Are you looking for free circuit diagrams, project ideas, and solutions? Are you interested in getting personalized help with an electronics project you're having trouble with?

Feel absolutely free to contact me through the comment box below the articles for getting quick solutions to your queries. I'll try my best to get it done for you absolutely FREE!

For submitting schematics or circuit diagrams you can send them to the following emails addresses.

Email ID

homemadecircuits

@gmail.com

Work Address

Comments

Swagatam DA,

Can we make an AC energy saver like Airtron. https://greenco.in/casestudy/Technical%20Bulletin%20No%205%20%20-%20Energy%20Savers%20For%20Air%20Conditioners%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20.pdf

The unit is very expensive. we can make it easily with Arduino and a temperature sensor. That will affordable for everyone. Please check the scope.

Thanks Abhirup,

It looks interesting but we do not know about the algorithm….if possible I will try to crack it and let you know…

Hi Swagatam. I’ve been following you for many years. I have two water pump motors, and a second one as a spare. They are activated by a pressure switch. I want them to operate sequentially each time a signal comes from the pressure switch. This way, both motors will wear out equally. Do you have any circuit recommendations? Thank you very much.

Thank you Ismail,

I guess you want to operate the motors alternately so that they share the load operation equally, and both the motors get prolonged life, and wear out uniformly.

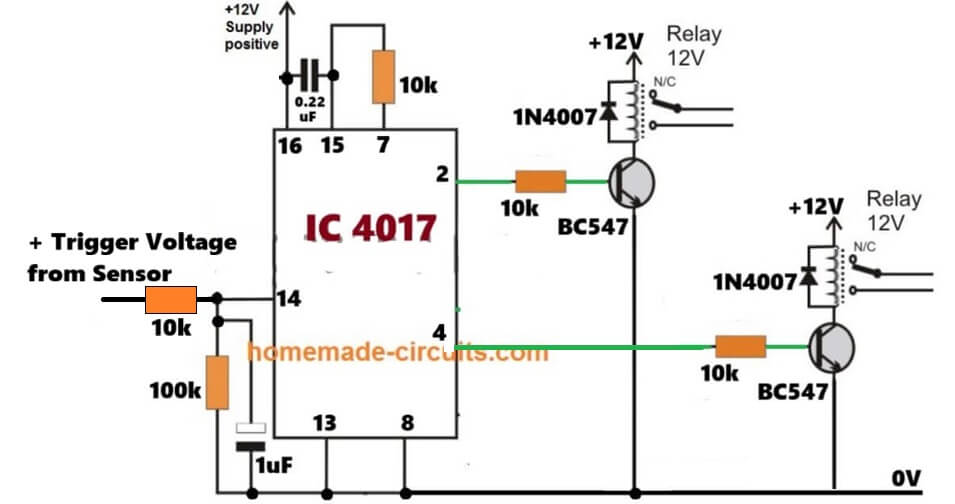

In that case I think you can try the following concept:

https://www.homemade-circuits.com/alternate-switching-relay-timer-circuit/

For triggering the circuit through a pressure switch, you can connect an SCR between the positive terminal and the pin#4 of the IC, with pin#4 also connected to ground through a 10k resistor.

Next, the gate of the SCR can be configured to sense the trigger voltage through a suitable resistive divider network.

Sorry, I think I misinterpreted the question, the above concept will toggle the motors continuously on each triggering, which is not good….you want the motors to toggle sequentially, for alternate sensor triggering. In that case, the following 4017 IC would be a better option.

I built the circuit, but it didn’t work. I can’t see any voltage across the 10k resistor on pin 14. What voltage is required for triggering?

That means the voltage from your pressure sensor is too small, you need minimum 5V at pin#14….. please check it separately and let me know how much voltage are you getting from the pressure sensor output…then I will suggest the required modifications…

Thank you very much, sir. I will try it as soon as possible. Greetings from Turkey.

You are welcome Ismail….

I replaced the 4017. There’s a gap in the timing belt transitions, as you can see in the video. It would be great if a relay activated with each timing signal.https://youtube.com/shorts/aVRog1_bwaM?si=5pOgRgnvTpT3QUYX

OK Understood! you do not want the switch off action for the motors after each sequence is completed.

In that case please do the following modifications in your existing circuit.

Replace pin#4 connection with pin#3

Replace pin#7 connection with pin#4

Pin#7 can remain open and disconnected.

Hello swagatam,

I’ve been looking at the Korg Volca Nubass and more specifically its supposed “vacuum tube VCO”. This really intrigues me but I was unable to find any available schematics or information on how this was done and I was wondering if you knew. Thank you!

Hi Emerson,

actually this “vacuum tube VCO” thing in Volca Nubass is not like those big old glass tubes we see in vintage synths or guitar amps, not that type. Korg Volca Nubass is using this small thing called Nutube, it is actually a real vacuum tube only but very tiny and low power, so it can run inside this small Volca box without heating or high voltage drama.

Now the company never released schematics, so nobody outside really knows the exact circuit but from what Korg itself says and from people who opened it, the tube is sitting in the oscillator sound path and also in the sub bass and drive part. So the oscillator is analog but the Nutube is there to add that tube like uneven harmonic feeling, not some fake digital effect.

So yes, it is a real vacuum tube, but done in modern style, not old school tube VCO like 1970 lab equipment, more like clever compact tube flavor added into an analog synth.

That’s so cool thanks for sharing.

Thanks, glad you liked it….

Hey Swagatam, I’m a big fan of your website and your audio circuits.I was wondering if you could help me out with a project Idea I have. I’m trying to make an analog pitch shifter guitar pedal with two pots. One pot goes from an octave lower than the sound source to an octave higher than the sound source, and the second is the ability to blend the original signal and the modulated signal. I’m not sure doable this is but I thought I’d reach out anyway in case you were able to make a schematic for this. Thank you!

Hey Emerson, thank you very much for liking my website and audio circuits.

About your idea, I must say that proper analog pitch shifter which can smoothly go from one octave down to one octave up using a pot, is not really possible with simple analog circuits. Pitch shifting needs time stretching and compressing of the signal which is why most good pitch shifters are digital.

With analog circuits, we can do octave down and octave up effects separately, using rectifiers, dividers or bucket brigade ICs but the sound will be rough, noisy and the range will be limited. Clean sweeping pitch control like modern pedals is not feasible using pure analog.

The blend control part is easy, we can mix original signal and effected signal using an op amp and a pot.

However, minus one octave to plus one octave with analog pots is not practical.

Thank you for the reply! I understand that this is likely not possible, but would a circuit that’s fixed at say a fifth (the music interval) be possible? I built your robot voice modulator and it seemed to have pretty defined fifth harmonics.

Yes now this is more doable, because fixed intervals like a fifth can be made with analog tricks. What you can do is use full-wave rectifiers, frequency dividers, and mixing to create harmonics at a specific interval. Like in my robot voice modulator, the circuit creates extra harmonics and when you mix them with the original signal, you get a defined interval effect, for example a fifth.

Hi Swagatam,

I’ve noticed that in your health related circuits the “Blood electrification unit” from Bob Beck isn’t included.

I think you will be interested.

But if you share this circuit, It is very important that the protocol is also followed. The effects of i.e. medical drugs can get 10x stronger during the electrification process.

I think the importance of this Device stands in one line with such like Joule Thief or Bedini SSG

Thank you so much Waldemar, for this interesting suggestion…

I will definitely investigate this concept, and if it is feasible i will include this concept on my website.

Many thanks again.

Dear Swagatham

I am looking for PCB kit for 1000Watt amplifier you published, do you know where can i get that kit ordered, Thanks.

Thank you Swagtham truly appreciate your response.

You are welcome Suresh!

Dear Suresh,

PCB kit may not be available readymade, you may have to contact a PCB manufacturer and get it fabricated for you. There are many PCB designers online whom you can contact and check who offers the most reasonable price.

sir how are you home was work

I have driver board circuit sg3525 lm 358

which is do ups transformer or ferried core transformer

which MOSFET is quality for power

please I need diagram for this circuit inverter circuit

Abdulkarim,

You can use UPS transformer or ferrite transformer as you like by adjusting the operating voltage, PWM etc of the circuit accordingly..

MOSFET will depend on the battery, load, transformer specifications…

Hello Swagatam,

I am looking for a circuit or circuits to run a 2 phase 4 wire stepper motor from a camera(low power stepper).

I want to use a single pole 2 way switch to set direction of motor.

I want motor to run for 2 to 5 seconds then turn off motor until switch is thrown again.

Can this be done without a micro-controller?

Any help would be appreciated

Hi David,

yes it is possible using the ICs A4988/DRV8825, for optimal performance.

Thanks Swagatam, Do you have any circuit diagrams showing this please?

Hi Swagatam, That is fabulous, thank you so much.

It is the best explanation of the stepper motor control that I have found anywhere.

Now to get parts and build it.

Regards and thanks again

David

Hello, thank you for the information. I am doing home appliance board repair. I am thinking of a circuit to test an air conditioner compressor. I want to drive the IGBT module directly. I have such an idea. If you want to help, I can send the detailed module. I would be happy if you can assist. Our Turkey will advance and develop. Regards.

Sure, please send the details, if possible I will try to help!

No Problems David, all the best to you, and let me know if you have any issues with the circuit…

Hi David, I have designed it now, please check the following article…the diagram is on the bottom end of the article:

https://www.homemade-circuits.com/a4988-motor-driver-circuit-diagram-with-ic-555/

Thanks David, It is quite easy and I will design it for you, and let you know soon, please give me 1 days time..

need an electronic circuit using 555 timer, which is fed with 12VDC via a switch for 1 hour. The output of 555 circuit must be a short pulse of 1 sec generated immediately when the switch is pressed..

You can try the following circuit, just replace the BC547 transistor with a push button switch:

https://www.homemade-circuits.com/wp-content/uploads/2022/08/555-monostable-with-trigger.jpg

Thanks for your replay but the switch must be ON for 1 hour and cannot be a pushbutton.

You can make it ON for 1 hour, no problem, and until it is released the circuit will not reset and its output will continue to be inactive and off.

I am looking for a device I can buy or make to do the following:

12 volt for auto use

When the ignition is turned on to start the car it sends a signal to a timer to light a light for an adjustable time.

When the timer times out the light will go off; and the light will remain off while the ignition remains on and the car is running.

When the ignition is turned off the timer will reset itself. Each time the car is started the sequence will happen again.

Sure, you can build the following circuit for the proposed application, it will do exactly as per the requirement:

https://www.homemade-circuits.com/wp-content/uploads/2025/10/lamp-timer-for-vehicle-ignition.jpg

I have used 3nos of 1 watt LEDs here for the lamp. If you want to use an external high power lamp then you may have to add a transistor driver at the pin#3 output of the IC..

I am having trouble with the diagram as I am not electronic literate.

1. I have searched for IC 1555 and have found them with only 5 and 10 connections and many letters and numbers after the 555.

2. The capacitors at the top of the diagram shows two capacitors on the 12V battery to ground with no details on the capacitance.

Thank you for your patience.

You can use any version of the IC 555, all will have 8 pins.

https://www.homemade-circuits.com/wp-content/uploads/2019/06/IC-555-timer.png

Those two capacitors at the top positive rail near the IC pin8 and pin4 are 100uF/25V and 0.1uF/50V capacitors.

Thanks for the quick rely.

How do I adjust the time the light stays on?

The delay time can be fixed by adjusting the 1M potentiometer or preset, if preset is used instead of a potentiometer….

sir need fan Regulator dimer PCB curcuit AC 220 volt

Waqas, sorry, I do not have PCB for this project..

Sorry, I have no idea how to get split-phase AC from H-bridge transformerless inverter design, in that case it is better to use a transformer…

Thank you for the information.

To clarify, I’ll be using two 110VAC split-phase outputs to achieve 220VAC. My current battery setup consists of two 48VDC strings, each with a 300A output. While I have some flexibility to adjust the battery configuration, connecting seven batteries in series might not be feasible.

Do you have any suggestions for inverter designs or configurations that could work with my existing setup?

Specifically, I’d appreciate guidance on:

1. Suitable inverter topologies for high-power applications

2. Potential modifications to my battery configuration

Any recommendations or resources you could provide would be greatly appreciated