In this post I have explained a high current sensorless BLDC motor controller circuit which does not depend on hall effect sensors for initiating the operations rather utilizes the back EMF from the motor for the sequential input

Overview

For proper commutation most 3-phase BLDC driver circuits rely either on a sensor based feedback or from an external 3-phase sync signal, contrary to this our present sensorless high power BLDC motor controller circuit does not depend on sensors or any external signals for operating the motor.

Instead, the circuit very simply processes the back EMFs from the motor winding to produce the required powerful synchronized rotational effect on the motor.

Coming back to our present concept, the circuit employs the IC ML4425 from Fairchild, and enables us to operate any type of BLDC motor regardless of whether the motor has sensors or not.

Most BLDC motor today have built-in Hall effect sensors which provide the necessary feedback to the controller circuit regarding the instantaneous position of the magnetic rotor with respect to the stator winding and informs the controller when the relevant power devices needs to be triggered with the precise sequence, this in turn allows the motor to rotate with perfect synchronization and maximum efficiency.

Working without Sensors

Some BLDC motors may be without sensors, and for such motors the BLDC controller is forced to employ an external 3 phase generator circuit for the required synchronized rotation of the motor.

However the present 3 phase sensorless BLDC controller eliminates all these hassles, and neither depends on sensors nor any form of external triggering, instead the system extracts the back EMF pulses from the stator coil of the BLDC motor for executing the rotational momentum on the connected motor.

This feature allows the controller to be universally used for all types of BLDC motors without going through the complications of the sensor connections or the external 3 phase generator stages.

Moreover since the full bridge circuit power devices are externally configured allows the system to be used with even high power BLDC motors without any restrictions whatsoever. One can simply change the rating of the power devices as per requirement and achieve the intended high current BLDC operation as per preference.

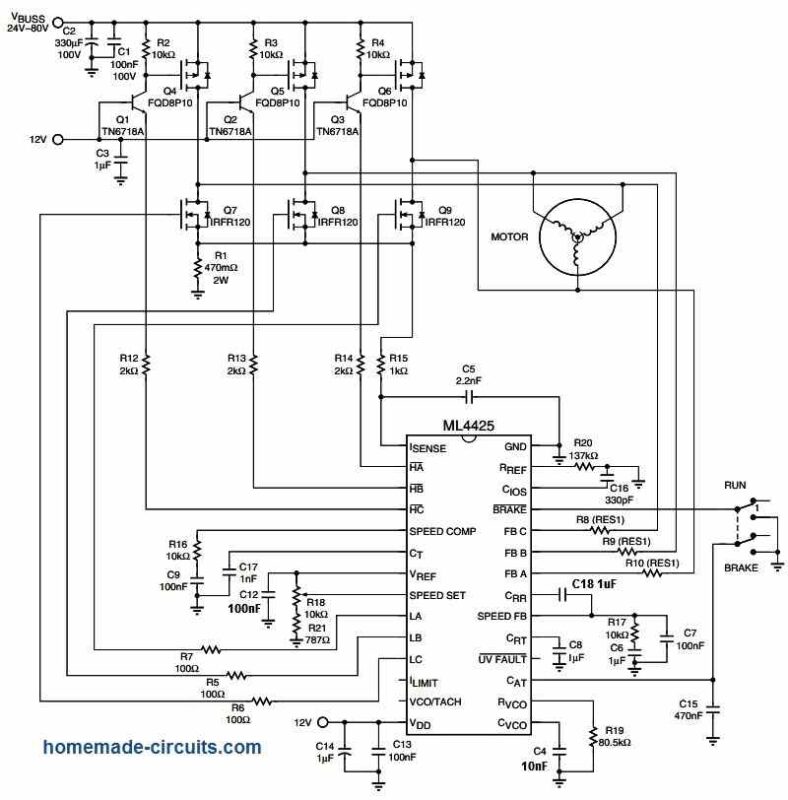

The following diagram shows the complete design layout of the proposed sensorless BLDC controller using back EMF as the triggering source.

Circuit Description

Courtesy: Mouser.com

The system looks pretty straightforward, you just have to solder the shown components in place and quickly start the BLDC operations. It is as simple as switching ON power and seeing the BLDC motor rotate with full efficiency.

The controls are also very easy to understand and implement, the RUN/BRAKE switch enables the motor to continue running as long as the switch is in the OFF position, or not grounded, while the motor is instantly stopped as soon as the switch is toggled at the ground level.

The POT R18 allows the user to control the speed of the motor linearly, simply by moving the pot knob across the specified range.

Main Advantage

The biggest advantage of this 3-phase sensorless BLDC controller is that it does not require the messy sensor based feedbacks from the motor, neither depends on a 3-phase sync signal from the an external source. As can be witnessed in the above diagram, the feedback is achieved from the motor's main 3 phase operating wires via R8/R9/R10 into the designated pinouts of the IC.

This allows the controller to be used with all types of BLdC motors whether or not a sensor is available. If sensors are available from a BLDC, those can be ignored and the motor may be configured without the sensor wires, as indicated in the above diagram.

Comments

Can I get the pcb for this sensor less BLDC controler? Please guide me on my mail ID. Thank you.

Sorry, pcb is not available for this project.

Thanks Sir,

This problem is solved and the other is when motor starts it takes three to four jirk just like dek, dek …. and then starts and same is the case when I slow down it with the variable it also starts jirking ( dek, dek…) but when I increase its speed it becomes smooth and steady. Please guide if you have any idea.

Thanks,

Pir Bukhsh,

Try adjusting the value of C18. Either increase it or decrease it and check how the motor responds.

Thank you Sir, one problem is solved. But, when the motor start it begin to jerk two are three time and them become smooth. What should I do now.

Thanks,

Hi Pir, sorry, I have no idea about it, because this circuit was taken from the datasheet, and the datasheet does not have any information about this issue.

Dear Sir, I have designed the circuit and try to run it but it gives only hissing sound but do not start. What should I do? Please give your value able suggestion.

Hi Pir Buksh, the above circuit was taken from the datasheet of the manufacturer, so unfortunately I cannot help much with this design. I think if you build it correctly then it should work without fail. You can refer to the original datasheet and see if this help:

https://www.mouser.com/datasheet/2/149/ML4425-189510.pdf

hi, sarin here

this sensorless BLDC circuit have two C14 and C4,C12 not mensioned value, can you explain this.

Sir,

I have completed this circuit and start successfully, but one of N-type mosfet become over heat . what should I have to do to over come this problem and motor starts with jirk.

Sir please guide me.

Thanks,

Hello Pir Bukhsh,

This circuit is taken from the datasheet of the IC so it is beyond my control, and I cannot suggest much. If one MOSFET is heating up then you can try replacing it and check the results.

Make sure to mount all the MOSFETs on heatsink

Hi Sarin,

I have updated the required information in the diagram…you can check it now.

Hello,

thank you for sharing!

I would like to replace a 24V DC/15W motor equipped with a tachogenerator by a brushless one, the stability of the rotation speed is very important, which circuit would you recommend?

A circuit with L6235 and Hall sensors or the circuit equipped with the ML4425 can do the job just as well, although simpler?

Thanking you in advance,

José

Hi, I think the circuit explained in the above article can be perfectly implemented for your sensorless BLDC motor application. So, the ML4425 is the one that might work for you the best!

hi

I need to run a bldc compressor its voltage is 60-220v dc what kind of mosfet i use plz give a reply

i hope to build this drive

Hi, what is the wattage rating of the motor?

Hello

Can i use d667 against tny6718 b’cause tny is not in our karachi market please guide me

you can use any transistors which an handle 100 V. If D667 is rated to handle 100V then you can use it.

Hello, could you please provide a BLDC controller (high current) circuit with hall effect sensors? need 48V, up to 50 A current.

Hello, you can try the following concept:

https://www.homemade-circuits.com/48v-3kv-electric-vehicle-circuit/

Thank you for your response sir.

Am a beginner in electronics and would appreciate if the missing values are pre-installed and later find a way on how to calculate to meet the load requirement.

I want to run a car alternator as BLDC motor ,what values can I put at C4,C14,C12 and RES1-3 to run it at it’s full speed(3000rpm)?

The above project is actually not recommended for beginners, since it has many complicated aspects to be taken care of.

you can refer to the following datasheet to know exactly how the missing values of R8, R9. R10 can be calculated

https://www.mouser.com/datasheet/2/149/ML4425-189510.pdf

Hello,

I need to drive a high Kv sensorless BLDC. It is easy to buy a cheap drive for up to 60 V.

But my back EMF amplitude will be 140 V.

How to do it?

Can I use that 60-Volt PCB to drive my external MOSFETs capable to, say, 250 Volt?

Maybe to simply use 2ED28073J06F-600 V Half Bridge Gate Driver to interface the PCB with HV MOSFETs?

Please advise.

Thank you very much!

Hello, yes you can drive external high voltage MOSFETs using a 60 V driver, but it is also possible to eliminate the back EMFs simply by adding external diodes across the existing MOSFET, drain/source pins

How come the assembly is not explained or at least the list of parts with the diagram, I do appreciate the diagram but was reading then all the sudden it was over thought I accidentally skipped it but after re-reading it I know I didn’t. I just thought this site was kinda like instructables. I’m pretty new to building electrical circuits and was looking forward to the step by step, guess only way to learn is to try until succeed

I have not built this project myself, so I cannot provide a step by step tutorial. Maybe You can refer to the datasheet of the IC for the detailed info.

Greeting Swagatam, can you please confirm the value of RES1 = 670Ω ⁄ V × (VMOTOR – 10V) if the VMOTOR = 300V?

647 ohms, if the supply V is also 300V

Greeting Swagatam, many thanks for your prompt response, much appreciated.

Glad to help, Santos!

Hi, firstly great site and some interesting circuits. I have converted a bike with a cheap bldc hub motor/controller kit. It works ok but a few months of use and I have already killed a speed controller so I don’t hold out much hope for the new one I just fitted lasting too long. I fancied a go at building one from a circuit. My existing bldc hub motor uses hall sensors and I believe the windings are connected in delta config (it only has 3 heavy duty drive wires). It runs from 36v @20A. While I understand the circuit shown here uses the normally undesirable back emf to sync up the drive so I can ditch the hall sensors I don’t understand how a star connected motor with the central common connection not connected to anything else works. Won’t any drive to the motor always energise 2 motor coils at once? Have I just misunderstood the diagram and the common centre tap is connected to gnd? In any case I am assuming it can only be used on bldc motors with star connected windings?

Hi, thanks, yes that’s correct. The two stator winding will be in series at any given instant of a phase input, but the transition will be very smooth across any two winding, creating a seamlessly transiting or rotating magnetic field on the rotor.

Good day sir, please sir can the mc33035 ic be used to generate pmw to drive external NPN fets to control brushed DC motor and making use of external current sensor like (allegro sensor ACS758) which is rated for 200 Amps to monitor the motor current through pin 9 (csensin).I would be happy if you can help me out with the circiut i just smoked my expensive Chinese DC controller sir

Marvin, I am not sure about that, because these are specialized ICs, designed to work only with the specified fixed parameters, so modifying there working can be risky

Hi Morgan, Yes I think that is possible, you an try that, but first I would recommend testing the circuit using the MOSFETs as exactly indicated in the diagram.

Swagatam can I change the MOSFET to 400-500v so that I can drive it with 310v MOSFET supply input?

You can get it from DIGIKEY.

thank you 🙏

I think you can replace the 80V input with 300V DC input after suitably upgrading all the MOSFETs to 400V rated MOSFETs.

what modification do I need to do about this circuit to drive my washing machine motor of 300v dc (5 amh)bldc motor thanks 🙏

Ok Thanks

Thanks Gulabkhan, I am glad you could make this project successfully. Yes while adjusting the 10K speed control the motor speed may fluctuate a bit. You can rectify the fault by using a multi-turn type 10K pot instead of an ordinary pot.

Yaa swag I made it very good just one thing fishy about 10k pot when im turning just little moter wows then normal can u understand what is this otherwis i found this circuit easy and gooood

Thanks

Yes R1 is 0.047 ohms

Hello!

Thanks for reply ,my next confusion is about R1, this is 470m,ohm is this milli ohm or mega ohm b’cause my experience is this mybe .047 ohm am I wright??

Hello Gulabkhan,

Please check the following datasheet, you will find the answer under “Back EMF Sampler”

https://www.homemade-circuits.com/wp-content/uploads/2018/08/ML4425CP-datasheet.pdf

The formula is:

RES1 = 670 Ω ⁄ V x (VMOTOR – 10V)

Hello swag how ru thank u for this bldc circuit I made it but confused in the value of R8,9,10 & c14 if possible mail me please or watsapp @009203078176990thanks

Fadzil, the design is suggested by the manufacturer datasheet, may be they have a specific reason for this.

Hi Swag;

I found it very strange the circuit have continuos 12Vdc connect to the base of the transistor and the signal connected to the emitter side. I saw a lot of H-bridge controller using the base of the transistor for a signal input but not this one.