In this post I have explained a simple car laptop charger circuit for charging laptops from a 12V car battery using a IC 555 based boost converter. The idea was requested by one of the avid readers of this blog.

Making a 12V to 19V Converter

May I request you for a circuit diagram for a transformerless small 100w inverter which can be used with a car 12V battery to power a laptop? I've found one circuit online but as I am a very new comer to electronics, I didn't understand that. Your help will be highly appreciated. Thanks

You may also like: 12 V to 19 V Converter Circuit

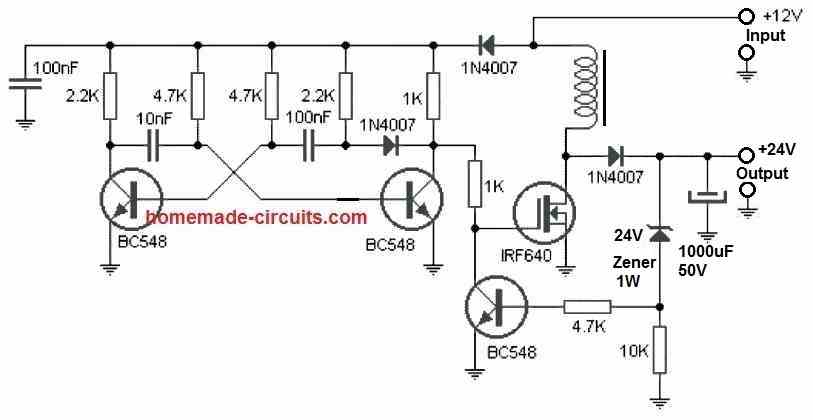

The Transistor Astable Design

A classic boost converter which will perfectly suit the proposed 12 V to 24 V car laptop charger application can be quickly built using a fully transistorized design as shown below:

All the shown parts are standard, or could be replaced with other suitable equivalents.

The inductor which is one of main parts of the circuit is built over a ferrite rod 1 cm in diameter, by winding 100 turns of super enameled copper wire having 1 mm thickness.

Actually, the inductor is dependent on the frequency of the transistor astable. For higher frequencies the number of turns will proportionately go down, and is a matter of some experimentation. The turn number will also depend on the ferrite core shape, and may significantly decrease if a ring type ferrite core is used.

Calculating the Part Values

Astable Multivibrator Section:

The astable multivibrator is designed to generate a square wave to drive the MOSFET. It uses two BC548 transistors with capacitors and resistors which forms the timing network.

Frequency Formula:

f = 1 / (1.44 * (R1 + 2R2) * C)

Here:

R1 = 2.2k ohms (astable feedback resistors)

R2 = 4.7k ohms (base resistors)

C = 10 nF

Calculations:

f = 1 / (1.44 * (2200 + (2 * 4700)) * 10 * 10-9)

f = 1 / (1.44 * 11600 * 10-8)

f ≈ 6.06 kHz

Thus the switching frequency of the square wave is approximately 6.06 kHz.

MOSFET Boost Converter Stage:

The IRF640 MOSFET switches the inductor to step up the voltage.

Inductor Value (L):

The inductor value depends on the peak current (Ipeak), duty cycle (D), and switching frequency (f).

The output voltage (Vout) is determined by:

Vout = Vin / (1 - D)

For Vin = 12 V and Vout = 24 V, the duty cycle is:

D = 1 - (Vin / Vout)

D = 1 - (12 / 24) = 0.5 (50 percent)

The inductor value is calculated using:

L = (Vin * D) / (f * ΔI)

Assume ΔI = 20 percent of Iload, where Iload = Pout / Vout.

For Pout = 20 W:

Iload = 20 / 24 ≈ 0.84 A

Peak-to-peak ripple current:

ΔI = 0.2 * 0.84 = 0.168 A

Now calculate L:

L = (12 * 0.5) / (6060 * 0.168) = 0.005893 Henry

L ≈ 5.893 mH

We will choose a standard inductor value of 6 mH.

Output Capacitor (Cout):

The output capacitor filters the ripple voltage.

Cout = (Iload * D) / (f * Vripple)

For general-purpose applications we can take output ripple voltage of 1-2% of the output voltage.

For Vout = 24 V

Vripple ≈ 0.02 * 24 = 0.48 V

However it is better to assume a smaller ripple such as 50 mV (much less than 2%) which can ensure much tighter output regulation.

So, assume Vripple = 50 mV:

Cout = (0.84 * 0.5) / (6060 * 0.05)

Cout ≈ 693 μF

Choose a standard capacitor value of 1000 μF, 50V.

Diodes (1N4007):

The diodes must handle the peak current and voltage. The current rating should exceed Ipeak = 0.42 A and the voltage rating should exceed Vout = 24 V.

The 1N4007 diodes (1A, 1000V) meet these requirements.

Feedback Network:

The 24V Zener diode ensures that the output voltage is regulated. It clamps the voltage at 24V to prevent overvoltage. The 4.7k resistor limits the current through the Zener diode.

Final Results:

- Frequency: 6.06 kHz

- Inductor: 6 mH

- Output Capacitor: 1000 μF, 50V

- Diodes: 1N4007

- Zener Diode: 24V, 1W

- Feedback Resistor: 4.7k ohms

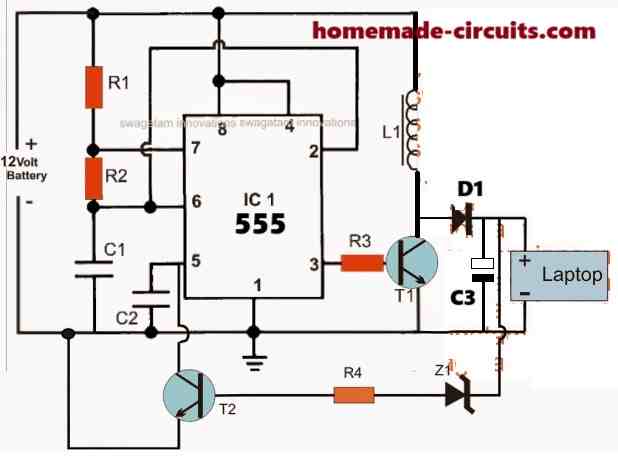

The IC 555 Design

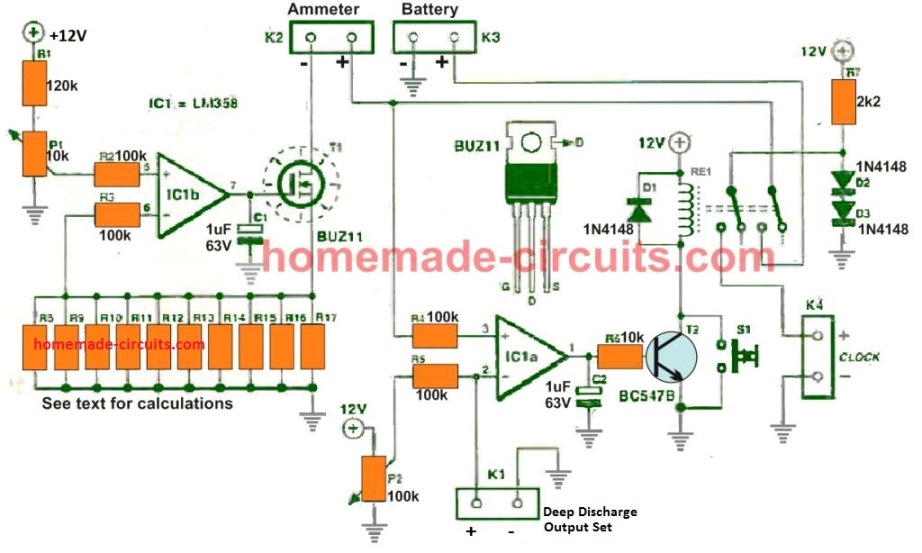

The proposed car laptop charger circuit is actually a simply boost converter unit designed for generating the required laptop charging voltage.

A simple boost converter can be made using the IC 555, I probably have discussed it through many other posts in this blog.

As may be witnessed in the following figure, a simple yet very efficient boost converter circuit can be constructed for using with laptops from any high current source having a lower voltage than the laptop charging level.

Circuit Diagram for the Boost Converter

The various stages included in the above 12 V laptop boost charger circuit may be understood as follows:

IC1 which is a 555 IC is configured as a standard astable for generating a stable predetermined frequency at the rate of 12 kHz which is acquired at pin3 of the IC.

The above high frequency output is fed to the base of a driver BJT T1 for inducing the above frequency with high current in L1.

Due to the inherent property of the inductor L1, during every OFF time of T1, an equivalent amount of boosted voltage is kicked back from the inductor L1 and supplied to the load connected at the output via the fast recovery diode BA159.

The load here is the laptop which accepts the boosted voltage for charging its internal battery.

Since the laptop may require a precise 19 to 20V for the operations, the output from L1 must be regulated and stabilized in order to make things safe for the connected laptop battery.

The above criterion is taken care of by introducing T2 and the associated R4 and Z1 components.

Z1 is selected to be exactly equal to the laptop charging voltage that is at 20 V (17V is wrongly shown in the diagram).

Whenever the output tends to drift away from this value, Z1 gets forward biased triggering T2, which in turn grounds pin5 of the IC.

The above situation immediately reduces the IC 555 pin3 voltage to minimal levels for that instant until Z1 stops conducting and the situation is restored to the safe zone....the switching is sustained at a rapid speed maintaining a constant voltage for the laptop.

This car laptop charger circuit can be used for charging a laptop in any car which uses a 12V battery.

Calculating the Part Values

The above 555 circuit is designed to convert 12V DC input to 19V DC output with a current of 2A for charging a laptop.

Output Voltage and Current:

- Input Voltage (Vin): 12V

- Output Voltage (Vout): 19V

- Output Current (Iout): 2A

Inductor Selection (L1):

The inductance is calculated using the formula:

L = (Vin * (1 - D)) / (f * ΔI)

Where:

- Vin = 12V (input voltage)

- D = (Vout - Vin) / Vout = Duty cycle

- Vout = 19V (output voltage)

- f = 50 kHz = 50,000 Hz (switching frequency of the 555 timer)

- ΔI = 20% of Iout = 0.2 * 2 = 0.4A (ripple current)

Step 1: Calculate Duty Cycle (D):

D = (19 - 12) / 19 = 7 / 19 ≈ 0.37

Step 2: Calculate Inductance (L):

L = (Vin * (1 - D)) / (f * ΔI)

L = (12 * (1 - 0.37)) / (50,000 * 0.4)

L = (12 * 0.63) / 20,000

L = 7.56 / 20,000 = 0.000378 H = 378 µH

Inductor Value: 378 µH

Output Capacitor (C3):

The output capacitor filters the ripple voltage. Use the formula:

Cout = (Iout * D) / (f * ΔVout)

Where:

- Iout = 2A

- D = 0.37

- f = 50,000 Hz

- ΔVout = 0.05V (assume 50mV ripple)

Cout = (2 * 0.37) / (50,000 * 0.05)

Cout = 0.74 / 2,500 = 0.000296 F = 296 µF

Capacitor Value: 296 µF (choose a standard value of 330 µF, rated at 25V or higher)

Feedback Zener Diode (Z1):

The Zener diode regulates the output voltage to 19V.

Zener Diode Value:

- Breakdown Voltage: 19V

- Power Rating: Pz = Ifeedback * Vz = 0.01A * 19V = 0.19W

Choose a Zener diode rated at 19V, 0.5W.

Base Resistor for Transistor T2 (R4):

The resistor R4 controls the base current of T2. Use the formula:

R4 = (Vout - VBE) / IB

Where:

- Vout = 19V

- VBE = 0.7V

- IB = Iout / hFE, assuming hFE = 100 (gain of T2)

Step 1: Calculate Base Current (IB):

Since IC555 pin#5 is a high impedance input, just a 10mA current would be enough to sink by T4 collector, so we can select Iout = 10 mA

IB = Iout / hFE = 0.01 / 100 = 0.02A

Step 2: Calculate R4 Value:

R3 = (19 - 0.7) / 0.0001

R3 = 183000 Ω or simply, 180 kΩ

Base Resistor for Transistor T1 (R3):

The resistor R3 controls the base current of T1. Use the formula:

R3 = (Vout - VBE) / IB

Where:

- Vout = 19V

- VBE = 0.7V

- IB = Iout / hFE, assuming hFE = 100 (gain of T1)

Step 1: Calculate Base Current (IB):

IB = Iout / hFE = 2 / 100 = 0.02A

Step 2: Calculate R3:

R3 = (19 - 0.7) / 0.02

R3 = 18.3 / 0.02 = 915 Ω

Resistor Value: 915 Ω (choose a standard value of 1 kΩ)

Final Component Values for the Boost Converter Stage:

- Inductor (L1): 378 µH

- Output Capacitor (C3): 330 µF, 25V

- Zener Diode (Z1): 19V, 0.5W

- Current-Sense Resistor (R4): 180 kΩ 1/4 watt

- Base Resistor (R3): 1 kΩ 1/4 watt

Calculating IC 555 Part Values

Now let use calculate the IC 555 astable circuit so that it becomes compatible with the above calculated boost converter parameters.

Main Calculations for R1, R2, and C1 in the 555 Timer Astable Circuit:

Our specific goal is to design the 555 astable circuit to operate at a frequency of 50 kHz with a duty cycle of 37% for the intended boost converter configuration.

Formulas:

- Frequency: f = 1.44 / ((R1 + 2R2) * C1)

- Duty Cycle: D = ((R1 + R2) / (R1 + 2R2)) * 100%

Data for satisfying the boost conversion:

- Desired Frequency (f): 50,000 Hz

- Duty Cycle (D): 37%

- Assume C1 is = 1 nF (0.000001 F)

Step-by-Step Calculations:

Step 1: Solve for R1 + 2R2 Rearranging the frequency formula: R1 + 2R2 = 1.44 / (f * C1)

Substituting the values: R1 + 2R2 = 1.44 / (50,000 * 0.000000001)

R1 + 2R2 = 1.44 / 0.00005 = 28,800 Ω

Step 2: Solve for R1 and R2 using the Duty Cycle formula

Rearranging the duty cycle formula: (R1 + R2) / (R1 + 2R2) = 0.37

Cross-multiply: R1 + R2 = 0.37 * (R1 + 2R2)

Expand and rearrange: R1 + R2 = 0.37R1 + 0.74R2

Rearrange further: R1 - 0.37R1 = 0.74R2 - R2

0.63R1 = 0.26R2

Solving for R1 in terms of R2:

R1 = (0.26 / 0.63) * R2 = 0.4127R

Step 3: Substitute R1 into R1 + 2R2 = 28,800

Substituting R1 = 0.4127R2: 0.4127R2 + 2R2 = 28,800

Simplifying: 2.4127R2 = 28,800

Solving for R2:

R2 = 28,800 / 2.4127 ≈ 11,940 Ω

Step 4: Calculate R1

R1 = 0.4127 * R2

R1 = 0.4127 * 11,940 ≈ 4,930 Ω

Final Component Values of the Astable 555 Stage:

- R1 = 4.93 kΩ (use standard value: 4.7 kΩ)

- R2 = 11.94 kΩ (use standard value: 12 kΩ)

- C1 = 1 nF

Verification:

Frequency: f = 1.44 / ((R1 + 2R2) * C1)

Substituting values: f = 1.44 / ((4,930 + 2 * 11,940) * 0.000000001)

f = 1.44 / (28,810 * 0.000000001)

f = 50,000 Hz

Duty Cycle = D = ((R1 + R2) / (R1 + 2R2)) * 100%

Substitute values: D = ((4,930 + 11,940) / (4,930 + 2 * 11,940)) * 100%

D = (16,870 / 28,810) * 100% ≈ 37%

So we have now verified the calculations and they are perfectly correct.

Full and Final Parts List

All resistors are 1/4 watt 5% CFR

- R1 = 4.93 kΩ (use standard value: 4.7 kΩ)

- R2 = 11.94 kΩ (use standard value: 12 kΩ)

- R3 = 1 kΩ 1/4 watt

- R4 = 180 kΩ 1/4 watt

- C1 = 1 nF

- C2 = 10nF

- C3 = 330 µF, 25V Electrolytic

- T1 = TIP122

- T2 = BC547

- Z1 = 19V, 1 W zener diode

- L1 = 378 µH, using 1 mm super enameled copper wire (magnet wire), over a 1cm diameter ferrite rod.

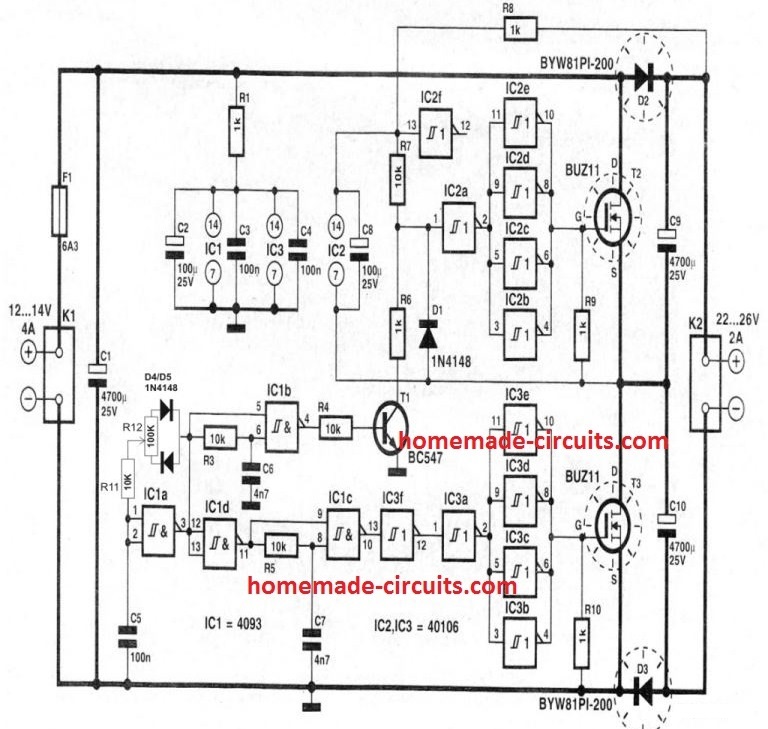

Using MOSFET Voltage Doubler Circuit

Nest, I have explained a simple circuit which may be incorporated for charging a laptop while driving in car or some other vehicle. The circuit runs without incorporating an inverter or inductors in its configuration Let's learn more.

Using Voltage Doubler without Inductor

The good thing about this circuit is that it does not rely on an inductor topology for the required actions, making the design simpler, and yet effective.

As we all know a laptop runs using a DC potential from an in built Li-Ion battery just as our cell phones do.

Normally we utilize a AC DC adapter for charging a laptop battery in homes and offices, these adapters are actually SMPS power supplies rated with the required and matching specs of the laptop battery.

However the above power supply units work only with AC supplies, and in places where an AC outlet may be available. These units will not work in places where an AC source is not present such as in cars and other similar vehicles.

A novel little circuit presented here will allow a laptop battery to be charged even from a DC source such as a car or truck batteries (12V). It's a very simple, cheap, versatile and universal circuit which may be dimensioned for charging all types of laptops by adjusting the relevant components provided in the circuit. It's a simple plug and play charger circuit.

Normally most of the laptop adapters are rated at 19V/3.5Amps, however some may be rated at higher currents for facilitating fast charging.

PWM Charging Control

The discussed circuit has a voltage adjustment features (via PWM) which may be suitably adjusted as per the required specs.

The current may be suitably safeguarded by adding a 3 ohm 5 watt resistor at the output positive terminal.

As can be seen in the circuit diagram, the design is basically a powerful DC to DC voltage doubler circuit which utilizes a push pull mosfet stage for the required boosting of the voltage.

The circuit requires an oscillator stage for initiating the proposed operations which is configured around IC1a.

The components R11, R12, C5 along with the two diodes becomes a neat little PWM controller which sets the duty cycle of the entire circuit and can be used for adjusting the output voltage of the circuit.

Typically the circuit would generate around 22V from a 12V source, by adjusting R12 the output may be tailored to an exact 19V, which is the required laptop charging voltage.

Comments

Hi,

Hey I’m looking at the picture you posted, is it really this circuit that is shown? ‘caus the components don’t match as far as I can tell(unless the BC547 and some other comps are hidden somewhere)…

I’m wondering about how this circuit is optimized for a laptop requiring 19.5V/4.74A(90w), and how much current it would consume on the 12V input side…

I wonder if there is any way to have the inductance(ex. 150mH or 330µH or other value, if relevant) equivalent for the inductor, If possible… I have access to NI Multisim, a circuit simulation software and I’d like to run some tests before purchasing the parts(In case I need bigger/smaller caps or resistors or a TIP142 instead of the TIP122)…

It would be for a sailboat(the less current we use, longer battery autonomy we have)…

’till now we’re using a 12->120V(AC) 200W power invertor, I don’t remember the power consumtion it pulls as we haven’t used it since september ’17…

I understand the basics of your circuit, but sadly I don’t yet have enough knowledge to determine if this circuit would allow any power saving, if anybody has any info on this matter, I’d be very grateful.

Best regards.

Hi, the picture and the diagram are different. The picture was referred by the requester, while the diagram was designed by me.

You can study the last expression presented in the following article, for evaluating the output voltage from the buck converter

https://www.homemade-circuits.com/calculate-current-voltage-buck-inductor/

However if you are using a 12V to 120V inverter then the above circuit won’t be necessary, you can simply purchase a ready made laptop charger and use it with your 120V output from the inverter

Ok so If I understand correctly, you’re saying that on the power/current consumtion and efficiency side, it’s better to keep using a 12V to 120V with the OEM(120V->19.5V 4.74A) laptop charger?

Thanks for the fast answer!

Yes that’s right, otherwise it would be an overkill, converting battery 12V to 120V, then back to 12V from 120V, and yet again from 12V to 19V.

Hi Swag,

I must really apologize for wasting you time, but I was like a kid in a toy shop with all the circuits. I should have read the description properly. This is a clever and very elegant solution. The trick lies in the Zener to protect the battery. Goes right to the heart of the problem.

I assume this will work for a 20V, 3.25A input. I cannot see any protection circuit for when the battery is full, so maybe I should look for another circuit. But that’s fine, I will build this one in any case for practice. See what it does.

The queries from project builders are very useful, so I should read them as well for problem solving.

Great!

Go well,

Christo.

The input will be 12V for the circuit which will be boosted to 20V for the laptop battery

Hi Christo, that’s the correct way to proceed! Reading the whole content will allow you to get clearer idea regarding the concept, and experimenting practically will help you to verify your learning…and never be afraid of failures, it is the part of the course.

Hi,

Thank you , this is a blessing. I can use your circuits with confidence because you explain component characteristics very well. I found two circuits, this one and the MPPT charge controller that I may use for my project.

I want to build a charger for a 12V battery as main back up power to my Lenovo G580 laptop when I am out of the car. I want to make this unit as compact as possible and preferably add a solar panel as first power source.

The input leads to the back up battery from the panel are connected in parallel to the output leads to the laptop. How do I isolate the laptop from the solar panel or grid power in case I forget to throw the DPDT switch to isolate the charging power?

I can also later power my Huawei B315 router from this with another small circuit. Could you possibly give me some search terms to find circuits like that here?

Thank you Christo,

If you have understood the stages well then surely you will be able to make them successfully, I wish you all the best!

If you have any further doubts please feel free express them here.

Is this circuit’s output current arround 5 ampere Sir? If i want to use it to supply 100watts/ 24volts dc stereo car amplifier do i need to change the tip122 to a higher one?

Azzam, for 5 amp you may have to upgrade the design by using thicker wire for the coil, and a 2N3055 BJT in place of TIP122

Thx v much sir..

hi bro, i am planning to build a phone battery charger (5v/500mA) ,from a 4v/2Ah rechargable battery. but i am having a problem to boost 4v to 5v. iv tried a joule thief circuit with zener stabilzation at 5.1v but its not working also i could not find a ready made ic

so plz can you tell me how to modify the joule thief circuit or is there any other method to charge mobile battery from 4v rechgble btry.

Hi Kiran, a Joule is the right circuit for such applications, just make sure that you dimension the secondary side winding optimally by using reasonably correct number of turns and by using bifilar winding technique, that is by using many thin copper wires together forming a bunch, and then winding it on the core….preferably use a torroial core, and try to adjust the winding such that it gives around 5.5V without a zener assistance.

PLEASE SIR AFTER DESIGNING THE BOOST CONVERTER MY MOSFET WAS HEATING VERY FAST. AND THE OUTPUT WAS 51VOLT BUT WHEN LOAD IS APPLIED IT GOES DOWN TO 11VOLT.

MOSFET USED IRF3205,IRF2805

BATTERY VOLTAGE 12VOLT 7AMPS

what is your load voltage and current specs?

to solve heating issue adjust the frequency by adjusting R1 value.

How do I use the ammeter,? I can use the voltmeter

connect ammeter probes directly across the output wires for a 1 or 2 seconds and check the reading quickly….make sure the ammeter’s range is appropriately set.

Good day Sir,I have been for a while ………………pls sir, how do I get the power rating of my inverter i.e ,The output ,using my voltsmeter,……thanks sir

Hi AG, you can do it using voltmeter and ammeter, check the output using both these meters and multiply the result

Many thanks sir.

Sorry to disturd again.

1. Can I also use panel of 100watt 5.1A 19v directly to the this circuit in a daytime.if not,suggest me any way to modifier the circuit? I will use the battry to at night.

2.your Automatic solar light circuit using relay changeover could use the above panel to charge the 14.5v.470wh battry alone ?if not possible suggests me other way.

Best of luck!

Abubakar,

the above circuit is for 12V input, not for 19V, what is your actual requirement by the way??

which automatic solar light with relay are you referring to??

Thanks sir ,But i do not know how to measure the output of my inverter.

measuring is not required, you can tell by refering to the specification of your inverter, I am sure it will be either 220V or 120V,

By the way you should be already knowing this??

sir now am geting exactly 25v and thats fine. thanks so much

am left now with handling the heating transistor only

That’s great OLupot, remember the frequency must match the inductance otherwise the transistor can get hot, therefore you can try tweaking the frequency also to control the heat…this might again result in the reduction in the output voltage and you may have to add a few more turns on the coil until you get just the right balance.

hello sir am now geting a doubled voltage of up to 40v from 12v but i want 24. i had made 23turns . but also it has blown up my tranistor. stil working on it

Good, that means your circuit is now working, connect a 1K resistor at the output and recheck the voltage, if still the voltage remains at 40V then you can reduce a few turns from the coil and check the response….use a 100V rated BJT uch as TIP31C etc

may be am not putting it right.All I needed is to use the battery for longer hours while watching TV. I have a smaller TV before.It uses an adaptor connected to a step down transformer.I also want something like that for this big TV 38” .how best can I go about it .Which circuit diagram ,do I build for it or how best can I do it sir.I need your expertise advice

you just have to tell me your TV input specs and inverter output specs…

if these two match then you can do nothing about it because everything is perfect in that case.

if your adapter is converting the inverter 220V to TV DC level then still it is perfect as long as the adapter is not malfunctioning or the TV is not malfunctioning

The battery is okay,blc I use it and its serves without the TV.What I need is the circuit diagram that will tap little from the inverter and boost it for the requirement of the Tv,which ic 220v,1.8A.Thanks

what is the output from the inverter? is it not 220V?

Hello Sir swaggatam .I really appreciate your contribution in simplifying electronics for the lovers of it .I am, AG, I love electronics.please I need a help,my flat screen TV drain my battery quickly when I use it on my inverter.

I need a circuit that supplies that will take little from my inverter and supplies (220v ,1.8A) that is required by the TV ,in other to make my battery last longer when am watching TV on my inverter. thanks

Thanks AG, your TV is probably consuming what it requires for operating correctly from the inverter…so it’s not the fault of your TV.

Your battery may be draining quickly either because it is not appropriately rated as per the TV wattage specs or it is old and has lost its efficiency.

ya its giving out a clear sound and 6.7v.

keep increasing the frequency until the sound just vanishes…after this you can try it with the boost converter stage, it should work, I hope you have wound the coil over a ferrite core.

hello sir i get 6.5v at pin#6 and 12.7v at the output input 12.9v . i stil have a problem with the inductor but atleast its promising i keep looking out for where the fault is but also need ur help thanks

is your IC 555 oscillating? first you must verify this using a frequency meter or a small loudspeaker connected across pin#3

Salil, the current simply depends on the specs of the transistor and the coil provided the input is also sufficiently high in current…you can upgrade the transistor rating accordingly and use a thicker wire for the coil to acquire 6 amps at the output…

Sir…how much max current can it supply?

Can I use the same circuit for 19v, 6amp specs?

Hi, swagatam

i find your site useful alot and i visit it always, thumbs up to you and your good work

please, i want to ask can use a 12 volt @7AH lead acid battery for this project?

Thank you Koby, yes definitely you can use a 12V 7AH battery for the discussed purposed

hello, the circuit looks really promising on the photo so i tried to simulate it but didnt get any voltage or rather 93 nV which is basically nothing and i did try changing the inductor but that didnt make any difference either.

I really like you post which are very helpful for a newbie like me. It helps me to learn alot.

Thank you.

https://drive.google.com/file/d/0B4EByIot_JMncEV1SVdYc3pZVjQ/view?usp=docslist_api

https://drive.google.com/file/d/0B4EByIot_JMnQlNrLVh0c0wxbWs/view?usp=docslist_api

Hi, The circuit is a standard IC 555 boost converter design so there's no doubt about the configuration, it has to work. I would suggest you to build it practically and check it…I am sure you would be able to get the results instantly, because I could get an instant boost conversion when I tried it. I could boost a 12V source to 80V.

Alternatively you can try removing the BC547 feedback link and see if that helps the situation in your simulator.

very good post..

i should try..

swagatam ji can i salvage one of output filter choke (toroid core) of 450w coputer smps to use as a inductor for the boost charger?

regards

chinmaya

bhubaneswar

thank you chinmaya kumar, yes you can do it, but you may have to manually adjust the number of turns of the inductor with respect to the frequency and duty cycle for getting the most favorable results

can you send for me printed circuit of project ? Thank you

Hello sir

Tip 122 transistor heats up for the circuit that I followed as mentioned. And after sometimes it gets damaged. Any solution for it.

Try connecting a 1k series resistor on the input of the PWM,it helps on reducing the heat of the switch(transistor or mosfet). And heatsink too. I based this on your other circuit that uses PWM.

did you use a heatink for TIP122?….or you can also try a 2n3055 instead which is more powerful than TIP122

Sir why the voltage drop down from 19.5 to 14 or 15 volts when laptop is connected?

It's due to lack of adequate current….use more parallel wires with the existing coil turns to increase current…or may be the input itself is lacking the required current

So R2 will be a pot, do I need to increase the no of turns of the inductor to achieve a higher voltage at only 30 volt max?

yes higher coil turns will enable proportionately higher level of voltage

hello sir,

is it possible to acquire an adjustable voltage by replacing Z1 into a 30 volts zener and R4 into a potentiometer?

the output voltage would be 12-30 volts adjustable.

and if T2 will also be change what could be the replacement.

hello jerico, using a pot for R4 will not help to achieve this…a better approach would be to use a pot for R2, and use it as a PWM control and for varying the output voltage

I have connected 1k across 2200 uf

Are there any replacement of tip 122 with high current and voltage ratting?

Hi I have successfully adjusted this circuit for 19.5 v output now I m going to connect the charger pin. But the pin have three wires red and black for +ve and -ve and third one I think for sensing its color is white. Where to connect that wire or leave without connecting?

according to me the white wire could be left open and only the red and the black wire considered…..It's better to consult a laptop technician to be entirely sure.

TIP142 is one transistor that's rated higher than TIP122

you can also try 2N3055

I soldered this circuit it givese 18.5 V at the output but after a few seconds it heat up the tip122 any solution? I also coconnected 2200uf/25 v dielectric capacitor but still it heating up!

Zafar can i please have a diagram of your final circuit?

TIP122 may show some heating that's normal, however you can try changing the frequency and see the response.

Replace R1 with a 1M pot and experiment with its adjustment and check the results.

make sure to connect a 10k resistor in series with this pot otherwise your 555 may be at a risk of blowing-off while adjusting the pot.

also make sure to connect a resistor across your 2200uF cap…a 4k7 will do

The wire gauge is used is 25

gauge is not important, the diameter of the ferrite core and the number of turns are only critical

Respected sir I connectted 2200uf /25v and 1k across the output I also connected the bc547 and 1 ohm resistor with tip122 as u mansion in the other diagram. Now the output of the ckt is around 11.5 V . I changed the no of turns from 15 to 20 but the output is not increasing.

Zafar, it's simple boost circuit and should work as stated, it will be difficult to troubleshoot your assembly because I can't check it practically.

You can Google "IC 555 boost converter circuit" and see the other online versions, and correct the design accordingly.

read only those circuits which has a coil (inductor), other versions could be useless

Hello Majumdar happy to see this circuit.. as i was making a mini project "solar powered laptop charging" for my school competition..

im using a ups battery for the source which is powered by solar panel..

i need to know that this circuit can be used to charge the laptop from 12v 7.2ah ups battery..

Hello Sanjay, yes this circuit can be used with a 12V 7.2 ah source also….but the coil is crucial and should be experimented correctly to get the most favorable outcome.

the diameter of the ferrite rod that I used will be around 15 mm so can I reduce the no of turrens?

initially try with 30 turns and then you can experiment by reducing the turns and simultaneously checking the voltage.

if possible add a current control stage with the TIP as indicated in the following article in order to make the circuit failproof:

https://www.homemade-circuits.com/2015/11/make-this-power-bank-circuit-using-37v.html

I soldered this ckt but I did not find ba157 in market so I connected general diode 4001. when I connected the ckt to 12 v battery it burrent the tip 122. sir can u tell me the cause of burning of tip122

connect a 1K resistor and a 2200uF/25V across 1N4001 output and ground…if still it burns then the coil could be the one which will need to be examined, and wound again

Sir.can I use this circuit to charge a nickel cadmium battery of 9v.I am getting output from the solar panel in a range of 6v.300ma can I able to change this voltage into 9v for charging my nickel cadnium battery.I have one more doubt that how to choose a charging current to charge the nickel casnium type batterybattery.please reply sir

Vijay, yes you can use this circuit for your application, for controlling current you can employ a LM317 circuit and use it in between the solar panel and the above explained boost circuit.

You can use the first design shown in the following article:

https://www.homemade-circuits.com/2013/06/universal-high-watt-led-current-limiter.html

The circuit from the first picture was sold to me as a LED 12V 100W power booster supply. But the LED had a max of 38VCC and the circuit was burning out at 32V.

So now i am study your underwater LED light controller to see if i could get more light out of the LED with that one.

what was exactly burning in the circuit? if it was the capacitors you can change them to 50V specs, anyway thanks for updating the info.

sir if we charge our battery by too much high frequency,will not the battery damage???????

A pulsating voltage can actually induce healthy effects on a connected battery….but if you are not sure, you can add a 100uF/25V capacitor after the BA159 diode, which will convert the output to a pure DC

which email are you referring to? please click on the diagram and check the out parts list on the right, everything is given there….all the resistors are 1/4 watt rated

I have updated the bridge rectifier circuit at the bottom of the article

No, Inductances do not have substitutes

sorry I do not have any simulation details because I have not yet simulated it. I have only tested it practically with perfect results

simulation is not actually necessary for such a simple design, you can simply make it and start using it

this is one of the simplest and the most reliable one that you can get, anything simpler than this looks difficult

can anybody tell me from where should i get the inductor mentioned above please its urgent

just wind 20 to 30 turns using a 20SWG magnet wire over a ferrite rod, that's all your inductor will eb ready…

sorry no idea about it, you can try the above circuit instead.

A dc dc boost converter uses IC LT1370HVCT7 from linear technologies, i could not find this in markets , any possible substitutes for this? if so please help….

thank you…