In this article I will be discussing a list of simple 12V battery charger circuits which are very easy and cheap by its design yet extremely accurate with its output voltage and current specs.

All the designs presented here are current controlled meaning their outputs will never go beyond a predetermined fixed current level.

UPDATE: Looking for a high current battery charger? These powerful Lead Acid battery charger designs might help you to fulfill your requirement.

UPDATE: Looking for a car or an automobile battery charger circuit? Make sure to read this article on Regulated Car Battery Charger Circuit for Garage Mechanics

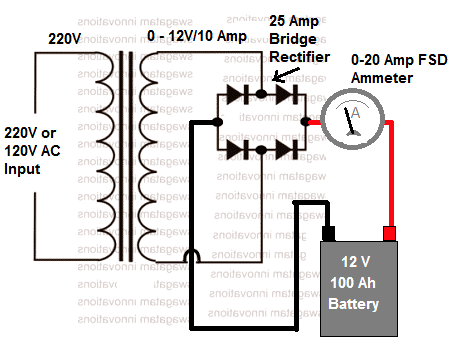

Simplest 12 V Battery Charger

As I have reiterated in many articles, the main criteria to charge a battery safely is to keep the maximum input voltage slightly below the full charge spec of the battery, and keep the current at a level that does not cause warming of the battery.

If these two conditions are maintained you can charge any battery using a minimal circuit as simple as the following one:

In the above simplest layout the 12 V is the RMS output of the transformer. That means, the peak voltage after rectification will be 12 x 1.41 = 16.92 V.

Although this looks higher than the 14 V full-charge level of the 12 V battery, the battery is not actually harmed due to the low current specification of the transformer.

That said, it is advisable to remove the battery as soon as the ammeter reads near zero volts.

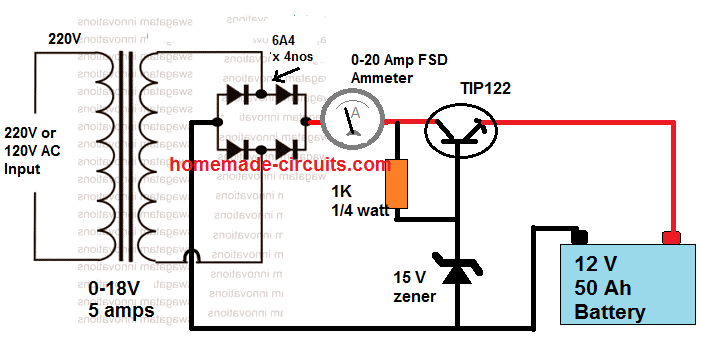

Auto Shut-OFF: If you want to make the above design to auto shut off when the full charge level is reached, you can easily accomplish this by adding a BJT stage with the output as shown below:

In this design, we have used a common emitter BJT stage which has its base clamped at 15 V, which means that the emitter voltage can never go beyond 14 V.

And when the battery terminals tend to reach above the 14 V level, the BJT gets reversed biased and simply goes into an auto shut down mode. You can tweak the 15V zener value until you have around 14.3 V at the output for the battery.

This transforms the first design into a fully automatic 12 V charger system, which is simple to build yet entirely safe.

Also, since there's no filter capacitor the 16 V is not applied as a continuous DC, rather as 100 Hz ON/OFF switching. This causes less stress on the battery, and also prevents sulfation of the battery plates.

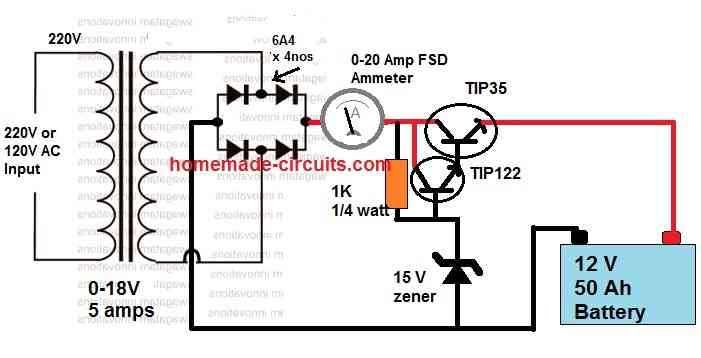

For High Current Battery Charging, the above Schematic can be Modified as Shown Below:

Why Current Control is Important (Constant Current Setup)

Charging any form of chargeable battery can be critical and involves some attention to be paid. When the input current at which the battery is being charged is significantly high, adding a current control becomes an important factor.

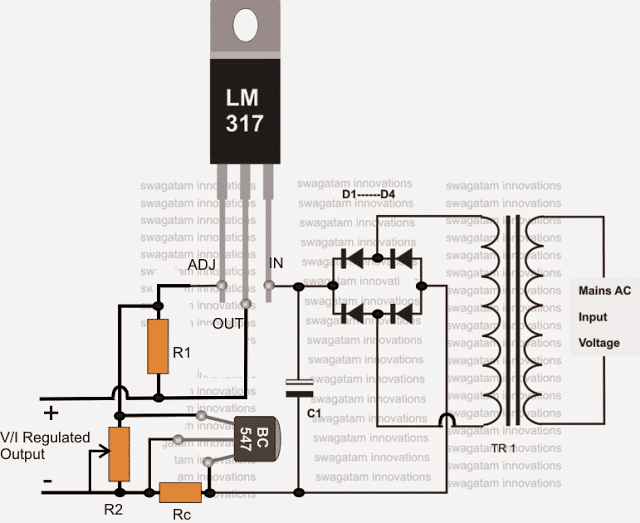

We all know how smart the IC LM317 is and it’s no surprise why this device finds so many applications requiring precise power control.

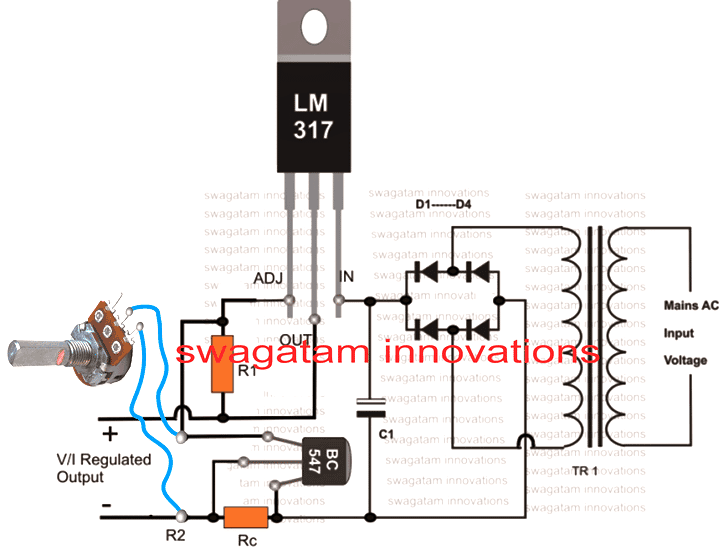

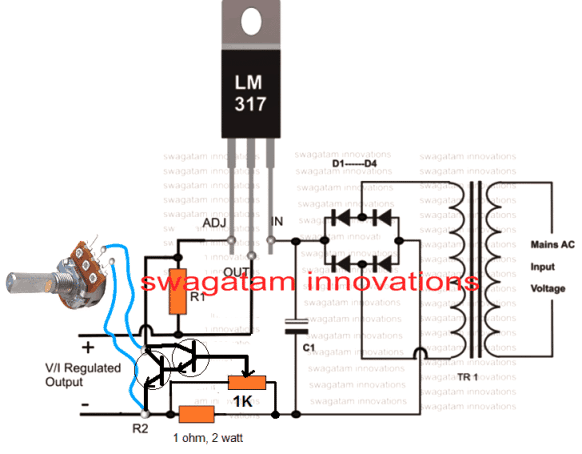

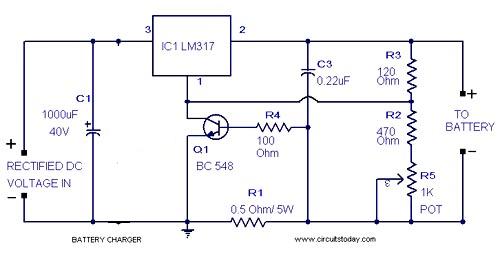

The Current Controlled 12V Battery Charger Circuit Using IC LM317 presented here shows how the IC LM317 can be configured using just a couple resistors and an ordinary transformer bridge power supply for charging a 12 volt battery with utmost accuracy.

How it Works

The IC is basically wired in its usual mode where R1 and R2 are included for the required voltage adjustment purpose.

The input power to the IC is fed from an ordinary transformer/diode bridge network; the voltage is around 14 volts after the filtration via C1.

The filtered 14 V DC is applied to the input pin of the IC.

The ADJ pin of the IC is fixed to the junction of the resistor R1 and the variable resistor R2. R2 can be fine set for aligning the final output voltage with the battery.

Without the inclusion of Rc, the circuit would behave like a simple LM 317 power supply where the current wouldn't be sensed and controlled.

However with Rc along with BC547 transistor placed in the circuit at the shown position makes it capable of sensing the current that’s being delivered to the battery.

As long as this current is within the desired safe range, the voltage remains at the specified level, however if the current tends to rise, the voltage is withdrawn by the IC and dropped, restricting the current rise any further and ensuring appropriate safety for the battery.

The formula for calculating Rc is:

R = 0.6/I, where I is the maximum desired output current limit.

The IC will require a heatsink for operating optimally.

The connected ammeter is used for monitoring the charge condition of the battery. Once the ammeter shows zero voltage, the battery may be detached from the charger for the intended use.

Circuit Diagram #1

Parts List

The following parts will be required for making the above explained circuit

- R1 = 240 Ohms,

- R2 = 10k preset.

- C1 = 1000uF/25V,

- Diodes = 1N4007,

- TR1 = 0-14V, 1Amp

How to Connect pot with LM317 or LM338 Circuit

The following image shows how the 3 pins of a pot needs to be correctly configured or wired with any LM317 voltage regulator circuit or a LM338 voltage regulator circuit:

As can be seen the center pin and any one of the outer pins is selected for connecting the potentiometer or the pot with the circuit, the third unconnected pin is kept unused.

Circuit Diagram #2

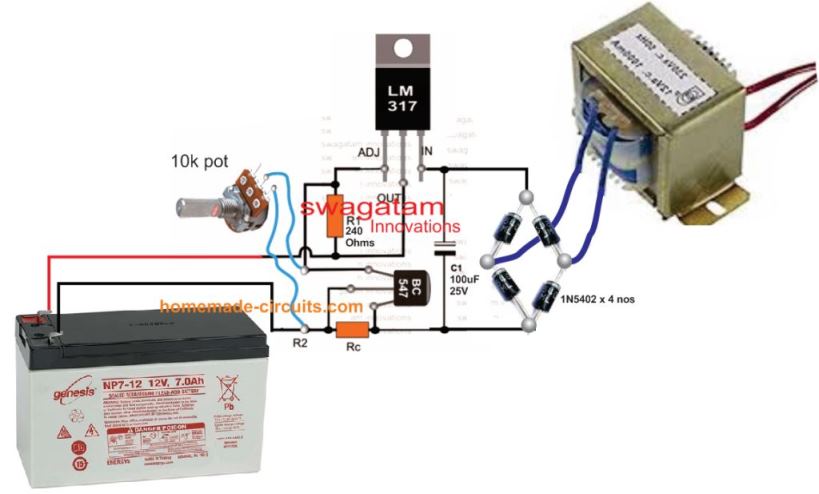

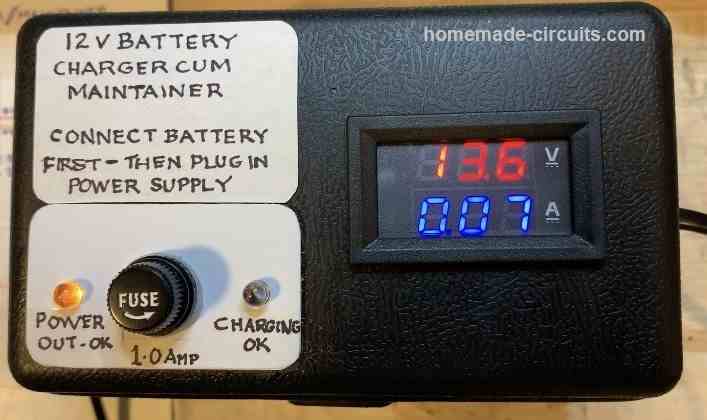

Practical Results

The above LM317 battery charger circuit was suitably modified using fixed resistors, by one of the dedicated members of this blog Mr. V. The modified circuit was then utilized to charge a battery optimally and safely.

The following circuit diagrams exhibit how this was implemented, and the next prototype image shows the test results.

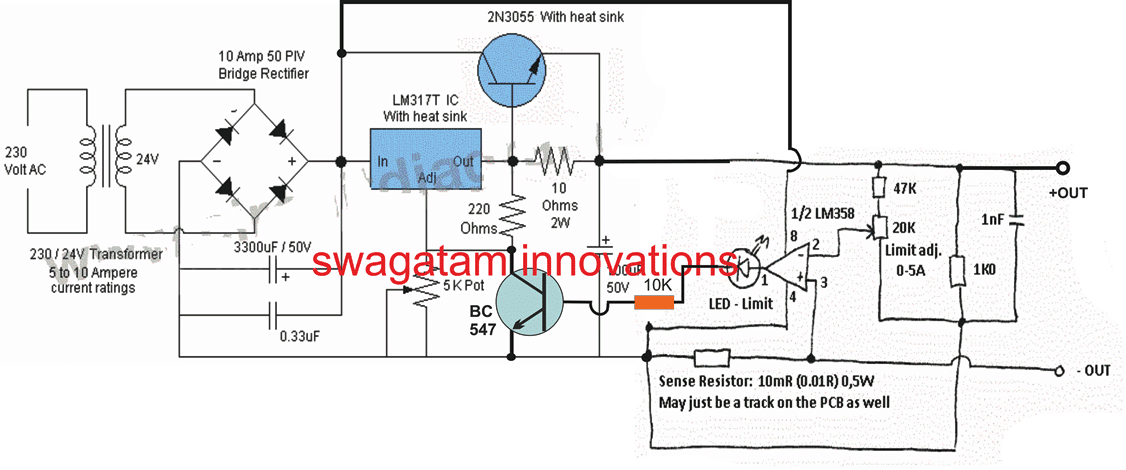

Adjustable High Current LM317 Battery Charger Circuit #3

For upgrading the above circuit into a variable high current LM317 battery charger circuit, the following modifications can be implemented:

Adjustable Current Charger Circuit #4

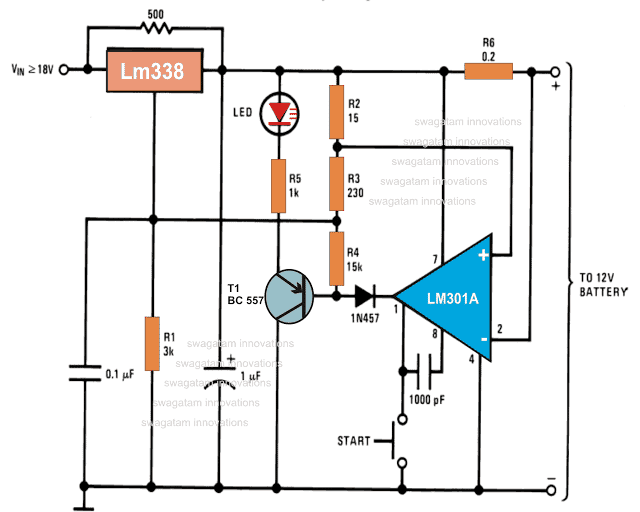

5) Compact 12 volt Battery Charger Circuit Using IC LM 338

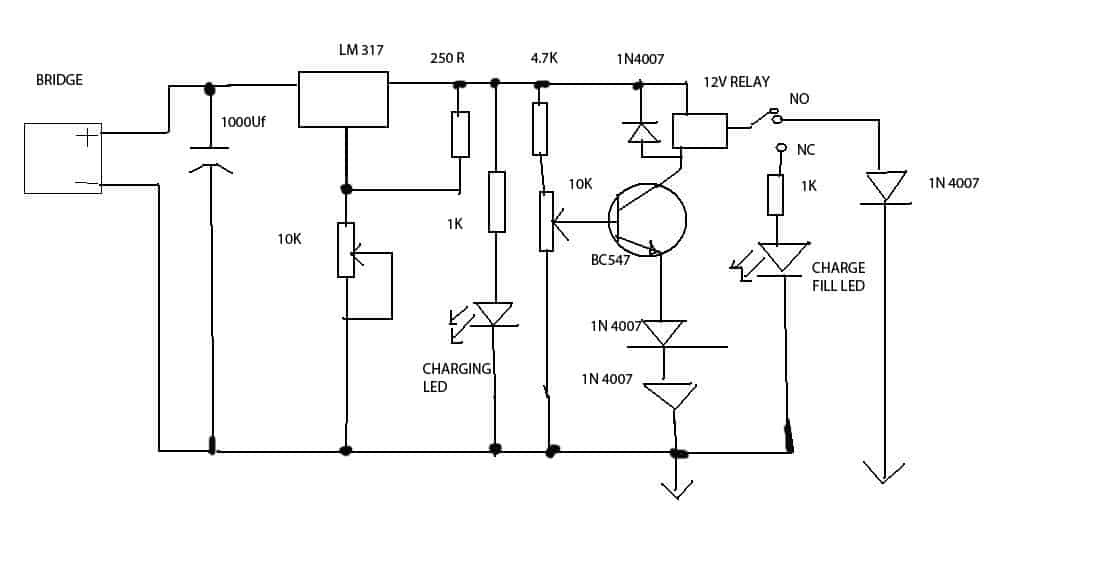

The IC LM338 is an outstanding device which can be used for unlimited number of potential electronic circuit applications. Here we use it to make an automatic 12V battery charger circuit.

Why LM338 IC

Basically the main function of this IC is voltage control and can also be wired for controlling currents through some simple modifications.

Battery charger circuit applications are ideally suited with this IC and we are going to study one example circuits for making a 12 volt automatic battery charger circuit using the IC LM338.

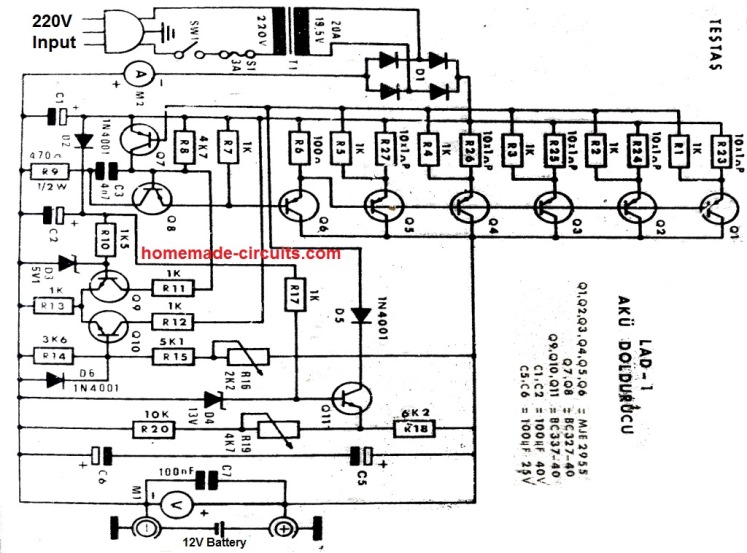

Referring to the circuit diagram we see that the entire circuit is wired around the IC LM301, which forms the control circuit for executing the trip off actions.

The IC LM338 is configured as the current controller and as the circuit breaker module.

Using LM338 as a Regulator and Opamp as the Comparator

The whole operation can be analyzed trough the following points:The IC LM 301 is wired as a comparator with its non inverting input clamped to a fixed reference point derived from a potential divider network made from R2 and R3.

The potential acquired from the junction of R3 and R4 is used for setting the output voltage of the IC LM338 to a level that’s a shade higher than the required charging voltage, to about 14 volts.

This voltage is fed to the battery under charger via the resistor R6 which is included here in the form of a current sensor.

The 500 Ohm resistor connected across the input and the output pins of the IC LM338 makes sure that even after the circuit is automatically switched OFF, the battery is trickle charged as long as it remains connected to the circuit output.

The start button is used to initiate the charging process after a partially discharged battery is connected to the output of the circuit.

R6 may be selected appropriately for acquiring different charging rates depending upon the battery AH.

Circuit Functioning Details (As Explained By +ElectronLover)

" As soon as the connected battery is charged fully, the potential at the inverting input of the opamp becomes higher than the set voltage at non-inverting input of the IC. This instantly switches the output of the opamp to logic low."

According to my assumption:

- V+ = VCC - 74mV

- V- = VCC - Icharging x R6

- VCC= Voltage on pin 7 of Opamp.

When The battery charges fully Icharging reduces. V- become greater than V+, output of the Opamp goes low, Turning on the PNP and LED.

Also, R4 gets a ground connection through the diode. R4 becomes parallel to R1 reducing the effective resistance seen from the pin ADJ of LM338 to GND.

Vout(LM338) = 1.2+1.2 x Reff/(R2+R3), Reff is the Resistance of pin ADJ to GND.

When the Reff reduces the output of LM338 reduces and inhibit charging.

Circuit Diagram

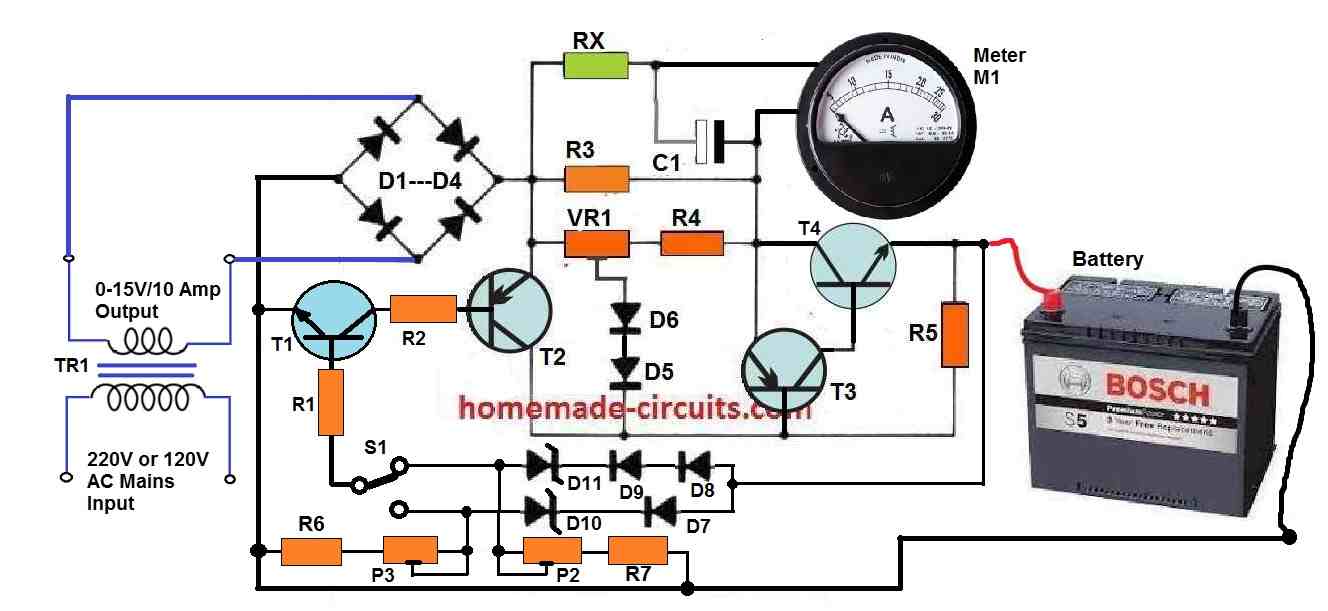

6) 12V Charger Using IC L200

Are you looking for a constant current charger circuit to facilitate a safe charging battery? The 5th simple circuit presented here using the IC L200 will simply show you how to build a constant current battery charger unit.

Importance of Constant Current

A constant current charger is highly recommended as far as maintaining safety and long battery life is concerned. Using the IC L200, a simple yet a very useful and powerful automobile battery charger providing constant current output can be built.

I have already discussed many useful battery charger circuits through my previous articles, some being too accurate and some much simpler in design.

Although the main criteria involved with charging batteries largely depends on the type of the battery, but basically it’s the voltage and the current which particularly needs appropriate dimensioning to ensure an effective and safe charging of any battery.

In this article I have explained a battery charger circuit suitable for charging automobile batteries equipped with visual reverse polarity and full-charge indicators.

The circuit incorporates the versatile but not so popular voltage regulator IC L200 along with a few external complementing passive components to form a full fledged battery charger circuit.

Let’s learn more about this constant current charger circuit.

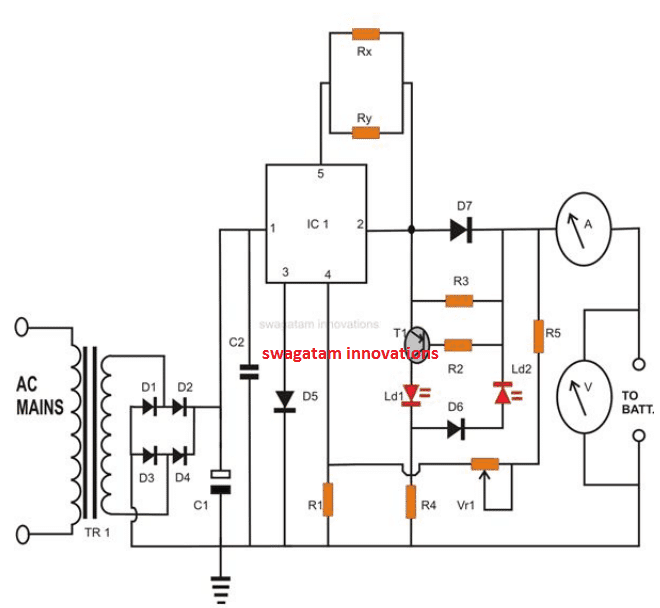

Circuit diagram using L200 IC

Circuit Operation

The IC L200 produces a good voltage regulation and therefore ensures a safe and a constant current charging, a must for any kind of chargeable battery.

Referring to the figure, the input supply is acquired from a standard transformer/bridge configuration, C1 forms the main filter capacitor and C2 being responsible for grounding any left residual AC.

The charging voltage is set by adjusting the variable resistor VR1, with no load connected at the output.

The circuit includes a reverse polarity indicator using LED LD1.

Once the connected battery becomes fully charged i.e. when its voltage becomes to the set voltage, the IC restricts the charging current and stops the battery from over charging.

The above situation also reduces the positive biasing of T1 and creates a potential difference of above -0.6 volts, so that it starts conducting and switches LD2 ON, indicating that the battery has reached its full charge and may be removed from the charger.

The resistors Rx and Ry are the current limiting resistors required to fix or determine the maximum charging current or the rate at which the battery needs to be charged. It is calculated using the formula:

I = 0.45 (Rx + Ry) / Rx.Ry.

The IC L200 may be mounted on a suitable heatsink to facilitate consistent charging of the battery; however the built-in protection circuitry of the IC virtually never allows the IC to get damaged. It typically includes built-in thermal run away, output short circuit and over load protections.

Diode D5 ensures that the IC doesn’t get damaged in case the battery accidentally gets wrongly connected with reverse polarities at the output.

Diode D7 is included to restrict the connected battery from getting discharged through the IC in case the system is switched OFF without disconnecting the battery.

You may quite easily modify this constant current charger circuit to make it compatible with the charging of a 6 Volt battery by doing the simple changes in the value of a few resistors. Please refer the parts list to get the required info.

Parts list

- R1 = 1K

- R2 =100E,

- R3 = 47E,

- R4 = 1K

- R5 = 2K2,

- VR1 = 1K,

- D1—D4 AND D7 = 1N5408,

- D5, D6 = 1N4148,

- LEDS = RED 5mm,

- C1 = 2200uF/ 25V,

- C2 = 1uF/25V,

- T1 = 8550,

- IC1 = L200 (TO-3 Package)

- A = Ammeter, 0-5amp,

- FSDV =Voltmeter, 0-12Volt FSD

- TR1 = 0 - 24V, current = 1/10 of the battery AH

How to Set up the CC Charger Circuit

The circuit is set up in the following manner:

Connect a variable power supply to the circuit.

Set the voltage close to the upper threshold volt level.

Adjust the preset so that the relay remains activated at this voltage.

Now raise the voltage slightly more to upper threshold volt level and again adjust the preset such that the relay just trips off.

The circuit is set, and can be used normally using a fixed 48 volts input for charging the desired battery.

A request from one of my followers:

Hi Swagatam,

I got your email from a website www.brighthub.com where you shared your expertise with regards to construction of a battery charger.

Please i have a little problem that i hope you could help me out:

I am just a layman with no much knowledge of electronics.

I have been using a 3000w inverter and recently i discovered it doesnt charge the battery (but inverts). We have no much experts around here and for fear of further damaging it, i decided to get a separate charger to charge the battery.

My question is: the charger i got has an output of 12volts 6Amps will that charge my dry-cell battery with 200ahs capacity?

If yes, how long will it take to full and if no, what charger capacity do i get to serve that purpose? I have had experience in the past where a charger damaged my battery and i don't want to risk that this time.

Many thanks.

Habu Maks

My Answer to Mr. Habu

Hi Habu,

The charging current of a charger should be ideally rated at 1/10 of the battery AH. That means for your 200 Ah battery the charger must be rated at around 20 Amps.

At this rate the battery will take around 10 to 12 hours for getting fully charged.

With a 6 amp charger it may take ages for your battery to get charged, or simply the charging process might fail to initiate.

Thanks and Regards.

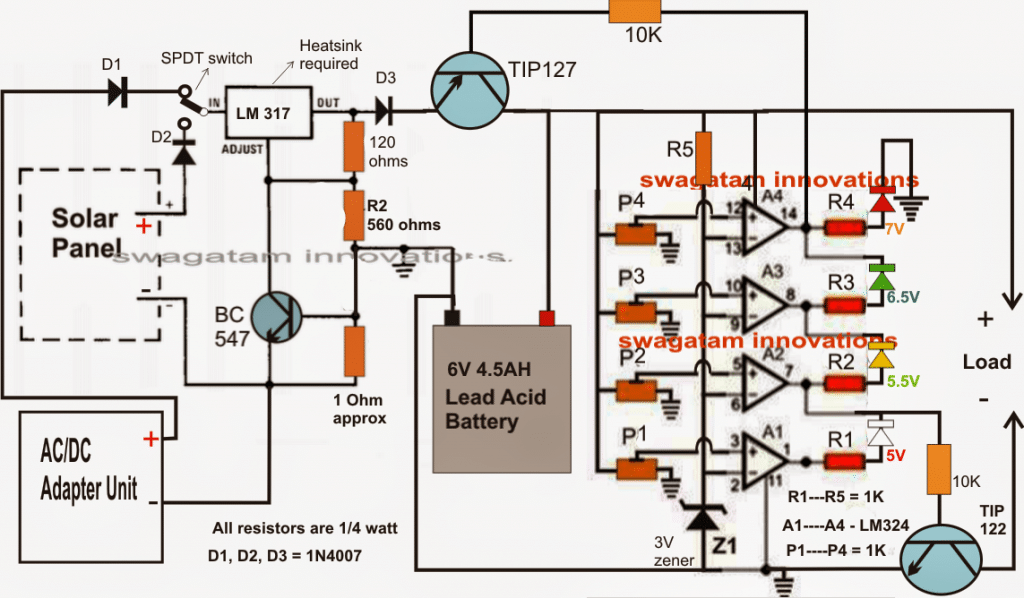

7) Simple 12V Battery Charger Circuit with 4 LED Indicator

A current controlled automatic 12V battery charger circuit with 4 LED indicators can be learned in the following post. The design also includes a 4 level charging status indicator using LEDs. The circuit was requested by Mr. Dendy.

Battery Charger with 4 LED Status Indicator

I would like to ask and look forward to you to be made Automatic cellphone charger circuit 5 Volt and Battery Charger Circuit 12 V (in the schematic circuit and the first transformer CT) automatic / cut off by using a battery indicator and

LED lights red as an indicator were charging (Charging On Indicator) using IC LM 324, and

LM 317 and a full battery using a green LED and breaking electrical current when the battery is full.

For cellphone charger circuit 5 Volt I want to have levels of the following indicators:

0-25% battery is in the charger using a red LED.25-50% using a blue LED (red LED goes out)55-75% using a yellow LED (LED red, blue outages)75-100% using a green LED (LED red, blue, yellow outages) next to Battery Charger Circuit 12 V I want to use the 5 LED lights as follows:0-25% using a red LED25-50% using orange LED (red LED goes out)50-75% using a yellow LED (LED red, orange outages)75-100% using a blue LED (Led red, orange, yellow outages)more than 100% using the green LED (LED red, orange, yellow, blue outages).

I hope you, the components are common and accessible and made a circuit schematic above as soon as possible because I really need schematics details.

I hope you will help me to find a better solution.

The Design

The requested design make use of 4 level status indicator and can be witnessed below.

The TIP122 controls over-discharge of the battery while the TIP127 ensures an instant supply cut-of for the battery, whenever an overcharge limit is reached for the battery.

The SPDT switch can be used to select the battery charging either from a mains adapter or from a renewable energy source such as a solar panel.

Circuit Diagram

UPDATE:

The following tested 12V charger circuit schematic was sent to be by "Ali Solar" with a request to share it in this post:

Smart 12V Battery Charger Circuits

The following automatic 12V smart battery charger circuit was exclusively designed by me in response to requests from two keen readers of this blog, Mr. Vinod and Mr.Sandy.

Let's hear what Mr.Vinod discussed with me through emails regarding the making of a smart battery charger circuit:

8) Discussing a Personal 12V Battery Charger The Design

"Hi Swagatam, My name is vinod chandran. Professionally i am a dubbing artist in malayalam film industry but i am an electronic enthusiast too. I am a regular visitor of your blog. Now i need your help.

I just built an automatic SLA battery charger but there is some problems with that. I am attaching the circuit with this mail.

The red LED in circuit is supposed to glow when battery is full but it glows all the time .(my battery shows only 12.6v).

Another problem is with 10k pot. there is no difference when i turn the pot left and right. . So i request you to either correct these problems or help me to find an automatic charger circuit which gives me a visual or audio alert when battery is full and low .

As a hobbyist i used to make things from old electronic appliances. For the battery charger i have some components. 1. Transformer from an old vcd player. out put of 22v, 12v,3.3v.

And i don't know how to measure ampere. My DMM has only the ability to check 200mA. It has a 10A port but i can't measure any ampere with that.(meter shows "1") So i assumed that the transformer is above 1A and below 2A with the size and requirements of the vcd player. 2. Another transformer -12-0-12 5A 3.

Another transformer - 12v 1A 4. Transformer from my old ups(Numeric 600exv). Is this transformer's input is regulated AC ? 5. couple of LM 317's 6. SLA battery from old ups- 12v 7Ah. (Now it has a 12.8v charge) 7.

SLA battery from old 40w inverter - 12v 7Ah. ( the charge is 3.1v) One thing i forgot to tell you.

After the first charger circuit, i made another one (i'll attach this too). This is not an automatic one but it is working. And i need to measure the ampere of this charger.

For that purpose i googled for an animated circuit simulation software but didn't get one yet.

But i can't draw my circuit in that tool. there is no parts like LM317 and LM431(variable shunt regulator). not even a potentiometer or led.

So i request you to help me to find a visual circuit simulation tool. I hope you will help me. regards

Hi Vinod, The red LED should not glow all the time and turning the pot should change > the output voltage, without the battery connected.

You can do the following things: > > Remove the 1K resistor in series with the 10K pot and connect the pot's relevant terminal directly to ground.

Connect a 1K pot across the base of the transistor and ground (use center and any one of the other terminals of the pot).

Remove everything that's presented at the right side of the battery in the diagram, I mean the relay and all.....

Hopefully with the above changes, you should be able to adjust the voltage and also adjust the base transistor pot for making the LED glow only after the battery is fully charged, at around 14V.

I don't trust and use simulators, I believe in practical tests, which is the best method of verifying. For 12v 7.5 ah battery, use a 0-24V 2amp transformer, adjust the output voltage of the above circuit to 14.2 vollts.

Adjust the base transistor pot such that the LED just starts to glow at 14V. Do these adjustents without the battery connected at the output.

The second circuit is also good but is not automatic....is current controlled, though. Let me know your thoughts. Thanks, Swagatam

Hi Swagatam,

First of all let me say thank you for your fast replying. I will try your suggestions. before that i need to confirm the changes you mentioned. I will attach an image consisting your suggestions. So please confirm the changes in the circuit.

Hi Vinod,

That's perfect.

Adjust the transistor base preset until the LED just starts glowing dimly at around 14 volts, with no battery connected.

Regards.

Hi Swagatam Your Idea is great. The charger is working and now one LED is glowing to indicate the charging is in progress. but how can i configure the charge full indicator LED. When i turn the pot to ground side (means lower resistance) LED starts glowing.

when resistance goes high LED will be off. After 4 hours of charging my battery shows 13.00v. But that charge full LED is off now. Plz help me.

I am sorry disturb you again. The last email was a mistake. i didn't see your suggestion correctly. So please ignore that mail.

Now i adust the 10k pot to 14.3v(it's quite difficult to adjust the pot, because a slight variation will result a bigger voltage output. ). And i adjust the 1k pot to glow a little. Is this charger supposed to indicate a 14v battery?. After all let me know the danger level full charge of the battery.

As you suggested, everything was alright when i test the circuit from breadboard. But after solder into PCB thing are happening strangely.

The red LED is not working. charging voltage is ok. Anyway i am attaching the image that shows the present condition of the circuit. plz help me. After all let me ask you one thing. Could you please give me an automatic charger circuit with a battery full indicator. ?.

Hi swagatam, Actually i am in the middle of your automatic charger with hysteresis feature. I just added a few modifications . i will attach the circuit with this mail. plz check this out. If this circuit is not ok then i can wait for you to tomorrow .

Simple Circuit Diagram #8

I forgot to ask one thing. My transformer is about 1 - 2 A. I don't know what is the correct. how can i test with my multimeter?.

Besides if it is a 1A or 2A transformer, how can i reduce the current

to 700mA.

regards

Hi Vinod, The circuit is OK, but won't be accurate, will give you a lot of trouble > while adjusting.

A 1 amp transformer would provide 1amp when short circuited (check by connecting the meter prods to the supply wires at 10amp range and set to either DC or AC depending upon the output).

Meaning the maximum power of is 1 amp at zero volts. You may use it freely with a 7.5 Ah battery, it won't do any harm, as the voltage would drop to the battery voltage level at 700 ma current and the battery would get safely charged. But remember to disconnect the battery when the voltage reaches 14 volts.

Anyway, a current control facility would be added in the circuit that I would be providing you, so there's nothing to worry

Regards.

I'll provide you with a perfect and easy automatic circuit, please wait until tomorrow.

Hi swagatam,

I hope you will help me to find a better solution. Thank you.

regards

vinod chandran

In the meantime, another keen follower of this blog Mr.Sandy also requested a similar 12V smart battery charger circuit through comments.

So finally I designed the circuit which will hopefully satisfy the needs of Mr.Vinod and Mr.Sandy for the intended purpose.

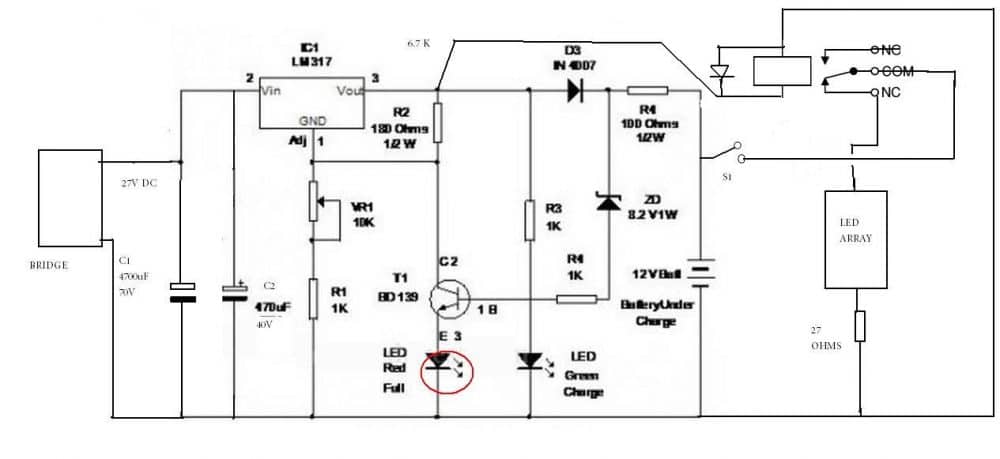

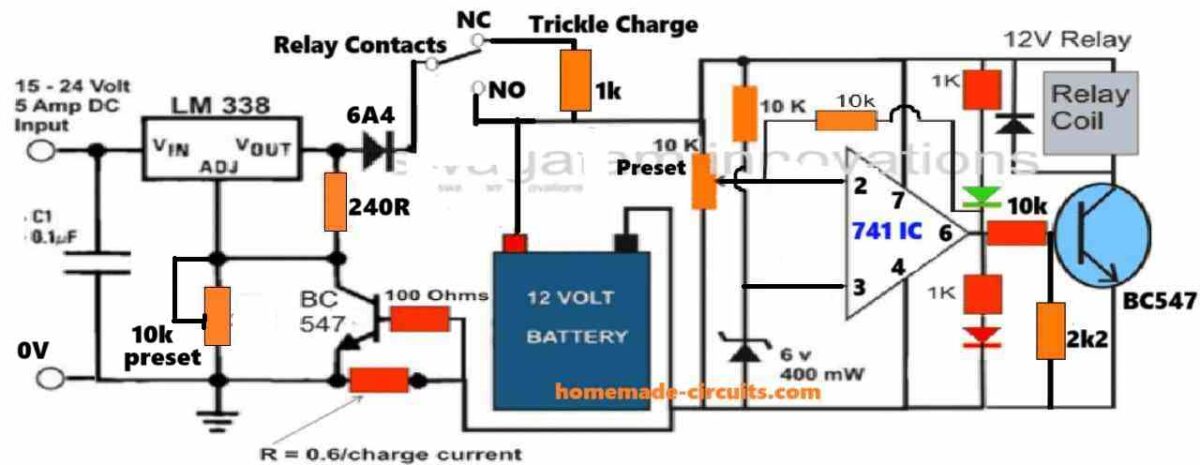

The following 9th figure shows an automatic 3 to 18 volts, voltage controlled, current controlled, double stage battery charger circuit with standby charging feature.

Circuit Diagram #9

How to Set up the Circuit

The circuit can be set up using the following points:

1) Initially, keep the power switched OFF, and keep the 10k feedback resistor between pin#6 and pin#2 disconnected.

2) Do not connect any battery yet.

3) Adjust the 10k preset wiper fully towards the ground supply side.

4) Adjust the LM338 output voltage to the full-charge battery level.

5) Short circuit the LM338 output with the N/O of the relay, so that the LM338 output voltage gets connected directly with the opamp circuit.

6) Switch ON the power supply to the LM338 input.

7) The red LED should light up, and the relay should click ON.

8) Now slowly adjust the 10k preset until the relay just clicks OFF.

9) This will also turn OFF the green LED and turn ON the red LED.

10) That's all, the circuit is fully set now, remove the shorting between the LM338 output and the N/O contact, and reconnect the 10k feedback resistor.

11) You can test the actual auto cut-off function of the circuit by connecting a discharged battery across the indicated battery points.

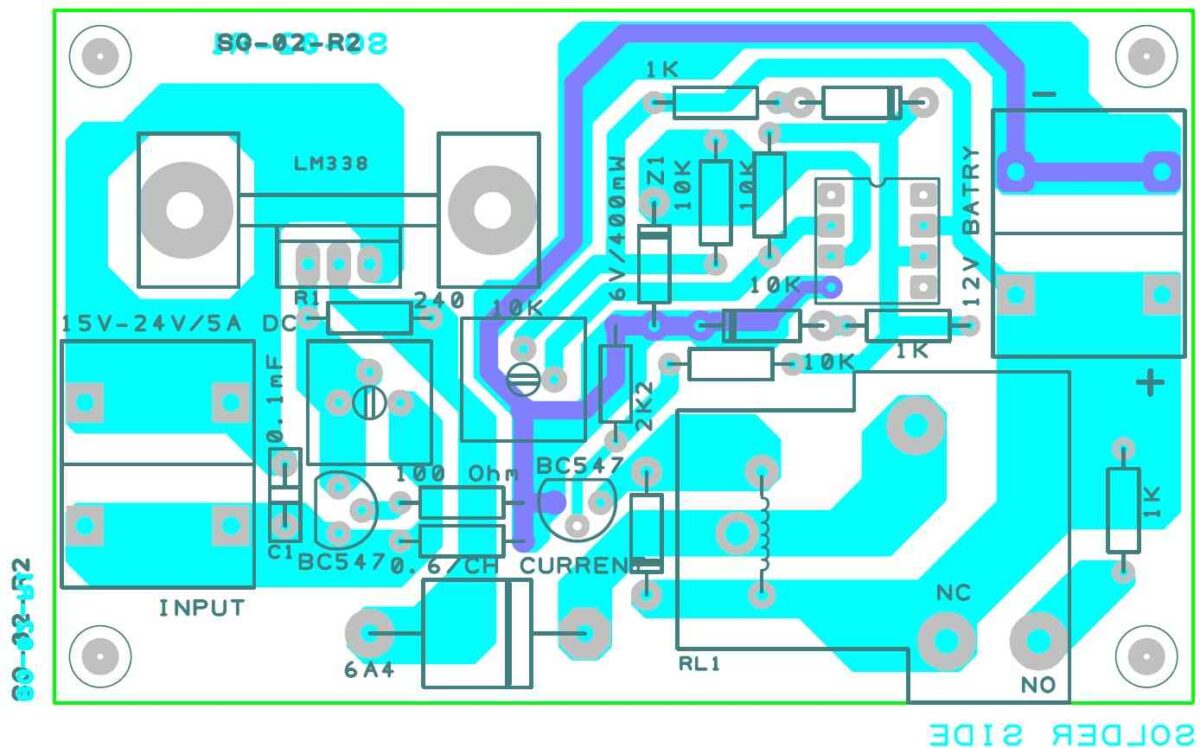

PCB Designs and Gerber Files

The following PCB design and the Gerber file details were kindly contributed by Mr. Sudipta Ghose who is an avid reader of this blog. I am grateful to him for his kind contributions to this website.

Pls sir , I have built an auto cut off charger with npn 547 and relay. But now I to modify it by using lm 317 to give me variable output up 28 40 ah how can I do that

Asikpo, you just need to supply the input power to the battery charger from your LM317 power supply, and then adjust the voltages and the cut-off range accordingly.

Sir, can u Can you help me with a battery charging circuit diagram for 24V 26AH lead acid batteries?

Deepak, you can try the following circuit. Adjust the output to a precise 28V, and make sure to replace the LM317 with a LM338 IC. Also calculate the Rc resistor using the following formula:

RC = 0.6 / 3 = 0.2 ohms

power = 0.6 * 3 = 1.8 watts or 2 watts…

https://www.homemade-circuits.com/wp-content/uploads/2020/06/simplest-and-the-best-12-V-7-ah-battery-charger-circuit.jpg

how can convert it to 24 vdc 20 amp charger?

You can try this circuit diagram:

https://www.homemade-circuits.com/wp-content/uploads/2023/05/LM317-boost-current-charger-circuit.jpg

Hi Swagatam,

I wondering if you can help me. I have a 120vac two primary and 12vac two secondary at 250 watts each. How can I use it to charge Lifepo4 12.8vdc 100ah battery?

Thank you for any info.

PS. Or buy this amazon.com/gp/product/B0DBZ92LVX/ref=ewc_pr_img_1?smid=A20TTZW7ZX0JHJ&psc=1 ?

Hi Milton,

Are you referring to the transformer specifications that you have? Yes it can be used for charging your battery but the charging rate will be slow because your transformer can provide a maximum current of 250/12 = 21 amps, and the battery requires an optimal 50 amps for charging within 3 hours.

Wow. Fast reply. Yes I have the transformer

But if I parallel the secondary I would get 42 amps?

Yes, that’s right, if you parallel the outputs through separate bridge rectifiers then you can double the current output.

What bridge rectifier and capacitor do you recommend?

You can search for 30 Amp or 50 Amp bridge rectifiers such as the KBPC50005, and buy two of them and configure each of those across the two 12V secondary outputs of your transformer. Make sure to use a large capacitor for stepping up the 12v over 12.6V and then use a 12.4V voltage regulator to supply and charge the battery.

Thank you

What does Rc represent in that circuit? And what is the value

It is the current sensing resistor…

Rc = 0.6 / Max Charging Current Limit

I want to charge my car’s 12v 35amp battery at home, I have a 12v transformer and 4 diodes of 6amp, please explain the simple domestic charger, including circuit diagrams. Content used, including their value. Thank you

You can use the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2020/06/simplest-and-the-best-12-V-7-ah-battery-charger-circuit.jpg

Make sure to replace the LM317 with LM338 IC.

Rc = 0.6/4 = 0.15 Ohms, 3 watt

Before connecting the battery, adjust the pot to get exactly 14V at the output.

Or you can simply replace the potentiometer with a 2.5 k 1/4 watt resistor.

Hi Swagatam,

I hope you’re doing well. I’m a final-year Electronics student currently working on my innovation project. I am planning to design a 12V Constant Current-Constant Voltage (CC-CV) battery charger with an auto-cutoff feature to stop charging once the battery is fully charged.

Could you kindly provide me with a circuit diagram or offer some guidance on how to approach this project? I would be extremely grateful for any advice or rough ideas you could share.

Thank you so much for your time and assistance.

Best regards,

Rijal

Hi Rijal,

You can try the following simple yet effective design which will provide constant current, constant voltage, auto cut-off and trickle charging for your battery.

https://www.homemade-circuits.com/wp-content/uploads/2024/09/constant-current-constant-voltage-battery-charger-with-auto-cut-off.jpg

Let me know if you have any further doubts and questions…

Hello Sir!I am an Electrical Engineer and I would like to humbly ask you for a Solar battery regulator circuit diagram,which is needed in my project.

Thanks

Hello Gilbert, can you please provide the input/output voltage and current specifications of the regulator? I will try to help!

I want to reference my project work in your name on the topic “design and construction of a 12v Battery charger ” and i also need 5 more same projects with the names of the authors and the year published ranging from 2020 to 2024 with the method and and how it should function

No problem, please feel free to use my name in your project work…

Do you have any ideas about electronic differential or EDMC ?

It is a difficult concept and might require an MCU based design, beyond the reach of my expertise.

please sir, I wonder how 18v 320ma charger can charge 25ah 12v new battery to full in 6hrs. please explain

Yes it cannot charge.

25 Ah will require a minimum of 2.5 amp current to charge in 12 hours for a lead acid battery. Lead acid battery cannot be charged in 6 hours.

It charged it to My amazement. I don’t know how possible and the battery is lasting hours on load

Battery will get charged but will take long hours if the charging current is less.

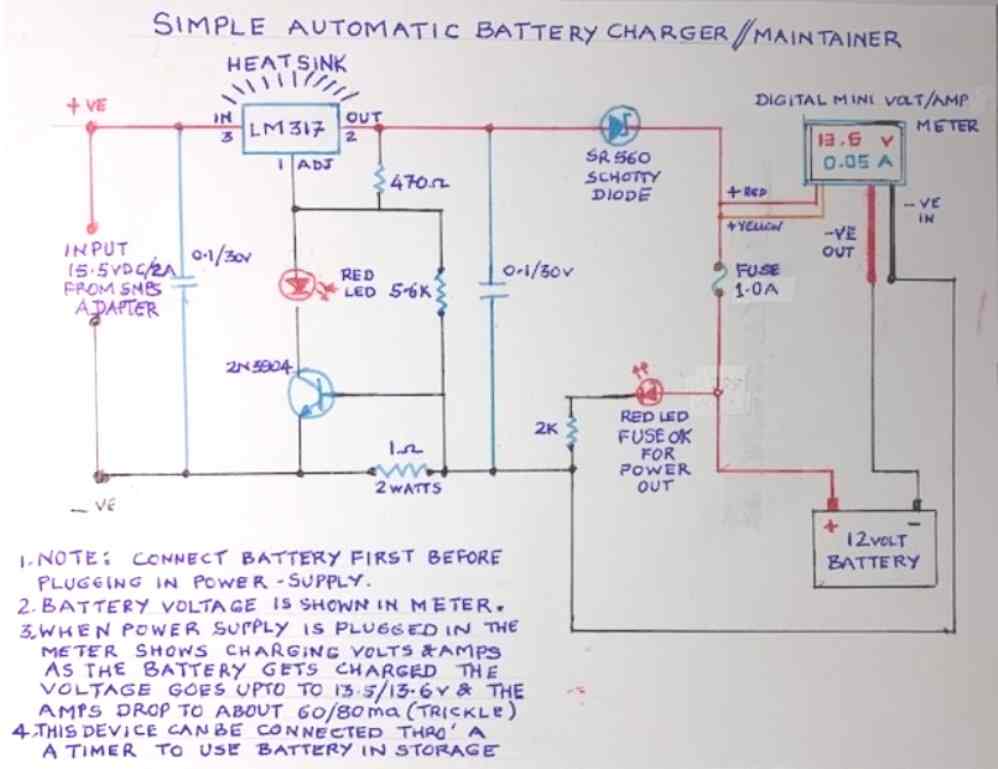

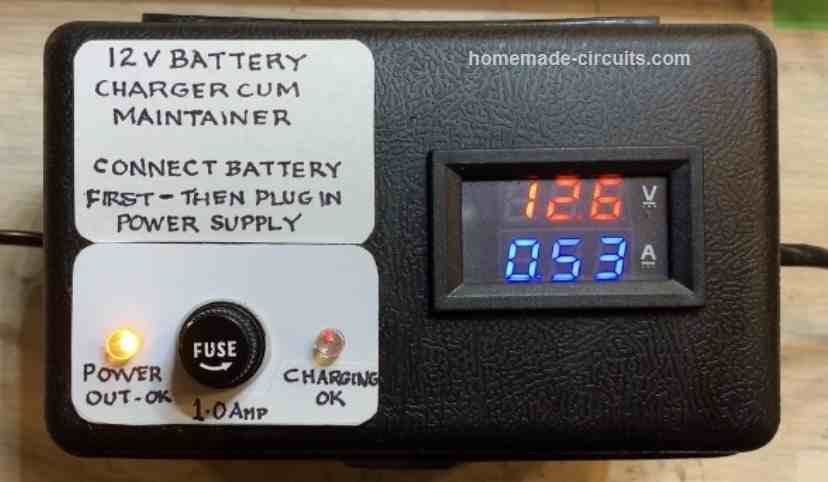

Hello. I built the battery charger/maintainer shown here using the LM317 and the NPN transistor (hand drawn diagram) that has the photos of the unit in operation. I am now reading 13.62 volts and the current to the battery is still .53 amps. I was expecting it to drop off to around 70-80 ma at this point. Voltage and current being measured by an external calibrated instrument. The charging LED is still dimly lit. What do you suggest is happening? Thanks for your help.

Hi, what is the Ah rating of your battery? At 13.6 V the battery could be only 60% charged and still requires some current to reach upto 14V or 14.3V to get fully charged. After around 14V the battery current might drop to 70 or 80 mA.

I hope you have connected the LM317 and the associated parts as shown in the following schematic:

https://www.homemade-circuits.com/wp-content/uploads/2020/06/simplest-and-the-best-12-V-7-ah-battery-charger-circuit.jpg

The battery isn’t marked with the Ah rating, but the stock battery in the car was 41 Ah. That’s not the circuit I built. It’s the one with the title “Simple Automatic Battery Charger/Maintainer” and has a Shottky diode and a digital volt/amp meter. I have the input voltage set at 15.5 volts per the diagram and I suspect that we won’t be able to get 14.3V to the battery. I have an adjustable supply, so could increase the voltage a bit. There are many differing opinions on what the max voltage to the battery should be for a maintainer. I don’t know the right level – just know what I’ve read in dozens of sources on the Web.

I understand which circuit you built, I referred the other diagram just to make sure you connected the 317, BC547 and the pot connections correctly according to that diagram.

Assuming the battery Ah is 41 Ah, the minimum charging current will need to be 4 amps which the 317 cannot supply. In that case you may have to replace the 317 with an LM338 IC with a heatsink.

14.3V is not required, 14V would be just enough in my opinion.

And if we assume the battery is a 41 Ah, then the 0.5 A at 13.6V is quite acceptable. Let it reach 14V and you might see the current dropping to 100 ma.

The circuit I built did not have the pot – it used a fixed 5.6K resistor instead. I will be replacing that with a pot so I can set the voltage with that instead of varying the input voltage. I left the charger run all night at 14.4 volts and the current did drop below 100ma, so guess all is well. The charger will be used only to keep the battery topped up and not to charge it from a discharged state so I think the 317 should be adequate. Last spring I installed an Android radio in the car and if not driven for 3 weeks or so it discharges the battery to below where the car will start. This charger/maintainer should prevent that. But, I built this one just as a proof of concept so will look into the LM338 as an enhancement. Thanks!

Sounds good, thanks for the feedback. Let me know if you have any further questions.

In you L200 circuit isn’t LD2 forward biased and On if the Battery is connected backwards? And T1 is on when the Battery Voltage is less than the Charger Output. With T1 On then LD1 should indicate that the Battery is Charging?

Yes, I think your assumptions are correct.

1. I had wanted you to design/make a simple solar charge controller

2. And how can we make 12v DC to 12v DC pure

3. Is there a way you can design 5v DC to 12v DC

Thank you. wow very good information. Bookmarked: I think I’ll have to go over it a few times. Thank you for sharing!

I noticed a typo in the circuit diagram titled “Simple Automatic Battery Charger / Maintainer” where the shottky diode as a “shotty diode” I hope it’s not a shotty one.. xD

Thank you very much for your kind feedback, much appreciated.

Yes it definitely looks like a typo, and this diagram was contributed by an external author.

Hi Swagatam,

I like your concepts for battery charging, so I thought you may have an idea for my power concept for a miniature ride-on railway locomotive with auxilliary battery charging system.

I intend to run a 48 volt 1000 watt dc motor via v-belt on a small petrol engine which will then power 2 x 500 watt dc motors via a dc power controller t power the wheels of the locomotive. Note that the output voltage may vary depending on the petrol engine speed.

My question is:

Is there a circuit I can use to safely charge an auxilliary battery (lights, etc.) from the same 48 volt motor while running the train or would this be too much drain on the system.

Kind Regards

Geoff

Hi Geoff,

If you draw current from the motor drive then there will be obviously some drain depending on how much current is drawn. The second circuit concept shown in the above article is the easiest and safest one which can be used to charge your 48V battery. The 48V battery will require 56V for achieving the full charge level. So you can set the zener diode such that emitter of the transistor generates 56V. The transistor can be a combination of BD139 and TIP36 in the Darlington configuration.

Hi Swagatam,

I am looking for a Li-Ion charger that would work with a 2S2P configuration at 7.4V / 3.0A or more but most of what I find are specified as being for single or multiple cells connected in series. Have you ever done one of these and if so would you explain what the difference is when cells are in parallel?

Thanks,

Brian

Hi Brian,

In parallel configuration the current consumption multiplies depending upon how many cells are used in parallel, but voltage remains the same. In a series configuration it is just the opposite.

You can try the LM317 circuit with current control. For a 2S2P 3.7 V cells the full charge level will be around 2 x 4.2 = 8.4V.

So you will have to set the 317 output to 8.4 v or 8.2 V for enabling a full charging of the setup.

Since you would be using 3 amps, the LM317 won’t be suitable, you may have to replace it with a LM338 IC with a large heatsink.

Circuit Diagram #2 what is the mean by Rc

Rc is the current limiting resistor.

current limiting resistor mean what capacity ___ ohm

Rc = 0.6 divided by maximum charging current for the battery

Hi Swagatham

You say the over current formula is 0.6v/ ohm which is 0.6amps, which or what is the resistance referred to for calculating this over current

Is there a way to protect the LM317 circuit, at present I have a 2.0 A fuse at the output of the device to protect the SMPS power supply should I put a smaller fuse instead

Thanks Swagatham

Hi Val,

The resistor between the base and the emitter of the BC547 transistor controls the output current. This current control is meant for the output load and not for the LM317.

The LM317 already has ample protections internally, so it is virtually indestructible, unless and until the input voltage is exceeded beyond its maximum tolerable threshold, which is 40 V.

Hi Swagatham

Tried in trial & error and found that a 5.6 k resistor between the 470 ohm at pin one of IC and base of transistor gives an output of 14 vdc which I think is good

When connected to the battery which is fairly charged and is at 12.6 volts it starts charging at about 450ma and then goes down to about 210 ma and now is at 190 ma and 13.4 volts and remains like this for more than 20 minutes

Is this ok and safe, the lm317 is slightly warm

Can I keep it like this ?

Another ? is why is the red led not glowing is it supposed to be like that like a diode only

Thanks Immensely & God bless

Hi Val,

It looks OK and safe to me. You can keep it like this.

The safe and the recommended charging current for a lead acid battery is 1/10th of its Ah value.

The RED LED will illuminate only when there is an over current.

Over current formula is = 0.6 V / 1 ohm = 0.6 amps

All the best to you!

I am novice in electronic communication help me by suggestions ok

Good day Sir, Swag, please I made small 12v different chargers with 330mA, 500mA and 770mA with individual charging current.

But when I parallelled the Ac supply the rectified, total charging current was 675mA.

What could be the cause? Is it advisable to charge individually?

Hello Tinu,

which circuit did you use for making the chargers?

I did basic smps

OK, then you used a common bridge rectifier for supplying all the chargers, right? Did you measure the current with load connected to all the chargers individually? And where did you measure the current, is it in series with the common bridge rectifier positive?

Hello Swagatam, I have 3 batteries, all 12 volts but two are 150Ah and one is 200Ah connected in parallel, Sir, I need a simple charger circuit to charge them. Good God Bless your wisdom.

Thank you Itari,

You can try the following simple power supply circuit for charging your batteries. Make sure to calculate the RX value appropriately using the formula provided in the diagram. For the output voltage, you simply have to adjust the output 14 V using the 10K pot.

https://www.homemade-circuits.com/wp-content/uploads/2022/11/high-power-battery-charger-circuit-using-TIP35.jpg