The presented 3 phase VFD circuit (designed by me) can be used for controlling the speed of any three phase brushed AC motor or even a brushless AC motor. The idea was requested by Mr. Tom

Using the VFD

The proposed 3-phase VFD circuit can be universally applied for most 3-phase AC motors where the regulation efficiency is not too critical.

It can be specifically used for controlling squirrel cage induction motor speed with an open loop mode, and possibly also in the closed loop mode which will be discussed in the later part of the article.

Modules Required for 3 Phase Inverter

For designing the proposed 3 phase VFD or variable frequency drive circuit the following fundamental circuit stages are essentially required:

- PWM voltage controller circuit

- 3 phase high side/low side H-bridge driver circuit

- 3 Phase generator circuit

- Voltage to frequency converter circuit for generating V/Hz parameter.

I have explained the functioning details of the above stages with the help of the following explanation:

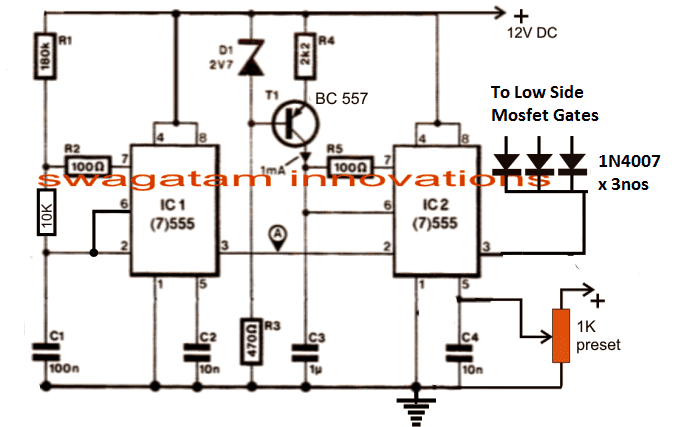

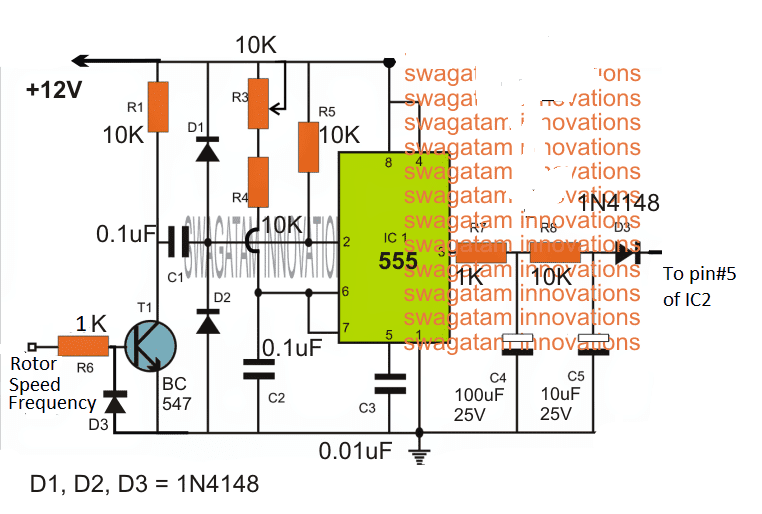

A simple PWM voltage controller circuit can be witnessed in the diagram given below:

The PWM Controller

I have already incorporated and explained the functioning of the above PWM generator stage which is basically designed for generating a varying PWM output across pin3 of IC2 in response to the potential applied at pin5 of the same IC.

The 1K preset shown in the diagram is the RMS control knob, which may be appropriately adjusted for acquiring the desired proportionate amount of output voltage in the form of PWMs at pin3 of IC2 for further processing. This is set to produce a corresponding output that may be equivalent to the mains 220V or 120V AC RMS.

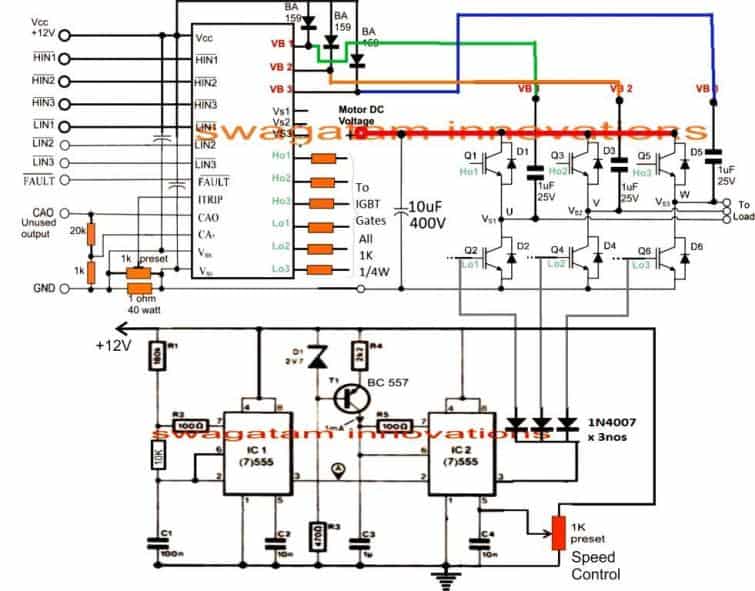

The H-Bridge Driver Circuit

The next diagram below shows a single chip H-bridge 3 phase driver circuit using the IC IRS2330.

The design looks straightforward as most of the complexities are handled by the chips in-built sophisticated circuitry.

A well calculated 3 phase signal is applied across the HIN1/2/3 and LIN1/2/3 inputs of the IC through a 3 phase signal generator stage.

The outputs of the IC IRS2330 can be seen integrated with 6 mosfets or IGBTs bridge network, whose drains are appropriately configured with the motor which needs to be controlled.

The low side mosfet/IGBT gates are integrated with the IC2 pin#3 of the above discussed PWM generator circuit stage for initiating the PWM injection into the bridge mosfet stage. This regulation ultimately helps the motor to gain the desired speed as per the settings (via the 1 k preset in the first diagram).

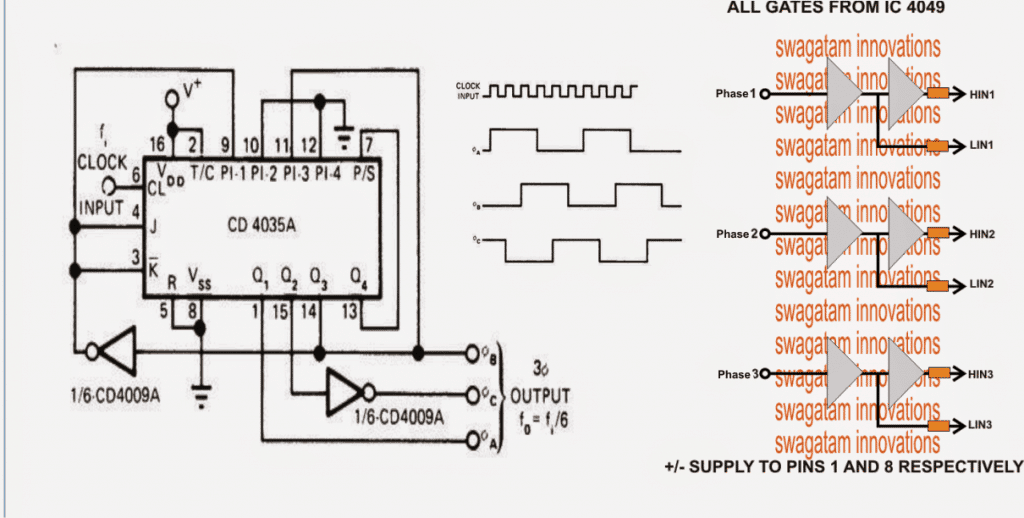

In the following diagram we visualize the required 3 phase signal generator circuit.

Configuring the 3-Phase Generator Circuit

The 3 phase generator is constructed around a couple of CMOS chips CD4035 and CD4009 which generates accurately dimensioned 3 phase signals across the shown pinouts.

The frequency of the 3 phase signals depends on the fed input clocks which should be 6 times the intended 3 phase signal. Meaning, if the required 3 phase frequency is 50 Hz, the input clock should be 50 x 6 = 300 Hz.

It also implies that the above clocks could be varied in order to vary the effective frequency of the driver IC which in turn would be responsible of varying the motor operational frequency.

However since the above frequency alteration needs to be automatic in response to the varying voltage, a voltage to frequency converter becomes essential. The next stage discusses a simple accurate voltage to frequency converter circuit for the required implementation.

How to Create a Constant V/F Ratio

Typically in induction motors, in order to maintain an optimal efficiency of the motor speed and toque, the slip speed or the rotor speed needs to be controlled which in turn becomes possible by maintaining a constant V/Hz ratio. Since the stator magnetic flux is always constant regardless of the input supply frequency, the rotor speed becomes easily controllable by maintaining the V/Hz ratio constant.

In an open loop mode, this can be done roughly by maintaining predetermined V/Hz ratios, and implementing it manually. For example in the first diagram this may be done by suitably adjusting the R1 and the 1K preset. R1 determines the frequency and the 1K adjusts the RMS of the output, therefore by suitably adjusting the two parameters we can enforce the required amount V/Hz manually.

However to get a relatively accurate control of an induction motor torque and speed, we have to implement a closed loop strategy, wherein the slip speed data needs to be fed to the processing circuit for an automatic adjustment of the V/Hz ratio so that this value always remains near about constant.

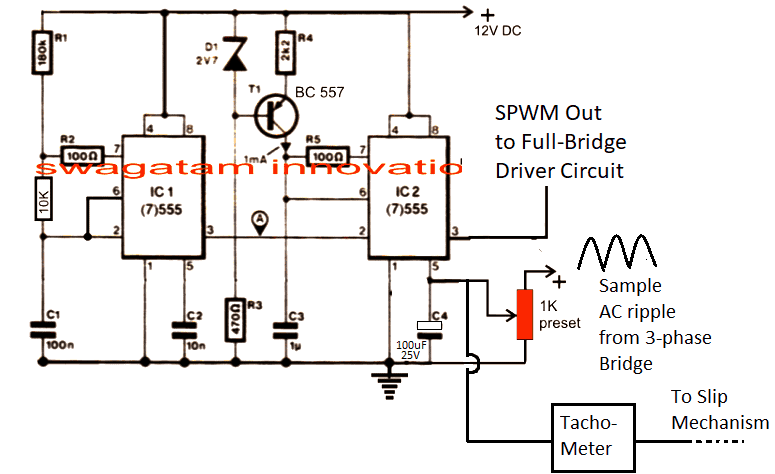

Implementing the Closed Loop Feedback

The first diagram on this page can be suitably modified for designing the closed loop automatic V/Hz regulation as shown below:

In the above figure, the potential at pin#5 of IC2 determines the width of the SPWM which is generated at pin#3 of the same IC. The SPWM are generated by comparing the mains 12V ripple sample at pin#5 with triangle wave at pin#7 of IC2, and this is fed to the low side mosfets for the motor control.

Initially this SPWM is set at some adjusted level (using 1K perset) which triggers the low side IGBT gates of the 3-phase bridge for initiating the rotor movement at the specified nominal speed level.

As soon the rotor rotor begins rotating, the attached tachometer with the rotor mechanism causes an proportional additional amount of voltage to develop at pin#5 of IC2, this proportionately causes the SPWMs to get wider causing more voltage to the stator coils of the motor. This causes further increase in the rotor speed causing more voltage at pin#5 of IC2, and this goes on until the SPWM equivalent voltage is no longer able to increase and the stator rotor synchronization attains a steady-state.

The above procedure goes on self adjusting throughout the operational periods of the motor.

How to Make and Integrate the Tachometer

A simple tachometer design can be seen in the following diagram, this could be integrated with the rotor mechanism such the rotational frequency is able to feed the base of the BC547.

Here the rotor speed data is collected from a hall effect sensor or a IR LED/Sensor network and is fed to the base of T1.

T1 oscillates at this frequency and activates the tachometer circuit made by appropriately configuring an IC 555 monostable circuit.

The output from the above tachometer varies proportionately in response to the input frequency at the base of T1.

As the frequency rises the voltage at the extreme right side D3 output also rises and vice versa, and helps to keep the V/Hz ratio to a relatively constant level.

How to Control Speed

The speed of motor using constant V/F can be achieved by altering the frequency input at the clock input of IC 4035. This can be achieved by feeding a variable frequency from a IC 555 astable circuit or any standard astable circuit to the clock input of IC 4035.

Changing the frequency effectively changes the operating frequency of the motor which correspondingly lowers the slip speed.

This is detected by the tachometer, and the tachometer proportionately reduces the potential at pin#5 of the IC2 which in turn proportionately reduces the SPWM content on the motor, and consequently the voltage for the motor is reduced, ensuring motor speed variation with the correct required V/F ratio.

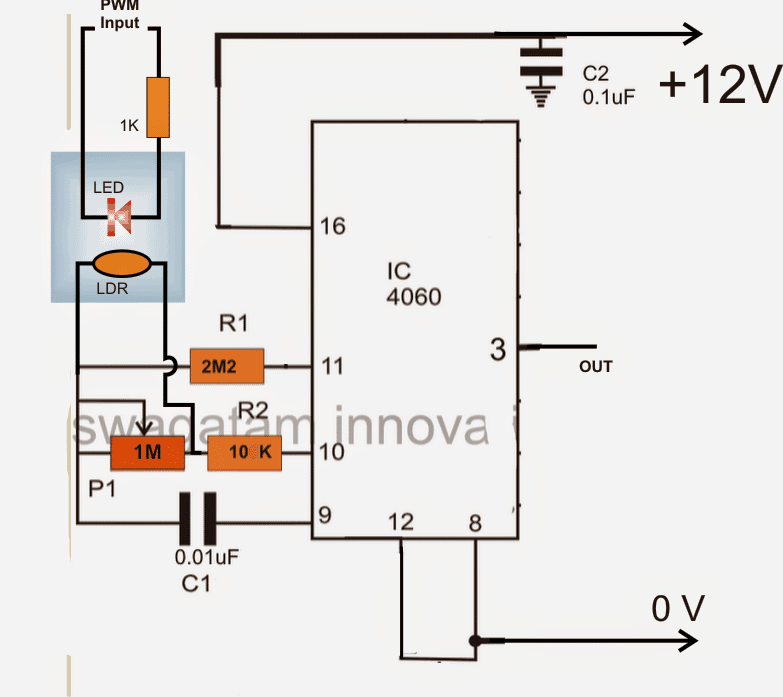

A Homemade V to F Converter

In the above voltage to frequency converter circuit a IC 4060 is used and its frequency dependent resistance is influenced through a LED/LDR assembly for the intended conversions.

The LED/LDR assembly is sealed inside a light proof box, and the LDR is positioned across a 1M frequency dependent resistor of the IC.

Since the LDR/LDR response is fairly linear, the varying illumination of the LED on the LDR generates a proportionately varying (increasing or decreasing) frequency across pin3 of the IC.

The FSD or the V/Hz range of the stage could be set by appropriately setting up the 1M resistor or even the C1 value.

The LED is voltage is derived and illuminated through the PWMs from the first PWM circuit stage. It implies that as the PWMs vary, the LED illumination will also vary which in turn would give rise to a proportionately increasing or decreasing frequency at pin3 of the IC 4060 in the above diagram.

Integrating the Converter with VFD

This varying frequency from the IC 4060 now simply needs to be integrated with the 3 phase generator IC CD4035 clock input.

The above stages form the main ingredients for making a 3 phase VFD circuit.

Now, it would be important to discuss regarding the DC BUS required for supplying the IGBT motor controllers and the setting up procedures for the entire design.

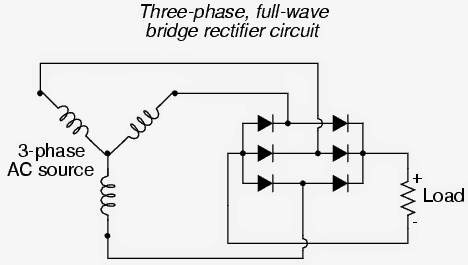

The DC BUS applied across the IGBT H-bridge rails may be obtained by rectifying the available 3 phase mains input using the following circuit configuration. The IGBT DC BUS rails are connected across the points indicated as "load"

For a single phase source the rectification may be implemented using standard 4 diode bridge network configuration.

How to Set Up the proposed 3 phase VFD circuit

It may be done as per the following instructions:

After applying the DC bus voltage across the IGBTs (without the motor connected) adjust the PWM 1k preset until the voltage across the rails become equal to the intended motor voltage specs.

Next adjust the IC 4060 1M preset in order to adjust any of IC IRS2330 inputs to the required correct frequency level as per the given motor specifications.

After the above procedures are completed, the specified motor may be connected and supplied with different voltage levels, V/Hz parameter and confirmed for an automatic V/Hz operations over the connected motor.

Comments

اريد صورة لكامل المشروع تجمع الدخل ودائرة التحكم والخرج في صورة واحدة

hello

good day

we are developing testing proposes in house used, IGBT base three phase regulator ,

1700 Voltage, 500amp

guided us controller and IGBT

Hi, do you want it to be an Arduino based design, or just an analogue version??

Dynamic Braking Resistor (DBR) or Dynamic Braking Unit (DBU) is an essential electrical component used in various industrial applications to safely dissipate extra energy produced when an electric motor or other devices are braking. When a motor slows down or stops, it behaves like a generator, creating a reverse electrical current called back electromotive force (EMF). If this energy isn’t managed properly, it could cause damage to both the motor and the connected drive system.

To handle this excess energy, dynamic braking is used in systems like elevators, cranes, electric trains, and vehicles—basically any equipment that requires frequent, controlled slowing down or stopping. In most setups, the DBR works alongside a Variable Frequency Drive (VFD), which is a motor-controlling system that helps regulate this braking process. In this guide, we’ll walk through how to connect a Dynamic Braking Resistor to a VFD.

Step-by-Step Connection Guide

Identify the DBR Terminals in the VFD:

Most VFDs come with specific terminals dedicated to connecting a DBR. Typically, there are two terminals, one for the positive connection and another for the negative. These terminals are usually labeled “+” and “-” or more commonly as “DC+” and “DC-”. In the wiring diagram provided, you’ll see that the VFD has clearly marked “DC+” and “DC-” terminals.

Connect the Input of the DBR to the VFD:

You’ll then connect one terminal of the DBR to the “DC+” terminal on the VFD and the other DBR terminal to the “DC-” on the VFD. This setup allows the DBR to absorb the extra energy generated by the motor while braking.

Consider a Resistor Contactor or Brake Chopper:

In some VFD setups, you might need an additional component like a resistor contactor or brake chopper to control how the DBR is connected to the VFD. A brake chopper is a solid-state device that regulates the flow of energy between the VFD and the DBR. If your system includes one, make sure to follow the manufacturer’s directions for proper installation.

Configure the VFD’s Parameters:

To enable the DBR to function properly, you’ll need to adjust some settings on the VFD. This might include turning on dynamic braking mode, entering the correct resistance value of the braking resistor, and configuring torque or current limits. These settings vary depending on the model of your VFD and the specific needs of your application.

Always follow the manufacturer’s instructions for both the VFD and DBR when making connections and adjusting parameters. Incorrect setup or misconfigured parameters can result in system errors or even damage the equipment. Consulting the user manuals is highly recommended.

How Dynamic Braking Works

When the motor is slowing down or stopping, the VFD senses this and switches to dynamic braking mode. Instead of just cutting power to the motor (as in normal stopping), the VFD directs the surplus energy generated during braking to the DBR.

In this system, the DBR is connected in parallel with the VFD’s DC bus and acts as a load that absorbs this excess energy. The DBR has a high-power rating and specific resistance designed to convert the energy into heat safely.

Because dissipating energy in the form of heat can cause the DBR to overheat, they are usually equipped with cooling systems like heatsinks or fans to keep the temperature down.

Once the braking process is complete, the VFD switches back to its normal mode, resuming its role of supplying the right amount of voltage and frequency to the motor for smooth operation.

In summary, a DBR ensures that the energy generated when slowing down a motor is safely and efficiently managed, preventing damage to the motor and other electrical components.

Thank you Jitu,

you can try the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2024/10/DBS-circuit.jpg

Sir, Namaskar.

I am technician

I won’t full circuit diagram of DBU

(DYNAMIC BRAKING UNIT ) & DBR for three phase motor.

My email : jvpateljv@gmail.com

Thank you.

Hi Jitu,

Can you please provide more details on how dynamic braking is supposed to work, about its working concept?

I will try to figure it out…

Dear Sir

IC IRS2330 is not available in Sri Lanka. Is it available in India. Otherwise manufacturers sells it in large quantities only.

Grateful for your help and guidance.

Regards

Pradeep

Thank you Pradeep,

The IC is available in India, or you can also try getting it from popular online stores like amazon or Ebay.

Dear Sir, what is the recommended IGBT for 110VX3 phase motor? Can we use IXSK 80N60B for this? Grateful for your advice.

Hello Pradeep, can you please provide the power rating (wattage) of the motor, I will try to figure it out…

Could you provide me a complete (composite) and clear diagram for the circuit.

The full diagram can be too large to fit on the screen, therefore I have shown the stages separately.

Do you have the circuit board & components for this as DIY project?

Sorry, PCB is not available for this project.

Hi Sir,

My circuit is almost completed earlier but due to my father’s cervical spine surgery I unable to take field trial bcz without his help and guidance it is risky (it is High voltage and high current power supply).

Now he is comfortable to do this.We will be planned it in this week.

after taking the same testing I will be shared all details to you.

I have required a information before it about heat sink. If I connected 5HP 3 phase submersible motor to the circuit load which heat sink I should be required?

Thank you Sanika, for updating the information!

Glad to know your father has recovered from the illness and is doing good.

Regarding the heatsink, it can be difficult to assume how large the heatsink should be. It can be verified only though some practical testing. Initially you can use a medium sized finned type heatsink and check whether it gets too hot or not. If it gets too hot you may have to increase the size and so on.

https://www.homemade-circuits.com/wp-content/uploads/2019/11/78xx-on-heatsink.png

Hi Sanika,

You will have to do according to the following circuit, please ignore the ripple circuit:

https://www.homemade-circuits.com/wp-content/uploads/2014/12/vfd.jpg

There’s another interesting way to vary the output of the IGBT.

You can do it by varying the PWM on pin6 of IC4035, meaning by varying the PWM output of the 555 IC in the following circuit:

https://www.homemade-circuits.com/wp-content/uploads/2016/07/speed.png

Your DC bus circuit is OK, but please add a 100 watt in series initially so that if anything is wrong then the IGBTs will not burn. If the IGBTs are working fine then the 100 watt bulb must remain switch OFF, if it’s glowing brightly that means something’s wrong.

Hi Sir

I don it, just as earlier.

I have a confusion about 1k pot connection which is connected to +12VDC at below diagram

https://www.homemade-circuits.com/wp-content/uploads/2014/12/vfd.jpg

And another circuit diagram showing it will be connected with AC ripple from 3 phase bridge

https://www.homemade-circuits.com/wp-content/uploads/2016/07/induction-PWM.png

Now I connected it with +12VDC

And plz check attached screenshot for DC Bus which I will be going to use my this project.plz suggest if any changes should be required.

https://drive.google.com/file/d/16I3bciz3KxAXmlGqV0qHBC4C1CBZyI3s/view?usp=drivesdk

Hi Sanika,

Now you will have integrate the PWM output with the low side gates of the IGBTs, just as you did before. As you can see the 555 PWM can be varied from low to high and high to low, this means when the PWM duty cycle is low the IGBT will conduct less and produce proportionately lower output voltage, an when the PWM is higher the IGBT will conduct more causing the output voltage to increase proportionately. In this way the VFD voltage can be varied by adjusting the PWM.

Hi Sir

Plz check attached video for wave form of IC555(2) output pin 3.

Voltage is increasing and decreasing while rotating the 10k variable resistor.

https://drive.google.com/file/d/160JtM7Xa7u7SuO5kA1WyyRWYZwrlfOje/view?usp=drivesdk

Now plz suggest for next stage.

No problem Sanika,

Thanks for sharing the video. It is very nice. You guys are real engineers.

Please let me know if you have any further questions, I will try to help.

Hi Sir

Sorry for delayed response.

Pappa was checked it and he told me about IC555 after that I also did it once again and I found it faulty.

https://drive.google.com/file/d/15zu8pEYrD64JA-aZCNAlov4lWdTwlIed/view?usp=drivesdk

Hi Sanika,

But, the varying waveform that you showed for the 555 PWM circuit looked good to me.

Anyway if yo think there’s some issue with this circuit you can rectify it.

You can use the water level controller circuit.

In the water level controller the relay will OFF the motor as soon the water touches the point “F” and the relay will switch ON the motor back as soon as the water level drops below the point “F”.

Hi Sir

I checked both the ICs in the PWM circuit and found one of them faulty. So we were not getting the desired result. I don’t have it available now, I will get it tomorrow after further inspection and will be forward all the results.

Until then I am making a circuit for my house water tank and borewell motor to automatically turn on and off and show the water level.

https://www.homemade-circuits.com/wp-content/uploads/2012/01/WATERLEVELINDICATOR.png

Hi Sanika,

It is difficult to understand why the low side IGBT PWM control is not regulating the speed, that should not happen. Try to set the narrowest possible PWM at pin#3 of IC2 555 and check the PWM across gate/ground of each LOW-SIDE IGBTS. If the low side IGBT switches as per the narrowest PWM then its average conduction should decrease causing the output voltage also to decrease proportionately.

If somehow this does not work out then we will have to try the PWM from the IC 555 circuit which is connected with the IC 4035:

https://www.homemade-circuits.com/wp-content/uploads/2016/07/speed.png

Hi Sir

I made the change as told. Also, when checked, the no-load voltage can be increased and there is no increase or decrease when the load is given. E.g. Given a voltage of 12DC it goes to 17-18 AC without the bulb but at the same time if the bulb is added to the load the same voltage comes to 11-12 AC.

During attached load no any increasing and decreasing happened while rotating 10k preset.

Sanika, that is strange, if the low side IGBT gate switching is altered with a PWM then the output voltage should also vary accordingly. Try with a 10K pot, then fix the pot at the narrowest (minimum) PWM on the low side IGBT gate and then check the output voltage and also check the response on the bulb illumination.

Yes Sir

PWM duty cycle increasing and decreasing but for setting it have very little margin can I replace with 10k preset.

Now voltage is equal to input DC voltage i.e. 24 VDC input and output 24 VAC ( adjustment done by 1k preset at IC555 PWM)

And plz find attached waveform video of IGBT output across the load.

https://drive.google.com/file/d/141j5nBKiR9McabH_zU_gumgOhvwhpnyK/view?usp=drivesdk

Hi Sanika,

When you decrease the 555 PWM duty cycle to minimum then the output voltage should also decrease proportionally. At minimum PWM, the low side IGBTs would be also conducting with minimal switching which should cause the output voltage to minimize. Conversely when you increase the PWM duty cycle the output voltage from the IGBTs must increase proportionately, because at higher PWM duty cycle the low side IGBT would conduct more and more causing an increase in the output voltage.

From where have you taken the waveform image, is it from the IGBT output across the load?

Hi Sir,

For time being I tried 1N4007 diode, after getting above mentioned diode I should replaced it.

Today I completed my ckt building with IC 555 PWM integration and conducted a trial with 24-25 VDC.

I noted below results

1). Output voltage at each load end 26.9 AC constant voltage no any fluctuations found.

2). AT the gate of HO 1/2/3 getting 17VDC and the gate of LO 1/2/3 getting upto 6.0 VDC.

3). I tested with oscilloscope LO 1/2/3, HO 1/2/3 and LOAD 1/2/3 output as well as Frequency Generator to the CD4035 clock input.

Plz check attached video and advice any changes will be required.

https://drive.google.com/file/d/13X5jvZj6vHsYNkxgedFWDBZXixZSkyOk/view?usp=drivesdk

Sanika, I don’t think parallel 1N4007 diodes will work, but for the time being you can try it. Most probably single 1N4007 diodes can be also tried for the time being if the load is a low current type load. For heavier 3 phase loads 1N5408 diode or 6A4 diodes will be required.

Ok Sir ,Thanks

Now I don’t have 1N5408 Diode available. Can I use 1N4007 Diode in parallel 3 together until it is available?

No problem Sanika,

1) The 555 frequency generator which you have connected to feed the clock pulses to the IC 4035 pin#6 is required, otherwise the 3 phase inverter cannot be supplied with the 3 phase signals. So it is required.

2) You can use 1N5408 for the D1—D6 diodes.

3) Any capacitor with a value higher than 220uF/400V can be used as the filter capacitor across the BUS line.

Ok sir,

I will integrate IC 555 with LOW side IGBT.

1. Is it required frequency generator which is I attached before CD4035 for clock input (300Hz)

2.which Diode should be used at (D1…D6 ) H-Bridge Driver Circuit across the IGBT.

3.For DC bus filter which capacitor and discharge resistor I have use bcz I want to test the circuit with 3HP 3 phase induction motor 415v.

After confirmation of above points I will be planned for final testing.

Hi Sanika,

That looks perfect to me. So your 555 PWM controller is also working perfectly. Now you can integrate this PWM with the gates of the low side IGBTs.

When you alter the 555 PWM, the output voltage from the IGBTs must also change proportionately from minimum to maximum.

Good Morning, Sanika,

Actually I am not sure about the V to F converter and the tachometer circuits, I am not sure whether they will give proper results or not. I am only sure about the first three circuits.

So it can be difficult for me to suggest about the V to F converter and the tachometer concepts.

I won’t recommend you to build the V to F and the tachometer circuits.

These are complex concepts, difficult to implement and have greater chance of a failure.

Hi Sir

Good morning

I built V to F convertor and tachometer circuit also.

I want to make confirm about integration of those ckt.

1.pwm input of LED/LDR from PWM IC 555 no.2 pin no.3 to LED positive and GND to negetive.

2.plz let me guide about Rotor Speed Frequency connection of Tachometer at base T1.

Hi Sir,

I built the IC 555 ckt with 1k pot and tested separately so plz check attached video ( increasing and decreasing pot)

https://drive.google.com/file/d/13ELmUbayV5csKZQfpsHfXDq79oyCCoM5/view?usp=drivesdk

Please let me suggest Is it ok or any changes will be required?

Sanika,

Yes 3.3V zener will also work, no issues.

Hi sir

Is it possible to use 3v3 ZD bcz 2v7 is not available at my end.

https://www.homemade-circuits.com/wp-content/uploads/2014/12/pwm2Bvoltage2Bregulator.png

You are very much right Sanika, I appreciate your understanding.

Yes you can surely start building the 555 circuit exactly as shown. If the 1K pot does not give proper results we can use a 4.7K pot or a 10K pot for the output PWM adjustment at pin#3 of IC2

Sir

That’s why I regularly posted comments and results with photos for reference of other like me .

Failure is the first step of success this is my concept. If we fail that means we can’t do it?

Forget it Sir

Can I start to built IC555 ckt?

You are right Sanika, all the best to you!

Yes sir we will get accepted results when will try for it positively

OK great, no problem, let’s see how it goes.

Hi sir

It’s all lights are 2 watts .

Another thing first we will check it on 300vdc if it’s run its ok if not then we will try for next step …

It is not compulsory to run it on decided voltage , it’s our project for us

Thanks Sanika,

that looks great, But still we are not sure how the inverter will respond to 300V or 400V DC with a 3 phase motor. Only time will tell. 1V voltage drop is OK since the bulbs are high amp bulbs.

If you want, we can proceed to the 555 speed controller stage next..

Hi Sir,

Tested 12vdc with 3 lamp on each phase. Plz check the attached pic.

https://drive.google.com/file/d/12iCguc41pjvaPigaI585zBuYmjquIO63/view?usp=drivesdk

Voltage is dropping around 1v to 1.5 volt in each phase ( input 12vdc output in each phase around 11.5,11 or 10.5)

Good Morning Sanika,

I am always glad to help, and I am also glad your 3 phase signal generator is working perfectly for you.

All the best to you.

Feel free to ask if you have any further questions.