In this post I have explained the construction of a car air ionizer circuit which can be used for cleansing the atmosphere of car interior from smoke, pollution, dust particles, bad odor, pollen particles etc. The circuit was requested by Mr. Edalcor Zuproc.

The Circuit Concept

In one of my previous posts we saw how simply a home air ionizer circuit can be built using a handful of capacitors and diodes. The unit works directly on our domestic mains outlet due to the availability of mains power.

The same circuit can be converted to function as a car air ionizer circuit by adding a converter stage to the above circuit.

The converter stage is a simple square wave inverter which converts 12V DC into the required 220V AC for operating the ionizer circuit.

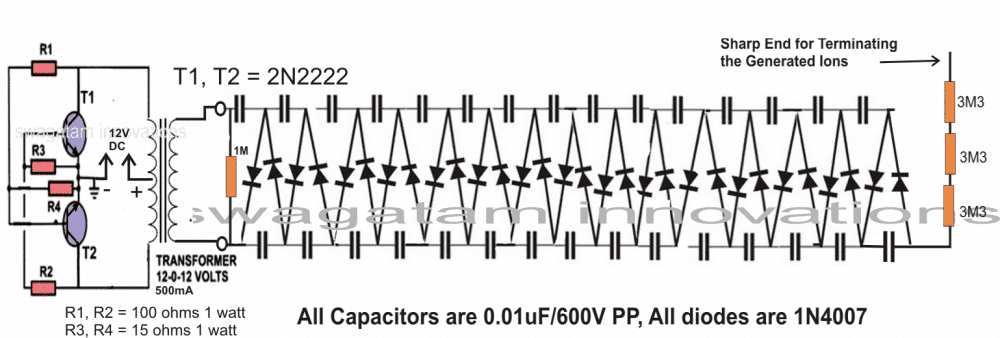

As explained in my previous article, the basic design of the ionizer is taken from the Cockroft-Walton Ladder Network which involves a series. parallel connection of many diodes and high voltage capacitors.

How it Works

When powered with mains voltage the arrangement creates a push pull effect inside the circuit which results in stepping up of the voltage across the subsequent stages. At the far end of the ladder network this stepped up voltage may be as high as 4kV.

For obtaining the fundamental ionizing effect which is supposed to be having many health benefits the stepped up voltage should reach about -4kv.

At this potential, the free end of the radiator tip release negative ions by losing an electron into the atmosphere.

These ions being negatively charged attract everything that's neutral or positively charged.

Dust particles or any suspended particle in the air is by nature a neutral element and therefore when these particles collide with the negatively charged ions, they instantly stick with these ions.

The ions continue colliding with the atmospheric particles until each ion become loaded with these unwanted particles and become too heavy to float. When this happens the ions either get attached to the nearest wall or drop on the floor.

In this way all pollutants are neatly cleansed away from the air by the ionizer unit.

How to Build this Car Inonizer

In the diagram below we can see the circuit to be made up of two distinct stages. The section at the extreme left is the inverter stage, while the section on the right of the transformer is the ionizer stage.

The two stages should be constructed separately on two different boards and tested separately before integrating together.

The ionizer circuit stage which consists mainly of capacitors and diodes looks to be an easy arrangement to assemble, however the entire configuration is quite sensitive to bad solder or leakages through flux deposits.

Even a slightest bit of mistake can render the circuit unresponsive.

All the connections should be made with utmost care, making sure there's no dry solder or flux deposits in between the joined tracks.

The ionizer stage may be tested by powering it with 220V AC at home.

Be extremely careful as the entire circuit is directly linked with mains potential and can inflict lethal shock if touched without precaution. The procedures are explained in this room air ionizer article

The inverter part is much easier as the design includes just a pair of transistor and a few resistors. The transformer is a small 12-0-12V 500 mA type. After making it, power it with a DC 12V source and check the output, it should provide around 220V AC.

For the final testing, the above inverter output AC may be applied to the input of the ionizer circuit for acquiring the required ionizing effect of release of ions across the extreme tip of the ionizer circuit.

Circuit Diagram

Comments

Sir on my capacitor mpp is written.is it polystyrene capacitor or not

Can we use 2000v instead of 600 v capacitor.

Sir on my capacitor, following values are written-

"630v103k

TN944MPP"

Is it the right one .

Reply fast sir,i am working on project.

it will do..

Can we use 2000v capacitor instead of 600v.

The inverter is not working the transistor keep getting hot. plz if possible could you show the arrangement on a bread board for me

the circuit is not recommended for breadboard assembly please build it on a PCB….the circuit will definitely work, if done correctly.

i do not have 2n2222 what is the nearest one to replace it plz

thank you

use any 1 amp npn transistor…8050 will do or D1351, D880 etc

Hi Swagatam, how many miliAmpere (current) draw by this circuit from 12V car battery?

When this project use continuously, how many current be need from 12V car battery?

If you can describing the current consumption, I think it can be modified to increasing the efficiency.

Regards

Hi Samueal, according to me it shouldn't be more than 50mA….

Hi,

can this circuit be used to induce static electricity in objects? can this circuit replace a van der graaf generator? can I use this circuit to levitate small objects and do fun things like in fun-fly-stick?

you can try it, but for best results a PCB is only recommended.

Sir can i do this on breadboard?

I have no idea about it, I'll have to investigate it and then I can suggest…

Hello Sir,

will this negative ion generator work same way as van der graaf generator? can I use the above circuit to induce static electricity and try static electricity experiment like Fun-fly-stick with this circuit? will this circuit also act as negative ion gun?

Thanks

you can read this article:

https://en.wikipedia.org/wiki/Cockcroft%E2%80%93Walton_generator

Sir can u explain or show the 12v to 220v step up circuit

Hi Swagatam

I want to make a smallest possible adapter to power a 40W soldering iron with a 12V battery. Can I use the converter circuit mentioned above. If not, would you please recommend me one.

You will have to use a 5amp trafo for optimal handling.

Multiply the transformer current with its voltage rating, does it equal 40 watts?? In fact the rating should be in excess to the required mark by a reasonable margin, only then it would produce the desired output.

12 x .5 = 6 watts, that's what you would get at the maximum from a 500 mA trafo.

Battery is not a problem. I was just wondering if 12-0-12, 500mA transformer would be suitable to give 40W at 220V.

According to my understanding, the input is

24V x 0.5A = 12VA ≈ 12W

So, maximum we can get 12W at the output. I think a 12-0-12, 2A would be suitable to give 48W. What do you say?

If yes, do we need to upgrade the transistors?

Hi Abu-Hafss,

Yes you can try the converter stage for powering a 40 watt soldering iron, but the battery will need to be at least 15ah rated.