This article discusses a method through which any ready made SMPS can be converted into a variable current smps circuit using a few external jumper links.

In one of the previous articles we learned how to make a variable voltage SMPS circuit by employing a simple shunt regulators stage, in the present hack also we employ the same circuit stage for implementing a variable current output feature.

What is SMPS

SMPS stands for Switch-Mode-Power-Supply, which uses a high frequency ferrite based switching converter for converting the AC 220V to DC. The use of a high frequency ferrite transformer makes the system highly efficient in terms of compactness, power loss, and cost.

The SMPS concept today has almost completely replaced the traditional iron core transformers and have transformed these units into a much compact, light weight and efficient power adaptor alternatives.

However since SMPS units are commonly available as fixed voltage modules achieving a preferred voltage as per the users application needs becomes quite difficult.

For example for charging a 12V battery one may need an output voltage of around 14.5V, but this value being quite odd and non-standard we may find it extremely difficult to get an SMPS rated with these specs in the market.

Although variable SMPS circuits can be found in the market, these may be costlier than the ordinary fixed voltage variants, therefore finding a method of transforming an existing fixed voltage SMPS into a variable type looks more interesting and desirable.

By investigating the concept a little I was able to find a very simple method of implementing the same, let's learn how to conduct this modification.

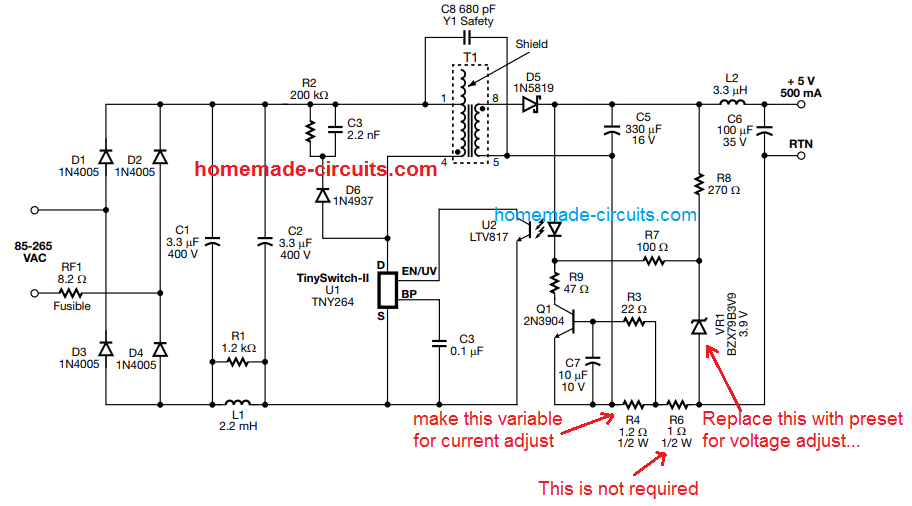

You will find one popular 12V 1amp SMPS circuit in my blog which actually has an in built variable voltage feature.

The Function of Opto-coupler in SMPS

In the above linked post we discussed how an opto coupler played an important role in providing the crucial constant output feature for any SMPS.

The function of the opto coupler may be understood with the following brief explanation:

The opto coupler possesses an inbuilt LED/photo-transistor circuitry, this device is integrated with the SMPS outputs stage such that when the output tends to rise above the unsafe threshold, the LED inside the opto lights up forcing the phototransistor to conduct.

The photo-transistor in turn is configured across a sensitive "shut down" point of the SMPS driver stage wherein the conduction of the photo-transistor forces the input stage to shut down.

The above condition results in the SMPS output to also instantaneously shut down, however the moment this switching initiates, it corrects and restores the output to the safe zone and the LED inside the opto deactivates which once again switches ON the input stage of the SMPS.

This operation keeps on cycling rapidly from On to OFF and vice versa ensuring a constant voltage at the output.

Adjustable Current SMPS Modification

In order to achieve a current control feature inside any SMPS we yet again seek the help of the opto coupler.

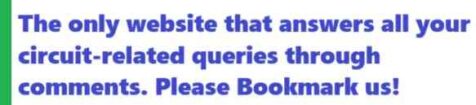

We implement a simple modification using a BC547 transistor configuration as shown below:

Referring to the above design we get a clear idea regarding how to modify or make a variable current SMPS driver circuit.

The opto coupler (indicated by red square) will be present by default for all SMPS modules, and assuming that the TL431 is not present then we may have to configure the entire configuration associated with opto coupler LED.

If the TL431 stage is already a part of the SMPS circuit, in that case we just have to consider integrating the BC547 stage which becomes solely responsible for the proposed current control of the circuit.

The BC547 can be seen connected with its collector/emitter across the TL431 IC's cathode/anode, and the base of BC547 can be seen connected with the output (-) of the SMPS via a group of selectable resistors Ra, Rb, Rc, Rd.

These resistors being in between the base and emitter of the BC547 transistor begin functioning like current sensors for the circuit.

These are appropriately calculated such that by shifting the jumper connection across the relevant contacts, different current limits are introduced in the line.

When the current tends to increase beyond the set threshold as determined by the values of the corresponding resistors, a potential difference is developed across the base/emitter of the BC547 which becomes sufficient to turn ON the transistor, shorting the TL431 IC between the opto LEd and ground.

The above action instantly lights up the LED of the opto, sending a "fault" signal to the input side of the SMPS via the opto's in-built photo transistor.

The condition immediately tries to execute a shut down across the output side which in turn stops the BC547 from conducting and the situation fluctuates from ON to OFF and ON rapidly ensuring that the current never exceeds the predetermined threshold.

The resistors Ra...Rd may be calculated by using the following formula:

R = 0.7/cut-of current threshold

For example if suppose we want to connect an LED at the output having a current rating of 1 amp.

We can set the value of the corresponding resistor (selected by the jumper) as:

R = 0.7/1 = 0.7 ohm

Wattage of the resistor can be simply gotten by multiplying the variants, i.e. 0.7 x 1 = 0.7 watts or simply 1 watt.

The calculated resistor ensures that the output current to the LED never crosses the 1 amp mark, thereby safeguarding the LED from damage, other values for the remaining resistors may be appropriately calculated for getting the desired variable current option in the SMPS module.

Modifying a Fixed SMPS into Variable Voltage SMPS

This following post tries to determine a method through which any SMPS could be made into a variable power supply for achieving any desired voltage level from 0 to maximum.

What is Shunt Regulator

We find that it employs a shunt regulator circuit stage for executing the variable voltage feature in the design.

Another interesting aspect is that this shunt regulator device implements the feature by regulating the input of the opto coupler of the circuit.

Now since a feedback opto coupler stage is invariably employed in all SMPS circuits, by introducing a shunt regulator one can easily transform a fixed SMPS into a variable counterpart.

In fact one can also make a variable SMPS circuit using the same principle as explained above.

You may want to learn more about what's a shunt regulator and how it works.

Procedures:

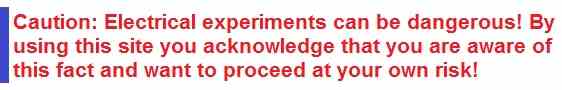

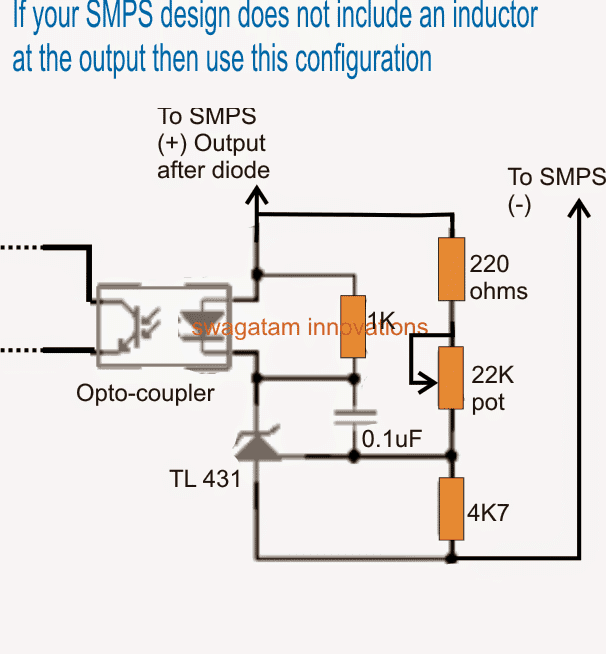

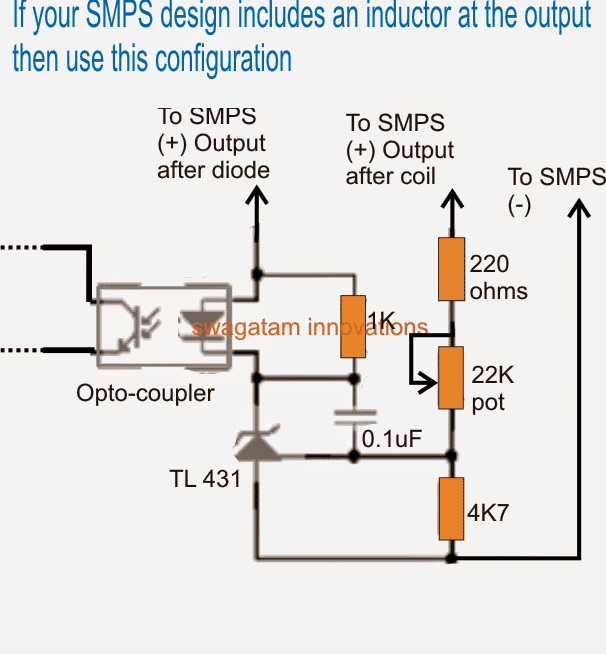

Referring to the following example circuit, we are able to find the exact location of the shunt regulator and its configuration details:

See the bottom right side of the diagram marked with red dotted lines, it shows the variable section of the circuit we are interested in. This section becomes responsible for the intended voltage regulation actions.

Here the resistor R6 can be replaced with a 22K pot for making the design variable.

Magnifying this section provides a better view of the involved details:

Identifying the Optocoupler

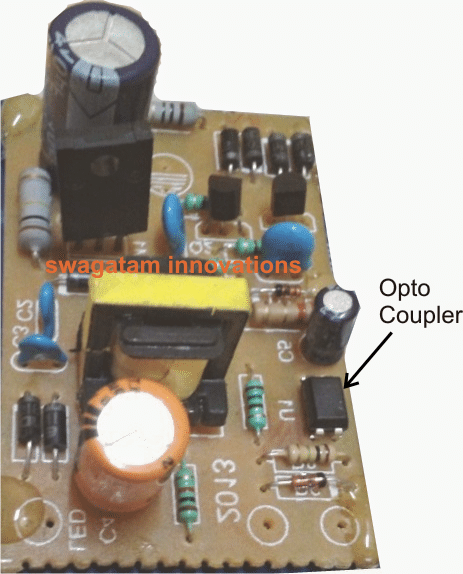

If you have a fixed voltage SMPS circuit, open it and just look out for the optocoupler in the design, it would be mostly located just around the central ferrite transformer, as may be seen in the following image:

Once you have found the opto-coupler, clean up by removing all the parts associated on the output side of of the opto, meaning across the pins which may be towards the output side of the SMPS PCB.

And connect or integrate these pins of the opto with the assembled circuit using the TL431, shown in the previous diagram.

You can assemble the TL431 section on a small piece of general purpose PCB and glue it on the main SMPS board.

If your SMPS circuit does not have an output filter coil, you can simply short the two positives of the TL431 circuit and join the termination to the cathode of the SMPS output diode.

However suppose your SMPS already includes the TL431 circuit with the opto coupler then simply find the position of the R6 resistor and replace it with a pot (see R6 location in the first diagram above).

Don't forget to add a 220 ohms or 470 ohm resistor in series with the POT otherwise while adjusting the pot to the upper most level could instantly damage the TL431 shunt device.

That's it, now you know exactly how to convert or make a variable voltage SMPS circuit using the above explained steps.

Warning: SMPS circuits are not isolated from AC Mains on the primary side, and can be lethal to touch while in uncovered and switched ON condition.

UPDATE

The following image shows perhaps the easiest way to customize an SMPS circuit for getting a variable voltage and current features. Please see how the pots or presets needs to be configured across the opto-coupler for getting the intended results:

If you have any further doubts regarding the design or the explanation, feel free to express through your comments.

Let's Summarize

In this write up we quickly try to summarize the main points regarding how to modify any SMPS circuit through an easy hack which may help us to get a desired customized output from the unit.

What is an SMPS

SMPS stands for switch mode power supply and it's the modern and most compact/efficient way of acquiring low voltage DC from mains AC source.

However making an SMPS at home may not be as simple as making power supply units using traditional iron core transformers.

Also getting an SMPS with custom specs may not be that easy, in fact impossible if the voltage/current specs are far away from the regular values.

So does that mean we have to be satisfied with the SMPS specs which are typically set, and available in the market?

For example how do we find an SMPS having an output of say 13 volts or 14 volts or 17 volts which are definitely not the normally accepted voltage ranges?

Customizing an SMPS unit

Since making such a customized unit may not be an easy task (due to complex layouts and part configurations) it would be a lot better if we could find ways of modifying a readymade one through some simple steps.

I have studied a few standard SMPS units and hopefully cracked ways of modifying the voltages and current as per individual choices. Let's learn it in details.

When you open any standard SMPS unit, you will come across the following things over the enclosed assembled card.

The populated PCB can be primarily divided into two sections by the presence of the center ferrite transformer.

The side of the transformer where the mains chord makes its entry is the input AC section while the other side from where the low voltage DC is derived is the DC section.

We are not interested in the AC section because we do not want to modify the input voltage so do not pay any attention there, moreover the AC section is POTENTIALLY VERY DANGEROUS TO TOUCH IN SWITCHED ON CONDITION, THEREFORE KEEPS YOUR HANDS OF IT WHILE TESTING.

The DC section will mainly consist of a couple of chokes, a couple of filter capacitors, a diode and a few other components.

Look for the Shunt Regulator

Search for a transistor shaped component in this section. If you find a couple of them, one will be actually a transistor, probably for limiting the output current, however the other one will be definitely THE PROGRAMMABLE SHUNT REGULATOR.

This shunt regulator is the component which fixes the feedback voltage to the AC section mosfet and in turn determines the output voltage.

This programmable shunt device is set up through a couple of resistors, changing which will instantly change the output voltage as per ones wish.

Try to locate the resistors connected with the leads of this shunt device. One of them can be simply varied for changing the output voltage as per your preferences.

Take an external resistor of any value may be a 4k7 1/4 watt, now step-wise go on connecting this resistor across the resistors which are associated with the shunt regulator device.

Check and Verify the Output

Verify the output voltage each time you do the above step.

The moment you find a change in the output voltage either becoming low or high, you might have just found the one which we are looking for.

Now through some trial and error you may find out the exact value of resistor which could be replaced in place of the particular shunt resistor.

That's it, it's as simple as that, once you do it, the output voltage would get adjusted to that particular value permanently.

But do remember to remove the zener diode if there's any at the output of the power supply before you do the above procedures.

Have Questions? Please Comment below to Solve your Queries! Comments must be Related to the above Topic!!