you in advance.

Thank you Bill,

Sorry, I tried searching, but i could not find out the circuit diagram you are referring to. If you want to operate an opto coupler from 120V source, you can build the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2024/02/connecting-opto-coupler-with-120V-AC.jpg

My Small LED take 0.01A at 230V AC 50Hz. I want to connect NTC for more protection and long life. let me know what value recommend. Currently I am using 100 ohms resistance to protect the inrush current.

You can use the NTC which is shown in the above article.

Thanks noted well

I need to simulate an inrush thermistor (like 5D-9) in Spice — any clue where to get a model?

Sorry, no ideas about it.

LOW voltage ceiling fan Bldc fan In surge test NTC burnt. Could please give the solution to pass the 4KVA surge test .

If the surge is for a few milliseconds then a stronger and bigger NTC will work. If the surge is longer a few milliseconds then nothing can work to stop it.

Pls what could be the problem 220v to 24v smps,no output?

Your SMPS MOSFET might have burned. That could be the main cause!

Thanks for your reply Sir. Actually the amperage is 16 . the circuit connects one fridge and one TV ( Not LED TV old sony TV). Instead can I use TVS diode P6KE180A??

Hi Micheal, you can use TVS, but EVS diodes will control high voltage spikes, it will not control switch ON current surge

Dear Swagatham,

I used NTC thermister as per your circuit that after fuse towards the load. It works for a week or so after that it was totally burnt,.Tthis has happned twice the total watts of that circuit is 800 watts/220 ac. What would be the cause or shiuld I use higher capacity NTC??

Dear Michael, The NTC is in series with the supply line and therefore at 800 watts, the device may be subjected to a current of more than 3 amps (800/220). Therefore you will have to make sure that your NTC is rated to handle around 5 amp current so that it is able to withstand 3 amp current surge easily. Please check and verify the current rating of your NTC or replace it with an appropriate one.

You can use industrial MOVs to suppress high voltage, but NTC cannot be used for high current loads, unless you have an NTC that is specially built for high current applications.

Ok sir But it can at least suppress surges on refrigerators and air conditioners

NTCs are used for protecting electronic circuits, not for high current loads.

CAN 5D-11 NTC BE SUFFICIENT TO BUILD A CIRCUIT THAT CARRY FROM 40A – 60A LOAD