In this article we discuss a circuit design which will help to optimize the torque of an induction motor used in electric vehicles, by analyzing its current consumption.

Using a IC 555 Inverter for Toque Control

The design is specifically intended for electric vehicles which are designed to work with induction motors, and therefore here an inverter is included for operating the induction motor from a battery.

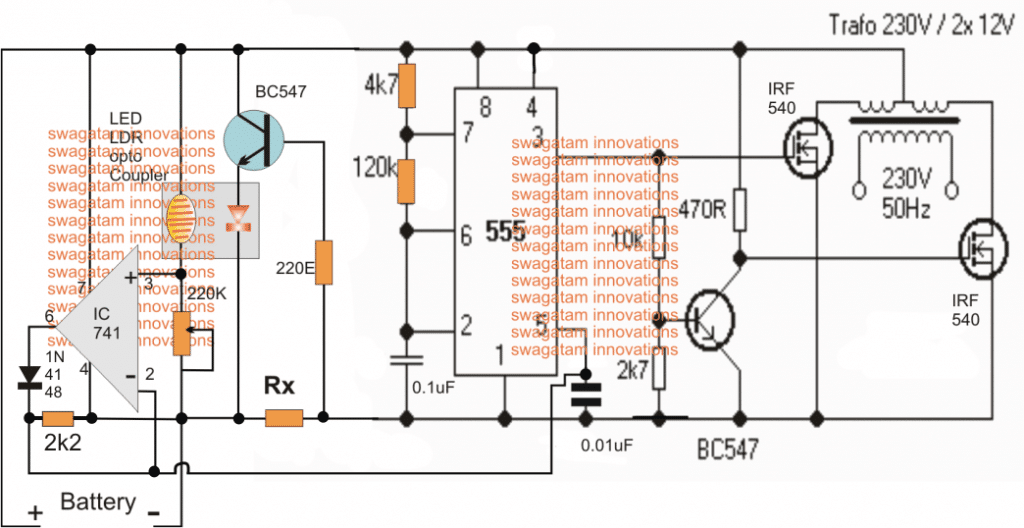

The proposed automatic torque optimizer circuit for induction motor can be witnessed in the following diagram. Since it’s designed for an electric vehicle, an inverter circuit is included, and built using an IC 555.

The IC 555 along with the associated mosfets and transformer forms a decent inverter circuit for driving the specified single phase induction motor from a 12V or a 24V battery. For a 24V battery the IC section will need to be stepped

down to 12V through a suitable voltage regulator stage.

Coming back to the actual design, here we need to make sure that the induction motor connected with the transformer initiates with a lower speed and begins gaining momentum, speed and torque as it gets loaded.

Using PWM Technique

Basically to implement this, a PWM becomes the best technique and in this design too we take the advantage of the IC 555’s built in PWM optimization feature. As we all know that the pin#5 of the IC 555 forms the control voltage

input of the IC, which responds to a varying voltage to adjust the pulse width level at its pin#3, meaning for higher potential levels at pin#5, the pulse width at pin#3 gets wider and for lower potentials at pin#5, the pulse width at pin#3 gets narrower.

In order to translate the load specification into a varying voltage at pin#5, we need a circuit stage capable of converting the rising load on the induction motor into a proportionately rising potential

difference at pin#5 of the IC 555

Role of Current Limit Sensor

This is done by introducing a current sensing resistor Rx, which transforms the rising current drawn by the load into a proportionately rising potential difference across itself.

This potential difference is sensed by the BC547 and transferred the data to the connected LED, which is actually the LED inside an LED/LDR opto coupler made at home manually.

As the LED brightness increases in response to a rising current consumption by an attached load, the LDR resistance proportionately goes down.

The LDR can be seen forming a part of the potential divider network across an Opamp’s non-inverting input, therefore when the LDR resistance falls, the potential at pin#3 of the opamp rises, which in turn causes a correspondingly rising voltage at the output of the opamp.

This happens because the opamp is configured as a voltage follower circuit meaning the voltage data at its pin#3 will be exactly replicated at its output pin#6 and in an amplified manner.

This correspondingly rising voltage at pin#6 of the opamp in response to the rising load on the induction motor feeds a rising potential at pin#5 of the IC555. This in turn causes the initial narrower PWM at pin#3 of IC 555 to become wider.

When this happens, the inverter mosfets begin conducting more current to the transformer enabling proportionately higher power to the induction motor, and the process enables the load to operate with more power and with optimal

performance.

Conversely as soon as the load is reduced, the current through Rx is also reduced which lowers the LED brightness, and the opamps output potential drops correspondingly, which finally causes the IC 555 to narrow down its PWM for the mosfets and reduce the power input to the transformer.

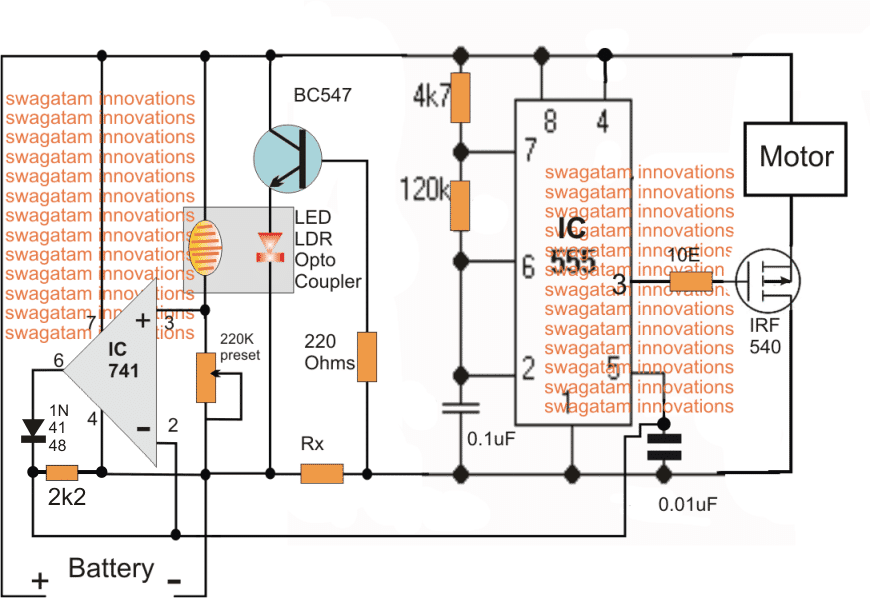

Using the Torque Optimizer for Treadmill Motors

The above explained torque optimizer circuit for induction motors is intended for electric vehicles, however if you are interested to operate an ordinary high power DC motor such as a tread mill motor, in that case the transformer section could be simply eliminated, and the motor could be directly connected as indicated in the following diagram:

I am sure you would be having many concerned questions, so please feel free to put them forth through your valuable comments. All your related queries will be answered at an earliest

Have Questions? Please Comment below to Solve your Queries! Comments must be Related to the above Topic!!