Generally it is noticed that while charging batteries people hardly pay any special attention toward the procedures. For them charging a battery is simply connecting any DC supply with matching voltage with the battery terminals.

A fast battery charger circuit charges a battery with enhanced speed so that it is charged in less time than the specified period. This is usually done through a step wise current optimization or control.

Objective

The main objective here is to accomplish rapid charging in lead acid batteries without causing any harm to its cells.

Normally, at 25 degrees Celsius atmospheric temperatures , a lead acid battery is supposed to be charged at C/10 rate which would take at least 12 to 14 hours for the battery to get fully charged. Here C = Ah value of the battery

The objective of the concept presented here is to make this process 50% quicker and enable the charging to finish within 8 hours.

Please note that an LM338 based circuit cannot be used to boost the charging rate of a battery, while it is a great voltage regulator IC, enhancing the charging rate requires a special step wise changeover in current which cannot be done using an LM338 IC alone.

The Circuit Concept

When we talk about how to charge a battery quickly we obviously are interested to implement the same with lead acid batteries, since these are the ones which are used extensively for almost all general applications.

The bottom line with lead acid batteries is that these cannot be forced to charge rapidly unless the charger design incorporates an "intelligent" automatic circuitry.

With a Li-ion battery obviously this becomes quite easy by applying the full dose of the specified high current to it and then cutting off as soon as it reaches the full charge level.

However, the above operations could mean fatal if done to a lead acid battery since LA batteries are not designed to accept charge at high current levels continuously.

Therefore in order to pressure current at a rapid pace these batteries need to be charged at a stepped level, wherein the discharged battery is initially applied with a high C1 rate, gradually reduced to C/10 and finally a trickle charge level as the battery approaches a full charge across its terminals. The course could include a minimum of 3 to 4 steps for ensuring maximum "comfort" and safety to battery life.

How to Correctly Charge a Lead Acid Battery

I have seen motor garage mechanics charge all types of batteries with the same power supply source irrespective of the AH rating associated with the particular batteries.

That's gravely wrong! That's like giving the batteries a slow "death". Lead Acid batteries to a very extent are rugged and are capable of taking on the crude charging methods, however it's always recommended to charge even the LA batteries with a lot care. This "care" will not only increase the longevity but will also enhance the efficiency of the unit.

Ideally all batteries should be charged in a step wise manner, meaning the current should be reduced in steps as the voltage nears the "full charge" value.

For a typical Lead Acid battery or an SMF/VRL battery the above approach can be considered very healthy and a reliable method. In this post we are discussing one such automatic step battery charger circuit which can be effectively used for charging most of the rechargeable types of batteries.

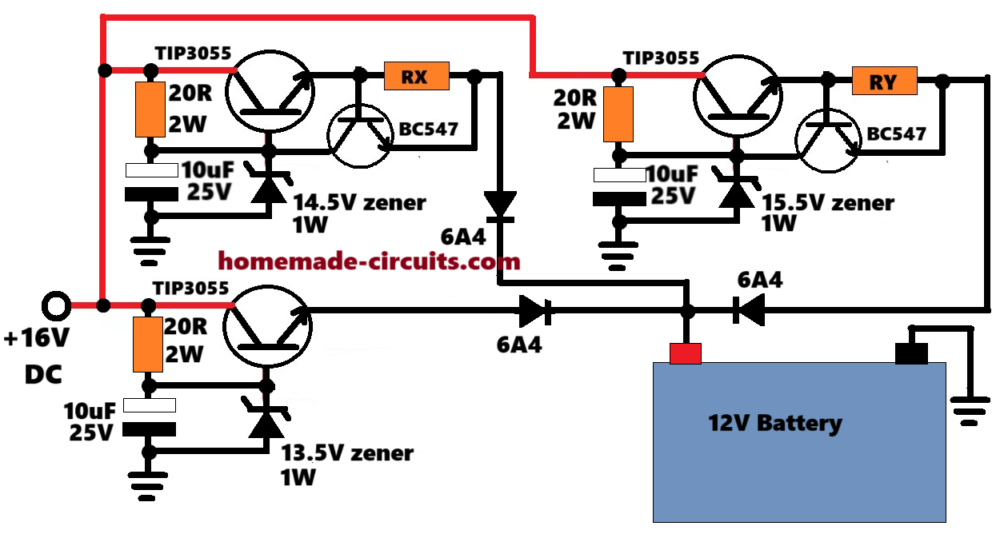

Solid State 3 Step fast Battery Charger Circuit using Only Transistors

The followng diagram shows how to create a simplest, solid state 3 step battery charger circuit using only tramsistors with 3 step current regulation for rapid battery charging.

With this process, a lead acid battery can be fully charged by at least 40 % earlier than the normal charging method.

The design is compact since it avoids the use of relays.

How it Works

Let's consider a12V battery, fully discharged at around 10V.

In this situation, all the 3 transistor stages become conductive and supplly the respective amounts of regulated voltages and current to the battery.

But the lower transistor regulator stage takes precedence over the other two, because it has no current regulation, and thus it supplies a high initial current to the battery.

In this situation, the battery enter the 1st step and starts charging rapidly with a maximum current supply from the bottom TIP3055 voltage regulator, but only until the battery reaches up to 12.3V. At this level, the bottom TIP3055 regulator becomes inactive, because according to its base zener value, its output to the battery positive can be only a maximum of 12.3V, so when the battery charges up to this level, the lower TIP3055 stage stops conducting and is automatically disabled.

Now let's consider, the upper TIP3055 regulator stage with the RX resistor is configured to supply higher current than the TIP3055 with the RY resistor.

Now, at this point, the transistor regulator stage having the RX resistor takes precedence over the RY resistor stage, since it is supposed to have higher current output than the RY stage.

So now the battery enters the second phase or 2nd step of the charging process and the battery continues to charge at a relatively fast pace. But when its terminal voltage reaches at around 13.3V, the RX transistor regulator likewise gets disabled, because according to the top left TIP3055 base zener diode value, its output can supply only up to a maximum of 13.3V to the battery, and at this level the 2nd step charging ends by disabling the top left TIP3055 regulator stage.

Now finally, the 3rd step get automatically reinforced, and top right side TIP3055 regulator stage takes the procedure ahead and continues with the last 3rd step charging process until the battery terminal voltage gradually reaches up to 14.3V, where the charging completely stops, and the battery continues to remains topped up with the attached trickle charging from the top right regulator stage.

In this way the battery completes its 3 step charging procedure silently and efficiently, at a relatively fast rate.

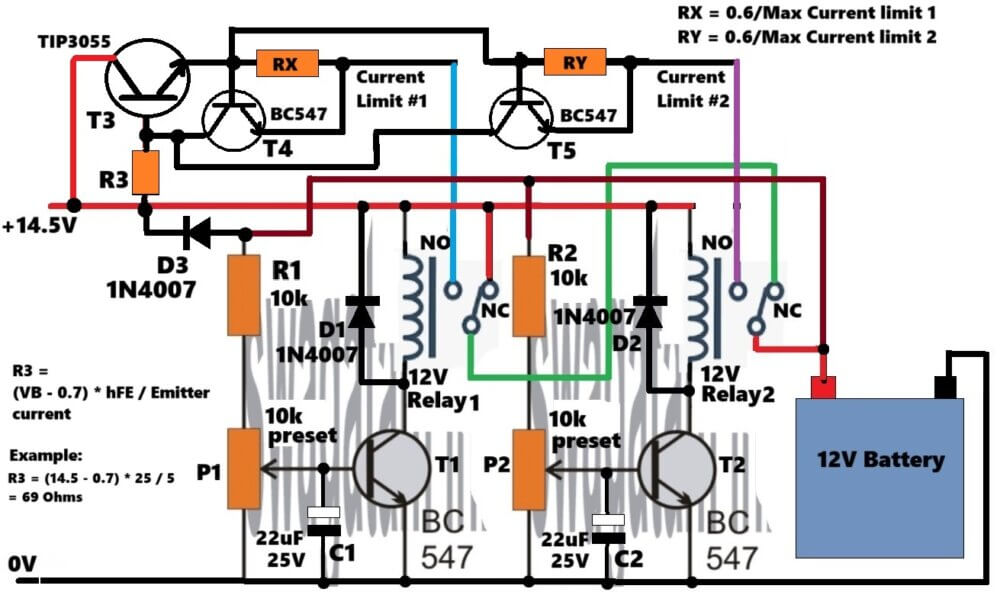

Fast, 3 Step Charger Circuit BJTs and Relays

The above circuit diagram shows a simplest 2 transistor, 3 step battery charger circuit using a couple of transistor relay drivers and a TIP3055 stage for the current control.

How the Circuit Works

The working of the circuit is rather simple. Considering a 12V battery, initially, at step 1, the battery charges at relatively high current through the N/C contacts of the two relays using the direct input supply of 14.5V volts.

Then, as soon as the battery voltage reaches above 12.5V, step 2 is initiated and the T1 conducts activating the relay 1, which causes its contacts to move to its N/O point, which allows the battery to receive a slightly reduced amount of current through the RX current sensor setting of the TIP3055 current limiting stage #1.

Now as the battery keeps charging, its terminal voltage keeps rising, and at around 13.5V, step 3 is triggered and the T2 transistor kicks in, activating relay 2. Now the relay 2 contacts move to its N/O position, enabling the battery to get a further reduced current (trickle charge) through the RY current sensor setting of the TIP3055 current limiting stage #2.

How to Set up the Presets

To begin with, do not connect any battery.

Adjust the P1 and P2 presets to keep there wiper arms fully towards the ground.

Make sure to temporarily short circuit the D3 diode with the positive supply.

Keep the current limiter stage disconnected from the relay circuit.

Next, connect a variable DC power supply at the 14.5V input side, and adjust its output to around 12.5V.

Now adjust the P1 until relay 1 just clicks in.

Next, increase the DC supply to around 13.5V, and now adjust P2,until the relay 2 just switches ON.

The P1, P2 setting up procedure is now complete.

Now, remove the D3 shorting, and restore the connections back to exactly as given in the diagram.

Also do not forget to connect the current limier stage with the relay stage, as given in the diagram.

That's it, your 3 step battery charger circuit is all set, and ready to be used with a real discharged battery for a rapid 3 step charging.

Calculating the RX, RY Current Sensing Resistors

Now, its time to adjust the RX, and RY resistors appropriately for the intended stepped current reduction.

Let's say, the initial high current charging was around 5 Amp current, then at the 1st step this needs to be reduced by 40% to around 3 Amps. To enable this we can set the RX value through the following calculations:

RX = 0.6 / 3 = 0.2 Ohms

Power = 0.6 * 3 = 1.8 watts or simply 2 watt resistor will work for RX.

Now, similarly, let's say the RY resistor stage needs to be adjusted for delivering 0.5 Amp current, then:

RY = 0.6 / 0.5 = 1.2 Ohms

Power = 0.6 * 0.5 = 3 watts

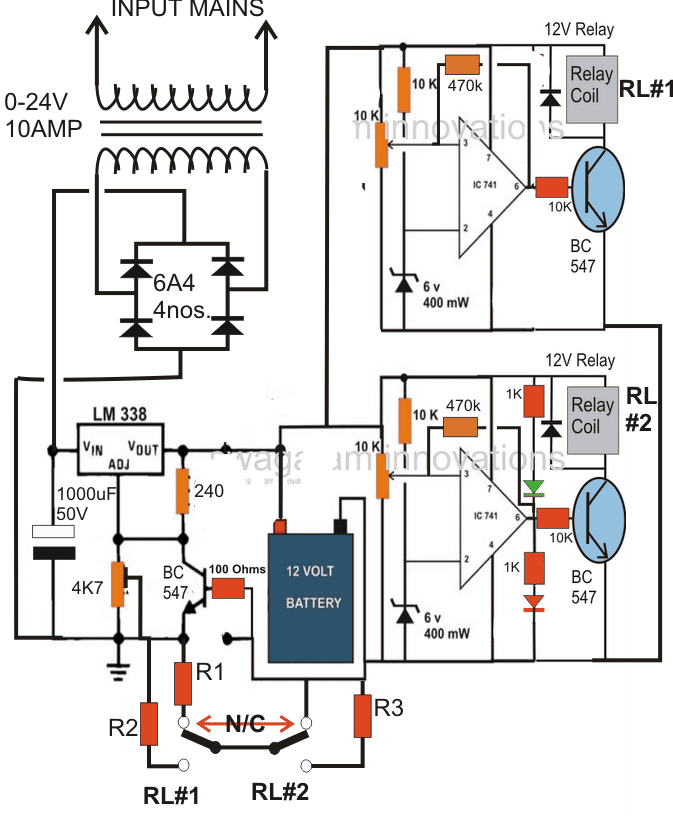

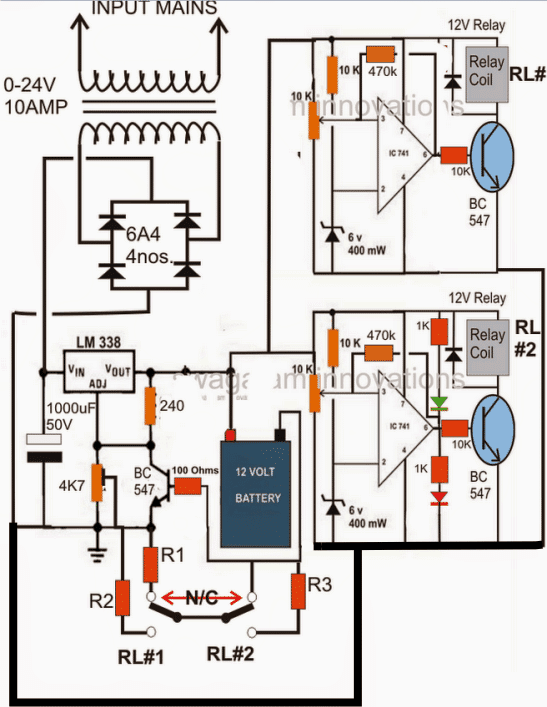

3 Step Battery Charger Circuit using op-amps and LM338 IC

Referring to the circuit diagram below, two 741 ICs are configured as comparaters. The presets at pin#2 of each stage is adjusted such that the output goes high after specific voltage levels are identified, or in other words the outputs of the respective ICs are made to go high in sequence after predetermined charge levels are accomplished discretely over the connected battery.

The IC associated with RL1 is the one which conducts first, after say the battery voltage reaches around 13.5V, until this point the battery is charged with the maximum specified current (determined by the value of R1).

Once the charge reaches the above value, RL#1 operates, disconnect R1 and connects R2 in line with the circuit.

R2 is selected higher than R1 and is appropriately calculated to provide a reduced charging current to the battery.

Once the battery terminals reaches the maximum specified charging voltage say at 14.3V, Opamp supporting RL#2 triggers the relay.

RL#2 instantly connects R3 in series with R2 bringing down the current to a trickle charge level.

Resistors R1, R2, and R3 along with the transistor and the IC LM338 forms a current regulator stage, where the value of the resistors determines the maximum allowable current limit to the battery, or the output of the IC LM338.

At this point the battery may be left unattended for many hours, yet the charge level remains perfectly safe, intact and in a topped up condition.

The above 3 step charging process ensures a very efficient way of charging resulting in almost a 98% charge accumulation with the connected battery.

The circuit has been designed by "Swagatam"

- R1 = 0.6/ half battery AH

- R2 = 0.6/one fifth of battery AH

- R3 = 0.6/one 50th of battery AH.

A closer inspection of the above diagram reveals that during the period when the relay contacts are about to release or move from the N/C position might cause a momentary diconnection of the ground to the circuit which in turn migh result in a ringing effect on the relay operation.

The remedy is to connect the ground of the circuit directly with the bridge rectifier ground and keep the ground from the R1/R2/R3 resistors attached solely with the battery negative. The corrected diagram may be witnessed below:

How to Set up the Circuit

Remember if you are using 741 IC then you must remove the red LED from the lower opamp and connect it in series with the base of the transistor to prevent permanent triggering of the transistor due to IC leakage current.

Do the same with the upper transistor base also, connect another LED there.

However if you use an LM358 IC then you may not have to this modification and use the design exactly as given.

Now I have explained how to set it up:

Initially keep the 470K feedback resistors disconnected.

Keep the slider of the presets towards ground line.

Now let's say we want the first relay RL#1 to operate at 13.5V, therefore adjust the LM338 pot to get 13.5V across the circuit supply line. Next, adjust the upper preset slowly until the relay just toggles ON.

Similarly, suppose we want the next transition to happen at 14.3V, ...increase the voltage to 14.3V by carefully adjusting the LM338 pot.

Then tweak the lower 10K preset such that RL#2 just clicks ON.

Done! your set up procedure is complete. Seal of the presets with some kind of glue to keep them fixed in the set positions.

Now you can attach a discharged battery to see the actions happening automatically as the battery charges with a 3 step mode.

The 470K feedback resistor can be actually eliminated and removed, instead you can connect a large value capacitor in the order of 1000uF/25V across the relay coils to restrict threshold chattering of the relay contacts.

4 Step Fast Battery Charger Working

For implementing a 4 step fast charger circuit, here we employ the versatile LM324 for sensing the different voltage levels.

The 4 steps include:

1) High Current Bulk Charging

2) Moderate Current Bulk Charging

3) Absorption Charging

4) Float Charging

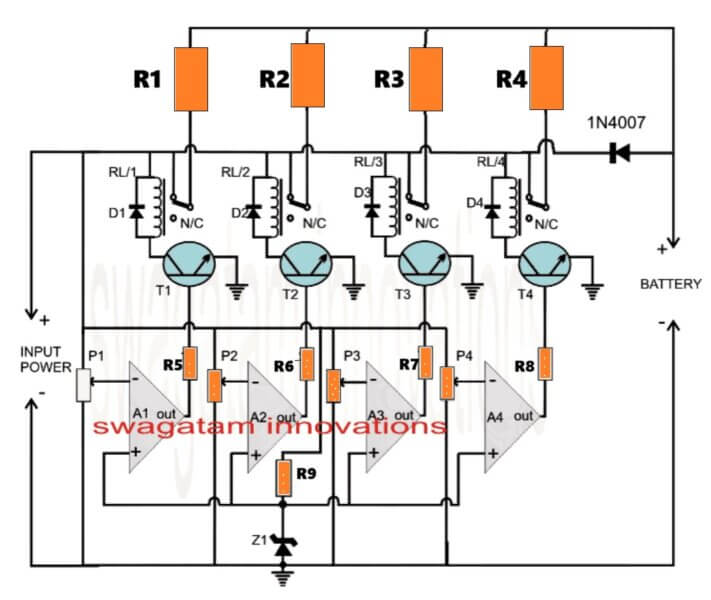

The following diagram shows how the IC LM324 may be wired up as a 4 step battery voltage monitor and cut off circuit.

Circuit Diagram

NOTE: Battery must be connected first before switching ON the input, to ensure that the circuit works correctly.

The IC LM324 is quad opamp IC whose all the four opamps are used for the intended sequential switching of the output current levels.

The proceedings are very easy to understand. opamps A1 to A2 are optimized for switching at different voltage levels during the course of the stepped charging of the connected battery.

All the non-inverting inputs of the opamps are referenced to ground through the zener voltage.

The inverting inputs are tied with the positive supply of the circuit via the corresponding presets.

If we assume the battery to be a 12V battery having a discharge level of 11V, P1 may be set such that the relay just disconnects when the battery voltage reaches 12V, P2 may be adjusted to release the relay at 12.5V, P3 may be done for te same at 13.5V and finally P4 could be set for responding at the battery full charge level of 14.3V.

R1----R4 values will be different and optimized to provide the battery with the required amount of current during the various charging voltage levels.

The value could be fixed such that each inductor allows a current passage rate that may be 1/10th of the battery Ah.

It may be determined by using ohms law:

R = I/V

How the circuit responds when switched ON

After connecting the discharged battery across the shown terminals when power is switched ON:

All the opamps inverting inputs experience a correspondingly lower voltage levels than the reference level of the zener voltage.

This prompts all the outputs of the opamps to become high and activates the relays RL/1 to RL/4.

In the above situation the full supply voltage from the input is bypassed to the battery via the N/O contacts of RL1.

The discharged battery now starts charging at a relatively extreme high current rate and rapidly charges upto a level above the discharged level until the set voltage at P1 exceeds the zener reference.

The above forces A1 to switch OFF T1/RL1.

The battery is now inhibited from getting the full supply current but keeps charging with the parallel resistances created by R1, R2, R3, R4 via the corresponding relay contacts.

This makes sure that the battery is charged at the next higher current level determined by the the three parallel inductor net value (resistances).

As the battery charges further, A2 shuts down at the next predetermined voltage level, switching OFF R2 and rendering R3, R4 only with the intended charging current to the battery. This makes sure that the amp level is correspondingly reduced for the battery.

Following the procedures as the battery charges to the next calculated higher level, A3 switches OFF allowing only R4 to maintain the required optimal current level for the battery, until it gets fully charged.

When this happens, A4 finally switches OFF making sure that the battery is now gets completely switched off after attaining the required full charge at the specified fast rate.

The above method of 4 step battery charging ensures a rapid charging without harming the battery internal configuration and makes sure the charge reaches at least at 95%.

R1, R2, R3, R4 may be replaced with equivalent wire wound resistors, however it would mean some heat dissipation from them compared the inductor counterparts.

Normally a lead acid battery would need to be charged for about 10 to 14 hours for allowing at least 90% of charge accumulation. With the above rapid battery charger circuit the same could be done within 5 hours of time, that's 50% quicker.

Parts List

- R1---R4 = As per the below given calculations.

- R5----R9 = 10k 1/4 watt 5% CFR

- P1---P4 = 10k presets

- T1---T4 = BC547

- RL/1---RL/4 = SPDT 12V relays 10amp contact rating

- D1---D4 = 1N4007

- Z1 = 6V, 1/2 watt zener diode

- A1---A4 = LM324 IC

How to Set up

To setup, first keep all the wiper arm of all the presets to ground.

Then connect a variable power supply to the INPUT side of the circuit, so that all the relays turn ON together.

Then adjust the voltage to 12.5V and slowly adjust P1 such that the relay RL/1 just turns OFF.

Next, increase the voltage to 13V and repeat the process for P2, RL/2.

Next, increase the voltage to 13.5V and repeat the process for P3, RL/3.

Next, increase the voltage to 14V and repeat the process for P4, RL/4.

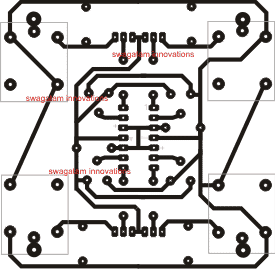

PCB design

This the original size PCB layout, from the track side, the high watt resistors are not included in the PCB design.

Solving the R1, R2, R3, R4 Resistor Value Problem:

Let's assume we want the relay to switch and deliver current to a 12V 15 Ah battery in the following sequence and conditions:

| Battery Voltage | Active Relays | Active Resistors | Individual Currents | Total Current |

|---|---|---|---|---|

| 11V → 12V | R1, R2, R3, R4 | All 4 ON | 3A + 1A + 0.7A + 0.3A | 5.0A |

| 12V → 13V | R2, R3, R4 | R1 OFF | 1A + 0.7A + 0.3A | 2.0A |

| 13V → 14V | R3, R4 | R1, R2 OFF | 0.7A + 0.3A | 1.0A |

| 14V → 14.3V | R4 | R1, R2, R3 OFF | 0.3A | 0.3A |

| >14.3V | All OFF | Charging stopped | 0 | 0A |

Resistor Values (Calculated at cutoff voltages):

| Resistor | Current | Cut-off Voltage | Vin - Vbat | Resistor Value |

|---|---|---|---|---|

| R1 | 3A | 12V | 2.3V | 2.3 / 3 = 0.77Ω |

| R2 | 1A | 13V | 1.3V | 1.3 / 1 = 1.3Ω |

| R3 | 0.7A | 14V | 0.3V | 0.3 / 0.7 ≈ 0.43Ω |

| R4 | 0.3A | 14.2V | 0.1V | 0.1 / 0.3 ≈ 0.33Ω |

Power Dissipation Formula:

Power = Current² × Resistance

P = I² × R

Full Power Calculations:

R1

- Current = 3A

- Resistance = 0.77Ω

- Power = 3² × 0.77 = 6.93W, so Use 10W or 15W

R2

- Current = 1A

- Resistance = 1.3Ω

- Power = 1² × 1.3 = 1.3W, so Use 5W

R3

- Current = 0.7A

- Resistance = 0.43Ω

- Power = 0.7² × 0.43 = 0.49 × 0.43 ≈ 0.21W, so Use 2W

R4

- Current = 0.3A

- Resistance = 0.33Ω

- Power = 0.3² × 0.33 = 0.09 × 0.33 = 0.0297W, so Use 1W

Final Resistor Table (with Power Ratings)

| Resistor | Resistance | Current | Power Dissipation | Safe Wattage |

|---|---|---|---|---|

| R1 | 0.77Ω | 3A | 6.93W | 10W or 15W |

| R2 | 1.3Ω | 1A | 1.3W | 5W |

| R3 | 0.43Ω | 0.7A | 0.21W | 2W |

| R4 | 0.33Ω | 0.3A | 0.03W | 1W |

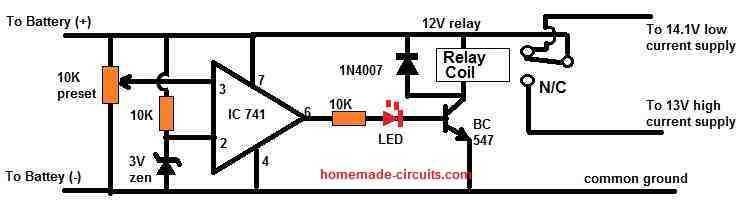

Simplest Single Op amp Fast Charger Design

The following diagram shows how a single op amp can be used to create a decent fast charger circuit for a 12V battery.

A discharged battery will be initially charged at a high current rate using the 13V supply, through the N/C contact of the relay. This will allow the battery to be charged quickly at the 13V mark within a few hours.

When the battery is charged up to 13V, the relay will changeover to the 14.1 V supply and the battery will start charging through the 14.1 V low current charging supply, until it is fully charged.

How to Set

- Initially keep the 10k preset wiper to the ground level.

- Connect a 13V fixed DC supply with the pin7 and pin4 supply lines of the IC.

- Next, adjust the preset until the relay just clicks ON from N/C to N/O, and the red LED turns ON.

- That's all, this single op amp fast charger circuit is all set now.

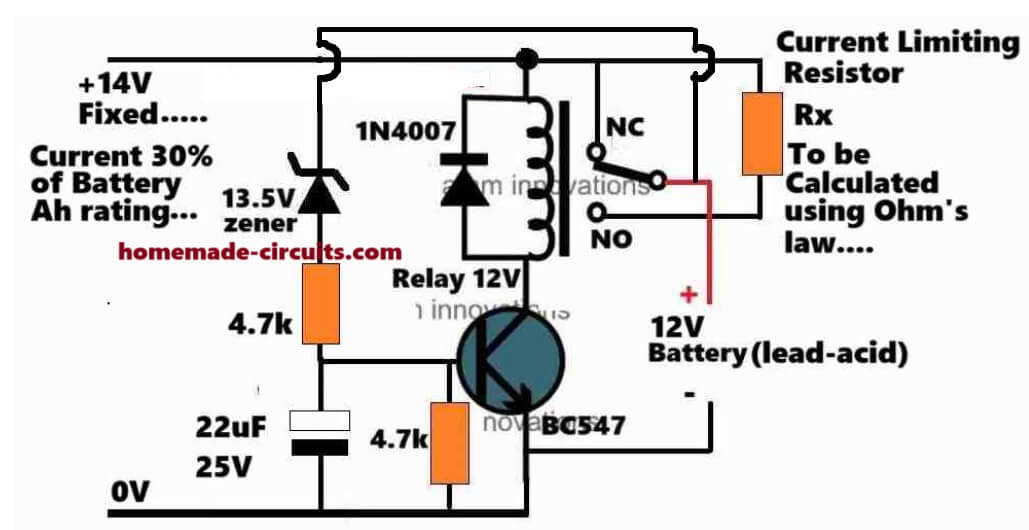

Simplest 2-Step Fast Battery Charger Circuit

In this section I will discuss a very simple yet effective battery charger circuit, which will charge your battery at a relatively faster rate than the normal charging methods.

This battery charger circuit can be used for fast charging of all types batteries, however make sure to adjust the current and the voltage of the charger according to the specifications of your battery.

That said, this fast charger circuit employs a step-charging process and therefore is specifically suitable for lead acid batteries and SMF batteries, since these batteries strictly require a step-charging method for implementing the fast charging effect. Li-ion batteries have no such restrictions, and can be quickly charged directly through a relatively high current input, and therefore do not strictly depend on step charging.

Now, let's understand how the circuit is designed to work.

How the Circuit Works

If you do not want to read the explanation below, you can simply watch this video instead:

Referring to the circuit diagram below, we can see that is basically a two step battery charger circuit, which will allow an initial high current charging for a lead acid battery, until the battery voltage has reached around 75% of its full charge level, wherein the circuit will switch the current to a lower level and continue the charging process until the battery attains the full charge level.

Here, the circuit is configured for fast charging of a 12 volt lead acid battery.

The NPN transistors works like a voltage sensor.

The Zener diode at the base decides at what voltage threshold the transistor needs to switch ON.

Here, the Zener diode is fixed at a 13.5 volt level, which means that the transistor will turn ON when the battery has charged up to the 13.5 volt level.

When the transistor turns ON, the connected relay also turns ON, causing its contacts to shift from its initial N-C contact to its N-O contact.

Initially, while the voltage level of the battery is below the 13.5 volt changeover threshold, the battery is allowed to charge with a relatively high current through the N-C contacts of the relay.

With this initial high current, the battery starts charging at a faster rate and quickly reaches the 13.5 volt level, wherein the transistor switches ON and causes the relay to changeover from its N-C contact to its N-O contacts.

The N-O contacts of the relay can be seen configured with a current limiter stage which consists of a high watt resistor, whose value determines the amount of current that needs to be reduced for the last phase of the charging process.

The battery now continues to charge but with a reduced current until finally it reaches its full charge level.

Please note that here the full charge level for the 12 volt lead acid battery must be restricted to a maximum of 14 volt which is around 0.3 volt lower than its actual maximum full charge level of 14.3 volts.

This reduced full charge level of 14 volt is intentionally chosen to ensure that the battery never reaches its highest 14.3 volt level, which in turn allows the battery to be connected with the reduced supply current indefinitely, without the need of an automatic cut off mechanism.

For a 12 volt lead acid battery, the initial high current charging may be done by using a maximum current which could be around 30% of its A-h rating.

For the current limiting, the above current may be reduced to around 7% of the battery A-h rating.

Calculating the Current Limiting Resistor Rx

The current limiting resistor must be calculated accordingly, using Ohm's law, as shown below:

Rx = V/I = (14 - 13.5)/Ah * 10%

Remember, the initial charging current which is selected here as 30% of the battery A-h must be thoroughly examined. If you find your battery warming up significantly with a 30% initial charging rate, you must reduce this level until the warming of the battery reduces to an acceptable level.

If you have any further questions regarding the above design please feel free to comment below with your queries.

Comments

Sir,

Good day to you I am back my name is Dr.Christopher Halgryn and my only HOBBY is ELECTRONICS apart from my professional work.

I really enjoy again all the circuits you design and provide but I have had enough now searching for the CAR (for my cars) BATTERY CHARGER a good circuit with a float mode as I want the battery to log onto FLOAT charge as soon as the battery reach full charge level .

I am sick and really tired of the circuit contributors on the internet out there with circuits that NEVER work properly and I have spend so much money on their designs and at the end NO LUCK so Sir, I fully trust you will be able to provide me a good professional circuit of a Car battery charger for my cars.

I have seen some of your charging circuits maybe please advise me which circuit to use and I will buy all the components need no worries.

I have build some of your designs in the past GREAT….they all worked perfectly and thank you for that.

Please advise me at your earliest convenience,

Respectfully,

Dr.Chris

Thank you Dr.Chris,

I greatly appreciate your trust on this website, however I would like to kindly suggest you that if you yourself make an effort to understand the working of the circuit, then you may not have to blindly trust an online resource, you can yourself judge and decide whether the design is worth trying or not.

Here’s one circuit which will fulfil your requirement, in order to add float charging facility just add a calculated resistor across the collector/emitter of the TIP36 transistor….the voltage specs of the charger can be modified appropriately…. if you can tell me the voltage and current specifications of your battery, I can fine-tune the circuit precisely to suit your requirements:

https://www.homemade-circuits.com/wp-content/uploads/2012/08/48V-battery-charger-with-current-control-constant-current.jpg

Hello sir, thank you for resistors calculation, I thought that Voltage for each step calculate in this way: V input- V battery in beginning of that step for example in step 1, battery voltage is 11v and input voltage is 14.3v then 14.3-11=3.3v. because Potential difference in first and end of resistor is input voltage – battery voltage (That doesn’t seem right).

Hello Ruhollah, You are absolutely correct. I have corrected the calculations now and updated it in the above article, please check it…

Hello sir, thanks for review and calculate amounts of resistors and power of them. Is 14.3V suitable for this circuit or 14.5V?

You ae welcome ruhollah, 14.3V is the perfect charging input for a 12V battery, although 14.5V will also work nicely…

I very much appreciate your help.

You are welcome!

Hello, in 4 step charger using op amp circuit, if initial current (about 30% of battery Ah) be 5A and input voltage be 14V, amount resistance and power for each Rx, Ry and Rz: 2Ohm 2W is correct? In this case, step 2 current is 3A, step 3, 1.5A and step 4, 0.25A

I will calculate it soon and let you know, the combined resistor current will be 5 amp and let’s assume the last trickle charge value can be 500 mA.

ruhollah, Please check the above article, I have updated the calculations accordingly…

Hello, in 4 step charger with initial current of 5A, step 2 current limit of 3A, step 3 current limit of 2A and step 4 current limit of 0.5 A these amounts for resistors are true? Rz: 1 ohm, 4W Ry: 3 ohm, 1.34=2 W and Rx: 6.2 ohm, 0.64=1 W

In 3 step charger using BJTs, can connect LED to specify charging step? how can do this? the LEDs where should connect?

Thank you, but in 3 Step fast Battery Charger Circuit using Only Transistors and 4 Step Fast Battery Charger circuit using Apamp IC, in final step, charging completely stops. these two method (stop charging completely and trickle charging in final step) not different? Are these have one influence? 14V or 14.3V fixed input supply is better? If one diode be series (forward bias) with a fuse and forward current of diode be small than fuse current (about 1/6 of it), in case that much current (>fuse current) pass through the circuit, then fuse burn or diode or both them?

In none of the above circuits, the battery is fully cut off, all the circuits are using trickle charging.

At 14V the battery will be maybe only 70% charged, and at 14.3V it could be above 90% charged….charging at 70% might help to keep the battery life longer..

The diode should be 2 times the input supply current level, and the fuse should be slightly higher than the set maximum charging current level of the battery.

Ok, when the battery voltage receive to 14V, relay cut step 1 charge and step 2 begin, this step (2) when cut and prevent over charge? In reverse polarity with fuse and diode, the diode place in circuit as revers bias and when battery connect to circuit as reverse polarity, the diode in forward bias and for short connection that happen, much current pass through diode and fuse, if forward current of diode be much smaller than fuse current, diode will not burn? In this case reverse current of diode not matter. I say it for current depletion in the limit of uA when everything is ok and reverse polarity not raised.

Step2 will never cut off and it will keep charging the battery forever, but nothing to worry, because it is only trickle charging. In that case make sure to use a fixed constant voltage of 14.3V input supply for the charger.

The reverse voltage from the battery can never burn the diode, no matter how big the reverse current is, until off course the PIV of the diode is exceeded, which can be as high as 1000V.

I have 20A 12V CCTV UPS with one step charger, I connect battery to it by revers polarity and then fuse and diode that have revers polarity protection role in circuit, burn. Fuse was 20A and diode was IN5408 (Average Rectified Current 3A), for this reason (prevent of diode burn in reverse polarity connection) I decide to exchange the diode with more forward current (> 20A) and small reverse current about 5uA (reverse current of IN5408 diode) such as MM60F060P that has forward current of 60A and reverse current of 10uA. In some circuit with reverse polarity protection by diode and fuse I see this problem that burn fuse and diode together. For increase battery life in UPS that say, I decide to replace one step charger with 2 or more step chargers. I want to use best choice for reverse polarity protection diode and charger for this UPS for increase efficiency of it and decrease the future problems. My much questions are for this subject and my like the electronic. excuse me

1N5408 will NEVER burn to a reverse supply as long as the reverse voltage is well below 1000V, the current does not matter in this case. It seems your diode was faulty or duplicate quality.

Hello, I have slight variable 12V power, If this power use instead DC input, what change in 2 step charger circuit? in each steps input voltage and in 2th step, current percent relative to battery Ah how much should be? If need potentiometer preset, please explain how do it. in 4 step charger, if use 30% of battery Ah for initial current, please say how much current ( percent relative to battery Ah ) is better in other steps.

30% means 30 percent. If battery is 100Ah then 30% of it is 30Ah.

Adjust R1 value to supply 5% when battery is charged up to 14V using Ohm’s law.

Input supply must be rated at not more than 30% of the battery Ah and voltage should be fixed at 15V.

Relay Cut off must be adjusted at 14V, when the current kicks in…

https://www.homemade-circuits.com/wp-content/uploads/2023/08/fast-car-battery-charger-circuit.jpg

Hi, for increase battery life, I want to reduce initial current to 10% of battery Ah, then in one step that all relays are on, current is 10% of battery Ah, in the end step that last relay is on, current about 2% of battery Ah is suitable? In 2th step ( relay 1 is off ) and 3th step ( relay 1 and 2 are off ), how much current ratio is suitable?

Another questions is that for reverse polarity protection with diode ( diode connect by revers bias of current ), ampere of fuse is about 2 times of diode ampere, in reverse connection of battery or input voltage, current pass through the diode then fuse and fuse burn because short circuit but diode may burn too, because ampere of it is lower than fuse and current ampere bigger than diode forward ampere, why do not use diode with ampere equal to fuse or bigger it to prevent diode damage?

If you want to use 10% initial charging current then what’s the point using the 4 step fast charging process? The charging current can be higher than 10% when the battery is discharged state, and then the current should be reduced to 10% and below as the battery reaches its full charge level. This will not affect the life of battery

If you want to use 10% initial current then no need of the 4 step charging, use two step charging as shown in the following diagram:

The diode rating must be two times the maximum current output from the transformer or the input DC supply source so it can never burn. The fuse should be slightly higher than the maximum charging current of the battery.

https://www.homemade-circuits.com/wp-content/uploads/2023/08/fast-car-battery-charger-circuit.jpg

Hello sir, in 4 Step Fast Battery Charger with LM324 IC circuit, in every steps, current how percent of initial current? ( in one step is 100 percent, in others, how much of this initial current )

Ruhollah, Initial combined current from all the relay outputs can be 30% of the battery Ah, then reduce it in steps for each relay operation, until the last relay gives only 5% current of the battery Ah.

Hello sir, in 4 Step Fast Battery Charger with LM324 IC circuit, please calculate Rx, Ry and Rz resistance and power for 2A initial current (about 1/10 AH of 12V 18AH battery), Is 14.5V input suitable for this circuit? How to Set up the Presets? What changes in this circuit should be take to make it into 12V online UPS?

Hello ruhollah,

You can use ohm’s law to calculate the values of those resistors.

Yes, 14.5V can be used for a 12V battery.

To setup, first keep all the wiper arm of all the presets to ground.

Then connect a variable power supply to the INPUT side of the circuit, so that all the relays turn ON together.

Then adjust the voltage to 12.5V and slowly adjust P1 such that the relay RL/1 just turns OFF.

Next, increase the voltage to 13V and repeat the process for P2, RL/2.

Next, increase the voltage to 13.5V and repeat the process for P3, RL/3.

Next, increase the voltage to 14V and repeat the process for P4, RL/4.

Checkout this article for online UPS

https://www.homemade-circuits.com/simple-online-ups-circuit/

Hello, ok, thank you very much, in initial current of 2A, how many percent of this should be in 2th, 3th, and 4th stage of charge (max limit current in percent in every stage)?

The current levels are not critical. At the initial stage use a combined current output which may be 30% of the battery Ah, then go on reducing it until at the last stage the current is reduced to maybe 5% of the battery Ah level. Assuming the battery is a lead acid battery…

Thank you so much Sir,

Please can you help to understand how the charging current is calculated at three different levels.

Also most of the charge controllers today are using programmable IC, does that mean it is better with programmable ic , if yes can you please help us in the future to post charge controller design using such programmable ICs.

Thank you Sir may God bless you.

You are most welcome Mudassir, programmable IC based chargers are used for enabling fast charging only, but normally these chargers are simply not required. The best way to charge a battery is through constant current and constant voltage for the full specified duration of time, which can be a bit slower but that guarantees longer life for the battery.

Hi there!! Thank you so much for your design and taking the time to do this and read this comment. I am doing a project right now that is a battery charger for a robot and we would like to use the AC-DC converter of a laptop charger (19V 3A). Currently I have a DC-DC buck converter conected to it and it seems to charge fine but the batteries are AGM and I would like to extend the battery life as much as possible. Anyways I was wondering how this circuit would work if it was a DC input and a DC output and what changes I would need to make. Thank you for your time!

Hi, yes you can definitely use the above design for charging AGM batteries. Here too the input is DC, from the bridge rectifier, so for your case you will just have eliminate the transformer and the bridge rectifier. The LM338 can provide upto 5 amp current, for higher currents you can replace it with a LM396, or upgrade the LM338 with an outboard transistor

Hi, just looking at your design it looks like it could work for me. I need to charge a 12 volt 75ah AGM battery, and need a charger that can be incorperated in a small portable inverter power supply unit. Could this circuit be modified for a maximum charge current of at least 8 amps?

Hi, yes you can increase the current either by connecting two LM338 ICs in parallel over a common heatsink, or by replacing the LM338 with a single LM196 IC

or this one

https://www.analog.com/media/en/technical-documentation/data-sheets/1038fa.pdf

Thanks Swagatam, Re the LT1308 I see it is now an obsolete item. I will investigate further for a decent replacememt. Right now I am going for a more basic charger and as time permits I will put an improved one in the system. As I am using AGM batteries I need a charger that I can trust to give it a full charge and to keep it there, in a float charge function.

No problem Edmund, the basic thing to consider is the over-charge cut off for any AGM battery.

I studied this article critically and I have a few questions

1. Why the need for the r1, r2… to reduce the current, since the current reduces as battery near full.

2. But at 13.5v the charging voltage should reduce from 14.4v to 13.8v for absorption mode

Thanks Adeyemi,for studying the article deeply.

If R1. R2, are not used then the 3 step process will become meaningless, and the battery will get damaged due to high current.

Lead acid battery must be charged at minimum 14.2V to get an optimal back up. Absorption begins after 14 V mark. At this level the voltage does not need to be reduced, rather the current needs to be reduced to initiate the absorption and also the float charging.

Hi Sir.

I want to ask some questions,

If I add 2 more steps, could it reduce the charging time?

If YES, could you design me for 5 steps of charging?

If NO, could you give me the reason?

THANK YOU, SIR!

Hi Geo, No, adding more steps will not help to increase charging speed, and fast charging is anyway not good for any battery.

In fact, even a 3-step charging is not necessary for a Li-Ion. A standard 0.5C rate charging is quite enough and will ensure a healthy battery life.

Ultimately it’s the temperature level of the battery that becomes crucial factor while charging. Whether it’s step charging or normal charging the battery temperature must not exceed 37 degrees Celsius. However in step charging since the initial charging current can be significantly high (at 1 C rate) the battery may become quite warm which must be monitored and controlled either using a fan cooler or an auto shut down circuitry.

Therefore, in my opinion a simple constant current, constant voltage charger should be the recommended one for maintaining healthy charging and long life for the battery.

Tolu, Glory, favour, you can swap the input pin 3 and 2 with each other…the source and R3 will now connect with the positive, and drain/load with negative..

connecting capacitor across base/emitter of the BC547 will definitely prevent relay chattering, try increasing the value to 100uF…also the 470K should latch the relay, once the relay switches ON, decrease the 470k to 100K for quicker latching…another option to ensure perfect relay operation is to add a 10uF or similar capacitor across pin#3 and ground of the op amps.

https://www.homemade-circuits.com/current-servo/

For this circuit how can I convert it to use p channel MOSFET instead of n channel

Ok sir, done but no difference sir

Hi Glory, you an connect a 10uF/25V across base/ground of the BC547, and check the response

Good day sir, please how can i latch this circuit below. at preset battery full voltage the relay flickers

You are welcome e_n,

yes the fast battery charger circuit can be used for charging high Ah batteries in 3 steps.

Swagatam Thank you so much!!

I understand, after reading through comments below, that this circuit is not really suitable for high AH battery. Actually, I am looking for a charger circuit that can fast charge lead acid battery with high AH. Do you think this circuit on your website (https://www.homemade-circuits.com/fast-battery-charger-circuit/) should work? If so, I will probably ask you several questions after I finish my reading on how the circuit works.

Best regards

Hi electronic noob,

R1, R2, R3 are toggled sequentially by the op amp and the relays to regulate the current for the battery as the battery reaches toward the full limit.

The 0.6 is the optimal switching voltage level of the BC547

Swagatam many thanks for quick response. If you don’t mind, I would like to ask few more questions regarding to the circuit.

Is the current limit set by the value of R1? and i am not sure if i understand how to calculate correctly. So here it goes

To calculate R1, you stated that R1 = 0.6/ half battery AH. If battery is 100 AH, R1 = 0.6/50 =0.012 ohm? can you explain where 0.6 come from? and What would be power rating for this R1?

Really appreciate your time in teaching me.