An automatic water level controller is a device which senses undesired low and high water levels in a tank, and switches a water pump ON or OFF accordingly to maintain an optimal water content in the tank.

The article explains 5 simple automatic water level controller circuits which can be used for effectively controlling the water level of a water tank by switching the pump motor ON and OFF.

The controller responds depending upon the relevant levels of water in the tank and the position of the immersed sensor points.

I received the following simple transistorized circuit contribution from Mr.Vineesh, who is one of the keen readers and followers of this blog.

He is also an active hobbyist who likes to invent and make new electronic circuits. Let's learn more about his new circuit which was sent to me via email.

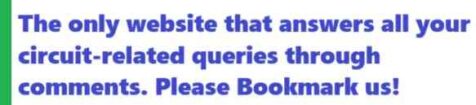

1) Simple Automatic Water Level Controller Using Transistors

Please find the attached circuit for a very simple and cheap water level controller. This design is only a basic portion of my own marketed product having unsafe voltage cutoff, dry run cut off and LED & alarm indications and overall protection.

Anyway, the given concept includes automatic water level control and high /low voltage cut off.

It is not a new design since we can find 100s of circuits for over flow controller in many sites and books.

But This ckt is simplified with least no: of cheap components. water level sensing and high voltage sensing is doing with same transistor.

I used to put all my ckts in observation for a few months and found this ckt OK. but recently some problems highlighted by some customer,which i will definitely write down the end of this mail.

CIRCUIT DESCRIPTION

When the water level in over head tank is sufficient , points B & C are closed through water and keeps T2 in ON condition , so T3 will be off , resulting the motor in off condition.

When water level lowers below B &C, T2 gets off and T3 on, which switches the relay and pump ON (pump connections not shown in ckt).

Pump get off only when water rises and touch the point A only , because point C becomes neutral condition when T3 get ON.

The pump switches on again only when the water level comes down below B & C . Presets VR2 is to be set to a high voltage cut off, say 250V when the voltage rises above 250V during pump ON condition, T2 gets ON, and relay off.

Preset VR1 is to be set to a low voltage cut off say 170V. T1 will be ON until zener z1 loses its breakdown voltage when voltage lowers to 170V, Z1 will not conduct and T1 stays OFF, which delivers a base voltage to T2 , resulting relay off.

T2 is handling the major role in this ckt. (high voltage cut off boards available in market can be easily integrated to this ckt)

Electronic components in this circuit worked very fine, but recently some problems were observed:

1) Minor deposits on sensor wire due to electrolysis in water, needed to be cleaned in 2-3 months( this problem is minimized now by applying ac voltage to sensor wire by means of additional circuit, which will be send to you later)

2) Due to relay contact terminal sparks, generated every time during initial current pull of pump, contacts get worn out gradually.

This tends to heat the pump because off in-sufficient current flow to pump (observed, new pumps works fine. older pumps heats up more).

For avoiding this problem, additional motor starter must be used, so that relay's function is limited to control the motor starter only, and pump never heats up.

- PARTS LIST

- R1,R11 = 100K

- R2,R4,R7,R9,= 1.2K

- R3 -10KR5 = 4.7K

- R6 = 47K

- R8,R10 = 10E

- R12 = 100E

- C1 = 4.7uF/16V

- C2 = 220uF/25 V

- D1,D2,D3,D4 = 1N 4007

- T1,T2 = BC 547

- T3 = BC 639( try 187 )

- Z1,Z2 = Zener 6.3 V,VR1,

- VR2 = 10K PRESET

- RL = Relay 12V 200E, > 5 AMP CONT ( According to pump HP)

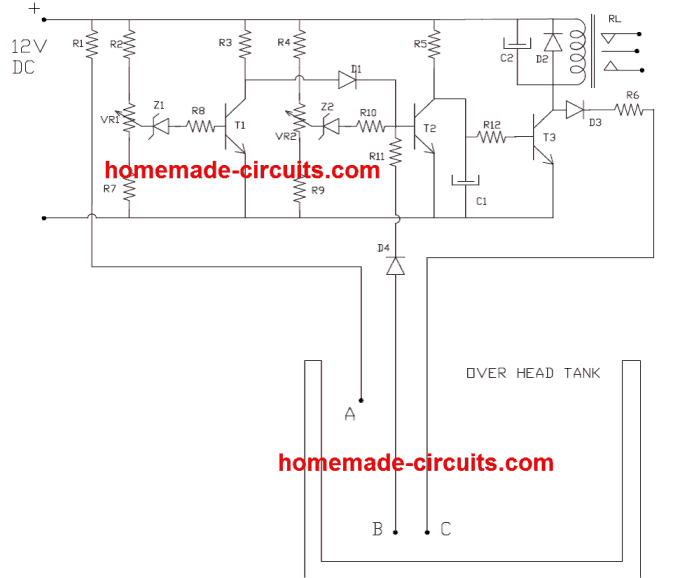

2) IC 555 Based Automatic water Level Controller Circuit

The next design incorporates the versatile work horse IC 555 for implementing the intended water level control function in rather very simple and yet effective manner.

Referring to the above pictorial schematic, the IC 555 working can be understood with the following points:

We know that when the voltage at pin#2 of the IC 555 drops below 1/3rd Vcc, the output pin#3 is rendered high or active with the supply voltage.

We can also observe that pin#2 is held at the bottom of the tank to sense the lower threshold of the water level.

As long as the 2-pin plug remains submerged in water, the pin#2 is held at the Vcc supply level, which ensures that pin#3 stays low.

However as soon as the water drops below the lower 2-pin plug position, the Vcc from pin#2 disappears, causing a lower voltage than 1/3rd Vcc to generate at pin#2.

This instantly activates pin#3 of the IC switching ON the transistor relay driver stage.

The relay in turn switches ON the water pump motor which now begins filling the water tank.

Now as the water starts filing, after some moments the water again immerses the lower two pin plug, however this does not revert the IC 555 situation due to the internal hysteresis of the IC.

The water keeps climbing until it reaches the upper 2-pin plug, bridging water between its two pins.

This immediately switches ON the BC547 attached with pin#4 of the IC, and it grounds the pin#4 with the negative line.

When this happens the IC 555 is quickly reset causing pin#3 to goes low and consequently switching OFF the transistor relay driver and also the water pump.

The circuit now reverts to its original condition and waits for the water to reach the lower threshold to begin the cycle.

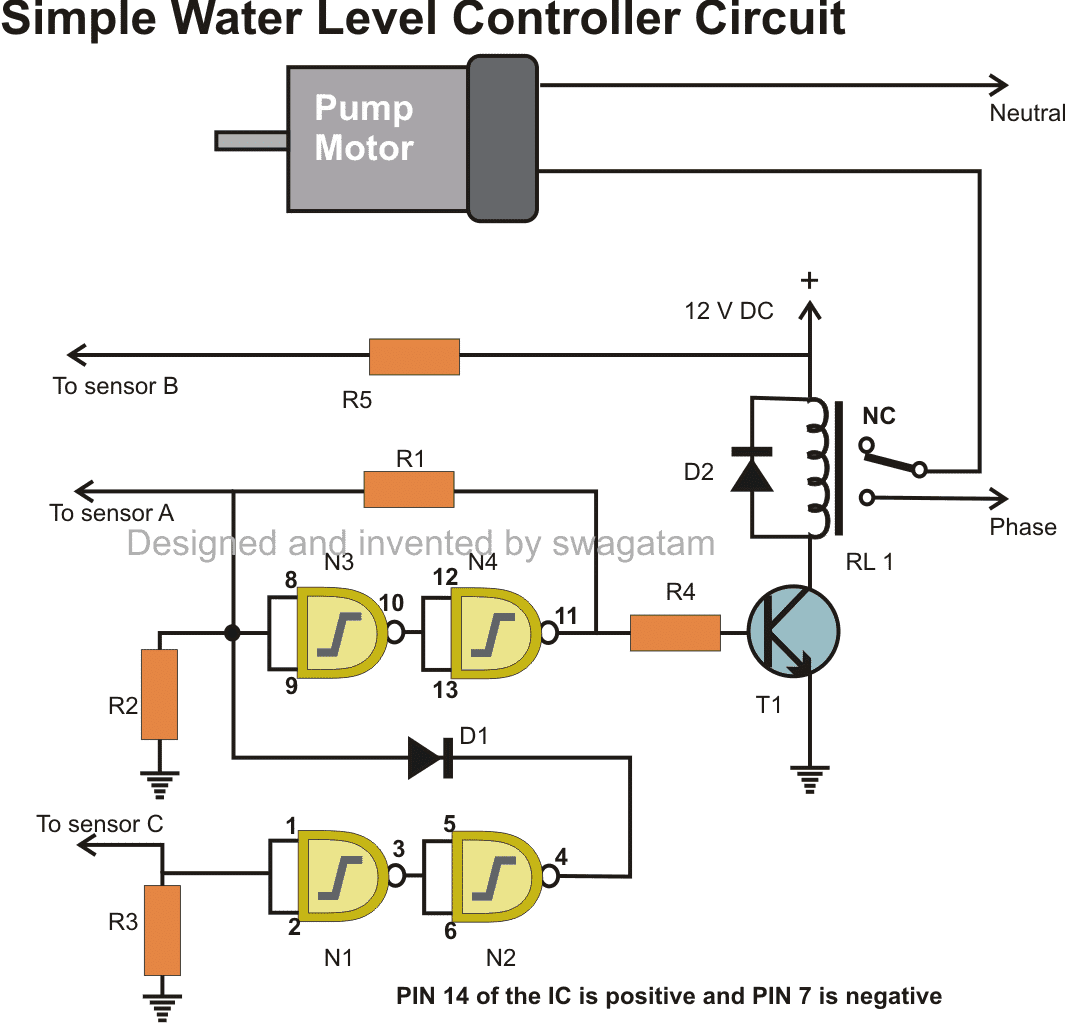

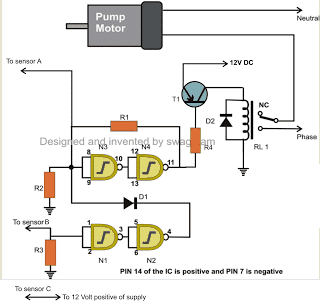

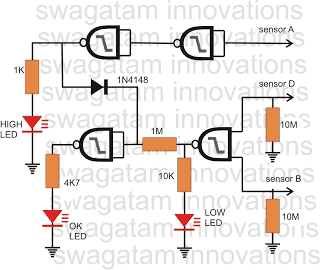

3) Fluid Level Control Using IC 4093

In this circuit we employ a logic IC 4093. As we all know water (in it’s impure form) that we get in our homes through our house water supply system, has a low resistance to electrical energy.

In simple words, water conducts electricity albeit very minutely. Normally the resistance of tap water might be in the range of 100 K to 200 K.

This resistance value is quite enough for electronic for exploiting it for the project described in this article that is for a simple water level controller circuit.

We have used four NAND Gates here for the required sensing, the whole operation may be understood with the below given points:

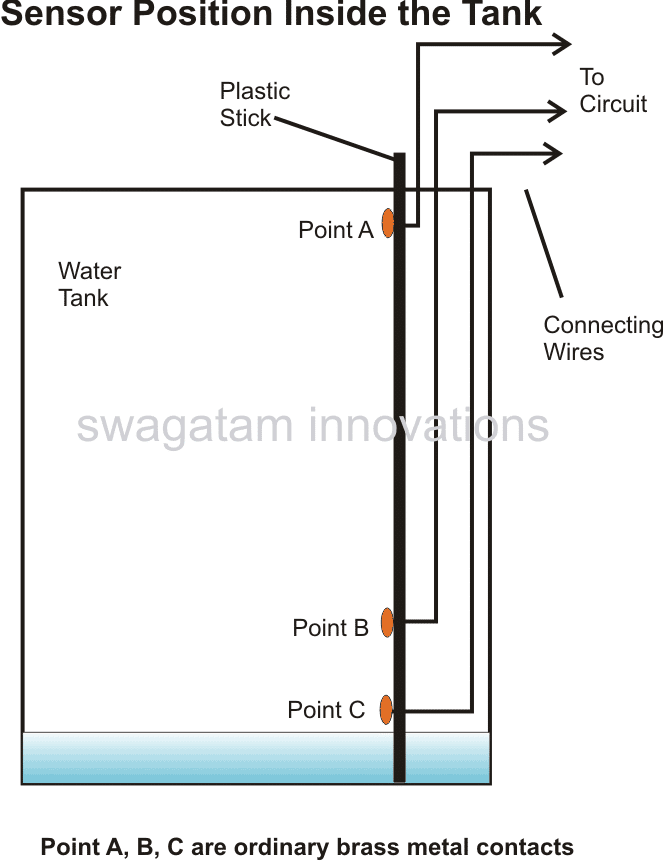

How the Sensors are Positioned

Referring to the above diagram, we see that point B which is at the positive potential is placed somewhere at the bottom section of the tank.

Point C is placed at the bottom of the tank, while point A is pinned at the top most section of the tank.

As long as water remains under point B, potentials at point A and point C remain at negative or ground level.

It also means that the inputs of the relevant NAND gates are also clamped at logic low levels because of the 2M2 resistors.

The outputs from N2 and N4 also remain at low logic, keeping the relay and motor switched OFF. Now suppose the water inside the tank starts filling and reaches point B, it connects point C and B, input of gate N1 becomes high making the otput of N2 also high.

However due to the presence of D1, the positive from the output of N2 does not make any difference to the preceding circuit.

Now when the water reaches point A, input of N3 becomes high and so does the output of N4.

N3 and N4 gets latched due to the feedback resistor across the output of N4 and input of N3. The high output from N4 switches ON the relay and the pump starts emptying the tank.

As the tank gets vacated, the position of water at some point of time goes below point A, however this does not affect N3 and N4 as they are latched, and the motor keeps running.

However once the water level reaches below point B, point C and the input of N1 reverts to logic low, output of N2 also becomes low.

Here the diode gets forward biased and pulls the input of N3 also to logic low, which in turn makes the output of N4 low, subsequently switching OFF the relay and the pump motor.

Parts List

- R1 = 100K,

- R2, R3 = 2M2,

- R4, R5= 1K,

- T1 = BC547,

- D1, D2 = 1N4148,

- RELAY = 12V, 400 OHMS,

- SPDT Switch

- N1, N2, N3, N4 = 4093

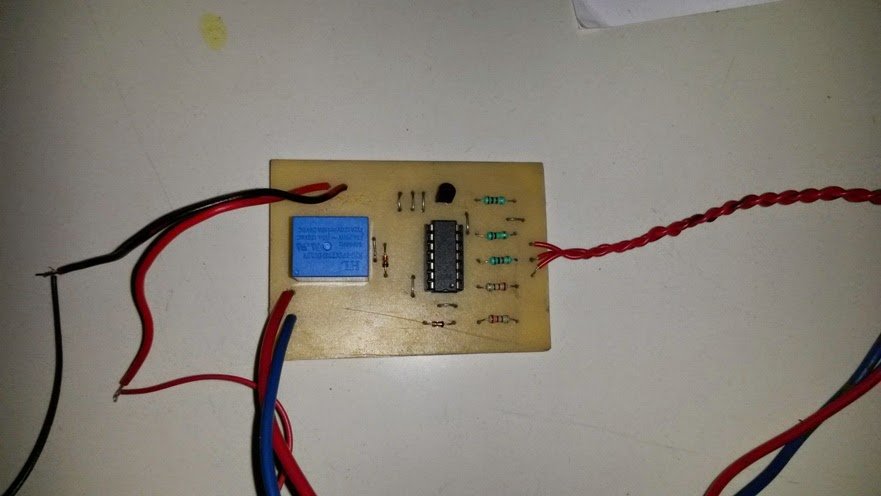

Prototype Images

The above discussed circuit was successfully built and tested by Mr. Ajay Dussa, the following images sent by Mr. Ajay confirm the procedures.

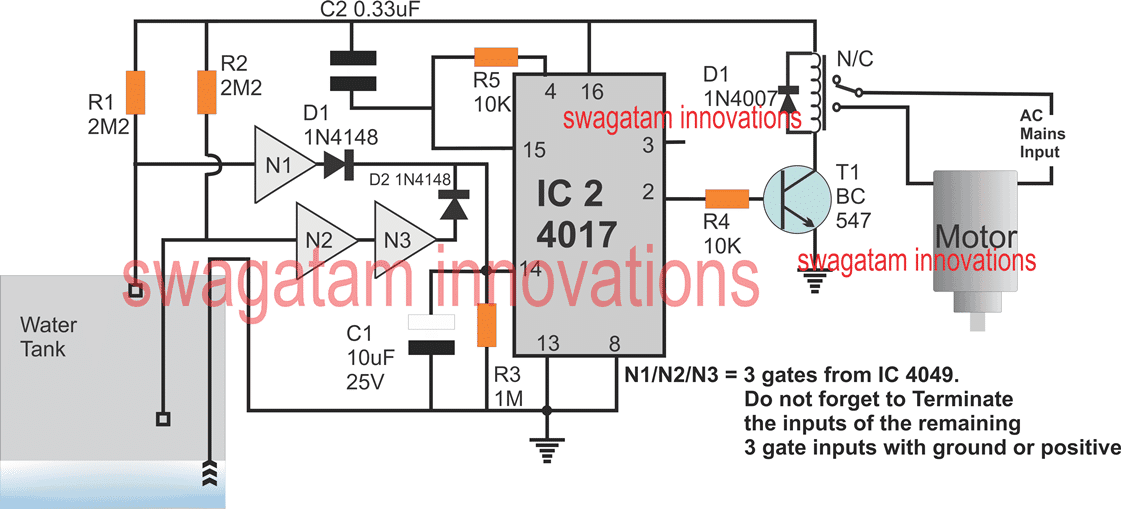

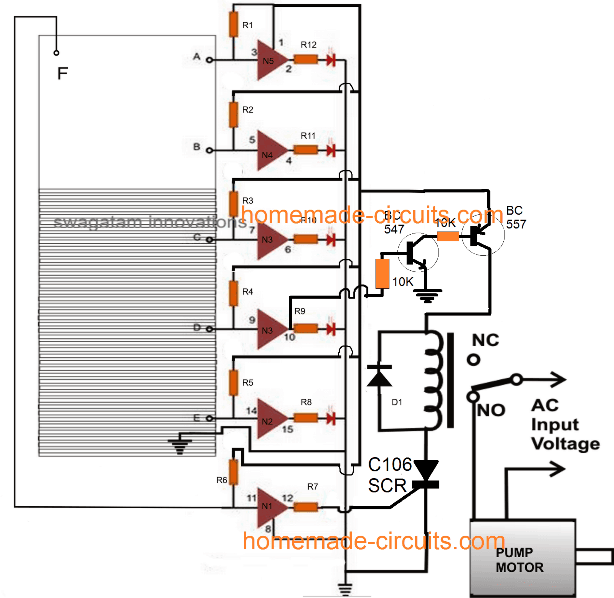

4) Automatic Water Level Controller Using IC 4017

The concept explained above can be also designed using the IC 4017 and a few NOT gates as shown below. The working idea of this 4rth circuit was requested by Mr. Ian Clarke

Here's the Circuit Requirement:

"I have just discovered this site with these circuits and wonder if you possibly can guide me….. I have a very similar necessity.

I want a circuit to avert a submersible bore pump (1100W) functioning dry, ie exhausting its water supply. I need the pump to shut off when the water level reaches approximately 1M above the pump intake, and start up again as soon as it reaches about 3M above the intake.

The pump body at earth potential would likely impart the typical reference. The probes and associated wiring to the surface area had been in place at those ranges.

Any assistance you can render would be much acknowledged. I will be able to put up circuits but hardly possess the understanding to figure the specific circuitry out. Many thanks in eager expectation."

Video Clipping:

Please note that the circuit diagram shown in the following video is slightly different to the diagram shown above. However, the working concept is similar.

Circuit Operation

Let's assume the setup is exactly as shown in the above figure, In fact this circuit needs to be initiated in the existing position that's shown in the figure.

Here we can see three probes, one having common ground potential attached at the bottom of the tank and is always in contact with water.

The second probe is around 1 meter above the tank bottom level.

The uppermost probe above 3 meters above the bottom of the tank level.

In the shown position, both the probes are at the positive potentials via the respective 2M2 resistors, which renders the output of N3 positive, and the output of N1 negative.

Both these outputs are connected with pin#14 of the IC 4017 which is used as a sequential logic generator for this application.

However during first power switch ON the initial N3 positive output does not have any effect on the IC 4017 sequencing, because at switch ON the IC gets reset through C2 and the logic is unable to shift from its initial pin#3 of the IC.

Now let's imagine water beginning to fill the tank and reaching the first probe, and this causes the output of N3 to go negative, which again has no impact on the output of IC 4017.

As the water fills and finally reaches the uppermost probe, this causes the output of N1 to go positive. Now this impacts the IC 4017 which shifts its logic from pin#3 to pin#2.

Pin#2 being connected with a relay driver stage, activates it and subsequently activates the motor pump.

The motor pump now starts drawing water out of the tank and keeps emptying it until a time when the tank level begins receding and goes below the upper probe.

This reverts the output of N1 at zero, which does not impact the IC 4017 output, and the motor keeps running and emptying the tank, until finally the water goes below the lower probe.

When this happens, the N3 output turns positive, and this impacts the IC 4017 output which shifts from pin#2 to pin#4 where it is reset through pin#15 back to pin#3.

The motor stops here permanently... until the time when the water again starts filling the tank and its level yet again rises and reaches the uppermost level.

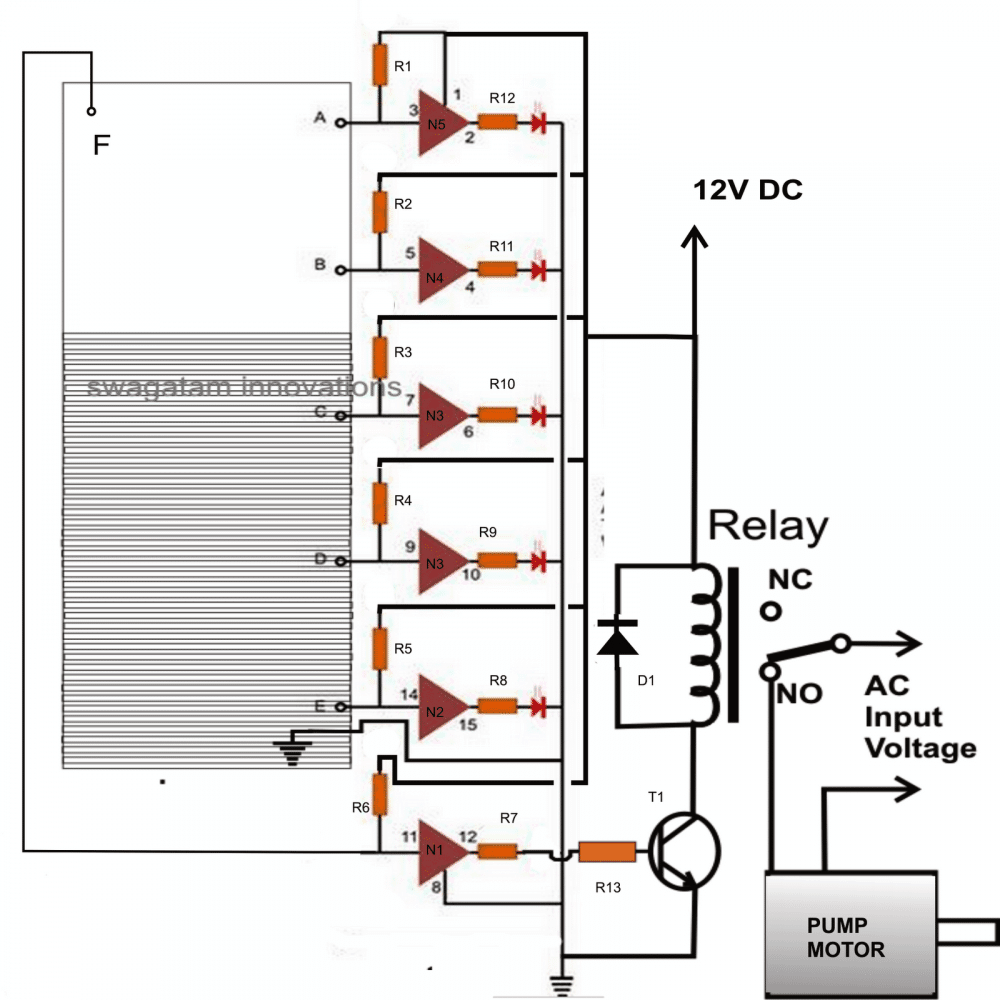

5) Water Level Controller Using IC 4049

Another simple water level controller circuit which is 5th in our list for controlling tank overflow can be built using a single IC 4049 and used for the intended purpose.

The circuit provided below performs a dual function, it includes an overhead water level control features and also indicates the different levels of water while the water fills the tank.

Circuit Diagram

How the Circuit Functions

As soon as the water reaches the uppermost level of the tank, the last sensor positioned at the relevant point triggers a relay which in turn switches the pump motor for initiating the required water evacuating action.

The circuit is as simple as it could be. Use of just one IC makes the entire configuration very easy to build, install and maintain.

The fact that impure water which happens to be the tap water that we receive in our homes offers a relatively low resistance to electricity has been effectively exploited for implementing the intended purpose.

Here a single CMOS IC 4049 has been employed for the necessary sensing and executing the control function.

Another interesting associated fact that’s associated with CMOS ICs has helped in making the present concept very easy to implement.

It is the high input resistance and sensitivity of the CMOS gates which actually makes the functioning completely straightforward and hassle free.

As shown in the above figure, we see that the six NOT gates inside the IC 4049 are arranged in line with their inputs directly introduced inside the tank for the required sensing of the water levels.

The ground or the negative terminal of the power supply is introduced right at the bottom of the tank, so that it becomes the first terminal to come in contact with water inside the tank.

It also means that the preceding sensors placed inside the tank, or rather the inputs of the NOT gates sequentially come in contact or bridges themselves with the negative potential as the water gradually rises inside the tank.

We know that NOT gates are simple potential or logic inverters, meaning their output produces exactly the opposite potential to the one that’s applied to their input.

Here it means as the negative potential from the water bottom comes in contact with the inputs of the NOT gates through the resistance offered by the water, the output of those relevant NOT gates sequentially start producing opposite response, that is their outputs start becoming logic high or become at the positive potential.

This action immediately lights up the LEDs at the outputs of the relevant gates, indicating the proportionate levels of the water inside the tank.

Another point that’s to be noted is, all the inputs of the gates are clamped to the positive supply through a high value resistance.

This is important so that the gates inputs are initially fixed at the high logic level and subsequently their outputs generate a logic low level keeping all the LEDs switched off when there’s no water present inside the tank.

The last gate which is responsible for initiating the motor pump has its input positioned right at the brim of the tank.

It means when the water reaches t the top of the tank and bridges the negative supply to this input, the gate output becomes positive and riggers the transistor T1, which in turn switches the power to the motor pump through the wired relay contacts.

The motor pump stats and begin evacuating or releasing the water from the tank to some other destination.

This helps the water tank from overfilling and spilling, the other relevant LEDs which monitors the level of the water as it climbs also provides important indication and information regarding the instantaneous levels of the rising water inside the tank.

Parts List

- R1 to R6 = 2M2,

- R7 to R12 = 1K,

- All LEDs = Red 5mm,

- D1 = 1N4148,

- Relay = 12 V, SPDT,

- T1 = BC547B

- N1 to N5 = IC 4049

All the sensor points are ordinary brass screw terminals fitted over a plastic stick at the required measured distance apart and connected to the circuit through flexible conducting insulated wires (14/36).

Upgrading the Relay Circuit

The above discussed circuit appears to have one serious drawback. Here the relay operation might continuously keep switching the motor ON/OFF as soon the water level reaches the overflowing threshold, and also immediately when the upper level reduces slightly below the topmost sensor point.

This action may not be desirable for any user.

The drawback can be eliminated by upgrading the circuit with an SCR and transistor circuit as shown below:

How it Works

The above intelligent modification ensures that the motor is switched ON as soon as the water level touches the point "F", and hereafter the motor keeps running and pumping the water out even while the water level drops below the point "F" .... until it finally reaches below the point "D".

Initially when the water level goes above the point "D" the transistors BC547 and BC557 are turned ON, however the relay is still inhibited from switching ON because the SCR is switched OFF during this time.

AS the tank fills and the water level rises upto the point "F" output of gate N1 turn positive latching ON the SCR, and subsequently the relay and the motor also switch ON.

The water pump begins pumping water out from the tank which results in emptying the tank gradually. The water level now drops below the point "F" switching OFF N1, but the SCR keeps conducting being in the latched situation.

The pump keeps running causing the water level to drop continuously until it reduces below the point "D".

This instantly switches OFF the BC547/BC557 network, depriving the positive supply to the relay, and eventually switching OFF the relay, the SCR and the pump motor. The circuit returns to its original situation.

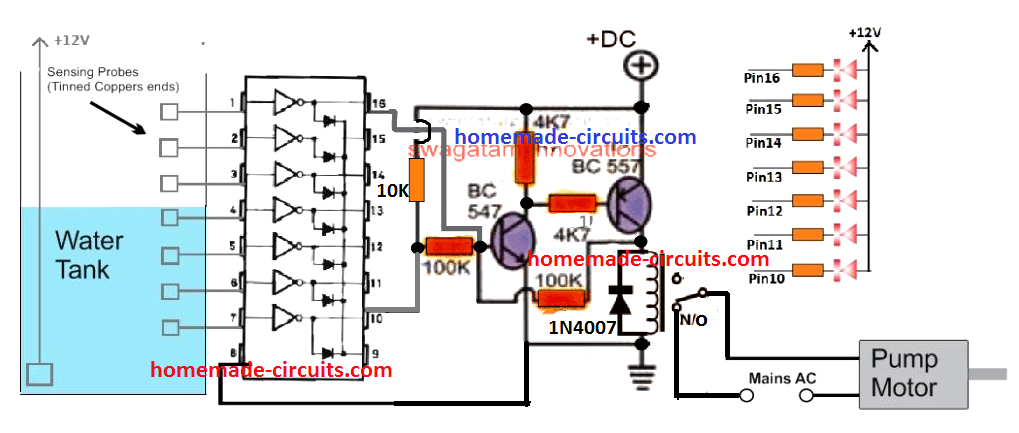

ULN2003 Water Level Controller Circuit

ULN2003 is a 7-step Darlington transistor array network inside a single IC chip. The Darlingtons are reasonably rated to handle current up to 500 mA and voltages up to 50 V.

The ULN2003 can be effectively used for making a full fledged automatic 7 stage water level controller with indicator as shown below:

How it Works

The transistor stage associated with the ULN2003 is basically a set reset circuit which is attached with the lowermost and the uppermost pins of the IC for the required set reset actions of the relay and the pump motor.

Assuming, the water level is below pin7 probe, the output pin10 remains deactivated, which in turn allows the positive supply to reach the base of the BC547 via the 10K resistor.

This immediately switches ON the PNP BC557, which instantly latches the two transistors via the 100K feedback across the collector of BC557 and the base of BC547.

The action also latches the relay switching ON the motor pump. The pump water starts filling the tank, and the water gradually climbs above the pin7 probe level.

Pin7 tries grounding the 10K biasing for the BC547 but this does not affect the relay switching, since the BC547/BC557 are latched through the 100K resistor.

As the water fills and climbs the tank, it finally reaches the uppermost pin1 probe level of the ULN2003.

Once this happens the corresponding pin16 goes low, and this grounds the feedback latch bias of the BC547 base, which in turn switches OFF the relay and the motor pump.

Making a Customized Water Level Controller

This customized ideal tank overflow controller circuit idea was proposed and requested to me by Mr. Bilal Inamdar.

The designed circuit attempts to enhance the above simple circuit into a more personalized form.

The circuit is exclusively designed and drawn by me.

Objective of the circuit

Well simply I want add a acrylic sheet bellow my tank which will contain tube lights. In short acrylic ceiling.

The tank level can't be observed because of the sheet. This is Also needed for terrace tank 1500 Ltrs to observe level indoors without going outside.

How it will help

It will help in many scenarios like to observe terrace tank level, to observe and operate overhead tank level and to observe underground tank water level and operate the motor.

Also it will save precious water from wasting due to overflow (go green). And release the tension caused due to human error ( forgetting to turn the pump on &filling the water also turn off the motor)

Application area :-

Overhead tank

Size - height = 12" width = 36" length = 45"

the tank is used for drinking, washing & bath.

The tank is 7 foot above the flooring.

The tank is kept in the bathroom.

Material of the tank is plastic (or PVC or fiber whatever non conductive)

The tank have three connection

Inlet 1/2", outlet 1/2" and whirlpool (overflow) 1".

The water fills from inlet. The water comes from outlet for use. The overflow connection prevent water overflowing on the tank and channelized it to drainage.

The hole of outlet is lower and the overflow and inlet is higher on the tank (ref height)

Scenario :-

The tank probes and level

|_A probe (overflow)

|__ok level

|_D probe (Medium)

|__low level

|_B probe

|__very low level

|_C common probe

As per the scenario I will now explain how the circuit should work

Circuit notes:-

1) Input of the circuit 6v AC/DC (for backup) to 12 AC/DC (for backup)

2) The circuit should mainly work on AC ( my mains is 220-240vac) with use of transformer or adaptor this will avoid probe rusting which occurs due to positive negative stuff.

3) The dc will drives from 9v battery easily available or from aa or aaa battery.

4) We have lots of power cut so please consider backup dc solution.

5) the probe used are aluminum wire 6mm.

6) The resistance of water changes as per location so the circuit must be universal.

7) There must be a sound which is musical as well as different for very high and very low. It can go bad so next sound is preferable. A buzzer is not suitable for big room 2000 sqft.

8) The reset switch must be a normal door bell switch which can be put in existing electric board.

9) There must be at least 6 led

Very high, very low, ok, low, mid, motor on/off. The mid must be considered for future expansions.

10) The circuit should indicate led of light gone when there is no AC current.

And switch to dc back. or add two led for indication On AC and On battery.

Circuit functions.

1) Probe B - if the water goes below this a indication led of very low must glow. The motor should start. The alarm should sound. The sound must be unique for very low level.

2) if the reset switch is pressed than the sound must go off everything else remains the same ( circuit armed, led glowing, motor)

3) if the water touch probe B the sound must be killed automatically. The very low indication led turn off the Low indication led turn on nothing else

4) Probe D - if the water touch probe The low indicator turn off. The ok level led turns on

5) Probe A - if the water touches this probe the then the motor turns off.

The ok level led goes off and the very high level led glows.

The bell/ speaker turns on with different tune for very high. Also if the reset button is pressed in this case than also there must be no other effect rather than killing the sound.

Last but not least the circuit diagram should be expandable to E,F,G etc for very big tank (like mine on terrace)

One more thing I m not able to know how the mid level should be indicated.

Too tired to write more sorry. Name of the project (just a suggestion) Perfect Water Tank level automation or perfect tank water level controller.

Parts List

R1 = 10K,

R2 = 10M,

R3 = 10M,

R4 = 1K,

T1 = BC557,

Diode = 1N4148

Relay = 12 volt, contacts as per pump current rating.

All Nand gates are from IC 4093

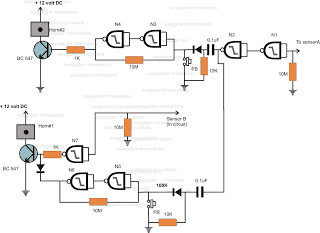

Circuit functioning of the above configuration

Assuming the water content to be at point A, the positive potential from point "C" in the tank reaches the input of N1 through water, making the output of N2 go high. This triggers N3, N4, transistor/relay and horn#2.

As the water comes down, below point "A" the gates N3, N4 maintain the situation due to the latching action (feedback from its output to input).

Therefore horn#2 remains switched ON.

However if the upper reset switch is pressed, the latch is reversed and maintained to negative, switching OFF the horn.

In the meantime, since point "B" is also at positive potential, keeps the output of the middle single gate low, keeping the relevant transistor/relay and horn#1 switched OFF.

The output of the lower two gates is high but has no effect on the transistor/relay and horn#1 because of the diode at the base of the transistor.

Now suppose, the level of the water falls below point "B", the positive from point"C" is inhibited and this point now goes logic low via the 10M resistor (correction required in the diagram which is showing 1M).

The output of the middle single gate immediately becomes high and switches ON the transistor/relay and horn#1.

This situation is maintained as long as the water threshold is below point B.

However horn#1 can be switched OFF by pressing the lower PB, which reverts the latch made from the lower couple of gates N5, N6. The output of the lower two gates becomes low, pulling the base of the transistor to ground via the diode.

The transistor relay switches OFF and hence horn#1.

The situation is maintained until the water level again rises above point B.

Parts List for the above circuit is given in the diagram.

Circuit functioning of the above configuration

Assuming the water level to be at point A, the following things can be observed:

The relevant input pins of the gates are at high logic due to the positive from point "C" coming via the water.

This produces a logic low at the output of the upper right gate, which in turn makes the output of the upper left gate high, switching ON the LED (bright glow, showing the tank is full)

The input pins of the lower right gate is also high, which makes its output low and therefore the LED marked LOW is switched OFF.

However this would have made the lower left gate output high, switching ON the LED marked OK, but due to the diode 1N4148 it keeps its output low so that the "OK" LED remains OFF.

Now suppose the water level falls below point A, the upper two gates reverts their position switching OFF the LED marked HIGH.

No voltage flows through 1N4148 and so the lower left gate switches ON the LED marked "OK"

As the water falls below the point D, the OK LED still glows because the lower right gate still remains unaffected and continues with a low output.

However the moment water goes below point B, the lower right gate reverts its output because now both its inputs are at logic low.

This switches ON the LED marked LOW and switches OFF the LED marked OK.

Parts List for the above circuit is given in the diagram

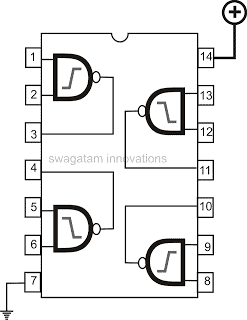

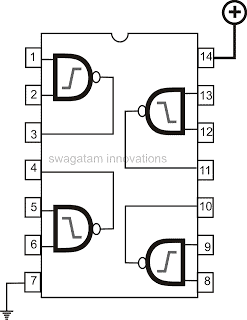

IC 4093 PIN-OUT Diagram

Note:

Please remember to ground the input pin of the remaining three gates which are not used.

In all three ICs would be required constituting 16 gates, only 13 will be used and 3 will remain unused, the above precaution must be followed with these unused gates.

All the relevant sensor points coming out from different circuits must be joined together and terminated to the appropriate tank sensor points.

Wrapping it up

This concludes our articles regarding the 5 best automatic water level controllers which can be customized for switching ON/OFF a pump motor automatically in response to the upper and lower water thresholds. If you have any other ideas or doubts please feel free to share them through the comment box below

Have Questions? Please Comment below to Solve your Queries! Comments must be Related to the above Topic!!